Abstract

In April 2002, Swedish researchers shocked the world when they presented preliminary findings on the presence of acrylamide in fried and baked foods, most notably potato chips and French fries, at levels of 30–2,300 ppb. The objective of this research was to study the effect of immersing potato slices in a NaCl solution over the acrylamide formation in the resultant potato chips. Potato slices (Verdi variety, diameter 40 mm, width 2.0 mm) were fried at 170 °C for 5 min (final moisture content of ∼2.0%). Prior to frying, the potato slices were treated in one of the following ways: (1) control slices (unblanched or raw potato slices); (2) slices blanched at 90 °C for 5 min in water; (3) slices blanched at 90 °C for 5 min plus immersed in a 1 g/100 g NaCl solution at 25 °C for 5 min; (4) slices blanched at 90 °C for 5 min plus immersed in a 3 g/100 g NaCl solution at 25 °C for 5 min; (5) slices blanched at 90 °C for 5 min plus immersed in distilled water at 25 °C for 5 min; and (6) slices blanched at 90 °C for 5 min in a 3 g/100 g NaCl solution. Blanching followed by the immersion of potato slices in 1 g/100 g NaCl solution was effective in reducing acrylamide content in ∼62%; however, almost half of this percentage (∼27%) could be attributed to the effect of NaCl and 35% to the effect of the slight heating treatment during salt immersion step (25 °C for 5 min). Blanching seems to make the NaCl diffusion in potato tissue easier leading to a significant acrylamide reduction in the potato slices after frying.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Frying is a widely used cooking method to prepare tasty and crispy snack foods. Potato chips are thin slices whose moisture content decreases from around 80% to almost 2% when they are fried (Maity et al. 2009). It is worth to mention that acrylamide, a chemical compound that is formed in potatoes during frying and is highly related to the color of potato chips, has recently been found to be critical for human health since it is a carcinogenic agent in rats (Rosen and Hellenäs 2002; Mottram et al. 2002; Stadler et al. 2005; Pedreschi et al. 2005).

In April 2002, Swedish researchers shocked the food safety world when they presented preliminary findings of acrylamide in some fried and baked foods, most notably potato chips and French fries, at levels of 30–2,300 μg/kg. Reports of the presence of acrylamide in a range of fried and oven-cooked foods have caused worldwide concern because this compound has been classified as probably carcinogenic in humans with significant toxicological effects, namely neurotoxic and mutagenic (Rosen and Hellenäs 2002; Tareke et al. 2002). French fries and potato crisps exhibit relatively high values of acrylamide of 424 and 1,739 µg/kg, respectively.

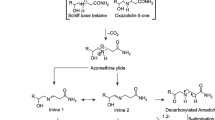

It has been stated that acrylamide is generated as one of the Maillard reactions. Crucial participants in this Maillard reaction in fried potatoes are an amino acid (asparagine) and reducing sugars (fructose and glucose) (Mottram et al. 2002). Asparagine provides the backbone of the acrylamide molecule, while reducing sugars are essential co-reactants in the formation of the N-glycoside intermediates, which lead to the formation of acrylamide. Fried products, especially French fries and crisps, belong to the food category with probably the highest concentration of acrylamide recorded so far. The reason for this strong susceptibility to acrylamide formation is the abundance of free asparagine present in potatoes (Zyzak et al. 2003). Besides, fried potato color is the result of Maillard reactions that depend on the superficial reducing sugar content, and the temperature and frying period (Márquez and Añón 1986).

The main pathway of acrylamide formation in foods is linked to the Maillard reaction, and in particular, the amino acid asparagines (Gomek and Palazoglu 2008). These authors indicate that, from a process control point of view, there is an urgent need to develop viable models for the estimation of acrylamide contents in heated foods during the stages of process design and optimization. Recently, research has focused on the possible mechanisms of acrylamide formation in foods in order to develop strategies to minimize its formation. Some international research groups have separately confirmed a major Maillard reaction pathway for acrylamide formation (Mottram et al. 2002; Stadler et al. 2005; Weiβhaar and Gutsche 2002). The potential of acrylamide formation is strongly related to the sugar content such as glucose and fructose (Biedermann et al. 2002; Pedreschi et al. 2006).

Levels of reducing sugars and asparagine can be lowered by blanching the cut potatoes in hot or warm water before they are fried. Haase et al. (2003) reported that a reduction of the sugar content by blanching could reduce the acrylamide concentration by about 60% depending on the raw material (potato variety and field site) and the production process variables (e.g., blanching conditions and frying temperatures). Besides, asparaginase, an enzyme that hydrolyzes asparagines to aspartic acid, presents a potentially very effective means for reducing acrylamide formation in foods via removal of the precursor, asparagines, from the primary ingredients. For instance, some researchers treated potato pieces with asparaginase after blanching, and the acrylamide levels in the resulting French fries after frying could be lowered by 60–85% and that in potato chips in 60% (Zhang et al. 2009).

The mitigation effect of mono- or divalent cations on the generation of acrylamide is as well an issue of major concern (Zhang et al. 2009). Kolek et al. (2006) proved considerable inhibiting effects of sodium chloride (NaCl) on the formation of acrylamide in mixtures of asparagines–glucose model systems. Similarly, the high mitigation efficiency of calcium chloride (CaCl2) on acrylamide formation in fried potato slices was also demonstrated (Ou et al. 2008). Subsequently, the effect of mono- or divalent cations has been systematically investigated. Added divalent cations, such as Ca2+, were found to prevent acrylamide formation completely, whereas monovalent cations, such as Na+, almost halve the acrylamide formed in the model system. On the other hand, Friedman and Levin (2008) found that changes of the ionic strength induced by positively charged Na+ ions affect the rate of addition reactions of amino groups of amino acids to the double bonds of conjugated vinyl compounds such as acrylamide.

Pedreschi et al. (2007) studied the effect of NaCl soaking after blanching in relation to the acrylamide formation in potato chips after frying. They determined that soaking blanched potato slices in the 3 g/100 g NaCl solution for 5 min at 25 °C reduces acrylamide formation by 11% in potato chips after frying. On the other hand, Franke et al. (2008) determined that blanching of potato strips in a solution containing about 1% of NaCl permitted a defined increase in salt content in the outer product layers without an intensive rise in the core. This internal salt gradient leads to the reduction of acrylamide in the outer layers but minimizes the impacts on sensory and possible health issues.

Currently, a substantial body of research has been carried out worldwide to build a greater understanding of acrylamide, how it is formed in foods, what the risks are for consumers, and how to reduce occurrence levels. Although many effective ways to reduce acrylamide contents have been confirmed, the corresponding effects in sensory attributes in most of the reduction studies in fried potatoes have not yet been clearly reported (Zhang and Zhang 2007; Zhang et al. 2009). The objective of this research was to study the effect of blanching and salt concentration in immersing potato slices in a NaCl solution in relation to the acrylamide formation in the potato chips. The effect of the temperature time treatment of the NaCl solution immersion was also considered.

Materials and Methods

Pre-treatments and Frying Conditions

Potatoes slices of Verdi variety (diameter 40 mm, width 2.0 mm, 72% moisture content) were fried at 170 ± 1 °C for 5 min until reaching a final moisture content of ∼2.0%. Palm oil (Fritex, Århus Oil, Denmark) was used in the experiments. Prior to frying, potato slices were treated in one of the following ways: (1) control slices (unblanched potato slices); (2) slices blanched at 90 °C for 5 min in water; (3) slices blanched at 90 °C for 5 min plus immersed in a 1 g/100 g NaCl solution at 25 °C for 5 min; (4) slices blanched at 90 °C for 5 min plus immersed in a 3 g/100 g NaCl solution at 25 °C for 5 min; (5) slices blanched at 90 °C for 5 min plus immersed in distilled water at 25 °C for 5 min; and (6) slices blanched at 90 °C for 5 min in a 3 g/100 g NaCl solution. The experiments were made in duplicates.

Acrylamide, Glucose, and Asparagine Determination

Chromatography–tandem mass spectrometry analytical methodology was used for the asparagine in the treated potatoes before frying (Nielsen et al. 2006). French fries were homogenized using a Brand handheld mixer (type 4169) fitted with a blended-like sample compartment (type 4297, Braun AG, Germany). An aliquot of approximately 0.3 g of homogenate was transferred to a centrifuge tube, and 30 ml of deionized water was added by using a dispenser. Internal standards were added at the following levels: 150 μl 880 μg/ml 15N2-asparagine. The sample was extracted by an Ultra Turrax T25 homogenizer (Janke & Kunkel, Germany) at 10,000–12,000 rpm for 2 min. The sample was centrifuged at 500 × g for 20 min (Heraeaus Multifuge, Osterode, Germany) and an aliquot of 4 ml was transferred to Eppendorf vials and frozen to −18 °C for 30 min or more and subsequently centrifuged at 12,100 × g for 10 min (Eppendorf Ag Minispin Centrifuge, Germany). The sample thaw during centrifugation and starch precipitated from the supernatant at this low temperature. The solid-phase extraction (SPE) cleanup was performed by an automated Gilson sampler (Gilson Aspec Xli, US) using LiChroLut Rp-C18 SPE cartridges (500 mg) from Merck (Germany) conditioned with 2 ml of methanol, 2 × 2 ml of water, and 0.5 ml of sample lead to waste. Subsequently, 1.75 ml of sample was loaded onto the cartridge and the eluate transferred to Miniprep PTFE filter HPLC vials with a pore diameter of 0.45 μm (Whatman Inc., USA). The acrylamide analyses were performed on 3-g aliquots of homogenized fried potato samples, then internal standard 200 μl 10 μg/ml D3-acrylamide and 30 ml of deionized water were added. The extraction was similar to the asparagine analyses. However, the cleanup was made on 300 mg Isolute Multimode SPE columns (IST).

The LC system consisted of a HP1100 liquid chromatograph (Agilent Technologies, Palo Alto, USA) equipped with a vacuum degasser, a solvent delivery compartment with high pressure mixing, an autosampler, and a column compartment. The autosampler was kept at 10 °C, and the injection volume was 10 μl. Separation was performed on a Hypercarb column (dimensions 2.1 mm × 100 mm, particle size 5 μm). In front of the LC column was a C18 ODS SecurityGuard column (dimensions 4 mm × 2 mm) from Phenomenex (Chesire, UK). The column was eluted with 0.1% formic acid in water with a flow rate of 0.2 ml/min.

The MS–MS detection was performed on a Quattro Ultima triple quadrupole instrument from Micromass (UK) equipped with an atmospheric pressure ionization (API) interface. The mass spectrometer was operated with an electrospray in the positive (ESI+) and negative ion mode (ESI). The source was kept at 120 °C and the desolvation temperature was 400 °C. Nitrogen was used as cone and desolvation gas with flow rates of 150 and 500 l/h, respectively. Argon was used as collision gas and kept at a pressure of 2.4 × 10−3 mbar. Detection was performed by multiple reactions monitoring. Cone voltage and collision energy were optimized for each analyte. Acrylamide and sugars were detected in positive mode, while asparagine was detected in negative ion mode. Quantification of the fragmentations was done using MassLynx software version 4.0 including QuanLynx.

The sugar analyses were performed by ion chromatography with amperometic detection (Dionex ICS-3000) using a Carbopac PA 20 column (3 × 150 mm) (Dionex) and a gradient of deionized water/0.2 M NaOH. Three grams of homogenized raw potato sample was ultrasonicated with 30 ml water and filtered through a 0.45-µm filter before the determination of glucose and sucrose.

Statistical Analysis

Multiple analyses of variance was carried out using Statgraphic Statistical Package (Statistical Graphics Corporation, Version 4, Rockville, USA) including multiple range tests (P > 0.05) for separation of least square means.

Results and Discussion

Blanching plus immersing potato slices in 1 g/100 g NaCl solution was effective in reducing acrylamide content by ∼62% (Fig. 1). However, from this 62%, about half (∼27%) could be attributed to the effect of NaCl and 35% to the slight heating treatment during salt immersion step (25 °C for 5 min). On the other hand, when blanched potato slices were immersed in 3 g/100 g NaCl solution, acrylamide reduction was around 41%. However, most of this reduction could be attributed to the effect of the slight heating treatment (25 °C for 5 min) during the NaCl impregnation step. Finally, when potato slices were blanched at 90 °C for 5 min in a 3 g/100 g NaCl solution, a reduction of almost 36% in acrylamide content in potato chips was achieved. Results suggests that blanching produces changes in the microstructure of potato tissue that makes easier the difussion of NaCl which produces some kind of inhibition in the mechanism of acrylamide formation.

Acrylamide content (µg/kg dry weight) of potato chips pre-treated in different ways and fried at 170 °C for 5 min. AA control slices (unblanched potato slices), CC slices blanched at 90 °C for 5 min in water, HH slices blanched at 90 °C for 5 min plus immersed in a 1 g/100 g NaCl solution at 25 °C for 5 min, II slices blanched at 90 °C for 5 min plus immersed in a 3 g/100 g NaCl solution at 25 °C for 5 min, KK slices blanched at 90 °C for 5 min plus immersed in distilled water at 25 °C for 5 min, MM slices blanched at 90 °C for 5 min in a 3 g/100 g NaCl solution

It is previously suggested that the inhibitory effect of salts is related to the ionic or electronic associations of the cations with asparagine supressing the early stage Maillard reactions (Lindsay and Jang 2006). Also, in the review by Friedman and Levin (2008), they refer to some of their own studies showing that the ionic strength induced by Na+ ions affects the rate of addition reactions of amino groups of amino acids in the double bonds of vinyl compounds like acrylamide. The directly inhibitory effect of 1%, 5%, and 10% NaCl on the acrylamide formation in a model test system of pure glucose–asparagine chemical mixtures was 32%, 36%, and 40%, respectively (Kolek et al. 2006). Hence, the inhibitory effects in model systems which do not include potatoes suggest a chemical mechanism of inhibition.

The amounts of asparagine and glucose only diminished significantly after the blanching treatment (even though this fact was not reflected in reducing the acrylamide content of blanched potato chips probably due to the high potato tissue variability). On the other hand, acrylamide precursor contents such as glucose and asparagine did not show significant differences after the treatments when compared to the blanched slices, suggesting that the mechanism by which NaCl contributes to decrease acrylamide formation is different from that which consists of acrylamide precursor reduction (Pedreschi 2009). This fact can be corroborated by the trends of glucose, sucrose, and asparagine behavior observed in the tested samples after the treatments and before frying (Table 1).

The immersion in 1% NaCl solution before frying seems to be a very useful way to lower acrylamide content because the fried potatoes are often salted before consumption. Earlier studies have shown that soaking in a NaCl solution of blanched potato slices before frying drastically diminished acrylamide formation in potato chips (Pedreschi 2009).

Conclusions

Soaking of blanched potato slices in NaCl solution decreased acrylamide formation after frying. Blanching seems to make the NaCl diffusion in potato tissue easier, leading to a significant acrylamide reduction in the potato slices after frying. The mechanism as to why salt penetration reduces acrylamide formation is not related to the amount of acrylamide precursors such as asparagine and glucose, fructose, and sucrose. It is more plausible that it is related to the changes in the chemical reactions in which the salt takes a critical role or changes in heat transfer due to reduced oil uptake in salt-treated chips.

References

Biedermann, M., Biedermann-Brem, S., Noti, A., & Grob, K. (2002). Methods for determining the potential of acrylamide formation and its elimination in raw materials for food preparation, such as potatoes. Mitteilungen aus Lebensmitteluntersuchung und Hygiene, 93, 653–667.

Franke, K., Strijowski, U. & Kießling, M. (2008). New solutions for fried potato products with respect to high product quality and reduced acrylamide contents. In: Development of new procedures for heated potato and cereal products with reduced acrylamide contents. Entwicklung von neuen Verfahren für Kartoffel- und Getreideerzeugnisse mit reduzierten Gehalten an Acrylamid. Research Association of the German Food Industry, (pp. 35–36). Bonn: BLL.

Friedman, M., & Levin, C. E. (2008). Review of methods for the reduction of dietary contents and toxicity of acrylamide. Journal of Agriculture and Food Chemistry, 56, 6113–6140.

Gomek, V., & Palazoglu, K. (2008). Acrylamide formation in foods during thermal treatment processing with a focus on frying. Food and Bioprocess Technology, 1, 35–42.

Haase, N. U., Matthäus, B., & Vosmann, K. (2003). Minimierungsansätze zur Acrylamid-Bildung in pflanzlichen Lebensmitteln-aufgezeigt am Beispiel von Kartoffelchips. Deutsche Lebensmittel-Rundschau, 99, 87–90.

Kolek, E., Simko, P., & Simon, P. (2006). Inhibition of acrylamide formation in asparagine/D-glucose model system by NaCl addition. European Food Research and Technology, 224, 283–284.

Lindsay, R. & Jang, S. (2006). Chemical intervention strategies for substantial suppression of acrylamide formation in fried potato products. In: M. Friedman and D. Mottram (Eds.), Chemistry and safety of acrylamide in food (pp. 393–404). New York: Springer.

Maity, T., Raju, P. & Bawa, A. (2009). Effect of freezing on textural kinetics in snacks during frying. Food and Bioprocess Technology. doi:10.1007/s11947-009-0236-5. Published online: 07 August 2009.

Márquez, G., & Añón, M. C. (1986). Influence of reducing sugars and amino acids in the color development of fried potatoes. Journal of Food Science, 51, 157–160.

Mottram, D., Wedzicha, B., & Dodson, A. (2002). Acrylamide is formed in the Maillard reaction. Nature, 419, 448–449.

Nielsen, N., Granby, K., Hedegaard, R., & Skibstead, L. (2006). A liquid chromatography–tandem mass spectrometry method for simultaneous analysis of acrylamide and the precursors, asparagine and reducing sugars in bread. Analytica Chimica Acta, 557, 211–220.

Ou, S., Lin, Q., Zhang, Y., Huang, C., Sun, X., & Fun, L. (2008). Reduction of acrylamide formation by selected agents in fried potato crisps on industrial scale. Innovative Food Science and Emerging Technologies, 9, 116–121.

Pedreschi, F. (2009). Acrylamide formation and reduction in fried potatoes. In E. Ortega-Rivas (Ed.), Processing effects on safety and quality of foods. Boca Raton: CRC.

Pedreschi, F., Moyano, P. C., Kaack, K., & Granby, K. (2005). Color changes and acrylamide formation in fried potato slices. Food Research International, 38, 1–9.

Pedreschi, F., Kaack, K., & Granby, K. (2006). Acrylamide content and color development in fried potato strips. Food Research International, 39, 40–46.

Pedreschi, F., Kaack, K., Granby, K., & Troncoso, E. (2007). Acrylamide reduction under different pre-treatments in French fries. Journal of Food Engineering, 79, 1287–1294.

Rosen, J., & Hellenäs, K. E. (2002). Analysis of acrylamide in cooked foods by liquid chromatography tandem mass spectrometry. Analyst, 127, 880–882.

Stadler, R. H., Robert, F., Riediker, M. C., Varga, N., Davidek, T., Devand, S., et al. (2005). In depth-mechanistic study on the formation and potential strategies of control. Nutritional Reviews, 62, 449–467.

Tareke, E., Rydberg, P., Karlsson, P., Eriksson, S., & Tornqvist, M. (2002). Analysis of acrylamide, a carcinogen formed in heated foodstuffs. Journal of Agricultural and Food Chemistry, 50, 4998–5006.

Weiβhaar, R., & Gutsche, B. (2002). Formation of acrylamide in heated potato products—model experiments pointing to asparagine as precursor. Deutsche Lebensmittel-Rundschau, 98, 397–400.

Zhang, Y., & Zhang, Y. (2007). Formation and reduction of acrylamide in Maillard reaction: a review based on the current state of knowledge. Critical Reviews in Food Science and Nutrition, 47, 521–542.

Zhang, Y., Ren, Y., & Zhang, Y. (2009). New research developments on acrylamide: analytical chemistry, formation mechanism, and mitigation recipes. Chemical Reviews, 109, 4375–4397.

Zyzak, D., Sanders, R. A., Stojanovic, M., Tallmadge, D. H., Ebehart, L., Ewald, D. K., et al. (2003). Acrylamide formation mechanism in heated foods. Journal of Agricultural and Food Chemistry, 51, 4782–4787.

Acknowledgments

The authors acknowledge financial support from FONDECYT Project N° 1070031. Lizzie Eriksen and Lone Hertz are acknowledged for skilled technical assistance with the chemical analyses. Århus Oil A/S and Kims A/S are acknowledged for delivering the frying oil and the potatoes, respectively.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pedreschi, F., Granby, K. & Risum, J. Acrylamide Mitigation in Potato Chips by Using NaCl. Food Bioprocess Technol 3, 917–921 (2010). https://doi.org/10.1007/s11947-010-0349-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-010-0349-x