Abstract

The formation of bainitic ferrite and that of grain boundary ferrite in low alloy steels have been two of the most important and interesting research topics in the field of solid state ferrous phase transformation for several decades, and various aspects of these two transformations have been discussed extensively in the literature. Recently, a so-called Gibbs energy balance (GEB) model was proposed by the authors to evaluate alloying element effects on the growth of bainitic ferrite and grain boundary ferrite. The model predicts a growth mode transition from paraequilibrium, negligible partitioning to partitioning during the isothermal formation of bainitic ferrite and grain boundary ferrite. Transformation stasis and bay phenomenon are well explained by the GEB model and both of them are found to be due to alloying element diffusion at the interface. This overview gives a summary of the authors’ recent progress in the understanding of the growth of bainitic ferrite and grain boundary ferrite, with particular focus on the growth mode transition, the transformation stasis phenomenon and the bay phenomenon.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Over the past decades, the formation of bainitic ferrite and grain boundary ferrite (also called ‘allotriomorphic ferrite’) in low alloy steels has attracted significant interest from physical metallurgists due to their great importance in steel design and production.1–6 Despite abundant efforts, the mechanism of bainitic ferrite growth is still one of the most controversial topics in the field of phase transformation.7–22 In brief, there are two competing schools: the diffusional school7,14,17 and the diffusionless school.9,12 The diffusionless school claims that growth of bainitic ferrite is diffusionless, and that its mechanism in principle is the same as that of martensitic transformation. There is no need for carbon and substitutional alloying element M (M = Mn, Ni, Si, Mo, etc.) to diffuse during the growth, but diffusion may take place after the growth. However, according to the diffusional school, bainitic ferrite grows at all times according to the paraequilibrium (PE) mode, e.g., during the growth of bainitic ferrite carbon redistributes at migrating austenite/bainitic ferrite interfaces but M does not. As a result the growth of bainitic ferrite is predicted to be controlled by carbon diffusion.

It is well known that the overall kinetics of phase transformation in steels is strongly influenced by substitutional alloying elements due to their effects on the kinetics of nucleation and growth. In the past decades, substitutional alloying element effects on the growth of grain boundary ferrite have attracted significant attention from the phase transformation community, and much effort has been made to improve the understanding of this topic.23,24 Despite abundant efforts, the effect of alloying elements on grain boundary ferrite growth is only understood to some degree.23,24 The effect of substitutional alloying elements on the growth of bainitic ferrite has been relatively less investigated due to the fact that both diffusional and diffusionless school assume that substitutional alloying elements do not redistribute (even at a local scale) at the migrating austenite/bainitic ferrite interfaces.

Recently, a so-called Gibbs energy balance (GEB) model, in which the chemical driving pressure at the interface is assumed to be equal to the dissipation of Gibbs energy caused by alloying element diffusion inside the interface, has been proposed to evaluate alloying element effects on the growth of bainitic ferrite and grain boundary ferrite.25–27 The GEB model predicts that there is a growth mode transition among PE,28,29 negligible partitioning (NP) and partitioning (P) during the isothermal formation of bainitic ferrite and grain boundary ferrite, and it also provides rationale for the transformation stasis and bay phenomenon. The prediction of the GEB model is supported by experimental data reported in the literature. Here, an overview of our recent progress in the understanding of alloying element effects on the growth of bainitic ferrite and grain boundary ferrite is provided.

The GEB Model

In the GEB model,25–27 it is assumed that there is a triangular potential well inside the interface as has been proposed originally by Purdy and Bréchet,30 and its depth depends on the nature of alloying elements, e.g., the binding energy (E 0) and the chemical potential difference at the interface (∆E). The schematics of the potential well for austenite stabilizing and ferrite stabilizing elements inside the interface are shown in Fig. 1. E 0 and ∆E for different alloying elements can be calculated using a first principles method31 and Thermo-Calc,32 respectively. Due to the presence of the potential well, alloying elements have a tendency to diffuse/segregate into migrating interfaces, which will lead to a dissipation of Gibbs energy according to either Cahn’s solute drag theory33 or the Hillert–Sundman Gibbs-energy dissipation theory.34 Dissipation of Gibbs energy is found to depend on the interface velocity, composition, nature of the alloying element (E 0 and ∆E) and temperature.26 The chemical driving pressure at the interface can be calculated using the Thermo-Calc TQ programming interface. To show how the GEB model works, the dissipation and chemical driving pressure as a function of interface velocity for the isothermal bainitic transformation in the Fe-0.1C-3Mn (all in wt.%) alloy at 500°C and isothermal austenite to grain boundary ferrite transformation in the Fe-0.1C-1.5Mn (all in wt.%) alloy at 700°C are reproduced in Fig. 2. The energy dissipation decreases with increasing interface velocity. The chemical driving pressure is found to decrease as the transformation proceeds, which in our model is because the carbon concentration in the remaining austenite increases instantaneously with the increases in the bainitic ferrite or grain boundary ferrite fraction. In the GEB model, it is assumed that the dissipation of Gibbs energy/volume is equal to chemical driving pressure, and the intersections between the chemical driving pressure curves and the dissipation curve give the growth rate and dissipation, which are found to vary as transformation proceeds. The variation of dissipation indicates that the magnitude of Mn diffusion inside the migrating interfaces changes during the transformation, which leads to growth mode transition, which will be discussed in the following section.

Dissipation and chemical driving pressure as a function of interface velocity for (a) the isothermal bainitic transformation in the Fe-0.1C-3Mn (all in wt.%) alloy at 500°C and (b) isothermal austenite to grain boundary ferrite transformation in the Fe-0.1C-1.5Mn (all in wt.%) alloy at 700°C. The dashed lines are chemical driving pressure curves, and the solid lines are dissipation curves35

Growth Mode Transition

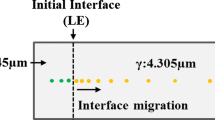

In general, the GEB model predicts that the isothermal bainitic transformation in Fe-C-M alloys can be divided into three stages according to the growth mode.26,27 In Fig. 3, the evolution of the growth mode during the isothermal bainitic transformation is sketched. The first transformation stage proceeds under PE conditions. Bainitic ferrite plates nucleated during this PE stage grows without M diffusion inside the migrating interfaces or in austenite, leading to zero energy dissipation. During this stage, the lengthening rate of bainitic ferrite is determined by carbon diffusion. As the growth of bainitic ferrite is very fast, the limiting factor for the overall kinetics of bainitic transformation in the PE stage would be the nucleation rate of bainitic ferrite. As the transformation proceeds, the fraction of bainitic ferrite and carbon in the remaining austenite increases, which leads to a decrease in chemical driving pressure for growth of newly nucleated bainitic ferrite plates. At a critical fraction of bainitic ferrite, the growth mode switches from PE to NP. This critical fraction is of great fundamental and practical interest as it is linked to the transformation stasis phenomenon, which will be discussed in the following section. In the NP transformation stage the newly nucleated bainitic ferrite plates (blue plates in the sketch of microstructure) have to grow with M diffusion inside the migrating interfaces but without bulk diffusion of M in austenite. This condition is similar to the local equilibrium–negligible partitioning (LE–NP) mode, but the interface condition could be different from the LE–NP condition. The growth of bainitic ferrite in NP stage is very sluggish as it is determined by the diffusivity of M inside the austenite/bainitic ferrite interface. During the NP stage, notwithstanding the remaining high chemical driving pressure and potentially high nucleation rate of bainitic ferrite plates, growth of newly nucleated bainitic ferrite plates is too sluggish to be of practical interest, and the overall transformation seemingly comes to a (premature) end, i.e. reaches stasis. Assuming carbides formation to be fully supressed, according to the GEB model, the growth of bainitic ferrite would finally proceed in the P mode. In the P mode, the growth kinetics of bainitic ferrite is determined by bulk diffusion of M in austenite, which is even much slower than that in the NP mode. In reality, at the late stage of transformation carbide could possibly form, which could change carbon concentration in the remaining austenite and possibly alter the growth mode of the bainitic ferrite. As the overall transformation kinetics in the NP and P stages are extremely slow, the experimentally observed bainitic transformation usually refers to the PE stage. In Ref. 13, the experimentally measured lengthening rate of bainitic ferrite in a series of alloys was found to be slightly lower than but in the same order of PE predictions. Given the uncertainties in experiments and simulations, this slight discrepancy is acceptable.

In a recent review by Pereloma,36 she correctly points out that experimental atom probe data on solute distribution across austenite/bainitic ferrite interfaces did not show any segregation of substitutional elements at or in the vicinity of the interface. However, it has to be emphasized that, as shown in Fig. 3, according to the GEB model all bainitic ferrite plates nucleated before the stasis (e.g., in the PE transformation stage) would grow without any segregation of substitutional elements at or in the vicinity of the migrating austenite/bainitic ferrite interface. These bainitic ferrite plates stop lengthening only when they impinge with the prior austenite grain boundaries or existing austenite/bainitic ferrite interfaces. Segregation is expected to occur at the stationary interfaces between austenite and bainitic ferrite plates formed in the PE mode on aging after completion of growth. Segregation of substitutional elements is predicted to occur only at migrating interfaces between austenite and bainitic ferrite plates nucleated at the stasis stage (e.g., in the NP or the P mode).

The GEB model was extended for the austenite to grain boundary ferrite transformation, and similar growth mode transition has been predicted for Fe-C-Mn and Fe-C-Ni alloys.37 In Fig. 4, the evolution of the growth mode during the isothermal austenite to grain boundary ferrite transformation is sketched. The high temperature austenite to ferrite transformation reaches a stasis state once the growth mode evolves into the P mode instead of the NP mode, and the overall transformation kinetics is still quite fast when the interface migrates in the NP mode. The GEB model predicts that before the stasis the interfaces mostly migrate in NP mode with a very short PE transformation stage at the very beginning of transformation.37 The kinetics of austenite/grain boundary ferrite interface migration predicted by the GEB model is very close to that by the LE–NP model. Therefore, it is not surprising that both the GEB and LE–NP models can well describe the austenite to grain boundary ferrite transformation kinetic in Fe-C-Mn and Fe-C-Ni alloy, as shown in Refs. 37 and 38. However, it is worth noting that the LE–NP model does not work for the growth of bainitic ferrite. The models by Purdy-Brechet,30 Enomoto,39 Odqvist et al.40 and Zurob et al.41 based on the same energy balance concept as the GEB model have also been used to investigate the growth mode transition during the austenite to grain boundary ferrite transformation, yielding comparable results and strengthening the notion that the local chemical composition at the moving austenite–ferrite interface plays a decisive role in the subsequent transformation.

So far, we have only studied the growth mode transition during the isothermal transformation, but growth mode transition is also theoretically expected to occur during transformation upon continuous cooling. According to the GEB model, the growth mode transition for both bainitic ferrite and grain boundary ferrite formation in Fe-C-M alloys is directly linked to the nature and concentration of M and temperature, which determines the critical point (e.g., time, ferrite fraction or temperature) at which the growth mode transition occurs. The growth mode transition is linked to the transformation stasis phenomenon, which will be discussed in the next section.

Transformation Stasis Phenomenon

The transformation stasis phenomenon,17 also called the incomplete transformation phenomenon,12 has been described as the formation of bainitic ferrite temporarily ceased before its fraction reaches the thermodynamic fraction predicted for the PE condition. According to the diffusionless theory, the formation of bainitic ferrite should (completely) stop when the carbon concentration in austenite reaches the critical limit for the diffusionless transformation \( T_{0} \) or \( T_{0}^{ '} \) line instead of the PE line.12 \( T_{0} \) is the temperature at which the free energy of austenite is equal to that of ferrite when their chemical concentrations are the same. In order to better fit with experiments, a strain energy of 400 J/mol due to the displasive nature of bainitic ferrite formation is assumed in the calculation of \( T_{0} \), leading to the concept of \( T_{0}^{ '} \). According to the level rule, \( T_{0} \) and \( T_{0}^{ '} \) would definitely predict a lower fraction of bainitic ferrite than the PE model, and thus the incomplete bainite transformation phenomenon (transformation stasis) can be well explained by the diffusionless theory. The presence of the incomplete transformation phenomenon has been regarded as key evidence to prove that the formation of bainitic ferrite is diffusionless.9,17

As discussed above, the diffusional GEB model also predicts that overall transformation reaches a stasis state when the growth mode of bainitic ferrite switches from PE to NP. However, unlike the diffusionless theory, the GEB model argues that the transformation stasis phenomenon is caused by the diffusion of alloying elements inside the interfaces, and thus is not a general characteristics of the bainitic transformation but only occurs in ferrous alloys containing alloying elements with a strong tendency of segregating or partitioning at the austenite/bainitic ferrite interfaces. In Ref. 26, a detailed comparison between experiments and predictions by different models has been made for a series of Fe-C-Mn and Fe-C-Mn-Si alloys, and the results for the Fe-0.1C-3.0Mn-1.5Si and Fe-0.6C-1.5Mn-1.5Si (all in wt.%) alloys are reproduced in Fig. 5. The binding energies of Mn and Si are assumed to be 9.9 kJ/mol and 12.3 kJ/mol. For the steel with 3% Mn, the \( T_{0}^{ '} \) concept appears to be reasonably consistent with experiments, while it deviates significantly from experiments for the 1.5% Mn steel. The \( T_{0} \) or \( T_{0}^{ '} \) concepts could not capture the effect of Mn concentration on the transformation stasis phenomenon,26 and the correctness of \( T_{0}^{ '} \) predictions for the 3% Mn steel could be accidental. Although Mn does not have a very large binding energy (it is assumed to be 9.9 kJ/mol), it has a very strong tendency to partition at the austenite/bainitic ferrite interface (i.e. ∆E is large). Mn could lead to a considerable dissipation, which has been found to be concentration-dependent. The GEB model predicts that the transformation stasis phenomenon could occur in the Fe-C-Mn and Fe-C-Mn-Si alloys, while the transformation is approaching PE with decreasing Mn concentration. As shown in Fig. 5, the bainitic transformation in the Fe-0.1C-3Mn-1.5Si alloy deviates significantly from PE, while transformation in the Fe-0.6C-1.5Mn-1.5Si alloy is very close to PE. The experimentally obtained dependence of transformation stasis phenomenon on Mn concentration is in good agreement with the GEB predictions.

The bainite fraction at the stasis as a function of temperature for (a) Fe-0.1C-3.0Mn-1.5Si alloy and (b) Fe-0.6C-1.5Mn-1.5Si alloy35

The GEB model has been used to study the Mo and Si effects on the transformation stasis phenomenon, and the predictions have been compared with experiments in a series of Fe-C-Mo and Fe-C-Si alloys.27 The binding energies of Mo and Si were assumed to be 30.3 kJ/mol and 12.3 kJ/mol.26,27 Some of the results are reproduced in Fig. 6. Mo could also lead to transformation stasis phenomenon due to its large binding energy, and the degree of incomplete transformation increases with increasing Mo concentration. The assumed binding energy of Si is smaller than that of Mo but larger than that of Mn, and it has been predicted that there is considerable segregation of Si at the interface in Ref. 25. However, the chemical potential difference at the interface (∆E) of Si is much smaller than that of Mn. Given the fact that the Gibbs energy dissipation is determined by both the chemical potential difference at the interface and the binding energy, the dissipation of Gibbs energy due to Si diffusion inside the interface has been predicted to be not very large.25 Furthermore, the addition of Si could increase the chemical driving pressure for the formation of bainitic ferrite as it is ferrite stabilizer. Therefore, the GEB model predicts that the bainitic transformation in the Fe-0.11C-1.83Si (in wt.%) alloy is close to PE. The transformation stasis phenomenon was also experimentally observed during the diffusional austenite to grain boundary ferrite transformation in Fe-C-Mn and Fe-C-Ni alloys,37 which suggests that transformation stasis is not a unique phenomenon of bainitic transformation and should not be regarded as evidence that bainitic transformation is diffusionless. The degree of incomplete (grain boundary) ferrite formation was found to depend on Mn and Ni concentration, and the dependence was well predicted by the GEB model. The physical origin of transformation stasis phenomenon during grain boundary and bainitic ferrite formation is exactly the same, and is due to alloying element diffusion inside migrating interfaces.

The bainite fraction at the stasis as a function of temperature: (a) Fe-0.064C-1.8Mo alloy; (b) Fe-0.22C-0.23Mo alloy; (c) Fe-0.11C-1.83Si alloy. Note that the temperature scales in each figure are different35

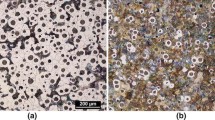

Transition Between Grain Boundary Ferrite and Bainitic Ferrite

The formation of grain boundary ferrite and of bainitic ferrite (plate-like ferrite) are usually investigated separately, and the link between them has not received enough attention. From a physical point of view, there is no difference between the thermodynamics of the grain boundary ferrite and bainitic ferrite as they have the same lattice structure (BCC). At any temperature below Ae3, there is chemical driving pressure available for both grain boundary ferrite and bainitic ferrite growth, and thus both of them are expected to form. However, in reality, grain boundary ferrite forms at low undercooling, while bainitic ferrite forms at relatively high undercooling. In Ref. 42, it is assumed that at temperatures below Ae3 both grain boundary ferrite and bainitic ferrite are allowed to form, and growth rates of both are calculated using the GEB model. In these simulations, the austenite/ferrite interface is assumed to be planar in the calculation of the growth rate of ferrite, while the lengthening rate of bainitic ferrite is calculated using the Zener–Hillert equation.43 In Fig. 7a, the calculated growth rate of bainitic ferrite and grain boundary ferrite as a function of temperature for the Fe-0.19C-1.81Mo (in wt.%) alloy is reproduced. The growth rate (lengthening rate) of bainitic ferrite does not change smoothly as a function of temperature, but instead there is a transition temperature (606°C) at which it changes dramatically. It is predicted that above the transition temperature the bainitic ferrite grows in the NP mode, while the growth mode changes to the PE mode below the transition temperature. A similar growth mode transition is also predicted for the grain boundary ferrite, while the transition temperature is slightly lower than that of the bainitic ferrite. At temperatures below 606°C, the growth rate of the bainitic ferrite is several orders faster than that of grain boundary ferrite, and thus overall transformation should be dominated by bainitic ferrite formation. Above 606°C, the growth rate of bainitic ferrite is quite close to that of grain boundary ferrite. Given the fact that the lateral surface area of bainitic ferrite is much smaller than that of ferrite, the overall transformation should be dominated by grain boundary ferrite formation. Therefore, the GEB model predicts that with decreasing temperature overall transformation is dominated by grain boundary ferrite formation and bainitic ferrite formation, respectively. The critical temperature at which the transition from grain boundary ferrite to bainitic ferrite formation occurs is regarded as the bainite start temperature. In Fig. 7b, the calculated growth rate of bainitic ferrite and grain boundary ferrite is shown as a function of temperature for the Fe-0.1C-2.0Mn (all in wt.%) alloy. The transition between grain boundary and bainitic ferrite formation (bainite start temperature) is well predict by the GEB model. For the Fe-0.19C-1.81Mo alloy shown in Fig. 7a, bainite starts at a temperature where the growth rate of grain boundary ferrite decreases with lowering the temperature (lower portion of the C-shaped curve), which leads to the bay phenomenon. The presence of the bay phenomenon in Fe-C-Mo alloys is found to be attributable to the strong segregation tendency of Mo (e.g., the large binding energy).42 However, for the Fe-0.1C-2.0Mn alloy as indicated in Fig. 7b, bainite starts at a temperature at which the ferrite growth rate increases with decreasing temperature (upper portion of the C-shaped curve), which means that there is no bay phenomenon. Based on the GEB model, the bay phenomenon is expected to occur in ferrous alloys containing alloying elements with a strong tendency of segregation, and it is also predicted to be concentration-dependent.42

The calculated growth rate of bainitic ferrite and grain boundary ferrite as a function of temperature for (a) the Fe-0.19C-1.81Mo alloy and (b) the Fe-0.1C-2.0Mn alloy42

The effect of strain energy on the transition between grain boundary ferrite and bainitic ferrite has been investigated using the GEB model, and it is predicted that the bainite start temperature decreases with increasing strain energy. GEB calculations have also been made for a series of Fe-C-Mo and Fe-C-Mn alloys to investigate the effect of Mn and Mo concentration on the bainite start temperature. The dependence of the bainite start temperature on Mo and Mn concentration predicted by the GEB model is in good agreement with the Steven and Haynes’s empirical equation derived from many experimental data,44 as shown in Fig. 8.

B S temperature predicted by the GEB model and Steven and Haynes’s empirical equation as a function of (a) Mo concentration and (b) Mn concentration42

Summary

The diffusional GEB model well predicts the effect of the type and concentration of alloying elements on the growth of bainitic ferrite and grain boundary ferrite. The growth mode transition from PE, NP to P is found to occur during the isothermal formation of both grain boundary ferrite and bainitic ferrite. The GEB model can replicate the transformation stasis phenomenon and the bay phenomenon, which are both found to be due to segregation and diffusion of alloying elements at the austenite/ferrite interfaces. The transition between grain boundary ferrite and bainitic ferrite formation is also well predicted by the GEB model.

References

B.C. De Cooman, Curr. Opin. Solid State Mater. Sci. 8, 285 (2004).

C. Garcia-Mateo, F.G. Caballero, and H.K.D.H. Bhadeshia, ISIJ 43, 1238 (2003).

H.-S. Fang, D.-Y. Liu, K.-D. Chang, C. Zhang, J.L. Gu, W.Z. Zhang, B.Z. Bai, and Z.G. Yang, J. Iron Steel Res. 13, 31 (2001).

A. Lambert Perlade, A.F. Gourgues, and A. Pineau, Acta Mater. 52, 2337 (2004).

I.B. Timokhina, H. Beladi, X.Y. Xiong, Y. Adachi, and P.D. Hodgson, Acta Mater. 59, 5511 (2011).

K. Zhu, H. Chen, J.P. Masse, O. Bouaziz, and G. Gachet, Acta Mater. 61, 6025 (2013).

M. Hillert, The growth of ferrite, bainite and martensite. Internal report, Royal Institute of Technology (1960).

R.F. Hehemann, K.R. Kinsman, and H.I. Aaronson, Metall. Trans. 3, 1077 (1972).

H.K.D.H. Bhadeshia and D.V. Edmonds, Acta Metall. 28, 1265 (1980).

W.T. Reynolds, F.Z. Li, C.K. Shui, and H.I. Aaronson, Metall. Mater. Trans. A 21A, 1433 (1990).

W.T. Reynolds, S.K. Liu, F.Z. Li, S. Hartfield, and H.I. Aaronson, Metall. Mater. Trans. A 21A, 1479 (1990).

H.K.D.H. Bhadeshia, Bainite in Steels (London: The Institute of Materials, 1992).

D. Quidort and Y.J.M. Brechet, Acta Mater. 49, 4161 (2001).

M. Hillert, L. Hoglund, and J. Ågren, Metall. Mater. Trans. A 35, 3693 (2004).

F.G. Caballero and H.K.D.H. Bhadeshia, Curr. Opin. Solid State Mater. Sci. 8, 251 (2004).

Z.G. Yang and H.S. Fang, Curr. Opin. Solid State Mater. Sci. 9, 277 (2005).

H.I. Aaronson, W.T. Reynolds, and G.R. Purdy, Metall. Mater. Trans. A 37, 1731 (2006).

A. Borgenstam, M. Hillert, and J. Ågren, Acta Mater. 57, 3242 (2009).

F.G. Caballero, C. Garcia-Mateo, M.J. Santofimia, M.K. Miller, and C. Garcia de Andres, Acta Mater. 57, 8 (2009).

Z.Q. Liu, G. Miyamoto, Z.G. Yang, C. Zhang, and T. Furuhara, Metall. Mater. Trans. A 46, 1544 (2015).

W. Gong, Y. Tomota, S. Harjo, Y.H. Su, and K. Aizawa, Acta Mater. 85, 243 (2015).

C. Garcia-Mateo, J.A. Jimenez, H.W. Yen, M.K. Miller, L. Morales-Rivas, M. Kuntz, S.P. Ringer, J.R. Yang, and F.G. Caballero, Acta Mater. 91, 162 (2015).

G. Purdy, J. Ågren, A. Borgenstam, Y. Bréchet, M. Enomoto, T. Furuhara, E. Gamsjäger, M. Goune, M. Hillert, C. Hutchinson, M. Militzer, and H. Zurob, Metall Mater. Trans. A 42, 3703 (2011).

M. Goune, F. Danoix, J. Ågren, Y. Bréchet, C. Hutchinson, M. Militzer, G. Purdy, S. van der Zwaag, and H. Zurob, Mater. Sci. Eng. R. Rep. 92, 1 (2015).

H. Chen, A. Borgenstam, J. Odqvist, I. Zuazo, J. Ågren, and S. van der Zwaag, Acta Mater. 61, 4512 (2013).

H. Chen, K. Zhu, L. Zhao, and S. van der Zwaag, Acta Mater. 61, 5458 (2013).

H. Chen and S. van der Zwaag, Mater. Trans. A 45A, 3429 (2014).

M. Hillert, Introduction to Paraequilibrium. Internal Report, Swedish Institute of Metals Research, Stockholm, 1953.

A. Hultgren, Trans. ASM 39, 915 (1947).

G.R. Purdy and Y. Bréchet, Acta Metall. 43, 3763 (1995).

H. Jin, I. Elfimov, and M. Militzer, J. Appl. Phys. 115, 093506 (2014).

Thermo-Calc is trademark of Thermo-Calc software. http://www.thermocalc.com/.

J.W. Cahn, Acta Metall. 10, 117 (1962).

M. Hillert and B. Sundman, Acta Metall. 24, 731 (1976).

H. Chen, S. van der Zwaag, Proceeding of International Conference on Solid-Solid Phase Transformation in Inorganic Materials (2015)

E.V. Pereloma, Mater. Sci. Technol., in press (2015)

H. Chen and S. van der Zwaag, Acta Mater. 72, 1 (2014).

Z.Q. Liu, G. Miyamoto, Z.G. Yang, and T. Furuhara, Acta Mater. 61, 3120 (2013).

M. Enomoto, Acta Mater. 47, 3533 (1999).

J. Odqvist, M. Hillert, and J. Ågren, Acta Mater. 50, 3211 (2002).

H.S. Zurob, D. Panahi, C.R. Hutchinson, Y. Brechet, and G.R. Purdy, Metall. Mater. Trans. A 44, 3456 (2013).

H. Chen, Z.G. Yang, C. Zhang, K.Y. Zhu, and S. van der Zwaag, Acta Mater. 104, 62 (2016).

M. Hillert, Metall. Mater. Trans. A 25A, 1957 (1994).

W. Steven and A. Haynes, J. Iron. Steel Inst 183, 349 (1956).

Acknowledgement

H. Chen acknowledges financial support from National Young 1000-Talents Program (D1101073) and the National Natural Science Foundation of China (51501099).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, H., van der Zwaag, S. The Effect of Interfacial Element Partitioning on Ferrite and Bainite Formation. JOM 68, 1320–1328 (2016). https://doi.org/10.1007/s11837-016-1848-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-016-1848-7