Abstract

The effect of drying conditions on the color of tarragon (Artemisia dracunculus L.) leaves was studied. Tarragon leaves were dried at temperatures of 40 to 90 °C with a constant airflow of 0.6 m/s. The samples were collected at 7%, 10%, 20%, and 30% moisture content wet basis for evaluation of the color change. The color parameters of fresh and dried leaves were measured by a colorimeter. The individual parameters of L*a*b* and L*C*h° color systems were evaluated and h° proved to be the best parameter to monitor color change. The smallest change of the color parameters was observed at 40 °C, in which temperature was low, and also at 90 °C, when drying time was short. The biggest change occurred at the temperatures of 50 to 70 °C. Most of the color change happened before the material reaches 35% moisture content. The combination of drying time and temperature defines the change of color.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Tarragon (Artemisia dracunculus L.) is a strong aromatic plant and is also considered as a medicinal plant (Simon et al. 1984). It is mainly produced with two varieties: French Tarragon and Russian Tarragon (Vienne et al. 1989; Yaichibe et al. 1997). Tarragon can be consumed as fresh, dried, and frozen product. Drying is the main step in the preparation of tarragon for marketing. This research was based on thin layer drying with heated air.

Color is an important component of quality throughout agriculture and food industry, because color is closely associated with factors such as freshness, ripeness, desirability, and food safety. It is often the primary consideration of consumers when making purchasing decisions (Ahmed et al. 2002; McCaig 2002). The color change kinetics of food is a complex phenomenon and there are not much reliable models to predict color change, which can be used in engineering calculations (Ahmed et al. 2002; Suh et al. 2003).

Thermal processing is one of the most widely used and important method of food preservation, and it affects the food quality as measured by sensory evaluation or instrumental methods (Guine et al. 2009; Maskan 2001). The effect of thermal processing on the color of food material has been studied by various researchers, and different color systems have been used for describing color changes of food material (Ahmed et al. 2002; Suh et al. 2003; Maskan 2001; Maharaj and Sankat 1996; Silva and Silva 1999; Lee et al. 2003; Krokida et al. 1998; Du Toit and Joubert 1998; Lozano and Ibarz 1997; Shin and Bhowmik 1995). Color can be used to define adequate thermal processing conditions for maximizing final product quality if its degradation kinetics are determined (Silva and Silva 1999). It was shown that color change measured by tri-stimulus reflectance of a colorimeter may be used to predict quality change in food (Lozano and Ibarz 1997).

The CIELAB color system (Commission Internationale de l’Eclairage 1986) is extensively used to evaluate food colors (Carreno et al. 1995). Numbers of researchers have already studied the color of food using the CIELAB color space for measurement of the color parameters (Ganjloo et al. 2009; McCaig 2002; Carreno et al. 1995; Berberich et al. 2002; Iwe et al. 2000; García-Esteban et al. 2003).

This research investigates the influence of temperature and relative humidity (RH) of the drying air on the color of tarragon. The effect of maturity on color of the dried leaves was also investigated by comparing of the mature and young leaves, which were dried at the same drying conditions. The main objective of this research is to establish the optimal drying conditions for tarragon leaves of two varieties: French Tarragon and Russian Tarragon.

Materials and Methods

Plant Material

Fresh and dried leaves of two tarragon varieties (French Tarragon and Russian Tarragon) were used in the experiments. French Tarragon was collected at a research farm in Elburg (The Netherlands), and Russian Tarragon was planted at the farm of Wageningen University (The Netherlands). Both were harvested just by hand before flowering in July, August, and September. To compare the influence of maturity, also young leaves were used. Young leaves have been harvested 2–3 weeks before flowering. Before drying, leaves were separated from the stalks manually.

Drying

Thin layer drying experiments were performed in a laboratory dryer of the Department of Agrotechnology and Food Science, Wageningen University (Arabhosseini et al. 2008). Samples of 100 g fresh tarragon leaves at a moisture content (MC) of 80% wet basis (w.b.) were put in a tray of 14 × 28 cm. The RH was changed using moistening system based on the psychometric chart. Airflow of 0.6 m/s was used for all experiments.

Two types of experiments were performed. In the first stage, samples were dried at inlet air temperatures of 40, 45, 50, 55, 60, 70, 80, and 90 °C at “low”, “medium” and “high” RH (Table 1; Arabhosseini et al. 2008). This range of temperatures is usually applied in industry for drying of medicinal plants. The samples were dried to equilibrium moisture content (Arabhosseini et al. 2005). Color was measured before and after drying.

In the second stage, experiments were done to investigate color changes during the course of drying. Samples were dried at 45 °C, 17% RH; 60 °C, 7% RH; and 90 °C, 2.5% RH. These combinations were selected to evaluate the critical level of temperatures obtained from the results of the first stage of the experiments. These RHs are the result of heating ambient air of ×g/kg abs MC. The samples were collected during drying at decreasing MCs from 80% to 5% w.b. (Table 2). As it was not possible to measure MC during the drying process, the samples were taken at estimated MCs (based on drying time) as close as possible to the target values given in Table 2.

Color Measurement

Quantitative evaluation of the color changes in tarragon leaves was done by a portable tri-stimulus colorimeter (Minolta Chroma CR-300, Osaka Japan) for direct measurement of the color parameters of the samples. Calibration was done every day before color measurement. A white calibration plate (Y = 92.40; x = 0.3137; y = 0.3194) was used as reference for calibration of the chroma meter. The leaves were evenly distributed in a tray of 20 × 10 cm. The diameter of the measuring area was 8 mm. Measurements were taken at five random points for each sample, and each measurement had three readings to compensate for the variation in the sensor of the measuring head.

The measurements were recorded in five color systems (Yxy, L*a*b*, L*C*h°, XYZ, and Hunter Lab). The L*a*b* (Patras et al. 2009; Maskan 2001; Krokida et al. 1998; Lozano and Ibarz 1997) and L*C*h° (Zhang et al. 2003) system were selected because these are the most used systems for evaluation of dried food material.

The suitability of the various color parameters was based on the visual judgment of experts of two Dutch companies dealing with herbs (Euroma B.V. and VNK B.V.). A collection of 15 samples of dried tarragon leaves as well as the photographs of the same samples was arranged in decreasing order of the values of the color parameters L*, a*, b*, C*, and h°. The parameter, which showed the best compliance between visual and measurement based ranking, was selected. Based on the expert judgment, a threshold was defined to distinct acceptable and unacceptable color of dried tarragon leaves.

Some photos of the samples were taken by a digital camera just to demonstrate the results in reports. The photos were taken in room conditions using artificial lights, and similar conditions were considered for all photos. The photos were sorted based on color parameter values derived by colorimeter.

Data Analysis

Statistical method of ANOVA with 95% confidence interval was applied to find the possible correlation between the data sets and also the significance differences among the experimental data sets.

Results and Discussion

Evaluation of Color Parameters

Figure 1 presents the photos of the dried Russian tarragon leaves, which are arranged in decreasing order of L*, a*, b*, C*, and h° values. The arrangement based on h° came closest to the experts’ visual ranking. The arrangements based on L* and a* values did not result in a continuous visual impression, whereas b* and the C* values showed some similarity to h° in the arrangement. Based on this result, h° was selected as main parameter for evaluation of color change. The experts defined h° = 95 as threshold for acceptable color of dried tarragon leaves.

Influence of Temperature and RH

The h° value of fresh Russian Tarragon leaves was 123. After drying, h° was lower for all treatments. Figure 2 shows h° of the dried Russian Tarragon leaves at drying temperatures between 40 and 90 °C. In a temperature range from 40 to 70 °C, h° decreased and increased again for 80 and 90 °C. In the temperature range of 55 to 80 °C, h° was below the quality threshold level of 95. Although the level of h° for different RH at the same temperature varied, no systematic correlation was found.

The L* value of fresh Russian Tarragon leaves was 48. L* decreased after drying, and the level was lower for higher temperatures. Figure 3 shows L* of the dried Russian Tarragon leaves at drying temperatures between 40 and 90 °C. The level of lightness at different RH varied at random so no clear relation was found for different RHs.

The C* value of fresh leaves was 15. Figure 4 represents C* values of the dried Russian Tarragon leaves at drying treatments of 40 to 90 °C. This value also decreased by increasing temperature. The C* value was almost at the same (lower) level for the dried material at the temperature 55 °C and higher. No correlation was found for different relative humidities.

Among h°, L*, and C*, h° shows the clearest correlation to the treatments. As h° was also identified by the experts to express visual quality best, further results are only presented for h°.

Influence of Variety

Table 3 presents the statistical results of ANOVA test for each variety. The effect of h° values of leaves dried with different treatments.

There was significant difference between the fresh leaves, and the leaves dried at any temperature at 95% probability. The results did not show any significant differences between varieties for fresh leaves and between the leaves dried at 45 and 90 °C for each variety.

Color Changes During Drying

Figure 5 shows h° of French Tarragon leaves at 80% MC to 5% dried at different temperatures. h° of the fresh leaves of French Tarragon was 124.5. The color changes of the leaves dried at 45 and 90 °C are close to each other. Most changes were observed at the earliest drying phase for the drying temperature of 60 °C. The level of leaves dried at 60 °C was lower than the threshold when they reached the storage MC, and for the leaves dried at 45 and 90 °C, this was higher. The trend line of all treatments was almost horizontal in the measured range from 35% to 5% MC for fresh tarragon.

Influence of Maturity

Figure 6 shows h° of mature and young tarragon leaves at drying temperatures of 45 and 90 °C. Almost the same difference was observed for the young and the mature leaves dried at 60 °C, which is skipped in Fig. 6. Larger changes were observed at both temperatures for young leaves compared to mature leaves. Major changes happened for the young leaves dried at 90 °C before they reach 40% MC, whereas the color change continuously occurred for the mature leaves during the whole drying process.

Color Change as a Function of Drying Time

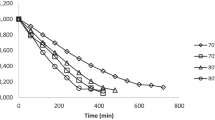

The color change of French Tarragon leaves as defined by h° versus drying time is shown in Fig. 7. The initial MC of the leaves was 80%, and the drying process was continued to reach 7% MC, w.b. The figure shows fitted lines using the equation:

In which C 1, C 2, and C 3 are coefficients and t is drying time (h). The coefficients at different drying treatments are shown in Table 4.

The h° value of the material changed slower at 45 °C compared to 60 and 90 °C drying temperature, and it almost reached the final level after 6 h drying time. The h° value decreased only to the level of about 108 for both the 45 and 90 °C drying temperatures. Figure 7 shows that at 90 °C the color degrades at a similar rate to that at 60 °C but the overall amount of degradation is lower because the time over which degradation can occur is reduced as a consequence of the higher drying rate. Because at this time the material reached 7% MC and drying process was stopped, there was no time for more changes. h° at 60 °C drying temperature decreased. The h° decreased at 60 °C drying temperature to the level of about 92 after 2 h. The decrease in h° value for 60 °C is twice the decrease of the 90 °C (Fig. 7).

Discussion

Drying of tarragon at 45 and 90 °C showed an acceptable level of h° but the value was too low for the material dried at 60 °C. It can be concluded that the temperature of 60 °C is not good for keeping quality. The sum of the temperature effect and drying time effect results in the total color changes during the drying process. To show these two effects looking together, a model is shown in Fig. 8 based on the experimental color changes data, which are presented in Fig. 2. The increasing temperature influences the change of h° for the temperature range of 40 to 60 °C, while the time effect is important from 70 to 90 °C.

More change was expected at 90 °C than the measured level. The explanation could be that the actual temperature in the material was lower than 90 °C during the drying process because of the large high evaporation during the earliest phases of the drying process, and the drying time was not long enough to change the color.

It seems that 90 °C is an acceptable drying temperature based on h° if preservation of over-drying is guaranteed. However, further color changes could occur during storage. So further research is required to resolve this problem. As the main goal of the drying process is to extent the shelf life, color change during storage time is also very important. Drying time at 90 °C is much shorter, and also temperature stress is much more than at 45 °C. Drying at 45 °C can guarantee an acceptable level of color change during drying so higher temperatures can be used also at the beginning of the drying process but the temperature in the material must not exceed 45 °C to avoid more color change.

The rate of color change decreases with the decrease of MC during the drying process at all temperatures.

Conclusion

The color of the tarragon leaves changes during the drying process. Based on expert evaluation, h° (hue) was found as the best parameter, to show the color changes of tarragon leaves during drying process. Temperature and drying time are the main parameters that affect the color change. Higher temperature and longer drying time make more changes for color. The color parameters showed less changes at 40 °C because of the low temperature and also at 90 °C because the drying time was short. The main changes of color were observed before the materials reaches 40% MC. Young leaves showed more sensitivity to temperature than the mature leaves. Drying temperatures below 50 °C are recommended for drying of tarragon leaves to avoid color degradation because the h° was above the acceptable level.

References

Ahmed, J., Kaur, A., & Shivhare, U. (2002). Color degradation kinetics of spinach, mustard leaves, and mixed puree. Journal of Food Science, 67(3), 1088–1091.

Arabhosseini, A., Huisman, W., van Boxtel, A., & Mueller, J. (2005). Sorption isotherms of tarragon (Artemisia dracunculus L.) [Sorptionsisothermen von Estragon (Artemisia dracunculus L.)]. Zeitschrift für Arznei- und Gewürzpflanzen, 11(1), 48–51.

Arabhosseini, A., Huisman, W., van Boxtel, A., & Mueller, J. (2008). Modeling of thin layer drying of tarragon (Artemisia dracunculus L.). Industrial Crops and Products, 28(2), 53–59.

Berberich, J., Dee, K. H., Hayauchi, Y., & Portner, C. (2002). A new method to determine discoloration kinetics of uncoated white tablets occurring during stability testing—An application of instrumental color measurement in the development pharmaceutics. International Journal of Pharmaceutic, 234(1–2), 55–66.

Carreno, J., Martinez, A., Almela, L., & Fernandez-Lopez, J. A. (1995). Proposal of an index for the objective evaluation of the colour of red table grapes. Food Research International, 28(4), 373–377.

Commission Internationale de l’Eclairage. (1986). Colorimetry (2nd ed). Vienna, Austria: CIE Publication No. 15.2.

Du Toit, J., & Joubert, E. (1998). Effect of drying conditions on the quality of honeybush tea (Cyclopia). Journal of Food Processing and Preservation, 22(6), 493–507.

Ganjloo, A., Rahman, R. A., Osman, A., Baker, J., & Bimakr, M. (2009). Kinetics of crude peroxidase inactivation and color changes of thermally treated seedless Guava (Psidium guajava L.). Food and Bioprocess Technology, doi:10.1007/s11947-009-0245-4.

García-Esteban, M., Ansorena, D., Gimeno, O., & Astiasarán, I. (2003). Optimization of instrumental colour analysis in dry-cured ham. Meat Science, 63(3), 287–292.

Guine, R. P. F., Henrriques, F., & Barroca, M. J. (2009). Mass transfer coefficients for the drying of pumpkin (cucurbita moschata) and dried product quality. Food and Bioprocess Technology, doi:10.1007/s11947-009-0245-4.

Iwe, M. O., Van Zuilichem, D. J., & Ngoddy, P. O. (2000). Color of single-screw extruded blends of soy-sweet potato flour—A response surface analysis. Plant Foods for Human Nutrition, 55(2), 159–168.

Krokida, M. K., Tsami, E., & Maroulis, Z. B. (1998). Kinetics on color changes during drying of some fruits and vegetables. Drying Technology, 16(3–5), 667–685.

Lee, H. S., Coates, G. A., & Lee, H. S. (2003). Effect of thermal pasteurization on Valencia orange juice color and pigments. Food Science and Technology, 36(1), 153–156.

Lozano, J. E., & Ibarz, A. (1997). Colour changes in concentrated fruit pulp during heating at high temperatures. Journal of Food Engineering, 31(3), 365–373.

Maharaj, V., & Sankat, C. K. (1996). Quality changes in dehydrated dasheen leaves: Effects of blanching pre-treatments and drying conditions. Food Research International, 29(5–6), 563–568.

Maskan, M. (2001). Kinetics of colour change of kiwifruits during hot air and microwave drying. Journal of Food Engineering, 48(2), 169–175.

McCaig, T. N. (2002). Extending the use of visible/near-infrared reflectance spectrophotometers to measure colour of food and agricultural products. Food Research International, 35(8), 731–736.

Patras, A., Brunton, N. P., Tiwari, B. K., & Butler, F. (2009). Stability and degradation kinetics of bioactive compounds and colour in strawberry jam during storage. Food and Bioprocess Technology, doi:10.1007/s11947-009-0226-7.

Shin, S., & Bhowmik, S. R. (1995). Thermal kinetics of color changes in pea puree. Journal of Food Engineering, 24(1), 77–86.

Silva, F. M., & Silva, C. L. M. (1999). Colour changes in thermally processed cupuaçu (Theobroma grandiflorum) puree: Critical times and kinetics modelling. International Journal of Food Science and Technology, 34(1), 87–94.

Simon, J. E., Chadwick, A. F., & Craker, L. E. (1984). Herbs: An indexed bibliography, 1971–1980: The scientific literature on selected herbs and aromatic and medicinal plants of the temperate zone. Amsterdam: Elsevier.

Suh, H. J., Noh, D. O., Kang, C. S., Kim, J. M., & Lee, S. W. (2003). Thermal kinetics of color degradation of mulberry fruit extract. Die Nahrung, 47(2), 132–135.

Vienne, M., Braemer, R., Paris, M., & Couderc, H. (1989). Chemotaxonomic study of two cultivars of Artemisia dracunculus L.: (“French” and “Russian” Tarragon). Biochemical Systematics and Ecology, 17(5), 373–374.

Yaichibe, T., Masanori, K., & Kenichi, A. (1997). Morphological characters and essential oil in Artemisia dracunculus (French Tarragon) and Artemisia dracuncloides (Russian Tarragon). Tokyo Nogyo Daigaku Nogaku Shuho, 41(4), 229–238.

Zhang, M., De Baerdemaeker, J., & Schrevens, E. (2003). Effects of different varieties and shelf storage conditions of chicory on deteriorative color changes using digital image processing and analysis. Food Research International, 36(7), 669–676.

Acknowledgment

Financial support from Aboureyhan Campus, Tehran University, Ministry of Science, Research and Technology of Iran is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Arabhosseini, A., Padhye, S., Huisman, W. et al. Effect of Drying on the Color of Tarragon (Artemisia dracunculus L.) Leaves. Food Bioprocess Technol 4, 1281–1287 (2011). https://doi.org/10.1007/s11947-009-0305-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-009-0305-9