Abstract

White-flesh (Hylocereus undatus; WF) and red-flesh (Hylocereus polyrhizus; RF) dragon fruit purees were subjected to heat treatment for 0 to 60 min at temperatures between 50 and 90 °C. The influence of the different heat treatments on the physicochemical properties, colour, betacyanins content, microbial destruction, antioxidative properties and rheological parameters were investigated. The physicochemical values and antioxidative properties of the unheated RF were significantly higher than that of the unheated WF (p < 0.05). The betacyanins content of RF after 90 °C for 60 min decreased to 32.35%, based on the initial puree. Total colour change (TCC) and betacyanins degradation followed the second-order kinetic. The L* and b* values of the purees can be recommended as an online quality control (R 2 ≥ 0.7733) and TCC of RF can be used to predict the betacyanins content (R 2 = 0.9442). The antioxidative properties of the heated WF and RF increased with heating treatment. The linear correlation among the antioxidative properties was strong (R 2 ≥ 0.8587). WF and RF showed shear thinning behaviour. After heating, the apparent viscosity of WF and RF increased and all cases fitted very well with the power law model (R 2 ≥ 0.9988). Thus, the heated dragon fruit purees, particularly the RF, offer possibilities to be applied in foodstuffs due to their interesting physicochemical properties and nutritional attributes after thermal treatment.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Thailand has a tropical climate ideal for the breeding of a large diversity of fruits. Dragon fruit, also known as pitaya and pitahaya, is a tropical fruit originating from South America and has been grown in Thailand for ages. In Thailand, two varieties are grown: a red-skinned fruit with white flesh (Hylocereus undatus; WF) and also a red-skinned fruit with deep red flesh (Hylocereus polyrhizus; RF). The pulp is tasteful, juicy and contains numerous small black seeds. Dragon fruit can be considered as a potential source of micronutrients and antioxidants which are found in the peel, flesh and seeds (Ariffin et al. 2009; Jaafar et al. 2009; Lim et al. 2007, 2010; Mahattanatawee et al. 2006; Wu et al. 2006). The dragon fruit flesh may also be a possible source of oligosaccharide for prebiotic production (Wichienchot et al. 2010). Nowadays, the fruit is exported to Europe and international markets where there is an increasing interest for novel tropical fruits. They are used as ingredients for innovative food products that respond to the consumers’ interest in new products (Bellec et al. 2006; Sabbe et al. 2009). The dragon fruit can be considered as an excellent fruit due to its taste, attractive colour and high nutritive values (To et al. 1999).

Thermal processing, which also refers to the sterilisation (high temperature and short time) and pasteurisation (low temperature and long time) processes, is an important method for fruit preservation and shelf life prolongation due to the inactivation of microorganisms. This process also has an influence on the nutrient content and colour. In general, colour degradation and browning pigment formation of fruits occur during heating (Awuah et al. 2007). On the other hand, heat treatment also enhances the bioavailability of antioxidative compounds in some fruits and vegetables (Choi et al. 2006; Kusznierewicz et al. 2008; Nicoli et al. 1997a, b; Patras et al. 2009; Rickman et al. 2007a; Yang and Gadi 2008). The study of thermal processing is necessary to design new processes for the production of safe food products with a maximum retention of the nutritional profile.

Polyphenolic compounds appear to have many functions in fruits such as colour, antimicrobial function, and antioxidant protection. Recent research has shown that polyphenolic compounds can act as an antioxidant and they also have interesting health benefits by reducing the risk for cardiovascular disease, cancer (Stevenson and Hurst 2007), neurodegenerative disease (Joseph et al. 2009), inflammation (Suzuki 2009) and liver damage (Morisco et al. 2008).

Betalains are water-soluble polyphenolic pigments, which comprise the yellow betaxanthins and the red-purple betacyanins, which are found in some fruits such as a red beet root and dragon fruit (Hylocereus sp.). The betacyanins consists of betalamic acid and an acyclic amine group, which are excellent electron donors which enables them to scavenge free radicals. The red-purple pigment, known as betacyanins, from dragon fruit has recently been suggested as a potential betalain source and probably can also be used as natural colourants in foodstuff (Moreno et al. 2008; Stintzing and Carle 2007, 2004; Stintzing et al. 2002; Wybraniec et al. 2001). However, this pigment is degraded by temperature, oxygen, UV light, pH and different cofactors during processing or storage (Herbach et al. 2006b).

Dragon fruit puree, especially the RF, has been thermally processed and is widely used as an intermediate product in concentrated juices, beverages, ice cream, jam and jellies processing (Barbeau 1993; Gibson and Nobel 1986; Tepora 2009). The chemical properties and rheological parameters are important factors to design equipment for these operations. Some compounds such as polyphenolic and pigment compounds can probably be used for the authenticity and quality control of fruit purees (Fugel et al. 2005).

However, no research is available on the changes of the qualities of dragon fruit puree during thermal processing. Therefore, two types of dragon fruit puree, WF and RF, were submitted to heat treatment of a maximum of 60 min. The temperatures varied between 50 and 90 °C, in steps of 10 °C, for 60 min. The purpose of this research was to study the influence of heat treatment on a wide variety of quality parameters: physicochemical properties, betacyanins content, colour, microbiological properties, total phenol content, antioxidant activities and rheological parameters.

Materials and Methods

Preparation of Dragon Fruit Purees

The dragon fruit was obtained from a Thai shop in Ghent, Belgium and two varieties were investigated: white-flesh (H. undatus; WF) and red-flesh (H. polyrhizus; RF) dragon fruit purees. The fruits were washed under running tap water and hand-peeled. The pulp was cut into pieces before homogenising in a blender. The puree sample was then passed through a 38-mesh sieve and 32-mesh sieve, respectively, to obtain a product of around 1.25-mm size of uniform consistency. These dragon fruit purees, containing the seeds, were then immediately submitted to a thermal treatment.

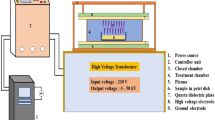

Thermal Treatment

The studied dragon fruit purees were submitted to an isothermal heating at selected temperatures (50, 60, 70, 80 and 90 °C) for a residence time of 60 min. Therefore, 150 g puree was poured into a 250-ml sterile glass container and covered with a sterile plastic screw cap. For each temperature, seven bottles with puree were prepared. The containers were then placed in a thermostatic water bath (model MP-Basis, Julabo, Germany) at selected temperatures and agitated by magnetic stirrer to ensure a uniform temperature profile during thermal treatment. The purees were heated for 0, 10, 20, 30, 40, 50 and 60 min, respectively, after reaching the desired temperature. A heating time of 0 min corresponds with a puree that was heated from room temperature to the preset temperature. When the desired temperature was reached, the bottle was instantly taken out and immediately cooled in an ice water bath to stop the reaction. The unheated puree was used as reference sample. All samples were stored at −18 °C prior to further study. The samples for phenol and antioxidant assays were directly extracted before storing them at −18 °C.

Chemical Properties

A whole set of chemical properties such as dry matter, ash, total dietary fibre, crude fat, protein and vitamin C of dragon fruit purees was determined according to the Association of Official Analytical Chemists methods (AOAC 1995). The density of the samples was measured with a pycnometer at 20 °C after resting for 30 min. Distilled water was used as reference. All analyses were performed in triplicate.

To determine the yield of the dragon fruit juice, the dragon fruit puree was centrifuged at 12,000×g for 20 min and the supernatant was used to calculate the yield of the juice which is given by Eq. 1:

The pellet after centrifugation was placed into a beaker. Water was added, vigorously agitated and sieved. The recovered seeds from the pellet were dried at 60 °C overnight and used to calculate the yield of the seeds (modified from Ariffin et al. 2009) following Eq. 2:

Total Betacyanins Content

The total betacyanins content was determined by using a spectrophotometer at a wavelength of 538 nm. The samples were diluted with distilled water to obtain absorption values between 0.8 and 1.0 and filtrated before analysis using a Whatman no. 1 filter paper. All determinations were performed in triplicate and calculated using Eq. 3:

where A is the absorption at 538 nm, DF is the dilution factor, MW is the molecular weight (550 g/mol), ε is the molar extinction coefficient in H2O (60,000 l/mol cm), and L is the path length of the cuvette (1 cm) (Rebecca et al. 2008; Stintzing et al. 2003).

Colour Parameters

The colour parameters (L*, a* and b*) were measured by using a spectrophotometer colorimeter (Minolta, Model CM-2500D). L* value corresponds to lightness and varies from 0 for black to 100 for perfect white, a* value measures redness when positive, grey when zero and greenness when negative and b* value means yellowness when positive, grey when zero and blueness when negative. Each measurement was repeated five times.

The total colour change (TCC; Eq. 4) is a correct approach to characterise the variation of colour. It appropriately investigates small to medium colour difference and fits for human observer responses (Luo et al. 2001). In this study, the unheated puree sample was used as the reference:

where ∆L*, ∆C* and ∆H* are the differences of the L*, a* and b* colour parameters between the heated puree sample and the reference, K L , K C and K H values are the parametric factors to be adjusted according to different viewing parameters of the lightness, chroma and hue components, respectively (the default values are normally set as 1.0; however, it depends on the application) and S L , S C and S H are the weighting functions of the lightness, chroma and hue components, respectively. R T is an interactive term between chroma and hue differences.

Microbiological Properties

The total plate count was obtained using the pour plate technique on plate count agar, standard method agar. Each dragon fruit puree was diluted with peptone solution and then 1 ml of each dilution was used for microbial count determination. The plates were inverted and incubated at 35 ± 1 °C for 48 h. Duplicates were done for each dilution. The number of microorganisms was expressed as colony-forming units per 1 g of sample.

Antioxidative Properties

Extraction of Polar Compounds

Twenty grammes of puree sample was extracted with 80 ml of chilled 80% acetone solution, at 4 °C, in a blender for 10 min. The slurry was vacuum-filtered over a Whatman no. 1 filter paper. The extracts were stored at −18 °C (modified from Mahattanatawee et al. 2006; Wu et al. 2006). The determination of the total phenol content and antioxidant activity were performed in triplicate.

Total Phenol Content

The Folin–Ciocalteu’s reagent was used for total phenol content determination (Lim et al. 2007). The aliquot of 0.3 ml of extract was added to 1.5 ml of Folin–Ciocalteu’s reagent (diluted 10 times with distilled water) and 1.2 ml of 7.5% sodium carbonate. After vortexing, the samples stabilised for 30 min. The total phenol content was determined by using a spectrophotometer at a wavelength of 765 nm. The standard curve was prepared using solutions of gallic acid (GA) and then total phenol content is expressed as GA equivalents (in milligrammes of GA per 100 g of puree).

Ferric-Reducing Antioxidant Power

The potassium ferricyanide–ferric chloride method was used for the ferric-reducing antioxidant power (FRAP) determination of the extracts (Lim et al. 2007). One millilitre of the polar extract was mixed with 2.5 ml 0.2 M phosphate buffer at pH 6.6 and 2.5 ml 1% potassium ferricyanide. The mixtures were incubated at 50 °C for 20 min in a water bath, and then 2.5 ml 10% trichloroacetic acid was added. Of this mixture, 2.5 ml was taken and 2.5 ml water and 0.5 ml 1% FeCl3 were added. The absorbance at 700 nm was measured after standing for 30 min at room temperature. Phosphate buffer served as a blank solution. Increasing the absorbance value indicated an increase of the reducing power.

DPPH Radical Scavenging Activity

One millilitre of the extract was mixed with 4 ml of 80% ethanolic 0.6 mM of 2,2-diphenyl-1-picrylhydrazyl (DPPH) solution. The absorbance was measured at 515 nm after standing for 3 h (modified from Wu et al. 2006). An 80% ethanol solution served as a blank. For this assay, solutions of GA were prepared for the standard curve, and DPPH value is expressed in GA equivalents (in microgrammes of GA per gramme of puree). The DPPH assay can be used to determine the radical scavenging capacity of the sample.

Browning Formation Pigment

For this determination, the browning formation pigment of the extract was measured by using a spectrophotometer at 420 nm. The extract was diluted with 80% acetone to obtain absorption values between 0.1 and 0.8 (modified from Kusznierewicz et al. 2008).

Rheological Parameters

Prior to the rheological determination, the puree samples were centrifuged at 12,000×g for 20 min. The supernatant was collected to perform the rheological measurements. Before measuring, the supernatants were kept at 25 °C to ensure a uniform temperature. The rheological measurements were carried out using an AR2000 Rheometer which was equipped with a 28-mm conical concentric cylinder. Stepped flow curves were recorded at 25 °C within a shear rate range from 0.06 to 500 s−1 (Vasquez-Caicedo et al. 2007). All the experiments were done in triplicate. The data of the rheological measurements and the suitability of the fitted models were analysed with the supporting rheometer software (TA Rheology Advantage Data Analysis Software). The viscosity of the supernatant was fitted with the power law model (Eq. 5):

where τ is the shear stress (in pascals) and γ is the shear rate (per second). In the power law model, K and n are required to characterise the flow behaviour in which K is the consistency coefficient (in pascal second raised to the nth power) and n is the flow behaviour index (dimensionless) (Shamsudin et al. 2009).

In this research, it was impossible to measure the apparent viscosity of the dragon fruit purees directly because the dragon fruit puree contains a lot of seed particles that might interrupt the viscosity measurement. Consequently, its viscosity can be calculated based on the properties of the supernatant using Eq. 6 (Toda and Furuse 2006):

where η p and η s are the apparent viscosity of dragon fruit purees and supernatant phase, respectively, and φ is the volume fraction of the dispersed phase which was estimated based on the ratio of the volume of the supernatant over the volume of the supernatant plus the volume of the pellet.

Statistical Analysis

The results were reported as means ± standard deviation. The significance of the differences between two sample means was subjected to the paired sample t test and among treatment means was determined by analysis of variance with 5% level of significance (p < 0.05) using SPSS software programme version 16. Linear correlations from regression analysis between the parameters were also analysed with the same software.

Results and Discussion

Properties of the Unheated Dragon Fruit Purees

In this work, the physicochemical and antioxidative properties of WF and RF dragon fruit pulps, the flesh without seeds, were investigated and the results are shown in Table 1. The pulp of two dragon fruit varieties was juicy, showing white colour for the WF pulp and red-purple colour for the RF pulp. From Table 1, it can be derived that the dry matter content and pH of WF and RF pulps are similar, whereas the total dietary fibre, vitamin C and antioxidative properties of RF dragon fruit pulp are significantly higher compared to the WF pulp (p < 0.05).

The flesh with the seeds of two dragon fruit varieties, WF and RF, were mashed into a puree and then the properties of the unheated WF and RF were determined. An overview of the results of the different analyses can be found in Table 2. The total dietary fibre, vitamin C content, yield of pulp, total phenol content and antioxidant activity of the unheated WF and RF are significantly different (p < 0.05). For all parameters, the values of the unheated RF were about two times higher compared to the unheated WF. On the other hand, the percentage of seeds, protein and fat of the two varieties were similar. The yield of the juice of WF was 17% higher than that of RF. The protein, fat and vitamin C content of RF were in correspondence with the values reported by Jaafar et al. (2009). Other researchers found that the vitamin C content of Hylocereus spp. varied from 3 to 170 mg/100 g fresh fruit (Lim et al. 2007; Mahattanatawee et al. 2006; To et al. 1999; Vaillant et al. 2005; Wu et al. 2006) due to regional and seasonal differences, harvesting period and storage time. The ash and protein content of dragon fruit puree of the study was higher than reported for ripe mango puree (Kansci et al. 2008), but pH values of mango puree (Ahmed et al. 2002) were similar to the values observed for dragon fruit puree. The pH of WF and RF was 4.50 and 4.64, respectively. Similar to the mango puree, pasteurisation can be applied to the dragon fruit puree as it is an acidic food.

The colour of WF and RF was grey and deep purple, respectively, with a large amount of black spots coming from the seeds. As can be seen in Table 2, the L* (lightness) and b* (yellowness) colour parameters of WF are significantly higher than that of RF (p < 0.05), although the a* (redness) value of RF was significantly higher compared to WF (p < 0.05) due to its red pigmentation. It is known that betacyanins are the dominant pigments present in red and purple fruit, including RF dragon fruit. The total betacyanins content of RF is 14.82 mg/100 g (Table 2), which is lower than that of an extracted acidic red beet root (Azeredo et al. 2007). The total betacyanins content in RF varied between very small amounts to up to 80 mg/100 g due to the varieties, fruit maturity and analysis method (Esquivel et al. 2007; Harivaindaran et al. 2008; Phebe et al. 2009; Rebecca et al. 2008). In addition, betacyanins can be easily degraded when they are exposed to oxygen, light, high temperature and out of pH range between 3 and 7 (Herbach et al. 2006a, 2007).

The total phenol content and antioxidant value varied depending on the variety. The total phenol content and antioxidative properties (FRAP and DPPH) of the unheated RF were significantly different compared to WF (p < 0.05), which was up to two times higher than that of WF. These results are similar to what Mahattanatawee et al. (2006) reported. The antioxidant activity of RF is higher compared to lychee, mango and longan, while the value for WF was lower than that of other tropical fruits such as guava, mangosteen, papaya, star fruit and water apple (Lim et al. 2007). However, the total phenol content of strawberries (Aaby et al. 2005) was eightfold that of RF. According to the results, the dragon fruit puree can be considered as a healthy fruit puree, particularly the RF variety.

Influence of Thermal Treatment on Physicochemical Properties

WF and RF were subjected to heat treatment at a constant temperature (50, 60, 70, 80 and 90 °C) for 0 to 60 min, with time intervals of 10 min. The physicochemical properties of the heated purees were evaluated as a function of time and temperature.

Vitamin C is normally used as a nutrient index for thermal processing. The vitamin C content was determined and the percentage of retention was calculated by considering the unheated dragon fruit puree as 100% vitamin C retention. The percentage of the vitamin C retention of WF and RF are represented in Fig. 1 and the value at 0 min corresponds with the time that the dragon fruit puree reached the preset temperature. It can be seen that the depletion of vitamin C of the puree occurred during heating up to the preset temperature; it was more pronounced at the high-temperature region. An increased temperature and time corresponded with the decrease of vitamin C content due to the heat sensitivity of vitamin C. As shown in Fig. 1a, it can be deduced that, after 20 min of heating at different temperatures for WF, the vitamin C retention remained stable at a level of about 20%. In the case of RF, vitamin C decreases continuously during heating (Fig. 1b). After 60 min heating at 50 °C, 33% of the vitamin C of RF was retained, but at higher temperatures, the vitamin C retention was <11%. Comparing the vitamin C retention of the two varieties after 90 °C for 60 min, it was about two times higher in WF than that of RF. These observations are in accordance with the vitamin C degradation reported by other authors who found that the thermal processing of various food products is causing a decrease of heat-sensitive nutrients like ascorbic acid, vitamin C, as illustrated for papaya puree (Parker et al. 2010), apple puree (Picouet et al. 2009) and tomato puree (Rickman et al. 2007a; Zanoni et al. 2003).

The influence of heat treatment on total dietary fibre at different temperatures after 60 min in WF and RF was also determined. The results are shown in Table 3; the amount of total dietary fibre of WF at 80 and 90 °C increased significantly (p < 0.05) compared to the other WF, while the total dietary fibre content of RF after heat treatment at 90 °C increases significantly (p < 0.05) among all heated RF. After 90 °C, the total dietary fibre content of WF and RF showed remarkable increases from 0.95% to 1.98% and from 2.06% to 3.00%, respectively (Table 3). These observations are related to changes in cell walls during heating. Cell wall material is added to food products to increase their dietary fibre content, but they can also be degraded by thermal processing. The changes occurring during processing are determined by mechanical and thermal stresses and by its composition (Kunzek et al. 1999). An increase in dietary fibre content during processing was also previously observed for wheat, rice, mung bean and soy bean (Azizah and Zainon 1997), mashed potato and French fries (Thed and Phillips 1995) and carrot (Rickman et al. 2007b). So, it may be concluded that a high temperature and long thermal treatment time might probably enhance the accessibility of the total dietary fibre. In contrast, Azizah and Zainon (1997) reported that the total dietary fibre of groundnut decreased after heat treatment.

Influence of Thermal Treatment on Colour Parameters and Total Betacyanins Content

As the colour of foodstuffs is an important factor for consumer acceptability, colour degradation during heat treatment has been widely studied. Several authors (Ahmed et al. 2002, 2004; Chutintrasri and Noomhorm 2007) have studied the colour parameters (L*, a* and b*) while working on thermal processing of pureed foods. They reasoned that all the three colour parameters can be used to describe the colour degradation of pureed foods during heating.

The L*, a* and b* colour parameters and TCC of the dragon fruit purees were evaluated and it was found that the heating time and temperature affect the colour of purees. During heating, WF and RF became browner and more pronounced when they were heated for a longer time at higher temperatures. All colour parameter values and TCC during heating are showing an upward trend, while the a* value of WF was on the decrease. In Table 4, the L* and b* values of WF and RF strongly influence the TCC during heating that can be described by a correlation equation with a relatively high coefficient (R 2 ≥ 0.7733), while the a* value is only slightly changed with no relation to the TCC. Therefore, the L* and b* values may be used together to indicate the colour degradation for the heated dragon fruit puree. It has been previously reported that, for the pineapple puree, the L* parameter may be used for quality control (Chutintrasri and Noomhorm 2007), while the b* value was used for mango puree (Ahmed et al. 2002). Figure 2 represents the TCC as a function of processing time for the two varieties of dragon fruit puree. From the colour changes as a function of reaction time for the purees, it can be derived that heating at temperatures higher than 80 °C results in more drastic colour changes compared to the lower-temperature region. The TCC of WF and RF during thermal treatment could be divided into two groups, at low temperature (50 to 70 °C) with gradual change and at high temperature (80 and 90 °C) with substantial increase, particularly RF due to the sensitivity of the pigment.

The total betacyanins content of the dragon fruit purees was also investigated, but it was found that the amount of betacyanins of WF was too small to be used as a parameter during the thermal treatment. The percentage of retention of total betacyanins content of RF was calculated by using the unheated RF as 100% betacyanins retention. As shown in Fig. 3, the betacyanins of all heated RF decreased with heating time and temperature. The retention of total betacyanins after heating at 50 to 90 °C for 60 min varied from 79.80% to 32.35%, respectively, so the higher temperature and time resulted in more betacyanins degradation. The betacyanins content was strongly influenced at temperatures higher than 80 °C. Up to 70 °C, 56% of the betacyanins were retained. At temperatures higher than 80 °C, a more drastic influence was observed as only 32% of the original amount of betacyanins was left (Fig. 3). This can be explained by the fact that betacyanins are heat-sensitive compounds due to the instability of the pigment structure. However, it has been shown that adding 1% ascorbic acid and adjusting to pH 4 of RF can enhance betacyanins stability (Herbach et al. 2006a, 2007).

In addition, the TCC of WF and RF and betacyanins degradation of RF during thermal treatment were found to fit a second-order kinetic. This can be expressed by Eq. 7 (Kaymak-Ertekin and Gedik 2005):

where k is the rate constant (per minute), A is the parameter value of the heated puree, A 0 corresponds to the initial value and t is the heating time (in minutes).

The relationship between the reaction rate and its temperature is then determined by the Arrhenius equation (Eq. 8) in order to calculate the activation energy (Ahmed et al. 2002) by using the k value from Eq. 7:

In Eq. 8, k 0 is the frequency factor or pre-exponential (per minute), E is the activation energy (in kilojoules per mole), R is the universal gas constant (8.314 J/mol K) and T is the absolute temperature (in kelvin).

In this work, the magnitudes of the activation energy give an indication of the heat sensitivity of the TCC and betacyanins content of the dragon fruit puree during thermal processing. Dependence of the rate constant on temperature obeyed the Arrhenius relationship (Eq. 8), the computed values of activation energies for TCC of WF and RF were 44.77 and 83.17 kJ/mol with R 2 = 0.7036 and 0.7321, respectively; this indicated that TCC of RF had more sensitivity to the change of temperature between 50 and 90 °C than WF. This could be explained by the fact that RF contained more heat-sensitive compounds such as betacyanins compared to WF. Moreover, the computed values of activation energies for betacyanins degradation of RF was 38.50 kJ/mol (R 2 = 0.7595), while it has been reported that the activation energies for the anthocyanin pigment of plum puree during thermal processing was 37.48 kJ/mol (Ahmed et al. 2004) and a TCC value of mango puree of 36.79 kJ/mol during heating was observed (Ahmed et al. 2002).

In the case of RF, it was observed that the TCC increased through thermal treatment, while betacyanins content decreased. Dependence of the TCC on the betacyanins content was described using the linear relationship; the degradation of betacyanins showed high and negative correlation with TCC (R 2 = 0.9442; Table 4). Betacyanin pigments, being most heat-sensitive, may preferably be used as an index of food product quality during thermal processing. The excellent linear correlation between TCC and betacyanins content of RF indicated that the TCC can probably be used to evaluate the betacyanins content of the puree during heating process. These results are in agreement with the results found by Ahmed et al. (2004) that anthocyanin pigment and TCC may preferably be used as an index of product quality for plum puree.

Influence of Thermal Treatment on Microbiological Property

The number of microorganisms is an important factor in thermal processing as it can be used to evaluate product safety. The total plate counts of the heated purees at different temperatures during heat treatment were determined. As expected, an increase of temperature and time resulted in a decrease of the microbial count (Fig. 4). All the dragon fruit purees contained <7 × 102 CFU/g of microorganisms after 60 min of heating. At temperatures higher than 80 °C for 50 min, the microbial count was <102 CFU/g. So, it can be assumed that, after the pasteurisation process, the dragon fruit purees are a microbially safe product which can be stored for a prolonged time. The dragon fruit purees are ordinarily used as an intermediate product for beverage and confectionary production so usually an extra heating step is applied during the processing of these products. It has been shown that the microbial count in banana puree after pasteurisation was sufficiently reduced (Ditchfield et al. 2006). Some non-pathogenic microorganisms in papaya puree also were eliminated by heating (Parker et al. 2010).

Influence of Thermal Treatment on Antioxidative Properties

As antioxidative compounds are heat-sensitive, it was expected that thermal processing would influence the antioxidative properties of the fruit purees. Several approaches have been used to measure antioxidant activity such as total phenol content, FRAP (Lim et al. 2007), Trolox equivalent antioxidant capacity (Wu et al. 2006), DPPH and oxygen radical absorbance capacity (Mahattanatawee et al. 2006). In this research, total phenol content, FRAP and DPPH were used to evaluate the antioxidant activity of the dragon fruit purees during heating because these methods are technically simple, rapid, stable and reproducible. Furthermore, browning formation pigment was also investigated because it is believed that the Maillard reaction products, represented by the browning formation pigment value, are related to the antioxidant activity (Kusznierewicz et al. 2008).

The changes in antioxidative properties of the dragon fruit purees during the heat treatment are shown in Fig. 5. Surprisingly, the thermal treatment resulted in an increase of all the antioxidative properties of both WF and RF. After heating at 90 °C for 60 min, the total phenol content and FRAP of RF were about two times higher compared to the WF. This can be explained by the fact that the initial value of the unheated RF was higher than that of WF (Table 2) and also suggested that the betacyanins in RF could play as an antioxidant compound (Moreno et al. 2008). The total phenol content and FRAP changes of the heated RF was also bigger than that of the heated WF as a function of heating time and temperature. Whereas the DPPH changes of WF and RF were similar, they increased up to 34.12 μg GA/g after heating at 90 °C for 60 min. The antioxidative properties of heated WF at each temperature showed the same trend: a steady increase as a function of temperature and time. For RF, on the other hand, results in the higher-temperature region (80–90 °C) differed from the lower-temperature region.

In general, the antioxidant activities of fruits and vegetables decrease with thermal processing as Murcia et al. (2009) reported that the antioxidative properties for pea, garlic and beet root lost around 50% of their unprocessed counterpart after thermal processing. However, it has also been reported that thermal processing for fruits and vegetables can lead to higher antioxidant activities due to the changes of the compounds during heat treatment (Choi et al. 2006; Kusznierewicz et al. 2008; Nicoli et al. 1997a, b; Patras et al. 2009; Rickman et al. 2007a; Yang and Gadi 2008).

It was suggested that the increase in antioxidative properties of heated WF and RF exposed to thermal treatment can be explained by the inevitable presence of seeds in dragon fruit purees. Therefore, an additional experiment was performed to verify the influence of seeds in dragon fruit puree. The seeds in dragon fruit puree were removed by centrifugation. After that, this puree without seeds was heated at 70 °C for 60 min, and then the antioxidative properties were evaluated. Figure 6 compares the results of the dragon fruit puree with and without seeds during the thermal treatment. The results of the puree without seeds showed, in contrast to the previous results, that the heating of the puree without seeds resulted in a decrease of the antioxidative properties: total phenol content, FRAP and DPPH. This study confirmed that the seeds in the dragon fruit puree provided some components which can act as antioxidants during thermal treatment and the heat treatment might break the cell wall and seeds and then release antioxidative compounds in seeds that were supposed to be tocopherol, phytosterol and phenolic acid such as GA (Lim et al. 2010).

In this work, the browning formation pigment values in WF and RF during heating were also measured. Similarly with the antioxidative properties, they also increased with thermal treatment for all cases (data not shown). When WF and RF were heated, they became browner due to the occurrence of some browning compounds which can be referred to as Maillard reaction products. The development of the Maillard reaction products as a consequence of heating caused the formation of some antioxidant compounds (Nicoli et al. 1997b). A similar result was found in sauerkraut. The increase of antioxidative properties during heat treatment is probably due to the formation of novel compounds having antioxidant activity (Kusznierewicz et al. 2008). However, it was found that the browning formation pigment of the puree without seeds also increased (data not shown) during heating due to Maillard reaction and colour degradation. They became browner and more pronounced at the high-temperature region, although their antioxidative properties decreased with thermal treatment as previously described. In this case, the Maillard reaction products may not play a role as antioxidant compounds like it was found for the heated WF and RF.

Furthermore, an excellent positive relationship among these antioxidative properties was noticed, showing R 2 values >0.8667. In case of the heated WF and RF, a strong positive linear correlation between browning formation pigment and antioxidative properties (R 2 value was between 0.8799 and 0.9698) were also observed. In contrary to the puree without seeds, a negative linear relationship between browning formation pigment and antioxidative properties (R 2 ≥ 0.8133) was found. It may be suggested that the browning formation pigment can probably be used to evaluate the antioxidative properties due to a perfect correlation. Time can be saved as the browning formation pigment analysis is much more simple and rapid than the methods to assess the antioxidative properties.

Influence of Thermal Treatment on Rheological Properties

The influence of heating time at a constant temperature on the rheological properties of the dragon fruit purees was investigated. The supernatant of the puree was used for rheological determination to prevent the interruption from the seed particles of the puree during measurement. The results show that the apparent viscosity of the unheated RF was five times higher than that of the unheated WF (Fig. 7). This can be explained by the fact that RF contains more oligosaccharides (Wichienchot et al. 2010) and had a double amount of pectin compared to WF (Mahattanatawee et al. 2006). The apparent viscosity of WF and RF at the low shear rate region clearly decreases with increasing shear rate range, showing shear thinning behaviour, while at the high shear rate region, the viscosity of the heated dragon fruit purees exhibited nearly Newtonian behaviour, particularly the heated WF. During heating, the apparent viscosity of the heated WF and RF increased with increasing heating time (Fig. 7). This may suggest that a dragon fruit has slime-like oligosaccharides which probably form a weak gel with pseudonetwork-like behaviour when heating up. There is an implication that a structural change happens while thermal processing is taking place. Similar results were seen for the effect of heating on the rheological properties (Fig. 8). It also was found that the apparent viscosity of WF and RF increased with increasing temperature, particularly for RF. These results are in agreement with the results found by Ditchfield et al. (2004) that the viscosity of banana puree clearly increased during heating from 50 to 60 °C probably due to starch gelation of the puree. However, the apparent viscosity can also decrease with increasing heating temperature and time as found for raspberry, strawberry, peach and prune purees (Maceiras et al. 2007) and Thai seedless guava juice (Shamsudin et al. 2005).

The influence of thermal treatment was investigated for the two parameters from the power law model (Eq. 5), consistency coefficient (K, in millipascal second raised to the nth power) and flow behaviour index (n, dimensionless). The rheological data of the dragon fruit purees fitted very well with the power law model (R 2 ≥ 0.9988; Fig. 9). For all dragon fruit purees, the K value increased while the n value decreased as a function of heating time and temperature. The K and n values of WF were slightly changed, whereas RF showed a big change when they were heated up. The power law model can also be used for flow behaviour prediction. In theory, non-Newtonian foods normally are pseudoplastic materials or shear thinning fluids with n < 1, while very few foods are dilatant or shear thickening fluids with n > 1. The apparent viscosity of Newtonian foods does not change when shear rate is increased, thus it shows n = 1. Krokida et al. (2001) reported that the n value is close to 0.5 for pulpy products and near 1.0 for clear juices. In the study, the n values of the heated purees varied between 0.89 and 0.99 for WF and between 0.69 and 0.85 for RF during thermal treatment; thus, it can be confirmed that the WF and RF showed shear thinning behaviour, while RF seemed to be more viscous compared to WF. The current results are in agreement with other studies for blueberry puree (Nindo et al. 2007) and pumpkin puree (Dutta et al. 2006).

Based on these results, it can be concluded that the temperature and heating time affected the rheological parameters of WF and RF, the apparent viscosity and K value increased, while the n value decreased with thermal treatment for all cases, which is a more pronounced effect in the case of RF.

As it was not possible to measure the apparent viscosity of the original WF and RF due to the large quantity of seeds, the apparent viscosity of the supernatant was analysed to predict the apparent viscosity of the original dragon fruit purees by using Eq. 6. As shown in Table 5, the predicted viscosity of the purees also gave the same trend as their supernatant. The predicted viscosity of the unheated RF was four times higher than that of the unheated WF. After heating at 90 °C for 60 min, they increased up to fourfold, based on the unheated WF. The predicted viscosity of WF was similar to apple, raspberry and orange (Krokida et al. 2001), whereas that of RF was similar to pineapple, guava and apricot (Krokida et al. 2001). Therefore, it can be suggested that RF can probably be used for gel system production which undergo high temperature and long time processing because this puree provided an increasing viscosity with increasing temperature and time while, WF may not be used due to a relatively low viscosity.

Conclusion

The outcome of this research can be used for commercial process optimisation and the different techniques can be used for online monitoring to obtain high-quality products. Based on the results, the dragon fruit puree is a potential source of nutrients and antioxidative components, particularly the RF which contained around double the amount of WF and the RF variety was also rich in betacyanins. The degradation of vitamin C, betacyanins and colour of WF and RF occurred during thermal treatment. The L* and b* values probably can be recommended as an online quality control for WF and RF and TCC can be used to estimate the betacyanins content for RF due to the strong correlation.

It is interesting that the antioxidant activities increased with heating time and temperature. This finding can be explained by the release of some antioxidant compounds from the dragon fruit seeds and probably that Maillard reaction products, represented by the browning formation pigment, might have occurred and may play a role as antioxidant during thermal treatment.

The WF and RF showed shear thinning behaviour and fitted very well with the power law model. The predicted apparent viscosity of the puree increased with thermal treatment, especially the RF. Therefore, it is suggested that the application of RF in foodstuffs such as jelly, jam and yoghurt would be very interesting.

References

Aaby, K., Skrede, G., & Wrolstad, R. E. (2005). Phenolic composition and antioxidant activities in flesh and achenes of strawberries (Fragaria ananassa). Journal of Agricultural and Food Chemistry, 53, 4032–4040.

Ahmed, J., Shivhare, U. S., & Kaur, M. (2002). Thermal colour degradation kinetics of mango puree. International Journal of Food Properties, 5, 359–366.

Ahmed, J., Shivhare, U. S., & Raghavan, G. S. V. (2004). Thermal degradation kinetics of anthocyanin and visual colour of plum puree. European Food Research Technology, 218, 525–528.

AOAC. (1995). Official methods of analysis of the association of the official analysis chemists. Arlington: Association of Official Analytical Chemists.

Ariffin, A. A., Bakar, J., Tan, C. P., Rahman, R. A., Karim, R., & Loi, C. C. (2009). Essential fatty acids of pitaya (dragon fruit) seed oil. Food Chemistry, 114, 561–564.

Awuah, G. B., Ramaswamy, H. S., & Economides, A. (2007). Thermal processing and quality: Principles and overview. Chemical Engineering and Processing, 46, 584–602.

Azeredo, H. M. C., Santos, A. N., Souza, A. C. R., Mendes, K. C. B., & Andrade, M. I. R. (2007). Betacyanin stability during processing and storage of a microencapsulated red beetroot extract. American Journal of Food Technology, 2, 307–312.

Azizah, A. H., & Zainon, H. (1997). Effect of processing on dietary fiber contents of selected legumes and cereals. Malaysia Journal Nutrition, 3, 131–136.

Barbeau, G. (1993). The red pitaya, a new exotic fruit. WANATCA: West Australian Nut and Tree Crops Association Yearbook, 17, 74–80.

Bellec, F. L., Vaillant, F., & Imbert, E. (2006). Pitahaya (Hylocereus spp.): A new fruit crop, a market with a future. Fruits, 61, 237–250.

Choi, Y., Lee, S. M., Chun, J., Lee, H. B., & Lee, J. (2006). Influence of heat treatment on the antioxidant activities and polyphenolic compounds of Shiitake (Lentinus edodes) mushroom. Food Chemistry, 99, 381–387.

Chutintrasri, B., & Noomhorm, A. (2007). Color degradation kinetics of pineapple puree during thermal processing. LWT - Food Science and Technology, 40, 300–306.

Ditchfield, C., Tadini, C. C., Singh, R., & Toledo, R. T. (2004). Rheological properties of banana puree at high temperatures. International Journal of Food Properties, 7, 571–584.

Ditchfield, C., Tadini, C. C., Machoshvili, I. A., & Penna, T. C. V. (2006). Polyphenol oxidase and peroxidase thermal inactivation kinetics used as indicators for the pasteurization of acidified banana puree (Musa cavendishii, Lamb.). Brazilian Journal Food Technology, 9, 77–82.

Dutta, D., Dutta, A., Raychaudhuri, U., & Chakraborty, R. (2006). Rheological characteristics and thermal degradation kinetics of beta-carotene in pumpkin puree. Journal of Food Engineering, 76, 538–546.

Esquivel, P., Stintzing, F. C., & Carle, R. (2007). Pigment pattern and expression of colour in fruits from different Hylocereus sp. genotypes. Innovative Food Science and Emerging Technologies, 8, 451–457.

Fugel, R., Carle, R., & Schieber, A. (2005). Quality and authenticity control of fruit purees, fruit preparations and jams—A review. Trends in Food Science & Technology, 16, 433–441.

Gibson, A. C., & Nobel, P. S. (1986). The Cactus Primer. Cambridge: Harvard University Press.

Harivaindaran, K. V., Rebecca, O. P. S., & Chandran, S. (2008). Study of optimal temperature, pH and stability of dragon fruit (Hylocereus polyrhizus) peel for use as potential natural colorants. Pakistan Journal of Biological Sciences, 11, 2259–2263.

Herbach, K. M., Rohe, M., Stintzing, F. C., & Carle, R. (2006a). Structural and chromatic stability of purple pitaya (Hylocereus polyrhizus [Weber] Britton & Rose) betacyanins as affected by the juice matrix and selected additives. Food Research International, 39, 667–677.

Herbach, K. M., Stintzing, F. C., & Carle, R. (2006b). Betalain stability and degradation—Structural and chromatic aspects. Journal of Food Science, 71, 41–50.

Herbach, K. M., Maier, C., Stintzing, F. C., & Carle, R. (2007). Effects of processing and storage on juice colour and betacyanin stability of purple pitaya (Hylocereus polyrhizus) juice. European Food Research Technology, 224, 649–658.

Jaafar, R. A., Rahman, A. R. B. A., Mahmod, N. Z. C., & Vasudevan, R. (2009). Proximate analysis of dragon fruit (Hylecereus polyhizus). American Journal of Applied Sciences, 6, 1341–1346.

Joseph, J., Cole, G., Head, E., & Ingram, D. (2009). Nutrition, brain aging, and neurodegeneration. The Journal of Neuroscience, 29, 12795–12801.

Kansci, G., Koubala, B. B., & Mbome, I. L. (2008). Biochemical and physicochemical properties of four mango varieties and some quality characteristics of their jams. Journal of Food Processing and Preservation, 32, 644–655.

Kaymak-Ertekin, F., & Gedik, A. (2005). Kinetic modelling of quality deterioration in onions during drying and storage. Journal of Food Engineering, 68, 443–453.

Krokida, M. K., Maroulis, Z. B., & Saravacos, G. D. (2001). Rheological properties of fluid fruit and vegetable puree products: Compilation of literature data. International Journal of Food Properties, 4, 179–200.

Kunzek, H., Kabbert, R., & Gloyna, D. (1999). Aspects of material science in food processing: Changes in plant cell walls of fruits and vegetables. Zeitschrift für Lebensmittel-Untersuchung und -Forschung A, 208, 233–250.

Kusznierewicz, B., Smiechowska, A., Bartoszek, A., & Namiesni, J. (2008). The effect of heating and fermenting on antioxidant properties of white cabbage. Food Chemistry, 108, 853–861.

Lim, Y. Y., Lim, T. T., & Tee, J. J. (2007). Antioxidant properties of several tropical fruits: A comparative study. Food Chemistry, 103, 1003–1008.

Lim, H. K., Tan, C. P., Karim, R., Ariffin, A. A., & Bakar, J. (2010). Chemical composition and DSC thermal properties of two species of Hylocereus cacti seed oil: Hylocereus undatus and Hylocereus polyrhizus. Food Chemistry, 119, 1326–1331.

Luo, M. R., Cui, G., & Rigg, B. (2001). The development of the CIE 2000 colour-difference formula: CIEDE2000. Color Research & Application, 26, 340–350.

Maceiras, R., Alvarez, E., & Cancela, M. A. (2007). Rheological properties of fruit purees: Effect of cooking. Journal of Food Engineering, 80, 763–769.

Mahattanatawee, K., Manthey, J. A., Luzio, G., Talcott, S. T., Goodner, K., & Baldwin, E. A. (2006). Total antioxidant activity and fiber content of select Florida-grown tropical fruits. Journal of Agricultural and Food Chemistry, 54, 7355–7363.

Moreno, D. A., Garcia-Viguera, C., Gil, J., & Gil-Izquierdo, A. (2008). Betalains in the era of global agri-food science, technology and nutritional health. Phytochemistry Reviews, 7, 261–280.

Morisco, F., Vitaglione, P., Amoruso, D., Russo, B., Fogliano, V., & Caporaso, N. (2008). Foods and liver health. Molecular Aspects of Medicine, 29, 144–150.

Murcia, M. A., Jiménez, A. M., & Martínez-Tomé, M. (2009). Vegetables antioxidant losses during industrial processing and refrigerated storage. Food Research International, 42, 1046–1052.

Nicoli, M. C., Anese, M., Manzocco, L., & Lerici, C. R. (1997a). Antioxidant properties of coffee brews in relation to the roasting degree. Lebensmittel-Wissenschaft und -Technologie, 30, 292–297.

Nicoli, M. C., Anese, M., Parpinel, M. T., Franceschi, S., & Lerici, C. R. (1997b). Loss and/or formation of antioxidants during food processing and storage. Cancer Letters, 114, 71–74.

Nindo, C. I., Tang, J., Powers, J. R., & Takhar, P. S. (2007). Rheological properties of blueberry puree for processing applications. LWT - Food Science and Technology, 40, 292–299.

Parker, T. L., Esgro, S. T., Miller, S. A., Myers, L. E., Meister, R. A., Toshkov, S. A., et al. (2010). Development of an optimised papaya pulp nectar using a combination of irradiation and mild heat. Food Chemistry, 118, 861–869.

Patras, A., Brunton, N., Pieve, S. D., Butler, F., & Downey, G. (2009). Effect of thermal and high pressure processing on antioxidant activity and instrumental colour of tomato and carrot purées. Innovative Food Science and Emerging Technologies, 10, 16–22.

Phebe, D., Chew, M. K., Suraini, A. A., Lai, O. M., & Janna, O. A. (2009). Red-fleshed pitaya (Hylocereus polyrhizus) fruit colour and betacyanin content depend on maturity. International Food Research Journal, 16, 233–242.

Picouet, P. A., Landl, A., Abadias, M., Castellari, M., & Viñas, I. (2009). Minimal processing of a Granny Smith apple purée by microwave heating. Innovative Food Science and Emerging Technologies, 10, 545–550.

Rebecca, O. P. S., Zuliana, R., Boyce, A. N., & Chandran, S. (2008). Determining pigment extraction efficiency and pigment stability of dragon fruit (Hylocereus polyrhizus). Journal of Biological Sciences, 8, 1174–1180.

Rickman, J. C., Barrett, D. M., & Bruhn, C. M. (2007a). Review: Nutritional comparison of fresh, frozen and canned fruits and vegetables. Part 1. Vitamins C and B and phenolic compounds. Journal of the Science of Food and Agriculture, 87, 930–944.

Rickman, J. C., Bruhn, C. M., & Barrett, D. M. (2007b). Review. Nutritional comparison of fresh, frozen, and canned fruits and vegetables II. Vitamin A and carotenoids, vitamin E, minerals and fiber. Journal of the Science of Food and Agriculture, 87, 1185–1196.

Sabbe, S., Verbeke, W., & Damme, P. V. (2009). Confirmation/disconfirmation of consumers’ expectations about fresh and processed tropical fruit products. International Journal of Food Science and Technology, 44, 539–551.

Shamsudin, R., Mohamed, I. O., & Yaman, N. K. M. (2005). Thermophysical properties of Thai seedless guava juice as affected by temperature and concentration. Journal of Food Engineering, 66, 395–399.

Shamsudin, R., Daud, W. R. W., Takrif, M. S., Hassan, O., & Ilicali, C. (2009). Rheological properties of Josapine pineapple juice at different stages of maturity. International Journal of Food Science and Technology, 44, 757–762.

Stevenson, D. E., & Hurst, R. D. (2007). Polyphenolic phytochemicals—Just antioxidants or much more? Celluar and Molecular Life Sciences, 64, 2900–2916.

Stintzing, F. C., & Carle, R. (2004). Functional properties of anthocyanins and betalains in plants, food, and in human nutrition. Trends in Food Science & Technology, 15, 19–38.

Stintzing, F. C., & Carle, R. (2007). Betalains—Emerging prospects for food scientists. Trends in Food Science & Technology, 18, 514–525.

Stintzing, F. C., Schieber, A., & Carle, R. (2002). Betacyanins in fruits from red-purple pitaya, Hylocereus polyrhizus (Weber) Britton & Rose. Food Chemistry, 77, 101–106.

Stintzing, F. C., Schieber, A., & Carle, R. (2003). Evaluation of colour properties and chemical quality parameters of cactus juices. European Food Research Technology, 216, 303–311.

Suzuki, K. (2009). Anti-oxidants for therapeutic use: Why are only a few drugs in clinical use? Advanced Drug Delivery Reviews, 61, 287–289.

Tepora, T.F. (2009). Processed dragon fruit products launched; pilot testing of dragon fruit jam, jelly, puree and juice. Southern Tagalog Agriculture and Resources Research and Development Consortium, Cavite State University, Philippines.

Thed, S. T., & Phillips, R. D. (1995). Changes of dietary fiber and starch composition of processed potato products during domestic cooking. Food Chemistry, 52, 301–304.

To, L.V., Ngu, N., Duc, N.D., Trinh, D.T.K., Thanh, N.C., Mien, D.V.H., et al. (1999). Quality assurance system for dragon fruit. In: The Australian Centre for International Agricultural Research Proceedings 100, Ho Chi Minh City, Vietnam.

Toda, K., & Furuse, H. (2006). Extension of Einstein’s viscosity equation to that for concentrated dispersions of solutes and particles. Journal of Bioscience and Bioengineering, 102, 524–528.

Vaillant, F., Perez, A., Davila, I., Dornier, M., & Reynes, M. (2005). Colorant and antioxidant properties of red-purple pitahaya (Hylocereus sp). Fruits, 60, 3–12.

Vasquez-Caicedo, A. L., Susanne Schilling, R. C., & Neidhart, S. (2007). Effects of thermal processing and fruit matrix on b-carotene stability and enzyme inactivation during transformation of mangoes into purée and nectar. Food Chemistry, 102, 1172–1186.

Wichienchot, S., Jatupornpipat, M., & Rastall, R. A. (2010). Oligosaccharides of pitaya (dragon fruit) flesh and their prebiotic properties. Food Chemistry, 120, 850–857.

Wu, L. C., Hsu, H. W., Chen, Y. C., Chiu, C. C., Lin, Y. I., & Ho, J. A. A. (2006). Antioxidant and antiproliferative activities of red pitaya. Food Chemistry, 95, 319–327.

Wybraniec, S., Platzner, I., Geresh, S., Gottlieb, H. E., Haimberg, M., Mogilnitzki, M., et al. (2001). Betacyanins from vine cactus Hylocereus polyrhizus. Phytochemistry, 58, 1209–1212.

Yang, J., & Gadi, R. L. (2008). Effects of steaming and dehydration on anthocyanins, antioxidant activity, total phenols and color characteristics of purple-fleshed sweet potatoes (Ipomoea botatas). American Journal of Food Technology, 3, 224–234.

Zanoni, B., Pagliarini, E., Giovanelli, G., & Lavelli, V. (2003). Modelling the effects of thermal sterilization on the quality of tomato puree. Journal of Food Engineering, 56, 203–206.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liaotrakoon, W., De Clercq, N., Van Hoed, V. et al. Impact of Thermal Treatment on Physicochemical, Antioxidative and Rheological Properties of White-Flesh and Red-Flesh Dragon Fruit (Hylocereus spp.) Purees. Food Bioprocess Technol 6, 416–430 (2013). https://doi.org/10.1007/s11947-011-0722-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-011-0722-4