Abstract

Yarrowia lipolytica is known to have the ability to assimilate hydrophobic substrates like triglycerides, fats, and oils, and to produce single-cell oils, lipases, and organic acids. The aim of the present study was to investigate the effects of different oil sources (borage, canola, sesame, Echium, and trout oils) and oil industry residues (olive pomace oil, hazelnut oil press cake, and sunflower seed oil cake) on the growth, lipid accumulation, and lipase and citric acid production by Y. lipolytica YB 423-12. The maximum biomass and lipid accumulation were observed with linseed oil. Among the tested oil sources and oil industry residues, hazelnut oil press cake was the best medium for lipase production. The Y. lipolytica YB 423-12 strain produced 12.32 ± 1.54 U/mL (lipase activity) of lipase on hazelnut oil press cake medium supplemented with glucose. The best substrate for citric acid production was found to be borage oil, with an output of 5.34 ± 0.94 g/L. The biotechnological production of valuable metabolites such as single-cell oil, lipase, and citric acid could be achieved by using these wastes and low-cost substrates with this strain. Furthermore, the cost of the bio-process could also be significantly reduced by the utilization of various low-cost raw materials, residues, wastes, and renewable resources as substrates for this yeast.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The current rise in agricultural and industrial production has led to an excessive generation of various low-cost by-products and/or residues/wastes. Fermentation of these products/residues/wastes for the production of high-added-value metabolites such as single-cell oils, organic acids, and lipases has an important economic significance for the industry [1–3]. The non-conventional dimorphic yeast Yarrowia lipolytica has the capability to assimilate hydrophobic substrates like triglycerides, fats, and oils, and to produce lipases and organic acids [1, 4, 5]. Furthermore, Y. lipolytica has the ability to produce bioemulsifiers and degrade fats and oils [1, 2].

Single-cell oils (SCOs) present a potential industrial interest since many types of oleaginous microorganisms are able to store lipids with either unusual composition (such as substitutes of high-value fats like cocoa butter, sal fat, and illipé fat) or conventional composition (such as biodiesel precursors) [2, 6–8]. In SCO production, the ability of oleaginous microorganisms to synthesize lipids containing medically and dietetically important polyunsaturated fatty acids has considerable interest [9]. Products that have been produced commercially include cocoa butter equivalents (from Apiotrichum curvatum), γ-linolenic acid (GLA, 18:3n-6) (from Mortierella isabellina, Chlorella and Mucor circinelloides), docosahexaenoic acid (DHA, 22:6n-3) (from Crypthecodinium and Schizochytrium), and arachidonic acid (AA, 20:4n-6) (from Mortierella, Porphyridium spp. and Pythium) [10–13]. Among the microbial sources, Y. lipolytica has been recognized as a promising yeast capable of accumulating oil, producing lipase, and living on fats and oils as carbon sources [14].

The addition of different oils to the cultivation media of Y. lipolytica may enhance the production of polyunsaturated fatty acids depending on the fatty acid contents of the added oils. In previous studies, the fatty acid composition of the hydrophobic substrates affected the lipid accumulation and fatty acid composition in the cells [6, 7]. The fatty acid composition of the oil produced by yeast was very similar to the substrate oil in the cited studies. Chatzifragkou et al. [15] also concluded that the addition of oil to the culture medium favored the accumulation of saturated fatty acids (C16:0 and C18:0) by Y. lipolytica.

Oleaginous microorganisms are able to assimilate many carbon sources, such as by-products of the food and agricultural industry, and produce SCO rich in polyunsaturated fatty acids or high-nutritional-value fatty acids [16]. These microorganisms accumulate SCO during secondary metabolic growth in media containing high amounts of carbon and limited amounts of nitrogen. They convert residual carbon into oil when the amount of nitrogen is depleted in the media [12, 17].

Economou et al. [16, 18] used sweet sorghum extract and rice hull hydrolysate as substrates for SCO production by oleaginous fungus Mortierella isabellina, and developed detailed mathematical models that can predict biomass growth, SCO production, and consumption of sugar and nitrogen. In their following study, they developed a biofilm model to describe the accumulation of oil in semi-solid state fermentation using M. isabellina and sweet sorghum as a substrate [17].

Citric acid (CA), which is an intermediate of the tricarboxylic acid cycle (TCA) and is used in the food and detergent industry as an acidulant, flavoring agent, antioxidant, preservative, stabilizer, and bleaching component, has important functions in the metabolism of microbial cells [4, 19–21]. Sugars, glycerol, and polysaccharides can be utilized as carbon sources by various types of microorganisms under nitrogen-limited conditions. After nitrogen depletion from the medium, growth is ceased and secondary metabolites are produced. These metabolites are organic acids (e.g., CA), lipids, and other extra-cellular compounds (e.g., polyols) depending on the microorganism [20, 22, 23]. Usually, molds such as Aspergillus niger and yeasts like Y. lipolytica, Candida guillermondii, and C. oleophila are used in microbial CA production [20, 24]. Using yeasts instead of molds for CA production is of particular interest due to higher resistance against high substrate conditions and metal ions, as well as the accumulation of lower amounts of solid and liquid wastes for the latter [25]. Y. lipolytica has the ability to produce organic acids such as CA, isocitric acid, and 2-ketoglutaric acid. This strain has many advantages including low sensitivity to low dissolved oxygen concentrations and heavy metals, greater tolerance to metal ions, high product yield and wide substrate range, as well as a greater resistance to high concentrations of substrate compared to other yeast strains [19, 26].

Lipases (triacylglycerol acyl hydrolases—E.C 3.1.1.3) are considered to be the most important industrial enzyme, with numerous applications reported. They are used in the production of detergents, cosmetics, pharmaceuticals, flavor enhancers, and foods [27]. Microbial lipases are used as biocatalysts, especially in food and detergent manufacture and also in other biotechnological applications. One of the most studied dimorphic lipolytic yeasts is Y. lipolytica, which naturally secretes the lipase enzyme [28, 29]. The lipase activity of Y. lipolytica was first reported by Peters and Nelson in 1948 [30, 31]. Pignede et al. [32] isolated and identified the LIP2 gene and showed its function on the extracellular lipase activity of Y. lipolytica. They demonstrated that LIP2 and POX2 promoters were induced by oleic acid, which functions as a stabilizer-activator of extracellular lipase, probably because of an expression system of the lipase gene under the control of LIP2 and the oleic acid-inducible POX2. Both genetic engineering and mutagenesis methods have been used to increase lipase enzyme production by Y. lipolytica strains. The expression system of the lipase enzyme contains cassettes carrying the LIP2 gene, and this gene is expressed under the control of the oleic acid-inducible POX2 promoter [9]. The objectives of this study were to investigate the growth, lipid accumulation, and metabolite production by the Y. lipolytica YB 423-12 strain with the addition of external carbon sources (oils and oil-cakes) such as linseed, sesame, borage, canola, trout oil, Echium spp. seed oil, olive pomace oil, hazelnut oil press cake, and sunflower seed oil cake, and to explore the possibility of producing high-value fatty acids by using low-cost oils and oil processing residues or wastes.

Materials and Methods

Microorganism and Culture Conditions

The Y. lipolytica YB 423-12 strain was kindly provided from the NRRL [Agricultural Research Service (ARS)] Culture Collection, Peoria, IL USA. The microorganism was kept on Potato Dextrose Agar (PDA) (Fluka) at +4 °C. During the experiments the strain was cultivated in 250-mL conical flasks at 28 °C and 150 rpm. Each flask contained 50 mL of sterile growth medium. The composition of the basal medium (in g/L) was: glucose 30.00; yeast extract 0.50; KH2PO4 7.00; Na2HPO4 2.50; CaCl2∙2H2O 0.15; (NH4)2SO4 1.00; MnSO4∙H2O 0.06; ZnSO4∙7H2O 0.02; FeCl3∙6H2O 0.15; MgSO4∙7H2O 1.50 (Merck, Darmstadt, Germany). Linseed, borage, sesame, and trout oils were donated from Ramazanoğulları Ltd. Şti (Istanbul, Turkey). Canola oil was purchased from a local market in İstanbul, Turkey. Echium seed oil, olive pomace oil, hazelnut oil press cake, and sunflower seed cake were kindly provided from Harke Group GmbH (Mülheim, Germany), Antgıda A.Ş. (Balıkesir, Turkey), Altaş Yağ A.Ş. (Ordu, Turkey), and Öztürkler Yem ve Yağ San. Tic. A.Ş. (Edirne, Turkey), respectively. All chemicals and reagents used in our analyses were of chromatographic or laboratory grade. Cultures were cultivated in 250-mL erlenmeyer flasks containing 50 mL of the growth medium noted above together with 10.00 g/L of oil/oil cake. The composition of the pre-culture medium was the same growth medium as described above [15, 22, 33–35].

Each flask was inoculated with 1 mL (2 % inoculum volume fraction) of 24 h exponential pre-culture (containing approximately 3 × 108 microorganisms per mL) and incubated in an orbital shaking waterbath (New Brunswick Scientific Co., Inc. Classic C76, Enfield, Connecticut, USA) operating at 150 rpm and 28 °C. The incubation period was 5 days, since the latter optimal period for oil accumulation and metabolite production by Y. lipolytica strains was reported by several researchers [7, 15, 20, 22, 35–37]. Control experiments were conducted using the same medium with no carbon source.

Proximate Analysis

Proximate analysis of the residues was performed according to the methods of AOAC (1984) [38]: crude protein was analyzed by the Kjeldahl method after acid digestion; crude fat was found by hexane extraction in a Soxhlet system; ash was determined via combustion at 550 °C in a muffle furnace for 12 h; moisture was examined with a model M0C63u Unibloc moisture analyzer from Shimadzu (Tokyo, Japan).

Determination of Biomass

Cells were harvested by centrifugation (Sigma 2-16 PK, Laborzentrifugen GmbH, Osterode, Germany) performed at 3,305 g for 20 min. In order to remove the remaining residual extracellular oils on the surface, all residual cells were washed successively with ethanol, hexane, and distilled water, and then centrifuged. For verification, lipid analysis was performed on the supernatant of the last wash [6, 39, 40]. Biomass content expressed as dry matter per liter of fermentation broth was determined after drying centrifuged cells at 105 °C for 24 h [2]. All experiments were performed in triplicate, and the average results were reported.

Lipid Extraction and Methylation

Total intracellular lipid content was extracted with a chloroform: methanol (2:1; v/v) mixture [41, 42], and solvents were removed by a rotary evaporator (Buchi Rotavapor RII, Flawil, Switzerland) at 40 °C. Lipid yields and lipid contents were expressed as grams of lipid per liter of fermentation broth and grams of lipid per grams of dry biomass, respectively. Lipids were converted to methyl esters for further fatty acid composition analysis [43].

Fatty Acid Composition Analysis

Fatty acid compositions of methyl esters were analyzed by capillary gas chromatography (GC), using a Thermo Quest Trace GC 2000 (Milan, Italy) equipped with a flame-ionization detector. DB-wax capillary column (30 m × 0.32 mm ID × 0.25 μm film thickness) (J&W Scientific Folsom, CA) was used for the analysis. The injector and detector temperatures were held at 250 °C and 260 °C, respectively. The conditions used were: the oven temperature was initially held at 150 °C for 3 min, and was then programmed to 225 °C for 10 min at a rate of 10 °C/min. Helium was used as a carrier gas at a flow rate of 1.5 mL/min and a split ratio of 1:70. A 1-µL sample was injected into the GC.

Enzyme Activity Assay

Lipase activity was analyzed by titrimetric assay according to an olive oil emulsion method with slight modifications [4]. The substrate emulsion was formed with olive oil and polyvinyl alcohol at 40 % (v/v) and 2 % (w/v), respectively. The solution was emulsified with an Ultra-Turrax homogenizer (Janke and Kunkel, IKA, Staufen, Germany) to obtain the dispersion of oil particles into the aqueous phase. The assay sample (500.00 µL) containing culture medium and cells were added to the substrate emulsion (5.00 mL). Subsequently, 0.05 M phosphate buffer (4.50 mL) was added to the mixture. The total mixture (10.00 mL) was incubated for 1 h in a water bath (New Brunswick Scientific Co, Inc. Classic C76, Enfield, Connecticut, USA), at 28 °C and 180 rpm. The effect of pH on lipase activity was studied at a broad range of pH (from 5 to 9). The optimal pH for lipase activity was found to be 8 (in accordance with Refs. [2, 4]). The reaction was terminated by adding 4 mL of acetone-ethanol (50:50 v/v) mixture to the medium. Lipase activity was determined by titration of the fatty acid released with 50 mM sodium hydroxide (up to a final pH of 9). One activity unit of lipase was defined as the amount of enzyme, which released 1 µmol of fatty acids per minute under assay conditions at 28 °C. Lipase activity was measured by the equation below, where V 1 and V 2 are the volume (mL) of NaOH (aq) for the sample and blank, respectively, C is the normality of NaOH (aq), t is time, and E is the volume taken from the fermentation medium:

CA Determination

Spectrophotometric analysis of citric acid (CA) was performed using the method of Marrier and Boulet [44]. Filtered aliquots of the culture liquid were used for the analysis[45–47]. In this method, citric acid esters were created by the reaction between acetic anhydride and citric acid, and spectrophotometric measurement was carried out. Supernatants were harvested by centrifugation operated at 3,305 g for 20 min. One mL of supernatant was mixed with 1.30 mL of pyridine and 5.70 mL of acetic anhydride, which are then incubated in a water bath (New Brunswick Scientific Co, Inc. Classic C76, Enfield, Connecticut, USA) at 32 °C for 30 min. The citric acid content was measured by spectrophotometer (Optima SP3000 nano Tokyo, Japan) at 420 nm wavelength [44].

Microscopic observations

Yeast morphology was detected by microscopic observations at × 100 and × 800 using a light microscope (Olympus Corporation, Shinjuku, Tokyo, Japan) after the cells were stained with methylene blue.

Statistical Analysis

The MINITAB program was used to perform statistical analysis of the data, employing an analysis of variance (ANOVA) using the General Linear Model, as well as Tukey's test with a 95 % confidence index (CI).

Results and Discussion

The Y. lipolytica YB 423-12 strain was cultivated in media containing glucose and various oils and oil industry residues as carbon and energy sources. The effects of different oils and residues on the growth and the production of lipids and metabolites from Y. lipolytica were determined by measuring dry biomass, lipid yield, fatty acid profile, citric acid concentration, and lipase activity. According to the findings, the protein contents of hazelnut oil and sunflower seed oil cakes were found to be quite high. However, sunflower seed oil cake contained low amounts of lipids when compared to hazelnut oil press cake (Table 1).

Growth and Morphology of Y. lipolytica on Various Substrates

The effects of different oils such as linseed, sesame, borage, canola, trout, and Echium were investigated for biomass yield. According to the findings, the biomass content varied between 14.40 and 26.67 g/L (Table 2). As can be seen from Table 2, the addition of oils to the medium caused a significant increase in the dry biomass of the strain (p < 0.05). The maximum dry biomass yield was obtained with linseed oil, and the minimum biomass yield was obtained with the control and trout oil.

Biomass and lipid production of Y. lipolytica strains have been analyzed by different researchers [2, 3, 7, 33, 46, 48–50]. Lipid production was found to be 7.90 mg/mL when industrial derivative of tallow was added to the culture medium [2]. Higher levels of biomass yields such as 9.73 and 8.30 g/L were obtained in the presence of casein and olive oil in the medium, respectively [3]. The maximum biomass was reported by Papanikolaou et al. [7] as 11.40 g/L in the medium containing 10 g/L stearin and 34 g/L glycerol. Papanikolaou et al. [33] studied the cultivation of Y. lipolytica on olive-mill wastewater-based media, and the biomass content was found to be in the range of 5.90–7.30 g/L. In the presence of glucose (28.10 g/L concentration), biomass yield was determined to be 7.30 g/L [33]. On the other hand, Aguirre et al. [49] determined the maximum biomass production with the Y. lipolytica S26 strain to be 25 g/L with the medium containing 40 g/L molasses and 5 g/L yeast extract. Different biomass results may be due to the differences between the strains and medium components. Lipid accumulation in the Y. lipolytica LGAM S(7)1 strain cultivated on glucose (9–46 g/L) and glycerol (15–120 g/L) was 5–9 %, and biomass yield was 5.20–8.00 g/L [46]. With the same strain, biomass yield was observed to be 14.5 g/L in the medium containing 25 g/L glucose and citrus oils [50]. The results indicated that, in the presence of linseed oil, biomass and lipid yields increased up to 85 and 93 %, respectively.

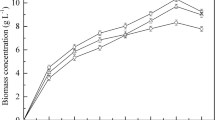

Yeast morphology was observed after a 5-day incubation period with medium containing linseed oil and glucose, respectively, and photographed cells are represented in Fig. 1. The typical mycelium morphology of the yeast observed in pre-culture is shown in Fig. 2. Mycelia forms like those seen in both figures have also been observed in all medium containing different substrate oils (photographs not shown). The mycelium form develops at a very early stage of fermentation and remains during nearly the entire fermentation period. In a similar manner, true mycelia form occurred with linseed oil, probably due to the morphological transition in the presence of the oil in the medium. It was stated that the presence of oil in the medium enhances the mycelium form of the Y. lipolytica strains [2]. According to the other investigations, a unicellular form of the Y. lipolytica strains occurred at low glucose concentrations, while at high concentrations almost all strains were in mycelium form at the end of 40 h of inoculation, and a mycelium-to-yeast transition occurred due to the depletion of glucose concentration in the medium. After 120–140 h of inoculation, nearly all strains were in unicellular (yeast-like) morphology [23, 45, 51].

Microscopical observations were similar to the results of Makri et al. [34], who observed that the true mycelia form was dominant during the exponential growth phase. After that, large cells with lipid globules appeared in the early stationary phase (lipogenic phase), and decreases in the size of the lipid globules were observed in the late stationary phase, as can be seen in Figs. 1 and 2 [34].

Lipid Accumulation and Composition of Cellular Lipids

Cellular lipid yields were in the range of 31.99–61.67 g/100 g of dry biomass. The increase in lipid content compared to the control was 92.78 % in the linseed oil medium. The effects of linseed and Echium spp. seed oil sources were found to be statistically important in the lipid production of Y. lipolytica (p < 0.05). Y. lipolytica exhibited the highest cell growth and lipid production in the presence of linseed oil. Previous studies indicated that the fatty acid composition of the hydrophobic substrate affected the lipid accumulation in the cells, and lipid accumulation increased with the increased concentration of stearin in the culture medium [6, 7, 52, 53]. It was indicated that Y. lipolytica accumulated lipids at high amounts when C18:0-rich media was used, and also grew better in the presence of fatty acid mixtures [6, 54]. If lipid accumulation in the cell was high, the microorganism consumed these lipids for cellular activities instead of external lipid sources [55]. Furthermore, another reason for the low level of transportation of external oil sources to the cell was due to the decreased biological activity of the membranes [6]. It is well-known that the fatty acid profiles of the produced lipids are affected by the fatty acid content of the oils in the substrate, which is consistent with the observations of this study. Chatzifragkou et al. [15] concluded that the addition of essential oil to the medium affected the cellular lipid composition and increased the saturation of fatty acids.

The results indicated that medium containing GLA favored the production of microbial oil with GLA content. A similar result was observed for trout oil regarding the eicosapentaenoic acid (EPA, 20:5n-3) and DHA content in the accumulated oil. Fatty acid compositions of added oils and the fatty acid compositions of the oils after the incubation period are given in Tables 3 and 4, respectively. Fatty acid compositions of the oils are in accordance with the literature [56–59]. Maximum lipid accumulation was observed as 16.45 and 14.86 g/L with linseed and Echium oils, respectively (after a 5-day incubation period), as seen in Table 2. The lowest lipid accumulation was observed as 11.02 g/L in trout oil medium. In all of the experiments, the C18:1 fatty acid was notably higher than other FAs in the accumulated lipid.

The free fatty acid content of the produced lipid was also analyzed and found to be 63.4 %, which was also consistent with the previous studies for Y. lipolytica strains. [6, 14, 60]. The high free fatty acid content was in accordance with the high lipase activity of the strain, as discussed below.

Y. lipolytica is very efficient in degrading hydrophobic substrates such as fats, oils, alkanes, and fatty acids. Triglycerides can be utilized by Y. lipolytica as a carbon source. Lipolytic enzymes (lipases) hydrolyze these triglycerides into free fatty acids that are taken up by the cell, whereas alkanes enter directly into the cell [1].

According to the investigations, selective fatty acid uptake of Y. lipolytica can be explained by two different chain-length selective transport systems: one carrier system is specific for C12 and C14 fatty acids, while the second one is specific for C16 and C18 fatty acids [3]. The fatty acids of C12, 14, and 16 are used for growth, while C18 is accumulated as a reserve lipid and stored [5, 6]. This can be explained by the fact that fatty acids will either be used for growth or biotransformation processes, to produce new fatty acids that did not exist in the substrate previously [55].

Papanikolaou et al. found that Y. lipolytica produced a highly saturated cellular lipid that contained C18:0 and C16:0 at 78–80 % and 17–20 % (w/w) of total lipids, respectively [2]. Generally, Y. lipolytica strains tend to accumulate mono-unsaturated and saturated fatty acids when cultivated on fatty materials [2, 5–7]. The growth and lipid accumulation by Y. lipolytica has been found to be increased in the media containing saturated fatty acids (C16:0 and C18:0), and the microbial lipid was found to contain high amounts of stearic acid [7, 54]. The microbial lipid was affected by the fatty acid composition of the substrate used, so it was possible to produce some fat substitutes with the desired fatty acid composition by using selected strains of Y. lipolytica, Rhodotorula sp., Mucor sp., Candida spp., and Rhodosporidium toruloides [8, 39, 40, 42]. Furthermore, modeling approaches can be used to select the strains or growth parameters of oleaginous microorganisms [54].

CA Concentration and Lipase Activity Analysis

Citric acid can be produced from alkanes, oils, glycerol, ethanol, molasses, and starch hydrolysates [1, 33, 48]. In this study, the effect of different oils and oil industry residues wastes on the lipase and CA production of Y. lipolytica YB 423-12 was investigated. The effects of different carbon sources in fermentation medium on citric acid content and lipase activity produced by Y. lipolytica YB 423-12 were tabulated in Table 5.

The highest CA concentration (5.34 ± 0.938 g/L) was observed in medium containing borage oil. Echium seed, trout, canola, linseed and sesame oils, and sunflower seed oil cake also had statistically important effects in CA production. In contrast, lipase production in medium containing borage oil was lower. Makri et al. studied the growth of Y. lipolytica ACA-DC 50,109 on glycerol, and three distinct phases—namely a biomass production phase, lipogenic phase, and citric acid production phase—were identified during the growth cycle. The results indicated that significant amounts of lipids were produced on glycerol. When citric acid is secreted into the medium, a low amount of the lipid is synthesized, whereas during the lipid turnover period, citric acid production was suppressed [34]. Anastassiadis et al. [20] concluded that nitrogen content and its exhaustion are important factors in citric acid formation by yeasts. There is a negative correlation between citric acid formation and growth rate, because nitrogen limitation increases the production rate of organic acids while decreasing cellular growth and glucose uptake [20]. Nitrogen limitation directed the metabolism towards the citric acid production [22, 46]. When glycerol was used as substrate for Y. lipolytica strains, high-value products such as SCO, CA, and mannitol were produced [22, 34].

A high concentration of glucose favored the accumulation of lipids and citric acid. The production rates of organic acids and growth rates on glycerol were very similar with the results on glucose. The microbial lipids are initially accumulated, and thereafter are degraded in favor of citric acid production [22, 23, 46]. It was reported that microbial lipids were principally composed of unsaturated C16 and C18 fatty acids; likewise, in Y. lipolytica, oleic acid was the major cellular fatty acid [20, 23, 26, 34].

The optimal pH for lipase activity was found to be 8.0 in accordance with the findings of Kamzolova et al [4]. The highest lipase activity (12.32 ± 1.538 U/mL) was achieved with the hazelnut oil press cake medium, as seen in Table 5. This result can be explained by the high oleic acid content of the hazelnut oil press cake since the extracellular lipase requires oleic acid as a stabilizer/activator. Increasing the amount of polyunsaturated fatty acids containing C18 fatty acids in the medium increased lipase activity as well [61, 62]. Hazelnut oil press cake includes 25.7 % oil and 52.2 % oleic acid (C16:0, 3.3 %; C18:2, 26.7 %; C18:3n6, 6.1 %). The lipase gene was expressed under the control of the oleic acid-inducible POX2 promoter [32]. The results indicated that sunflower seed oil cake also significantly increased lipase production (p < 0.05). Papanikolaou et al. [63] studied lipid accumulation with glycerol under nitrogen-excess conditions and concluded that 1.6-fold higher quantities of lipids were produced in nitrogen-excess conditions compared with nitrogen-limited culture. Therefore, in this study the presence of high amounts of metabolites in the media containing residues may be explained by excess nitrogen levels, since hazelnut oil press cake and sunflower seed cake contain 4.80 and 5.76 % nitrogen, respectively.

Lipase activities of different Y. lipolytica strains tested were reported to be between 1.9 and 45.5 IU/mL [2, 4]. In another study conducted by Nicaud et al. [61], lipase activity was increased to be as high as 60,000 IU/mL by gene amplification. It was indicated that lipase activity increased with the increasing level of C18 fatty acids (C18:1 and C18:n) in the substrate [62, 64].

It was observed that carbon sources in the fermentation medium also affect CA and lipase production considerably. Different carbon sources with equal masses present different energy capacities. Darvishi et al. [3] found that CA production by Y. lipolytica DSM3286 was found to be lower when yeast was cultivated with different oils than when it was cultivated with glucose. Glucose concentration increased citric acid production due to excess carbon conditions [20].

Conclusions

The results showed that hazelnut and sunflower oil industry residues, as well as Echium spp. seed and linseed oils appear to be promising substrates for Y. lipolytica YB-423-12 growth and metabolite production. Further studies should be carried out in order to produce high-value-added, tailor-made lipids and metabolites with this strategy. Since Y. lipolytica is able to accumulate lipids with a similar structure to vegetable oils containing unsaturated fatty acids in the 2-acylglycerol position [6–9], it may also be possible to produce cocoa butter substitutes or other functional oils using various hydrophobic wastes/by-products as substrates.

References

Fickers P, Benetti PH, Waché Y, Marty A, Mauersberger S, Smit MS, Nicaud JM (2005) Hydrophobic substrate utilization by the yeast Yarrowia lipolytica, and its potential applications. FEMS Yeast Res 5:527–543

Papanikolaou S, Chevalot I, Galiotou-Panayotou M, Komaitis M, Marc I, Aggelis G (2007) Industrial derivative of tallow: a promising renewable substrate for microbial lipid, single-cell protein, and lipase production by Yarrowia lipolytica. Electron J Biotechn 10(3):425–435

Darvishi F, Nahvi I, Zarkesh-Esfahani H, Momenbeik F (2009) Effect of plant oils upon lipase and citric acid production in Yarrowia lipolytica yeast. J Biomed Biotechnol 2009:1–7 Article ID 562943

Kamzolova SV, Morgunov IG, Aurich A, Perevoznikova OA, Shishkanova NV, Stottmeister U, Finogenova TV (2005) Lipase secretion and citric acid production in Yarrowia lipolytica Yeast grown on animal and vegetable fat. Food Technol Biotech 43(2):113–122

Papanikolaou S, Chevalot I, Komaitis M, Marc I, Aggelis G (2002) Single cell oil production by Yarrowia lipolytica growing on an industrial derivative of animal fat in batch cultures. Appl Microbiol Biot 58(3):308–312

Papanikolaou S, Chevalot I, Komaitis M, Aggelis G, Marc I (2001) Kinetic profile of the cellular lipid composition in an oleaginous Yarrowia lipolytica capable of producing a cocoa-butter substitute from industrial fats. Anton van Lee 80:215–224

Papanikolaou S, Muniglia L, Chevalot I, Aggelis G, Marc I (2003) Accumulation of a cocoa-butter-like lipid by Yarrowia lipolytica cultivated on agro-industrial residues. Curr Microbiol 46:124–130

Papanikolaou S, Aggelis G (2011) Lipids of oleaginous yeasts. Part I: biochemistry of single cell oil production. Eur J Lipid Sci Tech 113:1031–1051

Papanikolaou S, Aggelis G (2010) Yarrowia lipolytica: a model microorganism used for the production of tailor-made lipids. Eur J Lipid Sci Tech 112:639–654

Kyle DJ (2005) The future development of single cell oils. In: Ratledge C, Cohen Z (eds) Single cell oils, chap 15. AOCS Press, Champaign

Papanikolaou S, Komaitis M, Aggelis G (2004) Single cell oil (SCO) production by Mortierella isabellina grown on high-sugar content media. Bioresour Technol 95:287–291

Ratledge C (2004) Fatty acid biosynthesis in microorganisms being used for single cell oil production. Biochimie 86:807–815

Sinclair A, Attar-Bashi N, Jayasooriya A, Gibson R, Makrides M (2005) Nutritional Aspects of Single Cell Oils: Uses and Applications of Arachidonic Acid and Docosahexaenoic Acid Oils. In: Ratledge C, Cohen Z (eds) Single cell oils, chap 12. AOCS Press, Champaign

Bati N, Hammond EG, Glatz BA (1984) Biomodification of fats and oils: trials with Candida lipolytica. JAOCS 61:1743–1746

Chatzifragkou A, Petrou I, Gardeli C, Komaitis M, Papanikolaou S (2011) Effect of Origanum vulgare L. Essential oil on growth and lipid profile of Yarrowia lipolytica cultivated on glycerol-based media. JAOCS 88:1955–1964

Economou CN, Aggelis G, Pavlou S, Vayenas DV (2011) Modelling of single-cell oil production under nitrogen-limited and substrate inhibition conditions. Biotechnol Bioeng 108:1049–1055

Economou CN, Vasiliadou IA, Aggelis G, Pavlou S, Vayenas DV (2011) Modeling of oleaginous fungal biofilm developed on semi-solid media. Bioresour Technol 102:9697–9704

Economou CN, Aggelis G, Pavlou S, Vayenas DV (2011) Single cell oil production from rice hulls hydrolysate. Bioresource Technol 102:9737–9742

Barth G, Gaillardin C (1997) Physiology and Genetics of the dimorphic fungus Yarrowia lipolytica. FEMS Microbiol Rev 19:219–237

Anastassiadis S, Aivasidis A, Wandrey C (2002) Citric acid production by Candida strains under intracellular nitrogen limitation. Appl Microbiol Biot 60(1–2):81–87

Sauer M, Porro D, Mattanovich D, Branduardi P (2008) Microbial production of organic acids. Trends Biotechnol 26(2):100–108

André A, Chatzifragkou A, Diamantopoulou P, Sarris D, Philippoussis A, Galiotou-Panayotou M, Komaitis M, Papanikolaou S (2009) Biotechnological conversions of bio-diesel-derived crude glycerol by Yarrowia lipolytica strains. Eng Life Sci 9:468–478

Papanikolaou S, Chatzifragkou A, Fakas S, Galiotou-Panayotou M, Komaitis M, Nicaud JM, Aggelis G (2009) Biosynthesis of lipids and organic acids by Yarrowia lipolytica strains cultivated on glucose. Eur J Lipid Sci Tech 111:1221–1232

Kristiansen B, Sinclair CG (1979) Production of citric acid in continuous culture. Biotechnol Bioeng 21:297–315

Kamzolova SV, Lunina JN, Morgunov IG (2011) Biochemistry of citric acid production from rapeseed oil by Yarrowia lipolytica yeast. JAOCS 88:1965–1976

Rane K, Sims K (1993) Production of citric acid by Candida lipolytica Y 1095: effect of glucose concentration on yield and productivity. Enzyme Microb Tech 15:646–651

Corzo G, Revah S (1999) Production and characteristics of the lipase from Yarrowia lipolytica 681. Bioresour Technol 70:173–180

Fickers P, Fudalej F, LeDall MT, Casaregola S, Gaillardin C, Thonart P, Nicaud JM (2005) Identification and characterization of LIP7 and LIP8 genes encoding two extracellular triacylglycerol lipases in the yeast Yarrowia lipolytica. Fungal Genet Biol 42:264–274

Song HT, Jiang ZB, Ma LX (2006) Expression and purification of two lipases from Yarrowia lipolytica AS 2.1216. Protein Expres Purif 47(2):393–397

Peters II, Nelson FE (1948) Factors influencing the production of lipase by Mycotorula lipolytica. J Bacteriol 55:581–591

Peters II, Nelson FE (1948) Preliminary characterization of lipase of Mycotorula lipolytica. J Bacteriol 55:593–600

Pignede G, Wang HJ, Fudalej F, Seman M, Gaillardin C, Nicaud JM (2000) Autocloning and amplification of LIP2 in Yarrowia lipolytica. Appl Environ Microb 66(8):3283–3289

Papanikolaou S, Galiotou-Panayotou M, Fakas S, Komaitis M, Aggelis G (2008) Citric acid production by Yarrowia lipolytica cultivated on olive-mill wastewater-based media. Bioresour Technol 99:2419–2428

Makri A, Fakas S, Aggelis G (2010) Metabolic activities of biotechnological interest in Yarrowia lipolytica grown on glycerol in repeated batch cultures. Bioresource Technol 101:2351–2358

Papanikolaou S, Galiotou-Panayotou M, Chevalot I, Komaitis M, Marc I, Aggelis G (2006) Influence of glucose and saturated free-fatty acid mixtures on citric acid and lipid production by Yarrowia lipolytica. Curr Microbiol 52:134–142

Rymowicz W, Rywinska A, Zarowska B, Juszczyk P (2006) Citric acid production from raw glycerol by acetate mutants of Yarrowia lipolytica. Chem Pap 60:391–394

Aggelis G, Athanassopoulos N, Paliogianni A, Komaitis M (1998) Effect of a Teucrium polium L. Extract on the growth and fatty acid composition of Saccharomyces cerevisiae and Yarrowia lipolytica. Anton van Lee 73:195–198

AOAC (Association of Official Analytical Chemists) (1984) Official Methods of Analysis, 14th edn. AOAC, Washington, DC

Aggelis G, Papadiotis G, Komaitis M (1997) Microbial fatty acid specificity. Folia Microbiol 42(2):117–120

Montet D, Ratomahenina R, Galzy P, Pina M, Graille J (1985) A study of the influence of the growth media on the fatty acid composition in Candida lipolytica diddens and lodder. Biotechnol Lett 7(10):733–736

Folch J, Lees M, Stanley GHS (1956) A simple method for the isolation and purification of total lipids from animal tissues. J Biol Chem 226(1):497–509

Aggelis G, Komaitis M, Papanikolaou S, Papadopoulos G (1995) A mathematical model for the study of lipid accumulation in oleaginous microorganisms: II. Study of cellular lipids of Mucor circinelloides during growth on a vegetable oil. Grasas Aceites 46(4–5):245–250

AOAC (1969) AOAC official method 969.33 fatty acids in oils and fats preparation of methyl esters boron trifluoride method. Association of Official Analytical Chemists, Washington, DC

Marrier JR, Boulet M (1958) Direct determination of citric acid in milk with an improved pyridine acetic anhydride method. J Dairy Sci 41:1683–1692

Oswal N, Sarma PM, Zinjarde SS, Pant A (2002) Palm oil mill effluent treatment by a tropical marine yeast. Bioresour Technol 85:35–37

Papanikolaou S, Muniglia L, Chevalot I, Aggelis G, Marc I (2002) Yarrowia lipolytica as a potential producer of citric acid from raw glycerol. J Appl Microbiol 92:737–744

Karasu Yalçın S.(2007) Investigation of various parameters affecting citric acid production by Yarrowia lipolytica and Assessment of citric acid production capacities of some endogenic yeast strains. PhD Thesis, Food Engineering Department, Hacettepe University

Kamzolova SV, Finogenova TV, Lunina YN, Perevoznikova OA, Minachova LN, Morgunov I (2007) Characteristic of the growth on rapeseed oil and synthesis of citric and isocitric acids by Yarrowia lipolytica yeasts. Microbiology 76:20–24

Aguirre SN, Majolli MVI, Figueroa LIC, Callieri DA (2004) Effect of Phosphorus concentration on the citric acid production by Yarrowia lipolytica S26, in a medium containing yeast extract and sugarcane molasses. In: Jonas R, Pandey A, Tharun G (eds) Biotechnological Advances and Applications in Bioconversion of Renewable Raw Materials. Gesellschaft für Biotechnologische Forschung GmbH Bibliothek, Germany, pp 113–116

Papanikolaou S, Gortzi O, Margeli E, Chinou I (2008) Effect of citrus essential oil addition upon growth and cellular lipids of Yarrowia lipolytica yeast. Eur J Lipid Sci Tech 110:997–1006

Perez-Campo FM, Dominguez A (2001) Factors affecting the morphogenetic switch in Yarrowia lipolytica. Curr Microbiol 43:429–433

Glatz BA, Hammond EG, Hsu KH, Baehman L, Batı N, Bednarski W, Brown D, Floetenmeyer M (1984) Production and modification of fats and oils by yeast fermentation. In: Ratledge C, Dawson P, Rattray J (eds) Biotechnology for the oils and fats industry. American Oil Chemists’ Society, New York, pp 163–175

Athenstaedt K, Jolivet P, Boulard C, Zivy M, Negroni L, Nicaud JM, Chardot T (2006) Lipid particle composition of the yeast Yarrowia lipolytica depends on the carbon source. Proteomics 6:1450–1459

Papanikolaou S, Aggelis G (2003) Modeling lipid accumulation and degradation in Yarrowia lipolytica cultivated on industrial fats. Curr Microbiol 46:398–402

Aggelis G, Sourdis J (1997) Prediction of lipid accumulation-degradation in oleaginous micro-organisms growing on vegetable oils. A van Leeuw J Microb 72(2):159–165

Kapoor R, Nair H (2005) Gamma linolenic acid oils. In: Shahidi F (ed) Bailey’s industrial oil and fat products, chap 4 vol 3 6th edn. Wiley, New Jersey, pp 67–76

Ackman RG (2005) Fish oils. In: Shahidi F (ed) Bailey’s industrial oil and fat products, chap 11 vol 3 6th edn.Wiley, New Jersey, pp 279–304

Codex Stan 210-1999. Codex Standard for Named Vegetable Oils. www.codexalimentarius.orgAccessed Jan 2013

El-Beltagi HS, Salama ZA, El-Hariri DM (2007) Evaluation of fatty acids profile and the content of some secondary metabolites in seeds of different flax cultivars (Linum usitatissimum L.). Gen Appl Plant Physiol 33(3–4):187–202

Aoki H, Miyamoto N, Furuya Y, Mankura M, Endo Y, Fujimoto K (2002) Incorporation and accumulation of docosahexaenoic acid from the medium by Pichia methanolica HA-32. Biosci Biotechnol Bioch 66(12):2632–2638

Nicaud JM, Madzak C, Van der Broek P, Gysler C, Duboc P, Niederberger P, Gaillardin C (2002) Protein expression and secretion in the yeast Yarrowia lipolytica. FEMS Yeast Res 2(3):371–379

Erdem B (2008) Effects of bioprocess parameters on the enzyme activity and selectivity in the production of lipase from Candida rugosa. Master Thesis, Department of Chemical Engineering, Ankara University Graduate School of Natural and Applied Sciences

Papanikolaou S, Beopoulos A, Kolett A, Thevenieau F, Koutinas A, Nicaud JM, Aggelis G (2013) Importance of the methyl-citrate cycle on glycerol metabolism in the yeast Yarrowia lipolytica. J Biotechnol 168:303–314

Dominguez A, Costas M, Longo MA, Sanroman A (2003) A novel application of solid state culture: production of lipases by Yarrowia lipolytica. Biotechnol Lett 25:1225–1229

Acknowledgments

This research was financially supported by a grant from İTÜ BAP, Project No. 36,952 (Istanbul Technical University Scientific Research Projects Department).

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Saygün, A., Şahin-Yeşilçubuk, N. & Aran, N. Effects of Different Oil Sources and Residues on Biomass and Metabolite Production by Yarrowia lipolytica YB 423-12. J Am Oil Chem Soc 91, 1521–1530 (2014). https://doi.org/10.1007/s11746-014-2506-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-014-2506-2