Abstract

Pekmez is a concentrated and shelf life extended form of grape juice. We investigated the material behavior and the effect of processing factors during its solidification using in situ rheometry and color measurement by computer vision. Rheologically, pekmez (45.3 to 75 °Brix) is a Newtonian product. As expected, its viscosity increased with increasing solid content and decreasing temperature. A simplified model was proposed to describe the combined effect of concentration and temperature on pekmez viscosity. The color of pekmez changed from dark brown to white depending on the processing conditions such as the type and amount of whitener added and the rate and duration of mixing.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Pekmez is one of the most common grape products in Turkey. It is prepared by boiling the grape juice without adding sugar or other food additives (Karababa and Isikli 2005). Therefore, it is considered a natural food. The purposes of boiling and concentrating are to pasteurize the juice and to extend its shelf life by reducing the water content (Kaya and Belibaglı 2002). The first step in pekmez production is washing and crushing of grapes and extracting grape juice. The juice is then boiled with a calcareous substance called “pekmez earth” containing approximately 90% calcium carbonate. The pekmez earth lowers the acidity caused by naturally existing tartaric acid and malic acid by precipitation as calcium tartarate and calcium malate, respectively. Concentrated grape juice of 65 to 75 °Brix solid content is then obtained, which is called the liquid pekmez. Egg white or soapwort is used to produce a whiter end product. Soapwort (Saponaria officinalis) is a detergent which foams and creates soaplike cleaning action. High and low methoxyl pectins (∼1%) are used for gelling or solidification. The texture of solid pekmez is hard; its color may be white and may vary depending on the processing parameters such as the amount of whitening and gelling agents used and mixing rate and mixing time.

The knowledge of the flow behavior of concentrated juices is useful in quality control, calculating energy requirements, process control, and selection of proper process equipment. Modern technology requires the use of a film-type evaporator to produce pekmez. The type of evaporator, direction of feed, and heat transfer rate are all affected by viscosity of the fruit paste (Crandall et al. 1982).

Computer vision systems are used extensively for acquiring and analyzing images in order to obtain information or to control machines or processes in various agricultural and food processing operations (Gunasekaran 1996; Du and Sun 2004). A color vision system can be used to inspect and analyze visual information contained in agricultural and food products. The color vision has been used to measure the color distribution for many types of agricultural and food products (Leemans et al. 1998; Liu and Paulsen 2000; Jahns et al. 2001; Sun and Brosnan 2003; Wang and Sun 2003). Commission Internationale d’Eclairage (i.e., International Commission on Illumination) color space measurement system is a popular way to represent color and color changes of various foods (Nolsøe and Undeland 2008; Turabi et al. 2008).

During solidification of pekmez, its color changes from dark brown to white, which highly depends on the processing parameters: amount of whitener added and the rate and duration of mixing. Continuous monitoring of the change in pekmez color provides the information on the changing material behavior during its solidification and helps to control processing parameters for the desirable end-use properties of pekmez products.

The objectives of this investigation were to determine the material behavior of pekmez and the effect of processing factors during solidification using color image analysis and rheometry and to develop techniques to quantify the time-resolved, in situ solidification characteristics of the pekmez.

Materials and Methods

Sample Preparation and Chemical Analysis

A 75 °Brix liquid pekmez was procured from a local producer in Turkey (MND Food Industry, Ankara, Turkey). Samples with lower soluble solid contents (72.1, 66, 59, 53.7, and 45.3 °Brix) were obtained by diluting the concentrated pekmez with distilled water. Soluble solids, pH, and total acidity were determined according to the published Association of Official Analytical Chemists (AOAC) methods (AOAC 1980). Soluble solid content of the samples was determined by a refractometer (OPTON, F.G. Bode & Co., Hamburg) at 25 °C before each viscosity measurement and expressed as °Brix.

Rheological Measurement

Steady shear viscometry measurements were performed using a Haake (RheoStress RS1, Thermo Fisher Scientific, Newington, NH) controlled-stress rheometer equipped with a Transmission Control Protocol/Internet Protocol (TCP/IP) Peltier temperature controller unit and a thermostat. A cone and plate (diameter = 3.5 cm and angle = 2°) configuration was used in the cyclical shear rate range of 0 to 300 s−1. The rheological behavior of the pekmez (75 °Brix) and diluted samples were studied at different temperatures of 5, 10, 20, 30, 40, 50, and 60 °C. The experiments were replicated three times each, and average values were used.

Computer Vision System

A computer vision system was set up using a digital camera (CV-S3300, JAI A.S., Copenhagen, Denmark) and an image acquisition module (PCI (Peripheral Component Interface)-1411, National Instrument Corp., Austin, TX, USA). The camera is a high-resolution color charge-coupled device camera with 752 × 582 pixels available in NTSC format. This is able to send 30 frames of image to the image acquisition board via S-Video output every second. The image acquisition board consists of PCI image acquisition devices that accept analog video input from the camera. It offers a real-time color conversion especially useful for detecting high-speed color change. A lighting system with two General Electric 100-W incandescent and fluorescent lamps was used to shed constant illumination during image acquisition.

An image acquisition software using LabView (v. 6, National Instruments Corp.) was developed to acquire images from the imaging device. The software was able to control imaging environments and to monitor a real-time image. During image acquisition, the color components were measured and analyzed in real time.

Image Calibration

During image acquisition, the acquired image is affected by factors such as illumination, camera configurations, etc., which result in highly distorted images. Calibration software was designed to select the imaging environment for reliable imaging based on LabView. Image calibration was performed in two steps: (1) fixing the location of the sample and (2) adjusting illumination and lens magnification. A calibration reference was used to calibrate the imaging environment, which consisted of a blue-filled dot and a red-filled dot, each 20 mm in diameter, on a nonreflective black background. Under proper imaging environment, the locations (centroids) and radii of the two dots were determined and their mean Red–Green–Blue (RGB) values were measured. An image including the circumference of the two dots was used as a reference circumference image to fix camera location. The dots of the acquired image should fit inside the circumference. Their centroids and radii were calibrated by adjusting camera location and magnification. The mean RGB values of the two dots were used as indices to adjust the imaging environment such as illumination and iris of the camera system.

Color Measurement

The pekmez color was measured using a spectrocolorimeter (HunterLab ColorFlex, A60-1010-615 Model Colorimeter, HunterLab, Reston, VA, USA). Before measurements, the spectrocolorimeter was calibrated with a white reference tile supplied by the manufacturer (color values: L = 91.09, a = −1.11, b = 1.24). Standard illuminant A was used with a 10° standard observer.

Image analysis software was also developed to analyze the changes in color components of the samples. The color of the pekmez sample during mixing was measured. The pixel values in the region of interest (ROI) from the image were read and were converted into a data set containing RGB values, unsigned 8-bit integer (0 to 255). At the rectangle ROI, the mean RGB values at the pixels in the rectangle were used for color analysis. These measurements were performed continually at 3-min intervals.

All experiments were replicated three times. Average and standard deviations of the data are reported, where applicable.

Results and Discussion

The measured physical and chemical characteristics of liquid pekmez were: solid content = 75 ± 3 °Brix; pH = 4.76 ± 0.02; total acidity = 0.23 ± 0.01% and color, L = 2.82, a = 3.75, b = 1.64, Y = 204.78.

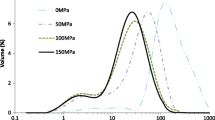

Flow Behavior

The flow curves (shear stress vs. shear rate) of 75 °Brix pekmez are presented in Fig. 1. The flow behavior was measured over a cyclical shear rate range of 0 to 300 s−1. There was no difference between both measurements. The shear stress linearly varied with the shear rate and passed through the origin without any indication of thixotropy. The data were fitted to the Newtonian model:

where τ is shear stress (Pa), η is Newtonian viscosity (Pa·s), and \(\dot \gamma \) is shear rate (s−1).

The Newtonian viscosity of pekmez samples at all concentrations and temperatures are summarized in Table 1. The data exhibited the well-known trends of increasing viscosity with increase in concentration and decreasing viscosity with increase in temperature.

Effect of Temperature

The flow behavior of the pekmez samples was further described by Arrhenius relationship.

where, η 0 = constant, E a = activation energy (kJ mol−1), R = gas constant (kJ mol−1 K−1), and T = absolute temperature (K).

The Arrhenius equation has been successfully used to predict the effect of temperature on the viscosity of different sugar-rich liquid foods and clarified fruit juices (Khalil et al. 1989; Manohar et al. 1991). The activation energy (E a) and the coefficient of determination (R 2) for each concentration are listed in Table 1. The E a values ranged from 67.87 to 20.57 kJ mol−1 at concentrations of 75 and 45.3 °Brix, respectively. It indicates the sensitivity of Pekmez viscosity to the temperature change is dependent on its solid content. Higher E a value at 75 °Brix means that the viscosity is relatively more sensitive to temperature change at higher concentration than at lower concentrations (Dak et al. 2006; Yanniotis et al. 2006). This tendency is similar to that of viscosity of other clarified juices (Saracavos 1970; Rao et al. 1984; Khalil et al. 1989; Ibarz et al. 1992).

Effect of Concentration

The increase in viscosity of pekmez with soluble solid content can be described by power-law and exponential models (Rao et al. 1984; Ibarz et al. 1987):

where η 1,η 2,b 1 and b 2 are constants, and C is the concentration in °Brix.

In order to calculate the model constants, the viscosity data in Table 1 were fitted to Eqs. 3 and 4 by least-squares method. The resulting values of the constants are listed in Table 2. Based on the r 2 values obtained, we observe that the exponential model was marginally better than the power-law model in describing the effect of soluble solids on pekmez viscosity.

For a given temperature, the activation energy for flow depends on soluble solid content which can be described by several models (Giner et al. 1996). We used two models, similar to Eqs. 5 and 6.

where A 1, A 2, B 1, and B 2 are constants. The E a values and their respective concentrations were fitted to Eqs. 5 and 6 by the least-squares method to determine the model parameters. The calculated parameters for these models are given in Table 3. The r 2 values of both the models were fairly similar indicating that both these models are equally suitable for describing the dependency of E a on soluble solid content.

Combined Effect of Temperature and Concentration

For practical applications, it is useful to obtain an equation describing the combined effect of temperature and concentration on pekmez viscosity (Ibarz et al. 1992). We investigated the following two models:

where η 3, η 4, D 1, and D 2 are constants.

The viscosity, concentration, and temperature data were fitted to these models by the least-squares method, and the values of the model constants were determined (Table 4). It can be observed that both the models estimated similar E a values. Fits to both models were suitable, but it seemed that model 1 described the combined effect of temperature and soluble solid better. Therefore, the following equation is proposed to describe the combined effect of concentration and temperature (T, °C) on viscosity (η, Pa s) of pekmez:

Color Analysis

During mixing, the color of pekmez sample changes from dark brown to white over time. However, individual RGB values were not sensitive to distinguish the gradual change in color from brown to white over mixing time. Color space transformations are effective means for distinguishing color images. Linear transformation such as Y transformation is the simplest method for color conversion from the RGB space to others. To increase the sensitivity of distinguishing between brown and white colors, RGB were converted to Y value, which represents luminance varying from white to black (Mitchell 1994). The color values measured were represented as luminance (Y), which is brightness ranging from white to black. The following formula was used (Mitchell 1994; Liu and Paulsen 2000):

where R, G, and B are red, green and blue color values which range from 0 to 255.

The experimental results for the color changes in pekmez at different amounts of egg white and soapwort added are shown as a function of mixing time in Figs. 2, 3, and 4 for mixing rates of 750 rpm, 1,000 rpm, and 1,500 rpm, respectively. It can be observed that the Y value of pekmez increased exponentially with mixing time. Since Y value of 255 is pure white, the pekmez tended to become whiter upon stirring even when no whitener was added. However, the addition of egg white or soapwort significantly improved both the extent and the rate of whitening of pekmez. In general, the higher amount of whitener added, the faster and the greater the whitening effect. Egg white (5%) and soapwort (3%) both whitened the pekmez about the same extent, and the effect of varying concentrations was not always statistically significant. The detergent-like cleaning action of soapwort is well known. It is likely that agitation of egg white protein creates foaming and hence the whitening effect. Furthermore, when heated, the primary and secondary denaturation of protein converts it into a whitish substance.

Mixing rate is one of the most important processing parameters during the manufacture of solid pekmez. After 125 min of stirring, the brightness of pekmez at 750 rpm was only 87 compared to 180 at 1,500 rpm. The reason for the effect of mixing rate is possibly due to increased color change reaction, which is not well known. The effect of mixing rate was further enhanced when egg white or soapwort is added both in terms of the brightness (higher Y value) and the rate of whitening (shorter mixing time). For example, peak Y values were 142, 200, and 230 when mixed at 750, 100, and 1,500 rpm, respectively. These peak values were reached in 58 min when mixed at 1,500 rpm compared to 83 min at 1,000 rpm and 112 min at 750 rpm.

The effect of increased addition of whitener is more profound at lower mixing rates than at higher mixing rate because the whitening effect tends to saturate at higher mixing rate. For example, statistically significant improvement in whitening was observed as egg white or soapwort was added at all levels when mixing rate was 750 rpm. However, the differences were not significant at 1,500 rpm between 3% and 5% egg white addition and 1% and 3% soapwort addition.

Conclusions

The flow behavior of pekmez and diluted pekmez samples were Newtonian, and the pekmez viscosity was affected by soluble solid content and temperature. The change in viscosity was more sensitive to change in temperature at higher solid concentration. Effects of soluble solid content and temperature on viscosity were described by exponential models. A simplified equation was developed to describe the combined effect of soluble solid content and temperature on pekmez viscosity. A computer vision technique was developed to quantify the time-resolved in situ color characteristics during pekmez solidification. The higher the amount of whitener added, the faster and more profound the whitening effect. The mixing rate is the most dominant factor affecting the rate and extent of color change from dark brown to white. The effect of added whitener is not significant at high mixing rate.

References

AOAC (1980). Official Methods of Analysis (13th ed.). Washington, DC: Association of Official Analytical Chemists.

Crandall, P. G., Chen, C. S., & Carter, R. D. (1982). Models for predicting viscosity of orange juice concentrate. Food Technologist, 36(5), 245–252.

Dak, M., Verma, R. C., & Sharma, G. P. (2006). Flow characteristics of juice of “Totapuri” mangoes. Journal of Food Engineering, 76(4), 557–561. doi:10.1016/j.jfoodeng.2005.06.002.

Du, C. J., & Sun, D. W. (2004). Recent developments in the applications of image processing techniques for food quality evaluation. Trends in Food Science & Technology, 15(5), 230–249. doi:10.1016/j.tifs.2003.10.006.

Giner, J., Ibarz, A., Garza, S., & Xhian-Quan, S. (1996). Rheology of clarified cherry juices. Journal of Food Engineering, 30, 147–154. doi:10.1016/S0260-8774(96)00015-5.

Gunasekaran, S. (1996). Computer vision technology for food quality assurance. Trends in Food Science & Technology, 7(8), 245–256. doi:10.1016/0924-2244(96)10028-5.

Ibarz, A., Vicente, M., & Graell, J. (1987). Rheological behavior of apple juice and pear juice and their concentrates. Journal of Food Engineering, 6, 257–267. doi:10.1016/0260-8774(87)90013-6.

Ibarz, A., Pagán, J., & Miguelsanz, R. (1992). Rheology of clarified fruit juices. II: Blackcurrant juices. Journal of Food Engineering, 15, 63–73. doi:10.1016/0260-8774(92)90040-D.

Jahns, G., Nielsen, H. M., & Paul, W. (2001). Measuring image analysis attributes and modelling fuzzy consumer aspects for tomato quality grading. Computers and Electronics in Agriculture, 31, 17–29. doi:10.1016/S0168-1699(00)00171-X.

Karababa, E., & Isikli, N. D. (2005). Pekmez: A traditional concentrated fruit product. Food Reviews International, 21(4), 357–366. doi:10.1080/87559120500222714.

Kaya, A., & Belibaglı, K. B. (2002). Rheology of solid Gaziantep Pekmez. Journal of Food Engineering, 54(3), 221–226. doi:10.1016/S0260-8774(01)00205-9.

Khalil, K. E., Ramakrishna, P., Nanjundaswamy, A. M., & Patwardhan, M. V. (1989). Rheological behaviour of clarified banana juice: effect of temperature and concentration. Journal of Food Engineering, 10(3), 231–240. doi:10.1016/0260-8774(89)90028-9.

Leemans, V., Magein, H., & Destain, M. F. (1998). Defects segmentation on ‘Golden Delicious’ apples by using color machine vision. Computers and Electronics in Agriculture, 20, 117–130. doi:10.1016/S0168-1699(98)00012-X.

Liu, J., & Paulsen, M. R. (2000). Corn whiteness measurement and classification using machine vision. Transactions of the ASAE, 43(3), 757–763.

Manohar, B., Ramakrishna, P., & Udayasankar, K. (1991). Some physical properties of Tamarind Tamarindus indica L. juice concentrates. Journal of Food Engineering, 13, 241–258. doi:10.1016/0260-8774(91)90045-T.

Mitchell, J. (1994). MPEG, an image compression standard. Englewood Cliffs, N.J.: Prentice Hall.

Nolsøe, H., & Undeland, I. (2008). The acid and alkaline solubilization process for the isolation of muscle proteins: state of the art. Food and Bioprocess Technology. doi:10.1007/s11947-008-0088-4.

Rao, M. A., Cooley, H. J., & Vizali, A. A. (1984). Flow properties of concentrated juices at low temperatures. Food Technologist, 38, 113–119.

Saracavos, G. D. (1970). Effect of temperature on viscosity of fruit juices and purées. Journal of Food Science, 35, 122–125. doi:10.1111/j.1365-2621.1970.tb12119.x.

Sun, D. W., & Brosnan, T. (2003). Pizza quality evaluation using computer vision-part 1 Pizza base and sauce spread. Journal of Food Engineering, 57, 81–89. doi:10.1016/S0260-8774(02)00275-3.

Turabi, E., Sumnu, G., & Sahin, S. (2008). Optimization of baking of rice cakes in infrared–microwave combination oven by response surface methodology. Food and Bioprocess Technology, 1, 64–73. doi:10.1007/s11947-007-0003-4.

Wang, H. H., & Sun, D. W. (2003). Assessment of cheese browning affected by baking conditions using computer vision. Journal of Food Engineering, 56(4), 339–345. doi:10.1016/S0260-8774(02)00159-0.

Yanniotis, S., Skaltsi, S., & Karaburnioti, S. (2006). Effect of moisture content on the viscosity of honey at different temperatures. Journal of Food Engineering, 72(4), 372–377. doi:10.1016/j.jfoodeng.2004.12.017.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kaya, A., Ko, S. & Gunasekaran, S. Viscosity and Color Change During In Situ Solidification of Grape Pekmez. Food Bioprocess Technol 4, 241–246 (2011). https://doi.org/10.1007/s11947-008-0169-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-008-0169-4