Abstract

To protect public health from indoor volatile organic compounds (VOCs) exposure, it is critical to estimate the emission rate and characteristic by indoor building materials. To this end, four different types of lumbers (Pinus densiflora, Pinus koraiensis, Cryptomeria japonica, and Larix leptolepis) and four different types of artificial building materials (particleboard (PB), medium density fiberboard (MDF), plywood of Radiata Pine (PRP), and plywood of Oceania Timber (POT)) were used. Total VOC (TVOC) from lumbers, excluding P. koraiensis, showed the highest level of emissions on the first day, and the level tended to decline with the passage of time. In particular, TVOC from P. densiflora showed the highest level at 10,793 μg/m2 · h and only 40 % of TVOC reduced even after 14 days. On the other hand, TVOC from artificial building materials showed lower levels of emissions in the order of MDF > PRP > PB > POT. Furthermore, The TVOC emissions from lumbers were approximately 1.3–47.6 times higher than those of artificial building materials. However, the levels emitted from P. densiflora and P. koraiensis stabilized afterwards, and the natural VOC beneficial to the human body was confirmed to exceed 90 %, most of which comprised α-pinene, β-pinene, d-limonene, camphene, and α-terpinene.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In general, volatile organic compounds (VOCs) have been well-documented because of forming photochemical oxidants with NOx in ambient air and causing adverse effects on human health (Yu and Crump 1998). Many of the VOCs are also toxic. In order to construct a building and to decorate its interior, various artificial building materials such as particleboard (PB) and medium density fiberboard (MDF) have been used worldwide. However, VOCs and formaldehyde are emitted from these materials because adhesives generate the toxic chemicals (Roodman and Lenssen 2002). As a result, modern people suffered from new types of disease like sick house syndrome, sick building syndrome, and multichemical sensitivity.

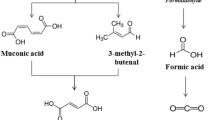

Recently, in order to solve these problems, ecological architecture has been introduced to Europe and Asia (Roodman and Lenssen 2002). It will be expected that VOCs and formaldehyde not much emitted from those buildings, but various natural VOCs (NVOCs) such as α-pinene and d-limonene are emitted from lumber which does not have the adhesives. When these compounds are emitted into indoor areas, they play an important role in physiological relaxation of human as a phytoncide (Lee et al. 2012). They reported that statistically significant reductions in systolic blood pressure were noted after inhalation of α-pinene and limonene, respectively. Brain activity was also significantly subdued. Furthermore, in many previous studies, it was found that the monoterpene had several functions such as antimicrobial, anti-inflammatory, antipruritic, analgesic activity, comfortable feeling, and stress reducing (Kordali et al. 2005; Park et al. 2010; Shaikh et al. 2010; Tsunetsugu et al. 2010; Yamaoka et al. 2005). Also, Kusuhara et al. (2012) reported that mice kept in a fragrant environment enriched with 0.035 ppm α-pinene which often appears in forest resulted in reducing melanoma growth and tumor volume. This occurred under the α-pinene environment which was about 40 % lower than that under control.

On the other hand, it was reported that the phytoncide among VOCs affected green shower and antimicrobial (Inous 2002; Li 2010; Li et al. 2011). Recently, Li (2010) found that forest bathing trips resulted in increase in natural killer (NK) activity, which was mediated by increasing the number of NK cells and the levels of intracellular granulysin, perforin, and granzymes A/B. Besides, Morita et al. (2007) reported that habitual forest bathing may help to decrease the risk of psychosocial stress-related diseases. Komori et al. (1995) concluded that the citrus fragrance found in forests affected human endocrine and immune systems, based on the measurement of urinary cortisol and dopamine levels, NK activity, and CD4/8 ratios.

These various results proved medically that the beneficial effects on human immune function were provided by the NVOCs such as terpenes (green shower). Therefore, the ecological architecture would give diverse advantageous effects on human health.

In fact, many studies regarding VOCs emitted from artificial building materials including MDF and PB have been reported (Brown 1999; Guo et al. 2002; Yrieix et al. 2010). However, no studies of VOCs emitted from ecological architecture materials such as various lumbers (especially for representative trees in southeastern Asia such as Pinus densiflora (PD), Pinus koraiensis (PK), Cryptomeria japonica (CJ) and Larix leptolepis (LL) have been published. Furthermore, studies on NVOC characteristics emitted from building materials have been hardly reported because most of the previous researches were focused on only toxic VOCs such as benzene, toluene, ethylbenzene, and xylene.

Accordingly, this study carried out to identify emission concentrations and characteristics of the VOCs that are emitted from building materials. We also focused on the NVOCs that proved to be beneficial to human health. A result of this research would be assisted to fields related to public health and indoor air quality.

Experimental method

Material

In this work, VOC emission characteristics, their variations with the passage of time, and constituent substances of lumber and artificial building material made from major trees in East Asia were compared and analyzed. The test objects included lumber such as P. densiflora, P. koraiensis, C. japonica, and L. leptolepis as well as artificial building materials including PB, MDF, plywood of Radiata Pine (PRP), and plywood of Oceania Timber (POT) (Table 1). The selected MDF and PB are made from waste wood attached with an adhesive of 10 % urea resin (based on weight), which meets the emission standards of E2 grade formaldehyde. In order to measure the VOCs emitted from the same area size, the sample size was uniform at 162 mm in width, 162 mm in length, and 15 mm in height.

A 20 L small chamber of stainless steel material was used in order to estimate the amounts of VOCs emitted from eight of those building materials based on the ISO 16000-9 method (2004). The chamber was placed inside a thermohygrostat to maintain temperatures of 25 ± 1 °C, and humidity levels of 50 ± 5 % during the test. Moreover, the chamber was dismantled and cleaned by water and ethanol and then heated in an oven at the temperature of over 260 °C for more than 15 min in order to volatilize the remaining chemical substances before the test. After the heat treatment, the chamber was cooled down to 25 °C. The background concentration inside the chamber was measured in order to check whether the condition of the chamber was clean, and whether the air flowing into the chamber was polluted. Figure 1 is a schematic diagram of the device showing that air from the outside is purified by a cleaning device and then flows into each of the four chambers. Moreover, the exposed sample area inside the chamber was 140 × 140 mm and the material loading factor (L), which means the ratio of the total surface area of the materials exposed to the volume of air in the chamber, was 1.96 m2/m3. The air exchange rate (N) was set at 0.5 h−1 with a flow of 167 mL/min. Samples were extracted for a total period of 14 days, 1 day after the sample was installed, in order to determine the declining tendencies of VOC emissions with the passage of time.

VOCs analysis

The adsorption trap for sample collection, a Pyrex tube which was used during the test, was manufactured by filling the tube with Tenax TA 110 mg (60/80 mesh, SUPELCO, USA) and CarbotrapTM 100 mg (20/40 mesh, SUPELCO, USA). During the experimental period, air sample volumes of 3.2 L at a sampling rate of 134 mL/min were collected at the outlet of the chamber using this trap. The samples collected from the chamber were stored in a refrigerator (at 4 °C) and were analyzed within 48 h.

An automatic thermal desorption device on a cryogenic system (Tekmar 6000, Tekmar-Dohrmann, USA), gas chromatography/mass selective detector (GC/MSD; Agilent 6890, USA), and gas chromatography/flame ionization detector (GC/FID; HP 5890, Hewlett Packard, USA) were used in order to carry out a qualitative and quantitative analysis on the samples that were collected in the adsorption trap.

In case of quantitative analysis, the thermal desorption process of the adsorption trap, which had extracted samples, continued for 5 min at a temperature of 280 °C with a consistent flow, which was cryogenically concentrated in the cryo trap, of which the temperature dropped to −155 °C by using liquid nitrogen. The concentrated samples were transported to the cryo focus through a 220 °C transfer line and then finally injected into the GC column. The column used was a Capillary RTX-1 (60.0 m × 530 μm × 3.0 μm). The temperature program comprising three rise sections was used for the analysis. The temperature was initially maintained at 40 °C for 5 min, and it was then increased to 100 °C at 5 °C/min to be maintained for another 5 min in the first stage. In the second stage, the temperature was increased to 150 °C at 2 °C/min, and it was again increased to 250 °C at 5 °C/min in the final stage and maintained for 5 min. After performing an analysis from this temperature program, FID was used for quantification.

In order to carry out a precise quantitative analysis on individual substance, seven artificial (n-hexane, benzene, toluene, ethylbenzene, m,p-xylene, styrene, and o-xylene) and nine natural VOCs (α-pinene, camphene, β-pinene, β-myrcene, Δ3-carene, α-terpinene, p-cymene, d-limonene, and γ-terpinene) were measured with GC/FID. In particular, the standard liquid substance produced by Aldrich (Milwaukee, MI, USA) was used to measure the monoterpene (Lim et al. 2008), and standard gas (Spectra Gases Inc., USA) was used to simultaneously conduct a quantitative assessment on substances emitted from the lumber and artificial building materials. Measurements were taken in five stages ranging from 10 to 585 ng, and the calibration curves for 16 substances were obtained (r 2 > 0.996). Sensitivity (below the method detection limit, 3 SD) for GC/FID analysis was 5.33 ng for toluene (RSE = 9 %). The recovery ratio of all the substances that were analyzed was more than 90 % (RSD < 6 %, n = 6) with a relatively exact degree of accuracy (±10 %) and precision (±5 %).

The degree of measurement precision for each sample that was continuously sampled with a certain time interval was below an average of 20 %, which validates the credibility of the sample extraction. Replicate analysis of samples and standards were regularly conducted and duplicate samples were taken to confirm sampling reproducibility.

On the other hand, total volatile organic compounds (TVOC) concentrations were calculated from the total area, which was obtained when the peak area, appearing for a period of retention time from n-hexane (C6) to n-hexadecane (C16) from the analyzed GC/FID chromatogram, was substituted for the calibration curve of toluene.

The amount of VOC emission is shown as the emission factor (EF; μg/m2 · h). The EF is calculated by the following equation:

where

- C :

-

Chamber concentration (μg/m3)

- N :

-

Q/V = air exchange rate (h-1)

- L :

-

Material loading (m2/m3)

The emission factor for building materials generally follows a first-decay model over time assuming perfect mixing and air exchange and negligible sink effects (Yu and Crump 1998). The emission profiles can be expressed as

where

- EF0 :

-

Initial emission factor (μg/m2 · h)

- k :

-

Emission factor decay constant (h-1)

- t :

-

Time (h)

A thermal desorber and a GC/MSD system were also used for qualitative analysis. A DB-1 capillary column (60.0 m × 320 μm × 1.0 μm) was used for GC/MSD. GC/MSD oven program was initially set at 40 °C for 5 min, and then increased to 80 °C at 3 °C/min to be maintained for 20 min. After then, the temperature was increased to 110 °C at 3 °C/min which was held 7 min, then by 10 °C/min up to 250 °C which was held for 5 min. In order to conduct a clearer qualitative analysis, a standard gas and solutions were injected into GC/MSD and checked the retention time of 16 substances. Additionally, the cracking patterns of each standard compound were compared by the Wiley 7.0 library program.

Results and discussion

Blank test

The air quality which flows in and out of the chamber is vital to determine the emission characteristics of indoor building material. Accordingly, a blank sample was installed to check the TVOC concentrations and characteristics by using a solid adsorption tube before installing a test sample. The test result showed that the TVOC concentrations inside the four small chambers were less than 20 μg/m3, which is the level recommended by ISO 16000-9 (2004).

Variations of TVOC and NVOC with elapsed time

Figure 2 shows the EF changes of measured and the modeled (first-decay model) TVOC on the tested materials with elapsed time. The TVOC of lumbers on the first day showed the highest emission and the emissions tended to decline over the next 7 days. Particularly, the initial TVOC EF of PD was the highest at 10,793 μg/m2 h−1 and was still high at 6,250 μg/m2 h−1, even after 14 days. The emission factor decay constants (k) of TVOC from PD, PK, LL, and CJ calculated by a first-decay model were 0.047, 0.035, 0.068, and 0.139 h−1, respectively.

The TVOC EFs of artificial building material were lower than that of lumbers and the EF of MDF on the first day was the highest at 633 μg/m2 · h followed by PRP (502 μg/m2 · h), PB (314 μg/m2 · h), and POT (227 μg/m2 · h). The k of TVOC from MDF, PRP, PB, and POT were 0.103, 0.078, 0.085, and 0.098 h−1, respectively. The TVOC EF of artificial building materials excluding MDF was the highest 1 day after the test started, and the figure gradually decreased with the time passage. However, the TVOC EF of MDF drastically dropped on the fifth day and briefly increased after 7 days, and then continually decreased afterwards. Moreover, the EFs for MDF, PRP, PB, and POT were at 326, 312, 160, and 100 μg/m2 h−1, respectively, when the TVOC was compared 7 days after the sample was installed. The differences in TVOC EFs among most of the building materials were significant (p < 0.044). However, the differences in EFs between LL and CJ (p = 0.609) and between MDF and PRP (p = 0.543) were not significant.

In a research conducted by Guo et al. (2002), the EF of PB at 21 h after the sample was installed were the highest at 154 μg/m2 h−1, and had a tendency to decline afterwards, which shows considerable similarity in terms of emissions despite variances in the time passage. In a research on PB conducted by Brown (1999), the TVOC value reduced by more than half of the initial figure after 7 days; however, the value slowly decreased afterwards, which confirmed the similar tendency of emissions in this research. In a research carried out by Tichenor (1987), acetone, hexanal, propanol, butanone, benzene, and benzaldehyde are also reported to be produced from PB. In a research conducted by Van de Wal et al. (1990), formaldehyde, terpenes, aromatic hydrocarbons, and aliphatic hydrocarbons are reported to be emitted from plywood and particleboard cupboards.

Furthermore, the substances including α-pinene and ∆3-carene were found to be significantly lower in the heat-treated materials than those in the air-dried when air-dried and heat-treated materials were compared in the research conducted by Manninen et al. (2002). Accordingly, the assumption can be made that the differences of initial emissions from this research, depending on the respective wood materials, could be attributable to varied treatment processes. According to research carried out by Lin et al. (2009), the VOC concentrations emitted from flooring materials tended to increase when temperatures and relative humidity increased, and they declined when air change rates increased. Wiglusz et al. (2002) also reported that a laminate flooring with particleboard as substrate increased the VOCs emission by a factor of ∼18 when temperature rose from 29 to 50 °C. Therefore, the differences in the initial emissions from building material in this research are primarily due to the diverse treatment processes of the respective materials as well as the characteristics of raw materials (e.g., molecular size, boiling point, and polar charges). Other contributions to such differences include environmental factors such as temperature, humidity, and air flow rates.

The initial NVOC EF of PD with elapsed time was the highest at 8,945 μg/m2 · h followed by P. koraiensis (4,032 μg/m2 · h), L. leptolepis (513 μg/m2 · h), C. japonica (313 μg/m2 · h), PRP (272 μg/m2 · h), MDF (190 μg/m2 · h), PB (87 μg/m2 · h), and POT (4 μg/m2 · h) and the order of NVOC EF from diverse building materials is different result to the test for TVOC emissions. While EFs from most materials considerably declined up until 5–7 days and remained stable afterwards (Fig. 3). Additionally, the k of NVOC from PD, PK, LL, CJ, PRP, MDF, PB and POT were 0.037, 0.027, 0.085, 0.118, 0.075, 0.136, 0.116, and 0.119 h−1, respectively. The differences in NVOC EFs among most of the building materials were significant (p < 0.030). However, the difference in EFs between CJ and PRP were not significant (p = 0.826).

In the research of six panels conducted by Yrieix et al. (2010), an analysis was conducted on VOC emission concentrations for 28 days by using ISO 16000-9, the same method utilized in this research. The test result showed that with a TVOC of 258 μg/m3, α-pinene was 54.9 μg/m3, and β-pinene was 58.5 μg/m3, which are relatively lower values than the outcomes from this research on artificial flooring materials. The causes for the differences are considered to be attributable to variances in the tested subjects on TVOC as well as the characteristics of raw materials. On the other hand, the average emission reduction level exceeded 40 % after 28 days compared to that for the initial emission as the emission test period increased, which is a similar result to this research.

Constituent ratios of TVOC

The TVOC EF of PD was highest at 8,121 μg/m2 h−1 among lumbers, and this value was twice as much as that of PK, and over 10 times higher than that of CJ and LL after 7 days. And, we confirmed the NVOC ratios among the TVOC, because the NVOCs have beneficial effects on human health.

Of the TVOC from lumber types, NVOC accounted for more than 50 %, excluding CJ (30 %), and the percentage of NVOC for PD and PK exceeded 90 % (Fig. 4). The TVOC emissions from CJ are exceedingly lower than those of other types of lumbers, which is probably why the VOC emission ratios were relatively low.

Generally, the grades of artificial building materials such as PB and MDF are categorized based on the emission standards of formaldehyde. The formaldehyde emission grade of PB and MDF used in this research was set at E2 grade (below 5.0 mg/L) based on the Korean standard regulation. Consequently, the emissions of all of the artificial building materials were particularly less than those of lumber; the concentrations of PB and POT were the lowest. On the other hand, of the TVOC, the NVOC ratio of the artificial building materials excluding PRP (60 %) was relatively low at below 30 %, and such result could be attributable to the diverse chemical and physical processes when processing wood products (Fig. 5).

Characteristics of NVOC constituent ratios with elapsed time

Figure 6 presents the constituent ratios of NVOC emitted from lumber and artificial building materials with elapsed time. The emission characteristics of NVOC, which comprise nine monoterpenes, showed different tendencies depending on the types of trees. However, when different lumbers were compared, the α-pinene ratio was the highest among the NVOC substances. Particularly, the α-pinene ratio (or EF) of PD exceeded 73.7 % (6,595.4 μg/m2 · h), the highest proportion, and d-limonene (13.8 %, 1,231.2 μg/m2 · h), β-pinene (7.7 %, 691.1 μg/m2 · h), and camphene (2.1 %, 185.8 μg/m2 · h) were confirmed to be significant substances (Table 2). Moreover, α-pinene ratio continually increased to 76.4 % with the passage of time, while β-pinene slightly decreased by about 6.9 %. On the other hand, α-pinene from PK accounted for 80.8 % (3,258.0 μg/m2 · h), the highest portion, which is a similar result to the test for that from PD, and other NVOC excluding qualitative NVOC from this research was below 2.9 %, a minimal portion. In a research conducted by Samuelsson et al. (2006), VOCs were measured when pine bark and pine chip were dried in an oven, and primarily α-pinene (45 %) and β-pinene (12 %) were confirmed to be produced.

The major constituent substances of NVOC for LL were discovered to be α-pinene (62.1 %, 318.1 μg/m2 · h), β-pinene (13.3 %, 68.3 μg/m2 · h), d-limonene (10.1 %, 51.5 μg/m2 · h), p-cymene (4.0 %, 20.3 μg/m2 · h), and camphene (3.5 %, 17.7 μg/m2 · h); most NVOC reduced with the passage of time. On the other hand, the EF level of α-pinene (41.6 %, 130.2 μg/m2 · h) from CJ was markedly less than that of other species of trees, while proportions of d-limonene and ∆3-carene were 18.6 % (58.1 μg/m2 · h) and 21.5 % (67.3 μg/m2 · h), respectively, which represents relatively higher emission ratios.

Constituent ratios of nine monoterpene types of artificial building materials are also presented in Fig. 6. The α-pinene ratio from the lumber was the highest among the NVOC constituent substances, while the Δ3-carene ratio was the highest from the PB (62.3 %, 54.5 μg/m2 · h) and MDF (50.4 %, 95.5 μg/m2 · h) of artificial flooring materials. Moreover, α-pinene (42.9 %, 116.8 μg/m2 · h), β-pinene (38.0 %, 103.6 μg/m2 · h), and d-limonene (15.9 %, 43.3 μg/m2 · h) were confirmed as significant NVOC constituent substances emitted from PRP. This was particularly evident in PB, which is distinct from other products which largely released α-pinene. The Δ3-carene accounted for the largest proportion out of the constituent substances of PB, and α-pinene (7.9 %, 6.9 μg/m2 · h) and β-pinene (24.2 %, 21.1 μg/m2 · h) were discovered to be key constituent substances. No changes were found in the primary constituent substances of artificial building materials during a 14-day emission test, excluding POT. Such disparities of constituent substance ratios are assumed to be caused by the minimal NVOC amount discharged from POT.

Conclusions

This study was conducted to discover the VOC emission characteristics of wood products, including lumbers made from major coniferous trees and artificial flooring materials, as part of basic research to improve indoor air quality. The TVOC emissions from P. densiflora and P. koraiensis were discovered to be 8,121 and 4,301 μg/m2 · h, respectively, on the seventh test day, which exceeded the emission standard regulated by the nation’s standard law (the Indoor Air Quality Management Law for Multipurpose Facilities). However, the NVOC beneficial to the human body was confirmed to exceed 90 %, most of which comprised α-pinene, β-pinene, d-limonene, camphene, and α-terpinene. Therefore, to create healthy indoor air quality, it is important to measure individual compound concentration as well as TVOC concentrations. This research results revealed that a greater amount of NVOC was released when lumber was used as building materials, creating a pleasant indoor environment. This is significant since the interest in indoor air quality is increasing and for many people natural and ecofriendly products are more favorable than artificial products. Therefore, in the future, the regulation of VOCs in indoor environment should be largely based on the research pertaining to effects to the human body with consideration for individual VOCs rather than focusing on quantitative regulations. The results of this study will provide basic information to improve indoor air quality and human health.

References

Brown SK (1999) Chamber assessment of formaldehyde and VOC emissions from wood-based panels. Indoor Air 9:209–215

Guo H, Murray F, Lee SC (2002) Emissions of total volatile organic compounds from pressed wood products in an environmental chamber. Build Environ 37:1117–1126

Inous S (2002) Microorganisms and aroma. Flagrance, Tokyo, ISBN 4-89479-057-2

ISO (International Organization for Standardization) 16000-9 (2004) Determination of the emission of volatile organic compounds—emission test chamber method

Komori T, Fujiwara R, Tanida M, Nomura J, Yokoyama MM (1995) Effects of citrus fragrance on immune function and depressive states. Neuroimmunomodulation 2:174–180

Kordali S, Kotan R, Mavi A, Cakir A, Ala A, Yildirim A (2005) Determination of the chemical composition and antioxidant activity of the essential oil of Artemisia dracunculus and of the antifungal and antibacterial activities of Turkish Artemisia absinthium, A. dracunculus, Artemisia santonicum, and Artemisia spicigera essential oils. J Agric Food Chem 53:9452–9458

Kusuhara M, Urakami K, Masuda Y, Zangiacomi V, Ishii H, Tai S, Maruyama K, Yamaguchi K (2012) Fragrant environment with α-pinene decreases tumor growth in mice. Biomed Res 33(1):57–61

Lee J, Li Q, Tyrväinen L, Tsunetsugu Y, Park BJ, Kagawa T, Miyazaki Y (2012) Public health—social and behavioral health. In: Maddock J (ed) Nature therapy and preventive medicine. Intech, New York, pp 325–350

Li Q (2010) Effect of forest bathing trips on human immune function. Environ Health Prev Med 15:9–17

Li Q, Otsuka T, Kobayashi M, Wakayama Y, Inagaki H, Katsumata M, Hirata Y, Li Y, Hirata K, Shimizu T, Suzuki H, Kawada T, Kagawa T (2011) Acute effects of walking in forest environments on cardiovascular and metabolic parameters. Eur J Appl Physiol 111:2845–2853

Lim JH, Kim JC, Kim KJ, Son YS, Sunwoo Y, Han JS (2008) Seasonal variations of monoterpene emissions from Piuns densiflora in East Korea. Chemosphere 73:470–478

Lin CC, Yu KP, Zhao P, Lee GWM (2009) Evaluation of impact factors on VOC emissions and concentrations from wooden flooring based on chamber tests. Build Environ 44:525–533

Manninen AM, Pasanen P, Holopainen JK (2002) Comparing the VOC emissions between air-dried and heat-treated scots pine wood. Atmos Environ 36:1763–1768

Morita E, Fukuda S, Nagano J, Hamajima N, Yamamoto H, Iwai Y, Nakashima T, Ohira H, Shirakawa T (2007) Psychological effects of forest environments on healthy adults: Shinrin-yoku (forest-air bathing, walking) as a possible method of stress reduction. Public Health 121:54–63

Park HS, Kim SR, Kim JO, Lee YC (2010) The roles of phytochemicals in bronchial asthma. Molecules 15:6810–6834

Roodman DM, Lenssen N (2002) A building revolution: how ecology and health concerns are transforming construction, Worldwatch Institute

Samuelsson R, Nillsson C, Burvall J (2006) Sampling and GC-MS as a method for analysis of volatile organic compounds (VOC) emitted during oven drying of biomass materials. Biomass Bioenergy 30:923–928

Shaikh AR, Tambe SR, Mishra RR, Soman VR (2010) Aromatherapy: the power of scent: a review. Int J Pharma Res Dev. ISSN 0974-9446

Tichenor BA (1987) Organic emission measurements via small chamber testing, indoor air quality and climate, vol. 1. Institute of Water, Soil and Air Hygiene, West Berlin, pp 8–15

Tsunetsugu Y, Park BJ, Miyazaki Y (2010) Trends in research related to “Shinrin-yoku” (taking in the forest atmosphere or forest bathing) in Japan. Environ Health Prev Med 15:27–37

Van de Wal JF, Steenlage R, Hoogeveen AW (1990) Measurement of organic compound emissions from consumer products in a walk-in test chamber. The Fifth International Conference on Indoor Air Quality and Climate, vol. 3. Toronto, Canada: 611–616

Wiglusz R, Sitko E, Nikel G, Jarnuszkiewicz I, Igielska B (2002) The effect of temperature on the emission of formaldehyde and volatile organic compounds (VOCs) from laminate flooring—case study. Build Environ 37:41–44

Yamaoka S, Tomita T, Imaizumi Y, Watanabe K, Hatanaka A (2005) Effects of plant-derived odors on sleep–wakefulness and circadian rhythmicity in rats. Chem Senses 30(1):i264–i265

Yrieix C, Dulaurent A, Laffargue C, Maupetit F, Pacary T, Uhde E (2010) Characterization of VOC and formaldehyde emissions from a wood based panel: results from an inter-laboratory comparison. Chemosphere 79:414–419

Yu C, Crump D (1998) A review of the emission of VOCs from polymeric material used in buildings. Build Environ 13(6):357–374

Acknowledgments

This work was supported by the Korea Forest Research Institute and by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, Science and Technology (2012R1A6A3A03039668).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Son, YS., Lim, BA., Park, HJ. et al. Characteristics of volatile organic compounds (VOCs) emitted from building materials to improve indoor air quality: focused on natural VOCs. Air Qual Atmos Health 6, 737–746 (2013). https://doi.org/10.1007/s11869-013-0207-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11869-013-0207-x