Abstract

The computer vision and a stereoscopy technique were used to characterize and detect changes in the capacity of the salmon fillet surface to recover its original form after a constant weight was applied. A curvature index (associated to fillet firmness) calculated by means of 3D information data obtained with the stereoscopy technique from the fat stripe on the fillets was estimated over 6 months and was suggested as a characteristic of the recovery property of the fresh salmon fillet surface. Simultaneously, instrumental firmness using a LFRA1500 texture was measured. The values for the fresh salmon fillet measurement curvature index during a period of 6 months were established in the range of 0.05 and 0.10 (dimensionless), and this value was used in the experiments to represent fresh salmon fillets. Changes in the curvature index (associated with similar changes in firmness) for salmon fillet surface treated with enzymes (pepsin and papain) were registered on the second day during storage at 2 °C. In general, stereoscopy is a technique that can be used on salmon fillets to detect changes in the recovery properties of the salmon fillet surface and to determine when salmon fillets can be classified as a fillet that has not been processed with enzymes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

One characteristic of fresh fish fillet muscles is the ability to return to its original position when a finger test or force test (load) is applied. If the muscle of the fish is altered (due to deterioration, processing, or another event) this characteristic could vary and so could the firmness of the muscle (Shigemura et al. 2003). The firmness of the raw muscle is a critical parameter that determines the acceptability of seafood products (Botta 1991; Sigurgisladottir et al. 1999), and this property depends on the connective tissue, mainly collagen (responsible for tensile strength), and the myofibrils, consisting of myosin and actin. Firmness is a property of the salmon fillet that has been measured and reported in many studies (Bjørnevik et al. 2004; Cardinal et al. 2004; Casas et al. 2006; Espe et al. 2004; Farmer et al. 2000; Folkestad et al. 2008; Hultmann and Rustad 2002; Jonsson et al. 2001; Kiessling et al. 2004; Roth et al. 2002). The common instrumental tests applied to fish may be divided into puncturing, compressing, shearing, cutting, and pulling. Double compression or puncturing allows a texture profile analysis, given plots of force vs. distance vs. time (Jonsson et al. 2001). Nevertheless, under commercial situations, firmness can only be subjectively measured by people touching and visually assessing the fillet using the “finger” test (Botta 1991), and their reliability depends upon the person involved and a variety of external factors.

The hypothesis of this work was that the mechanical hysteresis (associated to fillet firmness) of the muscle surface when force (or a constant weight) is applied for a few seconds on the salmon fillet surface can be characterized by using the computer vision technique and applying the stereophotography technique (stereoscopy).

The stereophotography involved (also called stereoscopy) is a technique in which three-dimensional (3D) information can also be obtained from two images of the same scene (stereo pairs), which are taken from slightly different viewpoints (Ankamuthu et al. 1999; Pastoor and Wopking 1997; Pratt 2001; Russ 1999). In stereoscopy, the elevation (h) between points on a surface can be estimated. The same scene is viewed from two different locations by moving the camera (S) or moving the scene. The parallax (d 1 − d 2), the distance between the points as they appear in the two different images (measured in a direction which is parallel to the shift), is proportional to the elevation difference (h) between the two points (Ankamuthu et al. 1999; Boyde 1973):

If the scene is moved horizontally only, just the x-coordinates for d in both images (matching) need to be calculated. This is known in stereoscopy as the stereo pairs with epipolar geometry (Abraham and Forstner 2005). Although Eq. 1 seems to be very simple, a considerable problem encountered with this method is identifying the points in both images (stereo pars) to determine the parallax (d 1 − d 2). WD/S can be found by calibrating the system with objects whose elevation is known.

Although the stereoscopy is very simple and has a low cost when compared to other 3D techniques, not many studies using this technique for food can be found in the literature available. This is mainly because automatic matching of points from stereo pairs is a difficult task for computer-based image analysis (Stefano et al. 2004). It is usually performed by using the pattern of brightness values in one image, for instance, the left one, as a template to search for the most similar pattern in the right image. Most food surfaces do not produce images with identical patterns of brightness values in both images (stereo pairs); however, in the case of salmon fillet, patterns based on the fat stripes can be used during the matching processes, and their 3D information can be estimated. The objective is to use the stereoscopy technique to detect changes in the capacity of the salmon fillet surface to recover its original form after a constant weight is applied.

Materials and Methods

Experimental System

In the experiment, a system similar to the one shown in Fig. 1 was used. The system consists of a Sony Cyber-shot DSC-S600 camera, which is placed above the sample base (30 cm). The settings of the camera used in our experiments are summarized in Table 1. Under the camera, the system has a base that allows the samples to move in a parallel direction (up to 13 cm) in relation to the shift, to take two images of the same scene (left and right images; Fig. 1). The displacement is carried out only in the x-direction to obtain a stereo pair with epipolar geometry (Stefano et al. 2004).

A representation of a stereo pair showing the left and right images. Arbitrary lines (dot lines) are traced over the images, and selected points (square point) are identified in both images. The parallax was calculated, and elevations of the points were conducted using the upper left point as the base point

Calibration of the Stereoscopy System

Given that a geometrical distortion in the camera image occurs, preliminary experiences were carried out to determine the area in the image without geometric distortion. This area was manually selected using an arbitrary horizontal line pattern. The selected area was the one with horizontal lines not showing a visual distortion. The area selected in the system to avoid the geometrical distortion corresponded to the 800 × 600 pixels. The area for image analysis to apply the stereoscopy technique was restricted to 240 × 200 pixels. Physical equivalence (lateral) of a pixel in the image was measured using a ruler (it was photographed under the same conditions as the experiments). Each pixel in the images corresponded to 0.18 mm in the lateral dimension.

Four plastic pyramids with well-known heights were used in the system to determine the WD/S. The pyramids were placed under the camera and were moved in a direction parallel to the shift (13 cm). A parallax value (d 1 − d 2), between the vertices of the base and the superior vertices in each pyramid, was calculated. Real heights (h) of the pyramids measured with a caliper (resolution 0.1 mm) were established to be 4.4, 9.5, 15.6, and 20.1 mm, respectively. A WD/S value was calculated for each pyramid using this information and Eq. 1.

Model Samples with “Fat Stripes”

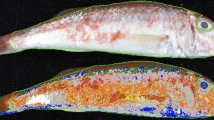

Experiments with iron sheets were performed to validate the system with another 3D capture system. A representation of “fat stripes” as they appear on the surface of salmon fillet was traced over 15 8 × 8-cm iron sheets (model samples). They were previously covered with orange-colored paper. White lines were arbitrarily traced on the paper (similar to the “fat stripes in the salmon fillets,” as shown in Fig. 2).

To produce deformations (depths) on the surface, three metal groups (five iron sheets each one) were made, and the surfaces of two groups were subject to impact (150 and 300 g from a height of 20 cm, respectively). This procedure made the white lines change on the surface of these groups, so they had a depth (curvature) in the z-plane.

Estimation of the Line Curvature in an Iron Sheet

A 3D arm digitizer (MicroScribe®) with Rhino version 4.0 was used to capture spatial coordinates for the white lines (a region with five lines) in each iron sheet. A resolution of 1 mm was used in the capture. A region containing five white lines was selected for the analysis. The plane x–z was used as the base plane in the calculation of a curvature for each white line in the iron sheet. A three-grade polynomial for each white line was fitted (spline interpolation using minimal square) to the x–z data. Subsequently, a slope for each point was evaluated using the fitted polynomial, and a mean value of these slopes was calculated for each line. This mean value represents the curvature for each white line in the iron sheet. Finally, for each iron sheet, an average of the curvature values was used as the “curvature index” of the metal in the selected region. We would expect iron sheet groups with no deformation (with a flat surface) to have a low curvature index value (near zero).

A Similar procedure was carried out to obtain a curvature index (using x–z data or x–h data) for the line iron sheets. However, in this case, the 3D information was estimated using stereoscopy. Iron sheets were put under the camera, and stereo pairs were taken for each one. A region defined by the zone where no geometrical distortion occurs in the image was selected and analyzed (five white lines were used, too). 3D information of the white line in the sheets was estimated by using discrete points in the white lines. Due to the epipolar geometry of the images in the stereo pairs, these discrete points were made by intercepting arbitrary horizontal lines (50 lines) that were previously traced on the stereo pairs, with the white lines in the images as shown in Fig. 2. Identification of the points in both images was undertaken manually, and the difference in their position in each image was calculated in pixel units (d). Note that we can also represent the elevation difference between points in pixels, because h is proportional to the parallax (pixels) in Eq. 1. Ten replicates for each iron sheet were carried out.

Using Stereoscopy to Characterize the Curvature Index of Fat Stripes in Salmon Fillets

To characterize the recovery property of the salmon fillet surface when it is stimulated by a physical impact, a curvature index in a selected region of the salmon fillet surface was calculated, before and after a physical stimulus was applied to 100 trimmed fresh salmon fillets (mean body weight was 4.5 kg) monthly, during 6 months.

Lipid content variations in different specific locations on salmon fillets can rebound in different forms and sizes of fat stripes. The stereoscopy technique uses fat stripes as a sort of spatial reference to calculate the curvature index, and this measurement could be affected by the variability. In view of this, a zone containing similar fat stripe patterns between regions on a salmon fillet and between salmon fillets was chosen (flat belly in Fig. 3).

The fillets were put under the camera, but in this case, a constant weight (50 g spherical probe) was allowed to fall (20 cm) on the selected region. After the spherical probe was removed (10 s), a stereo pair was taken (left and right images). Manual matching was carried out tracing 50 horizontal lines similar to the procedure used with the iron sheets. Four or five fat stripes in the selected region were used to calculate the curvature index for each fillet corresponding to the section shown in Fig. 3.

Instrumental Firmness of the Salmon Fillets

Firmness in salmon fillets was evaluated by the shear test using a Brookfield texture analyzer LFRA1500 controlled by the ProLite software and equipped with a flat-end cylindrical probe (Ø 12 mm). The zone analyzed in the fillet was the region shown in Fig. 3. To ensure that the flesh temperature was kept constant during testing, each fish was kept on ice (2 °C). During the experiments, the force (N) was continuously recorded during compression in a texture profile curve, with a 1.5-kg load cell and the trigger force of 0.01 N, at a deformation rate of 2 mm s−1 into the fillets, until it reached 60% of the initial sample height. The time between both compressions was 5 s. Maximum shear force (maximum resistance to shearing) of the first compression in the force–time curve was calculated as firmness, as described in the references (Gallart-Jornet et al. 2007; Veland and Torrissen 1999; Vieira et al. 2005).

Application in Processed Salmon Fillet

Four experiments (four groups of salmon fillet) were carried out to try to modify the recovery property of the fillets (associated with firmness). In each group, 40 fresh salmon fillets were used. In the first group, the fresh salmon fillet surface was only covered with polyethylene film. In the second group, fresh fillets were submerged in distillate water (pH = 6.8). The third group was submerged in a solution (pH = 5.5) containing 2% of the papain enzyme, and in the last group, salmon fillets were submerged in a solution (pH = 5.5) of 2% of the pepsin enzyme (Sigma). All groups were stored for 8 days at 2 °C. Five different fillets from each group were used every second day to determine instrumental firmness and curvature index using stereoscopy and computer vision.

Statistical Analysis

Statgraphics V 7.0 software (Statistical Graphics, Englewood Cliffs, NJ, USA) was used to conduct variance analysis (95% confidence level) to the experimental data to determine whether the instrumental texture and curvature index are affected by storage time or if any treatment (enzymes) affects firmness during storage. In addition, instrumental texture and curvature index for fillets treated with enzymes were fitted to a linear model. The fittings and the estimates of the parameters were significant at 95% probability level.

Results and Discussion

Calibration of the Stereoscopy System

The WD/S parameter calculated using the pyramids of previously established heights is shown in Table 2. The mean value for the WD/S parameter for all the pyramids, calculated using the stereoscopy system, was 0.349 mm per pixel. This value determines that a parallax value of one pixel for two different points in the stereo pairs corresponds to an elevation difference of 0.3 mm approximately between them. It also determines that the system (under the conditions used in the experiments) cannot detect heights (or depths) lower than 0.3 mm.

Curvature Index of the Lines in Iron Sheets

Figure 4 shows the 3D representation for the white lines (iron sheet loaded with 300 g) of images captured using a 3D arm digitizer and the stereoscopy system suggested here. A similar pattern in the form of lines can be observed (3D). This was captured using both methods. The 3D information was captured for both systems, and polynomial equations (three-degree) were fitted to x–z data for each line. In most cases, the correlation coefficient during the fitting of the polynomial to the lines was close to 0.95. Table 3 shows a curvature index for the lines calculated using the 3D arm digitizer and the stereoscopy for the three groups of iron sheets. No statistical differences (P < 0.05) were detected in the curvature index values when they were measured by the stereoscopy system and the 3D arm digitizer, at each level of pressure applied to the iron sheets, respectively. It shows the suitability of the stereoscopy system to give curvature index values similar to those obtained by the arm digitizer, and this information was only used to validate the system with another 3D capture system.

Using Stereoscopy to Characterize the Curvature Index of Fat Stripes in Salmon Fillets

Table 4 shows the instrumental hardness of the fresh salmon fillets evaluated during 6 months. The firmness (N) of the fillets was established between 11.90 and 14.20 N. Similar firmness values have been reported in literature on salmon fillets (Gallart-Jornet et al. 2007; Jonsson et al. 2001; Sigurgisladottir et al. 1999). In general, firmness (of the fresh fillets in the area analyzed) did not differ significantly over the 6-month period.

Table 5 shows the curvature index measured using the stereoscopy system. We can observe that no differences in the curvature index (before and after an impact of 50 g is applied to the surface) of the fat stripes in the selected area were detected (100 salmon fillets were evaluated monthly). Similar to firmness, the curvature index for the fillets (Table 5), before and after a constant weight (50 g) was applied to a given region of their surface, did not differ significantly over the 6-month period. The average curvature index for all salmon was established in the range of 0.05 to 0.10. Under the same conditions used in this experiment, we can use these range values as characteristics for defining the recovery properties of the fresh salmon fillets.

Application in Processed Salmon Fillet

Table 6 shows the instrumental firmness measured in treated salmon fillets. The instrumental firmness value for the fresh salmon fillet and for the salmon fillet submerged in water, stored during 8 days, showed no significant differences during cool storage at 2 °C. In contrast, salmon fillets treated with the enzymes (pepsin and papain) showed significant differences (low firmness values) indicating a softening after 2 days of storage at 2 °C. Usually, theses enzymes are used in the industry as additives to alter firmness and tenderness in meat (Ashie et al. 2002).

Similar to the firmness for the treated salmon fillets, in the case of the curvature index for the fresh salmon fillet and for the salmon fillet submerged in water, storage during 8 days showed no significant differences during cool storage at 2 °C (Table 7). In contrast, salmon fillets treated with the enzymes (pepsin and papain) showed significantly higher curvature index values, greater than those of the 2-day storage at 2 °C (Table 6) The recovery property of the salmon fillet surface measured by the curvature index (using the fat stripes) is affected due to the application of the enzymes in the salmon, and variations can be detected by the stereoscopy technique suggested here.

A linear model was proposed to correlate data between the instrumental texture (N) and the curvature index for salmon fillet treated with pepsine and papain, respectively. Estimated coefficients for the linear regression are shown in Table 8. Correlation coefficients indicated an inverse linear relationship between the instrumental texture and the curvature index. Slope values derived from the lineal model were very close for pepsin and papain, indicating a similar effect of the treatments over the texture.

Conclusion

A stereoscopy technique and the computer vision were applied to detect changes in the capacity of the salmon fillet surface to recover its original form after a constant weight was applied. The recovery property of the surface was measured by using a curvature index based on the fat stripes in a selected region (belly section) on the fillets. Curvature index values for the fresh salmon fillets measured during 6 months were established in the range of 0.05 to 0.10. Changes in the curvature index (associated to similar changes in firmness) for salmon fillets surface treated with enzymes (pepsin and papain) were registered 2 days after storage at 2 °C.

In general, stereoscopy is a technique that can be used on salmon fillet to detect changes in the recovery property of the salmon fillet surface and to determine when salmon fillets can be classified as a fillet that has not been processed with enzymes.

References

Abraham, S., & Forstner, W. (2005). Fish-eye-stereo calibration and epipolar rectification. ISPRS Journal of Photogrammetry and Remote Sensing, 59, 278–288.

Ankamuthu, S., Balnchandar, R., & Wood, H. (1999). Computational stereoscopy for three-dimensional scour depth measurement in channels. Canadian Journal of Civil Engineering, 26, 698–711.

Ashie, I., Sorensen, T., & Nielse, P. (2002). Effects of papain and a microbial enzyme on meat proteins and beef tenderness. Journal of Food Science, 67, 2138–2142.

Bjørnevik, M., Espe, M., Beattie, C., Nortvedt, R., & Kiessling, A. (2004). Temporal variation in muscle fibre area, gaping texture, colour and collagen in triploid and diploid Atlantic salmon (Salmo salar L). Journal of the Science of Food and Agriculture, 84, 530–540.

Botta, J. (1991). Instrument for nondestructive texture measurement of raw atlantic cod (Gadus morhua) fillets. Journal of Food Science, 56, 962–968.

Boyde, A. (1973). Quantitative photogrammetric analysis and qualitative stereoscopic analysis of SEM images. Journal of Microscopy, 98, 452–471.

Cardinal, M., Gunnlaugsdottir, H., Bjoernevik, M., Ouisse, A., Vallet, J. L., & Leroi, F. (2004). Sensory characteristics of cold-smoked Atlantic salmon (Salmo salar) from European market and relationships with chemical, physical and microbiological measurements. Food Research International, 37, 181–193.

Casas, C., Martinez, O., Guillen, M. D., Pin, C., & Salmeron, J. (2006). Textural properties of raw Atlantic salmon (Salmo salar) at three points along the fillet, determined by different methods. Food Control, 17, 511–515.

Espe, M., Ruohonen, K., Bjørnevik, M., Frøyland, L., Nortvedt, R., & Kiessling, A. (2004). Interactions between ice storage time, collagen composition, gaping and textural properties in farmed salmon muscle harvested at different times of the year. Aquaculture, 240, 489–504.

Farmer, L. J., McConnell, J. M., & Kilpatrick, D. J. (2000). Sensory characteristics of farmed and wild Atlantic salmon. Aquaculture, 187, 105–125.

Folkestad, A., Rørvik, K. A., Kolstad, K., & Mørkøre, T. (2008). Growth rates of individual farmed Atlantic salmon Salmo salar L. influence the texture of raw and smoked fillets. Aquaculture Research, 39, 329–332.

Gallart-Jornet, L., Barat, J. M., Rustad, T., Erikson, U., Escriche, I., & Fito, P. (2007). Influence of brine concentration on Atlantic salmon fillet salting. Journal of Food Engineering, 80, 267–275.

Hultmann, L., & Rustad, T. (2002). Textural changes during iced storage of salmon (Salmo salar) and cod (Gadus morhua). Journal of Aquatic Food Product Technology, 11, 105–123.

Jonsson, A., Sigurgisladottir, S., Hafsteinsson, H., & Kristbergsson, K. (2001). Textural properties of raw Atlantic salmon (Salmo salar) fillets measured by different methods in comparison to expressible moisture. Aquaculture Nutrition, 7, 81–89.

Kiessling, A., Espe, M., Ruohonen, K., & Mørkøre, T. (2004). Texture, gaping and colour of fresh and frozen Atlantic salmon flesh as affected by pre-slaughter iso-eugenol or CO2 anaesthesia. Aquaculture, 236, 645–657.

Pastoor, S., & Wopking, M. (1997). 3-D displays: A review of current technologies. Displays, 17, 100–110.

Pratt, W. (2001). Digital image processing (3rd ed.). New York: Wiley.

Roth, B., Moeller, D., Veland, J. O., Imsland, A., & Slinde, E. (2002). The effect of stunning methods on rigor mortis and texture properties of Atlantic salmon (Salmo salar). Journal of Food Science, 67, 1462–1466.

Russ, J. C. (1999). The image processing handbook (4th ed.). Florida: CRC.

Shigemura, Y., Ando, M., Tsukamasa, Y. Y. M., & Kawai, T. (2003). Correlation of type V collagen content with post-mortem softening of fish meat during chilled storage. Fisheries Science, 69, 842–848.

Sigurgisladottir, S., Hafsteinsson, H., Jonsson, A., Lie, Ø., Nortvedt, R., Thomassen, M., et al. (1999). Textural properties of raw salmon fillets as related to sampling method. Journal of Food Science, 64, 99–104.

Stefano, L., Marchionni, M., & Mattoccia, S. (2004). A fast area-based stereo matching algorithm. Imagen and Vision Computing, 22, 983–1005.

Veland, J. O., & Torrissen, O. J. (1999). The texture of Atlantic salmon (Salmo salar) muscle as measured instrumentally using TPA and Warner–Brazier shear test. Journal of the Science of Food and Agriculture, 79, 1737–1746.

Vieira, V. L. A., Johansen, S. J. S., Bickerdike, R., & Johnston, I. A. (2005). Impact of accelerated smoltification on muscle structure and fillet firmness at harvest in Atlantic salmon (Salmo salar). Aquaculture, 246, 197–208.

Acknowledgment

This research was supported by the project FONDECYT—Chile number 1060355.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Quevedo, R., Aguilera, J.M. Computer Vision and Stereoscopy for Estimating Firmness in the Salmon (Salmon salar) Fillets. Food Bioprocess Technol 3, 561–567 (2010). https://doi.org/10.1007/s11947-008-0097-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-008-0097-3