Abstract

Introduction

The present work has evaluated the time-dependent and steady-state shear rheological properties of tomato juice.

Materials and Methods

Three models were compared for describing the shear stress decay during shearing (Figoni–Shoemaker, Weltman, and Hahn–Ree–Eyring), and the parameters of each model were empirically related with the shear rate.

Result

The three evaluated models, as well as their modification as function of shear rate, described well the experimental data of tomato thixotropy. The Herschel–Bulkley and Falguera–Ibarz models have shown to be very adequate to describe the data from steady-state shear. The obtained data are potentially useful for future studies on food properties and process design.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Tomato is one of the most popular and widely grown vegetables in the world (Nisha et al. 2010). In fact, tomato is one of the most important vegetables for the food industry. Its products consumption is large and widely included in human diet. The rheological characterization of tomato products is important not only for unit operations design, but also for optimization process and high quality products assurance.

In fact, many studies have been published regarding the rheological characterization of tomato products. However, data presented in literature are very variable (Bayod et al. 2007) and concentrated only in steady-state shear stress measurements. Many studies have just considered one-condition measurement (just apparent viscosity evaluation) or empiric methods of evaluation (as the Bostwick consistometer).

Time dependence is related to the structural change due to shear (Ramos and Ibarz 1998), i.e., the destruction of internal structure during flow (Cepeda et al. 1999). Consequently, time-dependent rheological characterization is extremely important for understanding the products’ changes that occur during the process. However, these characterizations are rare in the literature for tomato products (Bayod et al. 2007; Hayes et al. 1998).

Mizrahi (1997) has modeled the apparent viscosity reduction with time subjecting the product to constant shear rate. The apparent viscosity decay was well modeled by a first-order kinetic (i.e., \( d{\eta_a}/dt = - k \cdot t \)). However, other studies have carried out little objective evaluations. Bayod et al. (2007), Tiziani and Vodovotz (2005a), and Vercet et al. (2002) observed a reduction in apparent viscosity of tomato products over time, obtained in an experiment of constant shear stress or shear rate. Tiziani and Vodovotz (2005a, b) and Vercet et al. (2002) observed only qualitatively the hysteresis area in the cycle of increase and decrease of the shear rate.

Thus, it is a lack of information concerning the time-dependent rheological properties of tomato juice, as well as its modeling as function of shear rate. Moreover, although the Herschel–Bulkley has been widely used for modeling tomato products steady-state shear properties, a recently proposed rheological model (Falguera and Ibarz 2010) has not yet been evaluated for tomato products.

This work has evaluated the time-dependent rheological properties of tomato juice, comparing three models for describing the shear stress decay during shearing (Figoni–Shoemaker, Weltman, and Hahn–Ree–Eyring). Moreover, the steady-state shear behavior of the tomato juice was evaluated by comparing two models (Herschel–Bulkley and Falguera–Ibarz).

Materials and Methods

A commercial tomato juice produced in Spain was used in order to guarantee the standardization and repeatability. The product is salt added and is aseptically packaged after thermal process. Its soluble solids content were determinated by using a refractometer, while its total solid content was measured by drying the samples in a vacuum oven at 70 °C (five replicates).

The rheological evaluation was carried out with new samples, with no mechanical history. Thus, samples were placed in the rheometer and kept at rest for 10 min before start shearing.

Rheological measurements were carried out in a Haake RS 80 rheometer with controlled stress (σ), using a Couette geometry (concentric cylinder; Haake Z40-DIN). The cup and bob radius ratio was \( {1}.0{847}\left( {{\hbox{bob radius}} = {2}0.000\pm 0.00{4}\,{\hbox{mm}}} \right) \). Temperature was maintained constant by using a water bath (Phoenix ThermoHaake C25P) with deviation lower than ±0.3 °C.

The experiments were carried out in three replicates, and the regressions were done for each replicate. The parameters of each model were obtained by non-linear regression using the software Stat-Graphics Plus v. 5.1 (Statistical Graphics Corp) and using a significant probability level of 95%.

The goodness of the models was evaluated by plotting the values of shear stress obtained by models (σ model) as function of the experimental values (σ experimental). The regression of those data to a linear function Eq. 1 results in three parameters that can be used to evaluated the description of the experimental values by the models, i.e., the linear inclination (a that must be as close as possible to the unit), the intercept (b that must be as close as possible to zero), and the coefficient of determination (R 2 that must be as close as possible to the unit).

Time-Dependent Shear Modeling

After rest, the samples were sheared at constant shear rate (γ at 50, 100, 250, 400, and 500 s−1) for 1,000 s, while the shear stress were measured. Temperature was maintained constant at 25 °C.

The shear stress decay was evaluated by three models, widely used for describing the thixotropy in foods (Ibarz and Barbosa-Cánovas 2003). The evaluated models were the Figoni and Shoemaker (1983: Eq. 2), Weltman (1943; Eq. 3), and Hahn, Ree, and Eyring (1959; Eq. 4). The kinetic parameters were obtained by non-linear regression using the software Stat-Graphics Plus v. 5.1 (Statistical Graphics Corp) using a significant probability level of 95%, and then evaluated as function of shear rate.

Steady-State Shear Modeling

Once the product time-dependent behavior was determined, i.e., its characteristics to flow, the steady-state shear behavior was evaluated in the temperature range of 0 °C to 80 °C. Samples were sheared at 250 s−1 for 250 s, predetermined condition for the elimination of product thixotropy. The shear stress data were evaluated in the shear rate range of 0.01 s−1 to 500 s−1, and thus, modeled using the Herschel–Bulkley model Eq. 5. The Herschel–Bulkley model comprises the Newton, Bingham, and Ostwald-de-Waele (power law) models and is being widely used for describing the rheological properties of food products.

The tomato juice flow behavior was also evaluated by using another rheological model, recently proposed by Falguera and Ibarz (2010). In the Falguera–Ibarz model, the variation of the apparent viscosity (η a = σ/γ) with the shear rate is described by a power decay from an initial value (η 0) to a equilibrium one \( \left( {{\eta_{\infty }}} \right) \) Eq. 5.

Results and Discussion

The tomato juice soluble solids content were 5.4 ± 0.2ºBrix, with 5.96 ± 0.02% (w/w) of total solids (mean of five replicates ± standard deviation).

Time-Dependent Shear Modeling

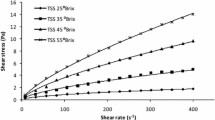

Figure 1 shows the shear stress decay of samples when sheared during 1,000 s. It can be seen that tomato juice shows a thixotropic behavior in the shear rate range of 50 s−1 to 500 s−1. In the original product, the internal structure formed by the insoluble pulp dispersed in the serum has a higher resistance to deformation, resulting in a higher shear stress. When shearing is carried out, this structure is broken, as one may notice by the stress decay. For the five shear rates evaluated, it takes 250–500 s for stress stabilization.

Table 1 shows the mean values for the parameters of the models of Figoni and Shoemaker, Weltman, and Hahn, Ree, and Eyring, respectively. The value of R 2 was always higher than 90% in each replicates.

In the Figoni and Shoemaker model, the parameter σ e is the equilibrium shear stress, i.e., its value after time of shearing enough to complete the break of the product internal structure. The parameter σ 0 is the initial shear stress, i.e., in the beginning of shearing, while k is related with its stress decay during time. As expected, due to the pseudoplastic nature of tomato juice, the parameters of Figoni and Shoemaker model have shown a tendency to increase with shear rate (Fig. 2).

Parameters of Figoni and Shoemaker model as function of shear rate. Vertical bars are the standard deviation in each mark, and the continuous lines are the empirical regressions of Table 3

In the Weltman model, the parameter A is related with the initial shear stress, while B is related with its stress decay. The parameter A has shown a tendency to increase with shear rate as expected due to the juice pseudoplastic behavior, while B has shown a tendency to vary closed to a mean value (Fig. 3).

Parameters of Weltman model as function of shear rate. Vertical bars are the standard deviation in each mark, and the continuous lines are the empirical regressions of Table 3

In the Hahn, Ree, and Eyring model, the parameter σ e is the same as in Figoni and Shoemaker model, and B is the same as k. The initial shear stress is giving by the parameter A. While the parameters σ e and B have shown a tendency to increase due shear rate, A has varied closed to a mean value (Figs. 4 and 5).

Parameter σ e of Hahn, Ree, and Eyring model as function of shear rate. Vertical bars are the standard deviation in each mark, and the continuous line are the empirical regressions of Table 3

Parameters A and B of Hahn, Ree, and Eyring model as function of shear rate. Vertical bars are the standard deviation in each mark, and the continuous lines are the empirical regressions of Table 3

The obtained values are in accordance with those described in the literature for fruit products, in special the parameters related with the stress decay with shearing (k in Figoni and Shoemaker model; B in Weltman and Hahn, Ree, and Eyring models).

The k value of Figoni and Shoemaker model in gilaboru juice at 43ºBrix vary from 0.0027 to 0.0031 s−1 in the shear rate range of 50–150 s−1 (Altan et al. 2005). In the same conditions, the value of B (Weltman model) varies from 0.89 to 1.17 Pa s−1. Abu-Jdayil et al. (2004) has used the Weltman model for modeling the time dependent rheological behavior of tomato paste (5.7% solids). The B value vary from 10−14 to 0.0187 Pa s−1 in the shear rate range of 2.2–79 s−1. Basu et al. (2007) has modeled the shear stress decay of pineapple jams using the Hahn, Ree, and Eyring model. The value of B varies from 0.0024 to 0.0094 Pa s−1 in the shear rate range of 10–100 s−1. Similar results were observed by Ravi and Bhattacharya (2006) for chickpea flour dispersions. The B value of Hahn, Ree, and Eyring model vary 0.0044 to 0.0059 Pa s−1 in the shear rate range of 5–200 s−1.

The experimental data were well described by the three evaluated models, as can be seen by the regression to the Eq. 1. The values of a and R 2 were always higher than 0.99, while the values of b were always lower than 0.03 (Table 2). Those models were successfully used in the characterization of concentrated mandarin juice (Falguera et al. 2010), gilaboru juice (Altan et al. 2005), Malus floribunda juice (Cepeda et al. 1999), tomato paste (Abu-Jdayil et al. 2004), pineapple jam (Basu et al. 2007), chickpea flour dispersions (Ravi and Bhattacharya 2006), quince puree (Ramos and Ibarz 1998), peach and plum pulps (Lozano and Ibarz 1994), and ketchup, mustard, and baby food (Choi and Yoo 2004).

Those parameters were then empirically modeled as function of shear rate, with the exception of the parameters A in Weltman model and B in Hahn, Ree, and Eyring model, whose values were assumed to be the average of the obtained values. The modeling was obtained with high values of R 2, as demonstrated in Table 3.

It is important to observe that, as expected, the expressions for the parameters σ e and k in Figoni and Shoemaker model were the same as the parameters σ e and B in Hahn, Ree, and Eyring model. It is expected that both models are essentially similar, with the same mathematical expression (if the exponential function is applied in both sides of the Hahn, Ree, and Eyring model).

The obtained expressions were then evaluated, as earlier described, by using Eq. 1. The parameters of the regression for the modified models whose parameters are function of shear rate are presented in Table 2. As one may see, the modified Figoni and Shoemaker, Weltman, and Hahn, Ree, and Eyring models, i.e., the models with parameters as the function of shear rate, described well the experimental data.

Although the three models can be well used to describe the time-dependent behavior of tomato juice rheology, the modified Hahn, Ree, and Eyring model has shown a slight better description of experimental data, followed by the modified Weltman and the Figoni and Shoemaker model.

Steady-State Shear Modeling

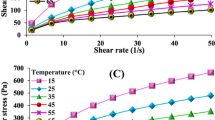

Figure 6 shows the flow curves (shear stress as the function of shear rate) of the tomato juice in the evaluated temperature range, as well as the apparent viscosity associated with each shear rate.

The values for the parameters of the Herschel–Bulkley model are shown in Table 4. As an alternative to the Herschel–Bulkley model, the apparent viscosity of the tomato juice was evaluated by the Falguera–Ibarz model, whose parameters are shown in Table 5. The value of R 2 was always higher than 99% in each replicates.

It is possible to observe that the tomato juice showed a small, but representative yield stress (σ 0, Herschel–Bulkley model). The yield stress is the minimum shear stress required to initiate the product flow, being related to the internal structure of the material that must be broken (Genovese and Rao 2005; Tabilo-Munizaga and Barbosa-Cánovas 2005). At stress below the yield stress, the material deforms elastically, behaving like an elastic solid; above the yield stress, it starts flowing, behaving like a viscous liquid (Bayod et al. 2007). The presence of a yield stress is a typical characteristic of multiphase materials (Sun and Gunasekaran 2009), as the tomato juice, formed by a dispersion of insoluble material (cellular walls and its materials) in a water solution (serum, containing sugars, minerals, proteins, and soluble polysaccharides). Moreover, as expected, the tomato juice showed a shear-thinning behavior, with the flow behavior index (n) always lower than 1.

The obtained values of yield stress (σ 0), flow behavior index (n), and consistency index (k) are closed to those described in the literature for fruit products as açaí and jabuticaba pulps and carrot and blackberry juices (Table 6).

The flow behavior index (n) is assumed to be relatively constant with temperature (Rao 1999), as illustrated in Table 4. It enables the utilization of a constant value equal to the average in the evaluated temperature range (0.563). The yield stress and consistency index (k) decay with temperature were modeled according to Arrhenius model (Eq. 7, where each parameter A is modeled by a pre-exponential factor—A 0, and the activation energy—Ea; R is the constant of the ideal gases, and T is the absolute temperature, i.e., in K). The parameters of Herschel–Bulkley model as function of temperature are shown in Table 7. The regressions R 2 were higher than 0.90.

As expected, the values of the initial (η 0) and equilibrium \( \left( {{\eta_{\infty }}} \right) \) apparent viscosity decay with temperature in the Falguera–Ibarz model. The value of k tends to show a small variation close to a mean value. As suggested by Falguera and Ibarz (2010), the apparent viscosity of the tomato juice was modeled according to Arrhenius model. The pre-exponential parameter (A 0) and the activation energy (Ea) where evaluated as power and logarithmic function of shear rate (Table 7). The regressions R 2 were higher than 0.98. As demonstrated in Table 8, the obtained activation energies are closed to those reported for fruit products.

The experimental data were well described by the two evaluated models, as one may notice by values of a and R 2 were always higher than 0.96, while the values of b were always lower than 0.2 (Table 9). The results have demonstrated that both models can be successfully used for describing the flow behavior of tomato juice.

Conclusions

The present work has evaluated the time-dependent rheological properties of a commercial tomato juice. Three models were used to describe the shear stress decay during shearing (Figoni and Shoemaker, Weltman, and Hahn, Ree, and Eyring). The parameters of each model were empirically related with the shear rate. Then, the steady-state shear behavior of the product was evaluated by using the Herschel–Bulkley and Falguera–Ibarz models. The tomato juice was characterized as a thixotropic fluid, with pseudoplastic behavior with yield stress. Its rheological properties were closed to those previously reported in the literature for other fruit products. All evaluated models described well the experimental values, contributing to the studies of physical properties of foods and process design.

References

Abu-Jdayil, B., Banat, F., Jumah, R., Al-Asheh, S., & Hammad, S. A. (2004). comparative study of rheological characteristics of tomato paste and tomato powder solutions. International Journal of Food Properties, 7(3), 483–497.

Altan, A., Kus, S., & Kaya, A. (2005). Rheological behaviour and time dependent characterization of gilaboru juice (Viburnum opulus L.). Food Science and Technology International, 11(2), 129–137.

Basu, S., Shivharey, U. S., Raghavan, G. S. V. (2007). Time dependent rheological characteristics of pineapple jam. International Journal of Food Engineering, 3(3), article 1.

Bayod, E., Mansson, P., Innings, F., Bergenstahl, B., & Tornberg, E. (2007). Low shear rheology of concentrated tomato products. Effect of particle size and time. Food Biophysics, 2, 146–157.

Barbana, C., & El-Omri, A. (2010). Viscometric behavior of reconstituted tomato concentrate. Food and Bioprocess Technology. doi:10.1007/s11947-009-0270-3.

Cepeda, E., Villarán, M. C., & Ibarz, A. (1999). Rheological properties of cloudy and clarified juice of Malus floribunda as a function of concentration and temperature. Journal of Texture Studies, 30, 481–491.

Choi, Y. H., & Yoo, B. (2004). Characterization of time-dependent flow properties of food suspensions. International Journal of Food Science & Technology, 39, 801–805.

Dak, M., Verma, R. C., Jaaffrey, S. N. A. (2008). Rheological properties of tomato concentrate. International Journal of Food Engineering, 4(7), article 11.

Falguera, V., & Ibarz, A. (2010). A new model to describe flow behaviour of concentrated orange juice. Food Biophysics, 5, 114–119.

Falguera, V., Vélez-Ruiz, J. F., Alins, V., & Ibarz, A. (2010). Rheological behaviour of concentrated mandarin juice at low temperatures. International Journal of Food Science & Technology, 45, 2194–2200.

Figoni, P. I., & Shoemaker, C. F. (1983). Characterization of time dependent flow properties of mayonnaise under steady shear. Journal of Texture Studies, 14, 431–442.

Genovese, D. B., & Rao, M. A. (2005). Components of vane yield stress of structured food dispersions. Journal of Food Science, 70(8), E498–E504.

Hahn, S. J., Ree, T., & Eyring, H. (1959). Flow mechanism of thixotropic substances. Industrial and Engineering Chemistry, 51, 856–857.

Haminiuk, C. W. I., Sierakowski, M. R., Izidoro, D. R., & Masson, M. L. (2006). Rheological characterization of blackberry pulp. Brazilian Journal of Food Technology, 9(4), 291–296.

Hayes, W. A., Smith, P. G., & Morris, A. E. J. (1998). The production and quality of tomato concentrates. Critical Reviews in Food Science and Nutrition, 38(7), 537–564.

Ibarz, A., & Barbosa-Cánovas, G. V. (2003). Unit operations in food engineering. Boca Raton: CRC.

Lozano, J. E., & Ibarz, A. (1994). Thixotropic behavior of concentrated fruit pulps. LWT Food Science and Technology, 27, 16–18.

Mizrahi, S. (1997). Irreversible shear thinning and thickening of tomato juice. Journal of Food Process and Preservation, 21, 267–277.

Nisha, P., Singhal, R. S., Pandit, A. B. (2010). Kinetic modelling of colour degradation in tomato puree (Lycopersicon esculentum L.). Food and Bioprocess Technology. doi:10.1007/s11947-009-0300-1.

Ramos, A. M., & Ibarz, A. (1998). Thixotropy of orange concentrate and quince puree. Journal of Texture Studies, 29, 313–324.

Rao, M. A. (1999). Flow and functional models for rheological properties of fluid foods. In M. A. Rao (Ed.), Rheology of fluid and semisolid foods: principles and applications. Gaithersburg: Aspen.

Ravi, R., & Bhattacharya, S. (2006). The time-dependent rheological characteristics of a chickpea flour dispersion as a function of temperature and shear rate. International Journal of Food Science & Technology, 41, 751–756.

Sato, A. C. K., & Cunha, R. L. (2007). Influence of temperature on the rheological behavior of jaboticaba pulp. Ciência e Tecnologia de Alimentos, 27(4), 890–896.

Sato, A. C. K., & Cunha, R. L. (2009). Effect of particle size on rheological properties of jaboticaba pulp. Journal of Food Engineering, 91, 566–570.

Silva, F. C., Guimaraes, D. H. P., & Gasparetto, C. A. (2005). Rheology of acerola juice: effects of concentration and temperature. Ciência Tecnologia de Alimentos, 25(1), 121–126. in portuguese.

Sun, A., & Gunasekaran, S. (2009). Yield stress in foods: measurements and applications. International Journal of Food Properties, 12, 70–101.

Tabilo-Munizaga, G., & Barbosa-Cánovas, G. V. (2005). Rheology for the food industry. Journal of Food Engineering, 67, 147–156.

Tiziani, S., & Vodovotz, Y. (2005a). Rheological characterization of a novel functional food: tomato juice with soy germ. Journal of Agricultural and Food Chemistry, 53, 7267–7273.

Tiziani, S., & Vodovotz, Y. (2005b). Rheological effects of soy protein addition to tomato juice. Food Hydrocolloids, 19(1), 45–52.

Tonon, R. V., Alexandre, D., Hubinger, M. D., & Cunha, R. L. (2009). Steady and dynamic shear rheological properties of açai pulp (Euterpe oleraceae Mart.). Journal of Food Engineering, 92, 425–431.

Vandresen, S., Quadri, M. G. N., Souza, J. A. R., & Hotza, D. (2009). Temperature effect on the rheological behavior of carrot juices. Journal of Food Engineering, 92, 269–274.

Vercet, A., Sánchez, C., Burgos, J., Montañés, L., & Buesa, P. L. (2002). The effects of manothermosonication on tomato pectic enzymes and tomato paste rheological properties. Journal of Food Engineering, 53, 273–278.

Weltman, R. N. (1943). Breakdown of thixotropic structure as function of time. Journal of Applied Physics, 14, 343–350.

Acknowledgments

Author PED Augusto thanks Fundación Carolina for the received fellow in the program “Movilidad de Profesores e Investigadores Brasil-España.”

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Augusto, P.E.D., Falguera, V., Cristianini, M. et al. Rheological Behavior of Tomato Juice: Steady-State Shear and Time-Dependent Modeling. Food Bioprocess Technol 5, 1715–1723 (2012). https://doi.org/10.1007/s11947-010-0472-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-010-0472-8