Abstract

Edible coatings made from tapioca starch/decolorized hsian-tsao leaf gum (dHG) containing cinnamon essential oil or grape seed extract (GSE) were developed and applied to minimally processed carrots. Coatings based on 0.3% dHG and 1.7% tapioca starch were prepared and incorporated with 0.1–0.3% cinnamon oil or 0.3–0.6% GSE as antimicrobial agents. Fresh-cut carrots were immersed into coating solutions, placed in expanded polystyrene trays, and sealed in polypropylene bag. Changes in the initial respiration rate, the headspace atmosphere, color, microbial growth, and sensory evaluation were then measured. During refrigeration, the initial respiration rates for carrots with various coating treatments slightly increased as compared to the control group carrots, and the coatings with cinnamon oil showed the highest rates. Headspace analysis revealed that coated samples also had higher CO2 and lower O2 concentrations, which were consistent with the initial respiration rate results. Though samples coated with the antimicrobial solutions (cinnamon oil or GSE) did not show advantages in reducing microbial growth as compared to the control group carrots, they presented better acceptance during the sensory evaluations. The use of edible coatings successfully maintained the surface appearance and retarded the formation of “white blush” on the surface of carrots during refrigeration. While the visual appearance quality of minimally processed carrots was significantly improved by the coating treatments, the microbial growth was the same or even worse in some cases. Based on the pronounced improvements of the carrots’ appearance and the comparable microbial control, the plain starch/dHG coating without cinnamon oil or GSE was recommended for extending the shelf life of minimally processed carrots.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

To meet the requirements of consumers for healthy, fresh, and conveniently prepared fruits and vegetables, the development of minimally processed agricultural products is increasing and obtaining much attention (Ahmed et al. 2011). These products have been physically changed from their original state (trimmed, peeled, washed, and/or cut) and are usually sealed in packages and stored at low temperatures (Olivas and Barbosa-Ćanovas 2005; Xu et al. 2007). However, minimal processing operations alter the integrity of the fruits and vegetables and cause negative effects on product quality such as browning, off-flavor development, texture breakdown, and the contamination of microorganisms on food which may bring about safety concerns (Rojas-Graü et al. 2009; Campos et al. 2011; Díaz-Mula et al. 2011). The carrot is a popular vegetable usually used to make salads, home-cooked meals in daily life, and ready-to-eat products. Lightly processed carrots are prepared by peeling off the outer layer of the carrots root and cutting. However, processing operations may induce physiological changes such as an increase in respiration and degradation of protein, carbohydrates, and lipids and may increase the opportunity for exposure to microbial contamination and bring off-flavors that limit the marketing of the minimally processed carrots (Li and Barth 1998). Furthermore, the minimally processed carrots lose the bright orange appearance by developing a whitish appearance or “white blush” on the surface due to dehydration and lignification, which may reduce consumers’ acceptability and purchase intention (Bolin and Huxsoll 1991).

Using edible films and coatings for food protection and preservation shows some advantages over synthetic materials, such as biodegradability and eco-friendliness (Tharanathan 2003). The ability of edible films (1) to retard physiological deterioration, biochemical changes, and microbial degradation and (2) to extend shelf life may be improved by including additives such as antioxidants, antimicrobials, colorants, flavors, fortifying nutrients, and spices in film formulation (Rico et al. 2007; Pranoto et al. 2005; Ahmed et al. 2011; Campos et al. 2011; Díaz-Mula et al. 2011). For example, essential oils (EOs) with a natural or “green” image are outstanding as an alternative to synthetic food preservatives and these products meet the demands for natural products and with a smaller impact on the environment (Burt 2004). Raybaudi-Massilia et al. (2008) evaluated the effect of malic acid and EOs (cinnamon, Palmarosa, and lemongrass) on fresh-cut melon by incorporating them into an alginate-based edible coating and found a reduction of inoculated Salmonella enteritidis population resulting in prolonged shelf life. Grape seed extract (GSE) contains large quantities of polyphenolic compounds, such as (+)-catechins, (−)-epicatechin, and (−)-epicatechin-3-O-gallate and dimeric, trimeric, and tetrameric procyanidins (Saito et al. 1998) and has been shown to possess pronounced antioxidant and antibacterial properties (Jayaprakasha et al. 2003; Xu et al. 2007). Xu et al. (2007) used GSE as a sanitizer for reducing the populations of pathogens on whole and fresh-cut cucumbers and lettuce which suggested that GSE could inhibit bacteria and prolong the shelf life of minimally processed vegetables.

Starch is a cheap, abundant, biodegradable, edible, easy-to-use, and natural biopolymer (Mali et al. 2002; Durango et al. 2006). Hsian-tsao herb (Mesona procumbens Hemsl), a member of the Labiatae family, has been used as one of the remedy herbs in Chinese folk medicine to alleviate heat prostration, hypertension, diabetes, and muscle and joint pain (Yen and Hung 2000). Chen and Lai (2008) found that by manipulating the ratio of tapioca starch to decolorized hsian-tsao leaf gum (dHG) and keeping it under a very low total solid concentration (2%), it was possible to generate a starch/dHG solution which would not form a “gel” after cooling, but would possess film-forming ability after being dehydrated. The objective of this study is to evaluate the feasibility of applying tapioca starch/dHG-based active coating with cinnamon oil and grape seed extract to minimally processed carrots. Changes in initial respiration rate, headspace atmosphere, color attributes, microbial growth, and sensory properties during refrigeration would be evaluated as well.

Materials and Methods

Materials

Dried hsian-tsao leaves were purchased from a contracted farmer (Sanyi, Miao-Li, Taiwan). Extraction and decolorization of hsian-tsao leaf gum were performed according to the method of Chen and Lai (2008). Native tapioca starch (22.5 ± 0.5% amylose on dry basis) was kindly provided by Ku-Tung Foods Inc. (Chia-Yi, Taiwan). Reagent-grade glycerol acted as plasticizer and sodium chloride were purchased from Shimakyu’s Pure Chemicals (Osaka, Japan). Cinnamon powder and grape seed extract were purchased from Tomax Enterprise Co., LTD (Taichung, Taiwan) and Bio/chem. Research (USA), respectively. Plate Count Agar (PCA), Potato Dextrose Agar (PDA), and peptone were purchased from Becton, Dickinson and Company (BD) (Sparks, MD, USA).

Preparation of Essential Oil

The extraction of cinnamon essential oil was performed by using the steam distillation method as described by Chen (2009). Anhydrous sodium sulfate was added to remove the trace water in essential oil after distillation, followed by filtration through a 0.45-μm filter membrane (MILLIPORE, Cork, Ireland). The essential oil was preserved in aseptic vials at −20 °C till analysis.

Active Coating Solution Preparation

The starch/dHG coating solution was prepared by dissolving 0.3% (w/w) decolorized hsian-taso leaf gum powder in deionized water with magnetic stirring, followed by mixing with 15% (glycerol/starch + dHG) glycerol and 1.7% (w/w) tapioca starch. The suspension was then heated to 95 °C in a water bath and maintained at 95 °C for 30 min with magnetic stirring. A stock solution of GSE (10%) was prepared by dissolving GSE in double distilled water (ddH2O) with 0.05% (v/v) Tween-80 as a surfactant, then filter-sterilized through a 0.22-μm filter (Great Engineering Technology Corp., Shanghai, China). Various edible coating solutions were prepared by incorporating 0.1–0.3% (w/w) cinnamon oil or 0.3–0.6% (w/w) GSE into the starch/dHG-based coating solutions and homogenizing for 3 min at 12,500 rpm by using a homogenizer (Polytron PT 3000, Kinematica, Switzerland).

Carrot Coating

Carrots purchased from a local market (Matusei supermarket, Taichung, Taiwan) were selected, washed, manually peeled, sanitized by immersion in an 80 ppm sodium hypochlorite solution for 2 min, and rinsed three times with distilled water. The peeled carrots were then cut into cubic pieces (about 10 × 10 × 10 mm).

The carrot pieces were immersed in different coating solutions for 2 min twice and allowed to drip off for 10 min before the second coating. The control group was submerged in distilled water under the same condition. The coated pieces were air flow dried at 25 °C, RH 45% for 1.5 h.

Initial Respiration Rate Measurement

Initial respiration rate was measured by analyzing the CO2 concentration in the headspace, where about 30 g of different coated samples were stored in a 1 L air-tight acrylic respiration container at 4 °C for 16 h. An aliquot of 1 ml of headspace gas for each container was taken with a gas-tight syringe and injected into an IR analyzer (Maihak, UNOR610, Hamburg, Germany) for CO2 concentration analysis. The initial respiration rate was expressed as milliliters of CO2 exhaled per kilogram of carrot pieces per hour. Each measurement was taken in duplicate with two replications.

Quality Evaluation During Refrigeration

An aliquot of 14 carrot pieces for each coating treatment was placed in a polystyrene tray, heat-sealed in a polypropylene bag (oxygen transmission rate, 3,100 cm3/25 μm/m2 day atm), and stored at 4 °C for 15 days. Each coating treatment package had two replications.

Headspace Gas Analysis

The concentrations of O2 and CO2 in the headspace during storage were determined by drawing approximately 25 ml headspace gas using a 30 ml gas-tight syringe, then dividing into portions of 1 ml for CO2 analysis and 3 ml for O2 analysis. CO2 concentrations were analyzed using an IR analyzer (Maihak, UNOR610, Hamburg, Germany) and O2 concentrations were analyzed using an oxygen analyzer (Toray Mocon, MN, USA). Headspace gas determination for each sample was duplicated.

Color Measurement

The effect of coating treatment on carrot color was evaluated using a color meter (ZE-2000, Nippon Denshoku Ind. CO., Tokyo, Japan). The L*, a*, and b* of the CIELAB color space coordinates were measured. Chroma \( \left[ {C{*_{{ab}}} = {{\left( {a{*^{{2}}} + b{*^{{2}}}} \right)}^{{0.{5}}}}} \right] \) and whiteness index \( \left[ {{\text{WI}} = {1}00 - } \right[{\left( {{1}00 - L*} \right)^{{2}}} + a{*^{{2}}} + b{*^{{2}}}\left] {^{{0.{5}}}} \right] \) were calculated (Bolin and Huxsoll 1991). Average values were obtained from three measurements, and ten replications were conducted for each treatment.

Microbiological Analysis

To evaluate the antimicrobial efficiency of the antimicrobial edible coatings on the carrots, the mesophilic aerobes, psychrophiles, yeast, and molds of each sample were enumerated at 0, 4, 8, 12, and 15 storage days. An aliquot of 10 g of carrot pieces from each package was transferred aseptically to a sterilized filter stomacher bag with 90 ml of sterilized peptone water (0.1% peptone + 0.85% NaCl). After being homogenized for 2 min, serial dilutions were taken and then poured in PCA for mesophilic aerobes and psychrophiles and PDA for yeast and molds on petri dishes. Plates were incubated at 37 °C for 2 days to enumerate mesophiles, 4 °C for 10 days to enumerate psychrophiles, and 25 °C for 5 days to enumerate yeast and molds. The results were represented as log colony-forming unit per gram of carrot. The measurements were taken in duplicate for each sample.

Sensory Evaluation

Hedonic sensory evaluation was performed according to the method of Simões et al. (2009) with modification. Sensory quality of coated carrot pieces was evaluated at 0, 2, 4, 8, and 15 days of storage. Thirty panelists, between 20 and 43 years old, were recruited from the Department of Food Science and Biotechnology of National Chung Hsing University, Taiwan to assist the analysis. Carrot pieces were coated with (1) distilled water (control), (2) starch/dHG coating without any additive (plain), or (3) starch/dHG coating with either 0.1% cinnamon oil or 0.3% grape seed extract. Each sample was randomly numbered. The scores of appearance, odor, flavor, and overall preference were given ratings from 1 to 9, where 1 = unusable/unacceptable, 3 = poor, 5 = fair, 7 = good, and 9 = excellent, as described by Selma et al. (2008). Whiteness index by examining the sample surface under white light was scored on a 1–9 scale, where 1 = none, 5 = moderate, and 9 = severe, as described by Simões et al. (2009) with some modification.

Statistical Analysis

The statistical analysis of the results was performed by using ANOVA procedures of the SAS software (version 9.1, Statistical Analysis System Inc., Cary, NC, USA, 2006). Duncan’s new multiple range test was used to determine the differences of means and the comparisons were made at 5% level of significance.

Results and Discussion

Initial Respiration Rate and Headspace Gas Analysis

The effects of the coating treatments on the initial respiration rate of carrots are shown in Table 1. It was found that the coated samples generally showed higher respiration rates than the control samples which were coated only with distilled water. The control samples showed the lowest respiration rate as evidenced by the lowest CO2 level (9.64 ml/kg/h) among the samples tested. Furthermore, the samples coated with cinnamon oil showed higher respiration rates, especially for samples coated with 0.3% cinnamon oil which had a CO2 level of up to 20.56 ml/kg/h followed by the samples coated with GSE and samples coated with plain starch/dHG in decreasing order. This is possibly due to the fact that the wounding of plant tissues by peeling and cutting as well as coating manipulation may impose additional stress on the carrots (Kays 1991). Simões et al. (2009) investigated the respiration rate of uncoated and coated carrot sticks and also reported that the treatments which combined coating and drying induced the higher respiration rate. Furthermore, the increase in respiration rate could be associated with the increase in microbial populations on the minimally processed products during storage with time (Toivonen and DeEll 2002).

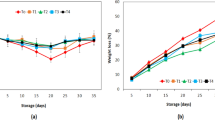

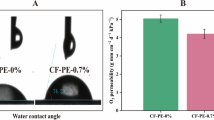

The results of headspace gas analysis for different coated carrots are shown in Fig. 1. In general, the O2 levels decreased and the CO2 levels increased during the 15 days of refrigeration. However, as shown in Fig. 1a, the CO2 levels for all samples during the first 4 days of storage had increased markedly, then remained relatively unchanged or slightly decreased except for the samples coated with 0.1% cinnamon oil, which showed the highest respiration rates with the CO2 concentrations in the headspace continuously increasing to the highest level measured during storage. Furthermore, as shown in Fig. 1b, the O2 level in the package declined rapidly in the first 4 days for all samples, then remained relatively unchanged except for samples coated with 0.1% cinnamon oil, which showed a continuous drop in the O2 levels during storage. Simões et al. (2009) and Li and Barth (1998) also described that the O2 and CO2 levels of coated carrot sticks changed rapidly in the first few days and then the change slowed down. As mentioned before, wounding of plant tissues by peeling and cutting as well as coating manipulation may impose additional stress for carrots, which results in an increase in respiration (Kays 1991; Martin-Diana et al. 2006). It was thought that the cells around the injury site may strengthen themselves by secretion of an additional structural component, which causes an activation of its metabolism and consequently a higher respiration rate (Martin-Diana et al. 2006). Moreover, the increase in respiration rate could be associated with the increase in microbial populations on the minimally processed products with time during storage (Toivonen and DeEll 2002). However, edible coatings may also possibly produce a modified atmosphere on coated fruits by isolating the coated product from the environment and resulting in a decrease in the interchange of oxygen, carbon dioxide, and water vapor of the coated fruits with selective permeability to gases (Olivas and Barbosa-Ćanovas 2005). Therefore, the results obtained in this study may be caused by a combination effect of the injury stress by peeling and the coating treatment, the microbial growth during storage, and the modified atmosphere created by the coating treatment. It seems that cinnamon oil may impose more stress to carrots as compared to GSE, as evidenced by the higher initial respiration rate for samples treated with starch/dHG coatings with cinnamon oil (as shown in Table 1). However, the antimicrobial effects of cinnamon oil and GSE in conjunction with the modified atmosphere environment created by coating treatment may reduce the changes in gas compositions. Some studies also showed that coating processing on fresh-cut fruit with essential oil could reduce the CO2 production and O2 consumption (Rojas-Graü et al. 2007; Raybaudi-Massilia et al. 2008). Carrots with 0.1% cinnamon oil have the highest respiration rates during storage possibly due to the fact that the stress induced by cinnamon oil is strong, but the antimicrobial effect is not effective under such a low concentration as 0.1%.

Color Changes

The effects of coating treatments on the color attributes of fresh-cut carrot surfaces were determined. It was found that the change in lightness (L*) values of fresh-cut carrots is less significant as compared to changes in a* and b* values, which showed a decreasing trend during storage (data not shown). Starch/dHG coating treatments significantly decreased the L* values and increased the a* and b* values. Consequently, the chroma values (shown in Table 2) for the control samples were significantly lower than those for the starch-/dHG-coated samples, which are possibly due to the dehydration of the uncoated samples during refrigeration.

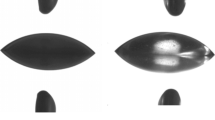

Another way to evaluate the appearance of fresh-cut carrots is by measuring their values of WI, which represent the extent of surface whitening, e.g., “white blush”, as a result of dehydration and lignification due to surface wounding (Bolin and Huxsoll 1991). Higher WI values indicate the greater development of surface whitening. As shown in Table 2, starch-/dHG-coated samples showed significantly lower WI values when compared with the control samples. During refrigeration, the WI values increased with time. However, the increase in WI was significantly retarded by application of the starch/dHG coatings. This is possibly due to the fact that edible coatings could decrease water transmission and therefore whitening by forming a thin protective layer on carrot surface. Moreover, the application of edible coatings may suppress peroxidase activity which is involved in lignification on the carrot surface (Li and Barth 1998). Fresh-cut carrots with the starch/dHG coating treatments therefore maintained the color attributes better by reducing surface whiteness and thus retaining redness appearance. Control samples, which were coated with distilled water, presented greater changes of color on their surfaces, implying aqueous coatings may promote color changes to a greater extent (Villalobos-Carvajal et al. 2009). Both active ingredients (cinnamon oil and GSE) did not show a pronounced impact on the color attributes of fresh-cut carrots, possibly due to the low concentrations used.

Microbiological Analysis

The growth of mesophiles, psychrophiles, and yeast and molds on fresh-cut carrots are shown in Tables 3, 4, and 5, respectively. It was found that all samples showed continued growth of mesophiles (Table 3) and psychrophiles (Table 4) during refrigeration. Moreover, samples coated with ddH2O (control) showed the lowest microbial counts, followed by samples coated with tapioca starch/dHG, and then those with tapioca starch/dHG/GSE, and finally, those samples coated with tapioca starch/dHG/cinnamon oil had the highest microbial counts. On the other hand, the growth of yeast and molds on fresh-cut carrots seemed to be controlled by the chosen coating treatment, except for the samples coated with tapioca starch/dHG and cinnamon oil (Table 5).

Several studies had reported that edible coatings with the addition of antimicrobial agents could control the microbiota on fruits and vegetables. For example, Durango et al. (2006) reported that edible coatings with the addition of chitosan as an antimicrobial agent had viable control on the microbiota in minimally processed carrots. Xu et al. (2007) reported that 0.1% GSE and mixtures of GSE, Nisin, and citric acid presented the ability to control the total aerobic psychrophilic count and the population of Salmonella and Listeria monocytogenes on cucumber and lettuce. Raybaudi-Massilia et al. (2008) showed that alginate-based coatings with essential oil (cinnamon, clove, and lemongrass) had antimicrobial effects and could extend the microbiological shelf life of fresh-cut melon. Ahmed et al. (2011) showed that the total counts and the growth of yeast and molds in fresh-cut tomatoes could be significantly retarded by a combination treatment of dipping and spraying of 3% delactosed whey permeate. However, the effectiveness of antimicrobial agents depended on the category of antimicrobial agent, the coating matrix, and the food material (Glass and Johnson 2004; Gutierrez et al. 2008; Campos et al. 2011). Gutierrez et al. (2008) suggested that the essential oil might be more effective against microorganisms when being applied to ready-to-use foods containing a high protein level at an acidic pH as well as lower levels of fats or carbohydrate. Therefore, the fact that the application of starch/dHG coatings with 0.1–0.3% cinnamon oil or 0.3–0.6% GSE did not provide antimicrobial advantages on minimally processed carrots may be related to the interaction between the carrot components, the starch/dHG coating matrix, and the antimicrobial agent, which reduced the antimicrobial effectiveness of the cinnamon oil and GSE on fresh-cut carrots. In addition, the surface wounding of the carrots by peeling and cutting may produce a new protective layer of lignin, also known as “white blush” to defend the plant tissues from microbial and oxidative damage (Rico et al. 2007). Starch/dHG coating treatments evidently diminished the protective mechanism provided by lignification and the formation of surface whiteness on carrot surfaces.

Sensory Evaluation

Edible coatings are desirable if they do not affect the original tastes and flavors of foods (Rojas-Graü et al. 2007). Figure 2 shows the appearance, odor, flavor, whiteness, and overall preference scores for fresh-cut carrots coated with (1) ddH2O, (2) tapioca starch/dHG, (3) starch/dHG/0.1% cinnamon, and (4) starch/dHG/0.3% GSE. Sensory results indicated that whiteness and appearance of fresh-cut carrots were greatly affected by the edible coating treatments. Coatings on fresh-cut carrots could retard the formation of “white blush” on surfaces significantly (p < 0.05). Therefore, the whiteness scores were relatively low and the appearance scores were higher than for the control samples. Simões et al. (2009) also reported that edible coatings could improve the visual quality of fresh-cut carrots, and thus, the visual quality was quite high and whiteness was relatively low. In addition, the odor scores and flavor scores did not show a significant difference among the coating treatments (p > 0.05), except for the samples coated with starch/dHG only, which showed lower scores on flavor and odor in the early stages of refrigeration (day 0 and day 2) (p < 0.05). However, at the end of the storage tests, the control samples were less acceptable due to the surface whiteness. In contrast, samples coated with starch/dHG coatings and the cinnamon essential oil and GSE presented better acceptance by consumers in sensory evaluation. These results implied that appearance was the key attribute that drove consumer preference. Starch/dHG coatings could well control the “white blush” of minimally processed carrots during refrigeration, while these treatments did not control microorgansim growth. Samples coated with starch/dHG coatings with 0.1% cinnamon oil remained acceptable in terms of flavor and odor attributes, possibly because the strong carrot odor itself diminished the impact of the strong odor of the cinnamon oil, particularly under a relatively low concentration as 0.1%.

Conclusion

The applications of edible coatings on minimally processed vegetables need to take into account the characteristics of the food ingredients and the coating matrix as well as the category of antimicrobial agents and the possible interactions between these components. In this study, the applications of tapioca starch/dHG edible coatings with antimicrobial agents on peeled cut carrots showed reduced whiteness on carrot surfaces and maintained the color quality of carrots. The coating treatments generally increased the respiration of carrots with increasing CO2 concentrations in the headspace as compared with the control carrots which were only coated with ddH2O. The increase in respiration rate could be associated with the increase in the metabolic stress and microbial populations with time during storage. Microbial analysis revealed that coatings with antimicrobial agents (cinnamon oil and grape seed extract) have no beneficial effect on controlling the mesophile aerobics and psychrophiles, though these treatments showed acceptable sensory quality. Based on the visual quality and microbial results, plain starch/dHG coating without cinnamon oil or GSE was recommended for extending the shelf life of minimally processed carrots.

References

Ahmed, L., Martin-Diana, A.B., Rico, D., & Barry-Ryan, C. (2011). Quality and nutritional status of fresh-cut tomato as affected by spraying of delactosed whey permeate compared to industrial washing treatment. Food and Bioprocess Technology, doi:10.1007/s11947-011-0623-6, In press.

Bolin, H. R., & Huxsoll, C. C. (1991). Control of minimally processed carrot (Daucus caroto 6a) surface discoloration caused by abrasion peeling. Journal of Food Science, 56(2), 416–418.

Burt, S. (2004). Essential oils: their antibacterial properties and potential applications in foods—a review. International Journal of Food Microbiology, 94(3), 223–253.

Campos, C. A., Gerschenson, L. N., & Flores, S. K. (2011). Development of edible films and coatings with antimicrobial activity. Food and Bioprocess Technology, 4, 849–875.

Chen, H-M. (2009). Evaluation of antimicrobial activity of essential oils from spices and their application potentials in buns. MS thesis. Department of Food Science and Biotechnology, National Chung Hsing University, Taichung, Taiwan.

Chen, C.-H., & Lai, L.-S. (2008). Mechanical and water vapor barrier properties of tapioca starch/decolorized hsian-tsao leaf gum films in the presence of plasticizer. Food Hydrocolloids, 22(8), 1584–1595.

Díaz-Mula, HM., Serrano, M., & Valero, D. (2011). Alginate coatings preserve fruit quality and bioactive compounds during storage of sweet cherry fruit. Food and Bioprocess Technology, doi:10.1007/s11947-011-0599-2, In press.

Durango, A. M., Soares, N. F. F., & Andrade, N. J. (2006). Microbiological evaluation of an edible antimicrobial coating on minimally processed carrots. Food Control, 17(5), 336–341.

Glass, K. A., & Johnson, E. A. (2004). Antagonistic effect of fat on the antibotulinal activity of food preservatives and fatty acids. Food Microbiology, 21(6), 675–682.

Gutierrez, J., Barry-Ryan, C., & Bourke, P. (2008). The antimicrobial efficacy of plant essential oil combinations and interactions with food ingredients. International Journal of Food Microbiology, 124(1), 91–97.

Jayaprakasha, G. K., Selvi, T., & Sakariah, K. K. J. (2003). Antibacterial and antioxidant activities of grape (Vitis vinifera) seed extracts. Food Research International, 36(2), 117–122.

Kays, S. J. (1991). Metabolic processes in harvested products. In Postharvest physiology of perishable plant products (pp. 78–142). New York: Van Nostrand Reinhold.

Li, P., & Barth, M. M. (1998). Impact of edible coatings on nutritional and physiological changes in lightly-processed carrots. Postharvest Biology and Technology, 14(1), 51–60.

Mali, S., Grossmann, M. V. E., Garcia, M. A., Martino, M. N., & Zaritzky, N. E. (2002). Microstructural characterization of yam starch films. Carbohydrate Polymers, 50(4), 379–386.

Martin-Diana, A. B., Rico, D., Frias, J., Mulcahy, J., Henehan, G. T. M., & Barry-Ryan, C. (2006). Whey permeate as a bio-preservative for shelf life maintenance of fresh-cut vegetables. Innovative Food Science & Emerging Technologies, 7(1–2), 112–123.

Olivas, G. I., & Barbosa-Ćanovas, G. V. (2005). Edible coating for fresh-cut fruits. Critical Reviews in Food Science and Nutririon, 45, 657–670.

Pranoto, Y., Salokhe, V. M., & Rakshit, S. K. (2005). Physical and antibacterial properties of alginate-based edible film incorporated with garlic oil. Food Research International, 38(3), 267–272.

Raybaudi-Massilia, R. M., Mosqueda-Melgar, J., & Martín-Belloso, O. (2008). Edible alginate-based coating as carrier of antimicrobials to improve shelf-life and safety of fresh-cut melon. International Journal of Food Microbiology, 121(3), 313–327.

Rico, D., Martín-Diana, A. B., Barat, J. M., & Barry-Ryan, C. (2007). Extending and measuring the quality of fresh-cut fruit and vegetables: a review. Trends in Food Science & Technology, 18(7), 373–386.

Rojas-Graü, M. A., Raybaudi-Massilia, R. M., Soliva-Fortuny, R. C., Avena-Bustillos, R. J., McHugh, T. H., & Martín-Belloso, O. (2007). Apple puree-alginate edible coating as carrier of antimicrobial agents to prolong shelf-life of fresh-cut apples. Postharvest Biology and Technology, 45(2), 254–264.

Rojas-Graü, M. A., Soliva-Fortuny, R., & Martín-Belloso, O. (2009). Edible coatings to incorporate active ingredients to fresh-cut fruits: a review. Trends in Food Science & Technology, 20(10), 438–447.

Saito, M., Hosoyama, H., Ariga, T., Kataoka, S., & Yamaji, N. (1998). Antiulcer activity of grape seed extract and procyanidins. Journal of Agricultural and Food Chemistry, 46(4), 1460–1464.

Selma, M. V., Ibáñez, A. M., Allende, A., Cantwell, M., & Suslow, T. (2008). Effect of gaseous ozone and hot water on microbial and sensory quality of cantaloupe and potential transference of Escherichia coli O157:H7 during cutting. Food Microbiology, 25(1), 162–168.

Simões, A. D. N., Tudela, J. A., Allende, A., Puschmann, R., & Gil, M. I. (2009). Edible coatings containing chitosan and moderate modified atmospheres maintain quality and enhance phytochemicals of carrot sticks. Postharvest Biology and Technology, 51(3), 364–370.

Tharanathan, R. (2003). Biodegradable films and composite coatings: past, present and future. Trends in Food Science & Technology, 14(3), 71–78.

Toivonen, P., & DeEll, J. (2002). Physiology of fresh-cut fruits and vegetables. In: Lamikanra (ed) Fresh-cut fruits and vegetables: science, technology, and market, pp. 91–123. CRC Press, Florida, USA.

Villalobos-Carvajal, R., Hernández-Muñoz, P., Albors, A., & Chiralt, A. (2009). Barrier and optical properties of edible hydroxypropyl methylcellulose coatings containing surfactants applied to fresh cut carrot slices. Food Hydrocolloids, 23(2), 526–535.

Xu, W., Qu, W., Huang, K., Guo, F., Yang, J., Zhao, H., et al. (2007). Antibacterial effect of grapefruit seed extract on food-borne pathogens and its application in the preservation of minimally processed vegetables. Postharvest Biology and Technology, 45(1), 126–133.

Yen, G. C., & Hung, C. Y. (2000). Effects of alkaline and heat treatment on antioxidative activity and total phenolics of extracts from Hsian-tsao (Mesona procumbens Hemsl.). Food Research International, 33(6), 487–492.

Acknowledgments

We would like to acknowledge the sponsorship from National Science Council, Taiwan (project number NSC95-2313-B-005-065-MY3). We would also like to thank Prof. Ching-Chang Shiesh from the Department of Horticulture, National Chung Hsing University, Taiwan for the assistance on the physiological analysis of carrots.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lai, TY., Chen, CH. & Lai, LS. Effects of Tapioca Starch/Decolorized Hsian-Tsao Leaf Gum-Based Active Coatings on the Quality of Minimally Processed Carrots. Food Bioprocess Technol 6, 249–258 (2013). https://doi.org/10.1007/s11947-011-0707-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-011-0707-3