Abstract

External laminar oscillatory shear applied during crystallization in combination with different temperature fields was used to modify the microstructure and physical properties of edible oil organogels. Crystallization at a high cooling rate (30 °C/min) resulted in a spherulitic microstructure with a higher oil-binding capacity, lower storage modulus and lower yield stress compared with a material (with a fibrillar microstructure) crystallized at a slow cooling rate (1 °C/min). The application of an oscillatory shear resulted in the formation of novel microstructures depending on the cooling regime used. The application of an oscillatory shear (strain > 500 % and frequency = 1 Hz) resulted in the thickening of fibers observed in the slow-cooled material and an increased incidence of spherulite nucleation in the rapidly cooled material. Increasing the frequency of the oscillatory shear applied did not change the microstructure for the slow-cooled gel but further increased the incidence of nucleation for the rapidly cooled gel. The application of controlled-strain oscillatory shear to the crystallizing gel at either cooling rates resulted in an oily and very soft, paste-like material. This material had a lower storage modulus and poorer oil-binding capacity compared with the same gel crystallized statically. Reduction of the oscillatory strain from a maximum of 1500 to 500 % moderately mitigated the loss of mechanical properties and oil-binding capacity although these properties were in no way comparable to those obtained from static crystallization. The study shows that the application of oscillatory shear and different cooling regimes can be used to tailor a crystalline organogel. However, the application of continuous shear must be done with care as application of excessive shear can result in a complete breakdown in gel structure and large amounts of oil loss.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

There is a recent trend within the food manufacturing industry of minimizing the use of fat and lipid ingredients containing saturated and/or trans fatty acids while simultaneously switching to ingredients that contain high amounts of unsaturated fatty acids [1, 2]. This trend is due to the perceived negative health effects believed to be associated with the ingestion of high amounts of saturated and trans fatty acids as well as the touted health benefits of consuming dietary fat predominantly in the form of unsaturated fatty acids [3–6]. This has necessitated a search for suitable substances to replace triacylglycerols (TAG) containing saturated and trans fatty acids as structuring agents of fats in food ingredients [7–9]. One class of such alternative materials currently being investigated are organogels [10, 11]. Organogels are viscoelastic materials composed predominantly of an anhydrous liquid phase such as an organic solvent or oil. The vast majority of organogels are structured by crystalline low molecular weight compounds as opposed to hydrogels which are structured mainly by polymeric substances [12].

Most organogelators under study in the chemical literature are highly toxic and cannot be used in foods. There are, however, several natural and non-toxic organogelators which can conceivably be used in foods. Most of these organogelators already have other applications as food ingredients (mainly as surfactants and emulsifiers) or nutraceuticals. Examples of such organogelators that may be usable in foods are ceramides, fatty acids and hydroxylated fatty acids, monoglycerides, plant sterols, lecithin and sorbitan esters and plant waxes (rice bran wax, candelilla wax, carnauba wax) [13].

The organogel material studied in the present research is an organogel composed of 12-hydroxystearic acid (commonly abbreviated as 12-HSA) as the gelator and a vegetable oil, canola oil, as the structured phase. The 12-hydroxystearic acid is a hydroxylated fatty acid obtained from the hydrogenation of ricinoleic acid, which is predominantly found in castor oil. Ricinoleic acid is an ω-9 unsaturated, 18-C fatty acid with a hydroxyl group at C-12 [14]. This 12-hydroxystearic acid is commercially available as “technical-grade 12-HSA”, which is a 12-HSA preparation composed of 15 % stearic acid and 85 % D-12-HSA [15]. For the purposes of this study and for use in food, 12-HSA is considered an ideal organogelator for the following reasons: (1) efficiency of organogelation, (2) relative non-toxicity [16, 17], (3) abundance. 12-HSA is currently used in Japan to gel waste engine and vegetable oils to facilitate their disposal [18]. 12-HSA also finds technological applications in the manufacture of lithium grease. The ability of 12-HSA to form organogels is possible due to 12-HSA’s unique fibrillar crystal habit (Fig. 1).

The extensive human experience with fats as well as a relatively deep understanding of the science of TAG molecules gives the fat manufacturer the ability to formulate and process fats for a wide range of applications and functionalities. Through careful control of the crystallization parameters (nucleation rate, crystal growth rate), the same fat substance can be made to form materials with different applications and functionalities. Such control can be achieved through various means, such as control of the supercooling, control of the cooling rate, the application of shear and the addition of surfactants.

Given that organogels are crystalline, control of their crystallization and subsequent solidification may also offer a route to tailor the material. Parameters that can be controlled to achieve a desired end include the thermal and perikinetic treatments mentioned before. Much is known about the influence of thermal variables on the crystallization and end properties of an organogel while relatively little research on the effect of shear on organogels is available. It is clear, however, that shear has an important effect on the gelation of an organogel.

Studies conducted by Lescanne and others [19] on the effect of shear on a fiber-like supramolecular assembly (2,3-di-n-decycloxyanthracene in N,N-dimethylacrylamide) showed that the application of steady shear during the solidification of a gel caused the fibrillar microstructures to orient along a given direction. The authors note that the shear stress has to be low enough (3 Pa) to be within the linear viscoelastic regime of the solid material such that the resulting material does not deform irreversibly upon the formation of the gel.

A similar study was conducted by Xiong and others on the effect of shear/mixing and centrifugation on the gelation of organic solvents by a dialkyl urea gelator, 1-methyl-2,4-bis(N′-octadecaneureido)benzene. It was found that the minimum concentration (for a given organic solvent) of gelator required to gel the solvent increased with an increase in the applied shear forces [20]. The solvent was considered gelled when no flow was observed upon inversion of the container holding the gel. Examination of the microstructure of these gels showed that the application of shear resulted in thicker (relative to the quiescently gelled sample) fibers oriented along a given axis.

Bot and Agterof [21] reported that the application of an oscillatory shear on the gelling solution greatly minimized the time required to form an oryzanol/β-sitosterol/vegetable oil organogel. It was postulated that the oscillatory shear increased the rate of collision between the fibrils responsible for forming a gel network. It was also noted that the stage of gelation at which the shear was applied greatly affected the storage modulus (G′) of the gel. The workers noted that the application of oscillatory shear stresses beyond 200 Pa (during crystallization) resulted in a drastic decrease of the storage modulus G′.

The primary objective of this paper was to characterize the simultaneous effects of applying thermal and flow fields (during crystallization) on the microstructure of a 12-HSA/canola oil crystalline organogel. The aim of this research was to investigate how these crystallization parameters can be controlled such that the macroscopic properties of the gel (primarily oil-binding and mechanical properties) can be engineered.

Materials and Methods

Gel Preparation

The organogels were prepared using the compound 12-hydroxystearic acid (CAS # 106-14-9) as the gelator and canola oil as the solvent. The 12-hydroxystearic acid (12-HSA) used in this study was of technical grade and was purchased from the Alfa-Aesar Company (Ward Hill, MA, USA). Technical grade 12-hydroxystearic acid flakes contain approximately 85 % 12-hydroxystearic acid with the remainder being stearic acid. The canola oil was obtained from a local supermarket. The 12-HSA flakes were added to the canola oil such that a final concentration of 2.5 % 12-HSA was achieved. This concentration was used exclusively for all measurements. The slurry was then heated and mixed for 30 min inside an oven set to 80 °C. Upon complete dissolution, the solution was allowed to set into a solid under ambient temperatures.

Solidifying the Gel under Shear

To cool the gel as well as to apply shear during the solidification process, previously solidified gel was melted at 80 °C on a Peltier plate attached to a rheometer (AR 2000 Rheometer, Q2000, TA Instruments, New Castle, DE). It was kept at a temperature of 80 °C for 5 min to allow the solution to equilibrate to this temperature. The gels were solidified non-isothermally to a final temperature of 30 °C using two cooling rates (1 and 30 °C/min). 1 °C/min is considered a “slow” cooling rate while 30 °C/min is considered a “fast” cooling rate.

Shear strain was applied during the non-isothermal solidification of the gel by conducting a temperature ramp/sweep experiment on the crystallizing solution. After reaching 30 °C, the gel was allowed to sit for 5 min prior to the measurement of its dynamic rheological properties and oil-binding capacity. The shear strain is reported in units of percent and is defined as:

where ΔL is the displacement between the upper and lower surfaces of material due to the applied shear strain and h is the thickness over which the shear stress is applied.

Rheo-optical Light Microscopy

The effect of shear on the microstructure of the organogels during crystallization was characterized in situ using a temperature stage with an attached shear cell (Linkam CSS450, Linkam Scientific Instruments, Surrey, UK). A single drop of the molten mixture of canola oil and 12-HSA (heated to 80 °C) was placed between a top stationary glass lid (32 mm in diameter) and a bottom moving glass plate (55 mm in diameter). The observation aperture (2.8 mm in diameter) was 7.5 mm from the center of rotation. Shear was applied by a step motor that in conjunction with a toothed gear belt, gave a maximum resolution of 0.0035° in angular displacement per step. As such, the shearing apparatus was strain-controlled and not stress-controlled. The gap setting of the sample chamber was controlled using a step motor.

The sample to be observed was crystallized non-isothermally to 30 °C by cooling the molten preparation from 80 to 30 °C using the previously-mentioned selected cooling rates. Shear, in the oscillatory mode, was applied as the gel solidified. A gap of 10 μm (to facilitate imaging) was used for shear applied in the oscillatory mode.

The resultant microstructure was imaged at a final magnification of 200× using a Leica DMRXA2 Deconvolution Microscope (Leica Micro-systems Canada Inc., Richmond Hill, Canada) with crossed polarizers. Images were acquired using a CCD camera (Q-imaging Retiga, Burnaby, BC, Canada). Scale bars were obtained by calibrating against a standardized 100-μm scale bar imaged under the same magnification.

As mentioned previously, two main cooling rates were used in this study: 1 °C/min (slow cooling rate) and 30 °C/min (fast cooling rate). The cooling rate of 30 °C/min was selected as it was sufficiently high to mimic isothermal crystallization conditions. The cooling rate inside the shear cell was controlled using a heating and cooling element. The heating element consisted of two silver resistive heaters in direct contact with both the moving and stationary glass plates. The cooling element consisted of a liquid nitrogen pump fed by a glass Dewar flask containing liquid nitrogen. The cooling rate was controlled automatically by the software supplied with the rheo-optical stage.

Spherulite Counting

The number of spherulites in a given micrograph (at a given magnification) was determined by manual counting. The reported number of particles was taken by averaging the number of particles from 5 different micrographs (dimensions of 866 × 686 μm) of the same treatment.

Thickness Measurement

The thickness of the fibers obtained via polarized light microscopy (PLM) was measured using the ImageJ package (Wayne Rasband, National Institute of Mental Health, Bethesda, ML, USA) after calibration against a 100-μm microscopy measuring standard. Fiber width was measured from 9 images of the same sample treatment (three different sections of three replicates). Fiber widths in scanning electron micrographs were also measured to provide a basis for comparison.

Freeze-Fracture Cryo-scanning Electron Microscopy (cryo-SEM)

The gels examined using cryo-SEM were prepared by solidifying the gels using a rheological instrument (Advanced Rheometer (AR) 2000, TA Instruments, New Castle, DE) with a built-in Peltier plate. Shear was applied during crystallization by performing a temperature ramp/sweep procedure on the solution as it solidified from 80 to 30 °C. The shear applied was stress-controlled (using a stress within the linear viscoelastic regime of the solid material). The shear stress applied during crystallization was 5 Pa. The application of this shear stress to the crystallizing fluid resulted in a corresponding shear strain of approximately 1,000 %.

The organogels were first de-oiled to produce xerogels prior to observation under the scanning electron microscope (Hitachi S-570, Hitachi High Technologies Canada, Inc., Rexdale, ON, Canada). De-oiling was conducted in two stages. Oil was removed by placing a 1-cm disk of the sample gel on Whatman #4 filter paper at ambient temperatures. About 90 % of the oil within the gel migrated into the filter paper within 24 h. The portion of the gel that did not wet the filter paper was then collected and solvent washed for 30 s with 2-methyl-1-propanol held at 10 °C to minimize dissolution of the structures to be examined. Residual solvent within the sample gel was removed via evaporation.

The de-oiled xerogel was mounted onto a copper holder using TissueTek® O.C.T. embedding medium for frozen sections (Canemco Inc., Lakefield, QC, Canada). The embedding medium consists of a mixture of water, unnamed resins, polyvinyl alcohol and polyethylene glycol. The mounted specimen was then cryo-fixed via immersion in liquid nitrogen slush with a temperature of approximately −207 °C. The slush was prepared by pulling a vacuum on liquid nitrogen (Temperature −196 °C). The purpose of immersing the mounted specimen in the nitrogen slush instead of liquid nitrogen was to minimize the Leidenfrost effect (the retardation of heat transfer to a material by a thin layer of vapour). After cryo-immersion, the stage was transferred to a cryo-preparation unit (Emitech K1250X Cryo-Preparation Unit, Ashford, Kent, UK) under argon (to prevent frost formation). The sample was then sublimated at −80 °C for 30 min to remove any residual water. After sublimation, the mounted specimen was fractured using a blade inside the Emitech K1250X Cryo-Preparation Unit. The sample was then sputter-coated with approximately 30 nm of gold, after which it was viewed under the SEM.

Small-Angle Oscillatory Shear Rheology

The storage (G′) modulus of the gels was determined via small-amplitude dynamic measurements using an AR 2000 Rheometer (Q2000, TA Instruments, New Castle, DE). The temperature during testing was kept at 30 °C. A 60-mm acrylic cone geometry (2°) with a truncation gap of 59 μm was utilized. The gap at the edge of the geometry was calculated using simple trigonometry. At a zero gap (tip of the cone touching plate), the gap at the edge of the plate was approximately 1,048 μm. At the truncation gap, the total gap at the edge of the plate is 1,107 μm.

To determine the linear viscoelastic region (LVR), a stress sweep was performed on the sample at a frequency of 1 Hz from 1 to 1,000 Pa. The G′ was obtained by selecting G′ values at a stress (10 Pa) well within the LVR of the sample. In samples where a linear viscoelastic region did not exist, the G′ for such samples were taken from the same stress as that described above (typically 10 Pa) for the purpose of providing a value for comparison. Samples that did not exhibit an LVR are indicated as samples that did not exhibit a yield stress.

The apparent yield stress was approximated as the critical stress σ*, which is the stress beyond which the material exits the linear viscoelastic regime. The yield stress can be obtained via visual examination of the stress sweep curve, which gives the storage modulus as a function of the applied oscillatory shear. Such curves can be typically divided into a linear (characterized by non-variability of the viscoelastic moduli with the applied shear stress) and non-linear regime (characterized by stress-dependence of the viscoelastic moduli). The transition between these two regimes is usually marked by a sudden and precipitous decline in the storage modulus. The yield stress can be taken as the stress at which this sudden decrease in the G′ is observed [22].

However, in certain samples, this sudden decline was not observed when the material left the linear viscoelastic regime. Instead, a gradual decline in the G′ and G″ as a function of the applied oscillatory stress was observed. As such, the above-mentioned method was not employed to determine the yield stress. Instead, the yield stress was calculated as the stress at which the G′ dropped to 80 % of the determined G′ value. It must be noted that the determination of the yield stress in this manner is highly variable—one author reported that the yield stress for the same 12-HSA/organic solvent gel ranged between 20 and 450 Pa [23].

Both the G′ and the yield stress were reported as the mean ± standard deviation of four replicates.

Oil-Binding Capacity

The oil-binding capacity was measured by centrifuging (Eppendorf Centrifuge 5410, maximum rotary speed: 14,000 rpm) a known quantity of sample for 30 min and then measuring the mass of expressed oil [24]. The oil-binding capacity is thus calculated as the percentage of oil mass retained within the gel matrix:

The oil-binding capacity was reported as the mean ± SD of four replicates.

Statistical Analysis

Statistical analysis was performed on the rheology and oil-binding data using the commercial software package Prism 5.0.1 (GraphPad Software, San Diego, CA, USA). A univariate analysis of variance (ANOVA) followed by a post hoc Tukey test to compare means was performed on data sets containing more than two factors. The level of significance used for the Tukey tests was 5 %. Where there were only two factors, a t test at a significance level of 5 % was conducted to compare means. It must be noted that statistical testing on the rheological and oil-binding data was only performed on samples crystallized under the same oscillatory shear strain and cooling rate.

Results and Discussion

A few general hypotheses regarding the effect of cooling rate on the microstructure and macroscopic properties of a 12-HSA edible oil organogel can be formulated based on similar studies in the literature. It is likely that a high cooling rate will result in the formation of more branched structures while a low cooling rate will result in the formation of fibrillar structures with minimal branching [25]. High cooling rates will also likely result in a material with excellent elasticity and mechanical strength relative to a gel developed at a low cooling rate [26].

The application of shear would most likely affect the aggregation, orientation and/or nucleation of the fibrillar crystals. How shear will affect the macroscopic properties of the gel material would most likely depend on the shearing regime applied. If steady shear or a high amplitude oscillatory shear is applied past the point of gelation, it is likely that the material will suffer mechanical injury and thus exhibit a lower mechanical strength and/or elasticity as well as a lower capacity to trap solvent [27]. However, if shearing is applied only to the extent of modifying the crystalline fibers with the applied shear being turned off prior to gelation; it is likely that gel materials with macroscopic properties different or perhaps comparable to those observed under quiescent cooling will be obtained [21].

Microstructure—Cooling Rate

When 12-HSA/canola oil organogels were crystallized at a high cooling rate of 30 °C/min, spherulitic microstructures exhibiting a pattern akin to a maltese cross were observed (Fig. 2a). At low cooling rates, fibrillar structures exhibiting segmented birefringence were observed (Fig. 2b). The segmented birefringence observed in Fig. 2b is attributable to twisting of the fiber such that the crystallinity of the fiber is alternately in- and out- of-phase with the polarized light leading to segmentation of birefringence. Such segmentation is commonly observed in 12-HSA fibers. Such segmentation is not readily observable in the spherulitic microstructures obtained via the high cooling rate.

The cooling rate can be treated as a time-dependent supersaturation term. If this is so, the microscopy results are in agreement with what is commonly reported for low-molecular weight organogels: high undercoolings/supersaturations will result in increased crystallographic mismatch branching. Wang and others [28] reported that the crystallization of an amide gelator at high supersaturations resulted in a spherulitic texture. A high degree of supersaturation was developed via rapid cooling (30 °C/min) to a relatively low crystallization temperature. According to these authors, the spherulitic texture observed in systems consisting of rapidly-crystallized gelator molecules in a solvent is due to the crystallographic mismatch branching of the fibers emanating radially from a central nucleation point [29]. Lam and others [30]as well as Rogers and Marangoni [31] found that significant fiber branching occurred between cooling rates of 5 and 7 °C/min as a result of impaired carboxyl dimerization during 12-HSA crystallization.

Work conducted in the field of polymer physics has also resulted in the development of a phenomenological theory to explain the formation of spherulitic patterns in polymers although the theory is also applicable to non-polymers [32]. The Keith and Padden theory states that spherulization is the result of limiting mass-transfer conditions in a nucleating melt. As the material crystallizes (characterized by the crystal growth rate), non-crystallizable components are ejected. To maintain growth of the crystal face, crystallizing components must diffuse to the growth site. Failure to adequately supply crystallizing components to the growing crystal face will result in spherulization. In essence, spherulization occurs when the linear growth rate exceeds the capacity of the system (quantified as the rate of diffusion) to supply the growing crystal with crystallizable material.

It can be suggested that the rapid increase in viscosity as a result of gelation of the organogel hinders the diffusion of crystallizable components and thus results in spherulization. However, this is highly improbable as the crystals in question are formed at a temperature of approximately 60 °C while the appreciable increase in viscosity associated with gelation is only evident at around 50 °C.

Microstructure—Oscillatory Shear and Low Cooling Rate

The application of oscillatory shear to a crystallizing solution of 12-HSA in canola oil at either low or high cooling rates resulted in the alteration of the observed microstructures. At low cooling rates, the application of shear resulted in the thickening of the fibrillar strands usually observed at low cooling rates (Fig. 3). The transition from a thin fiber to a thicker fiber appears to be controlled by the magnitude of the strain applied during shear crystallization. The thickening of fibers can be estimated to occur at a strain of approximately 500–700 %. At low strains (100–300 %), no thickening is observed. As a higher strain implies a higher displacement, the fact that thickening is strain-dependent suggests the following explanation.

Given a microparticle at a starting position under static conditions, the application of oscillatory shear displaces this microparticle from its starting position. However, the microparticle is eventually returned to its starting position as a result of the back-and-forth oscillatory motion. The strain of the oscillatory motion defines the amplitude at which the microparticle is displaced from its starting position. The farther a population of microparticles is displaced from its starting position, the more likely individual microparticles will come into contact. In the case of crystalline fibers, contact between individual crystalline fibers may conceivably result in “bunching” of fibers to create thicker aggregates. It is also possible that the application of oscillatory shear somehow improves the crystallization of 12-HSA in directions perpendicular to the predominant axis of crystallization (fiber axis).

The majority of the thickened fibers appear to have a thickness that is between 20 and 40 μm as can be ascertained from a number of micrographs. Measurements from SEM images (Fig. 4) of shear-crystallized (oscillatory) SAFiN gels also agree with the measurements obtained from the PLM images. From examination of the widths of fibers that were crystallized statically (in the absence of oscillatory shear) from a set of SEM and PLM micrographs, it can be noted that the approximate width of the fibers is between 3 and 4 μm. This being the case, the application of oscillatory shear increases the thickness of the fibers by nearly ten times.

At a low cooling rate, the variation in the frequency of oscillation applied during crystallization does not appear to affect the morphology of the fibrillar strands (Fig. 5). This suggests that the rate at which mechanical energy is introduced into the sample does not affect the microstructural development of the gels at a low cooling rate.

Microstructure—Oscillatory Shear and High Cooling Rate

The application of oscillatory shear to a rapidly-cooled (30 °C/min) 12-HSA/canola oil solution resulted in increased nucleation such that a greater number of spherulites were observed relative to the statically-crystallized sample (Fig. 6). The impact of shear on the nucleation characteristics in complex fluids is a well-described body of research. According to Ziegleder [33], the introduction of shear in the chocolate manufacturing process increases both the crystallization rate and the growth rate. Campos [34] also stated that the application of shear to crystallizing cocoa butter increases both the nucleation rate and the growth rate.

The extent to which the rate of nucleation increased can be approximated by counting the number of spherulites evident in a micrograph. An average of 10–15 spherulites can be observed for gels crystallized statically at 30 °C/min. In identically-sized micrographs, approximately 90–115 spherulites can be counted for a gel crystallized under oscillatory shear (Strain 1,500 % and Frequency 1.0 Hz) at 30 °C/min. By examining a series of micrographs in which the strain is progressively increased (Fig. 6), the strain at which increased nucleation occurs can be estimated at approximately between 300 and 500 %.

The effect of frequency on the microstructure of rapidly-cooled 12-HSA/canola oil gels is shown in Fig. 7. Unlike 12-HSA crystals crystallized under oscillatory shear at 1 °C/min, the frequency of oscillation results in changes to the morphology of 12-HSA crystals. An increase in the oscillation frequency appears to result in an increased incidence of nucleation. An increase in the frequency renders the spherulites so fine so as to appear speckled. Interestingly, at an oscillatory frequency of 10.0 Hz, no spherulites are observed. Instead, cylinder-like aggregates akin to fibers are observed (Fig. 7d). The formation of this microstructure at high frequencies is unexpected. The results suggest that a high frequency of oscillation somehow inhibits spherulization (fiber branching) and promotes fiber growth and thickening instead.

Mechanical Properties—Cooling Rate

The effect of the cooling rate on the material properties of a 2.5 % 12-HSA/canola oil gel is given in Fig. 8. The results show that the storage modulus decreased by about a factor of 10 when the cooling rate was increased from 1 to 30 °C/min. One trivial explanation for this is that the sample cooled under a low cooling rate experiences a longer time during which the crystal network responsible for the solidity of the gel can develop maximum structure whereas the crystal network developed under a high cooling rate does not experience as long a time to develop its network structure. However, after correcting for this time difference, the storage modulus of a gel developed at 30 °C/min and cured for 48 min did not result in a G′ comparable to that of a gel developed at 1 °C/min. The G′ of this gel was similar to the G′ of a gel developed at 30 °C/min without curing.

If the cooling rate is taken to be the time-dependent supersaturation, the sample cooled at 30 °C/min would have had a higher supersaturation at the onset of crystallization. Following the arguments of Liu and Sawant [35], a higher supersaturation experienced by a nucleating fibrillar crystal network will result in denser branching. A high density of branching will result in more permanent junction zones being created. This will conceivably result in a higher G′. The contrary is observed in Fig. 8a. This paradoxical behavior can be attributed to the spherulitic texture observed at higher cooling rates.

It was suggested by Wang and others [28] that each spherulitic domain can be considered to be a smaller network of fibers branching radially from a central point. Interactions between these small branched-fiber networks will form a “composite network” which is a network of smaller networks (spherulites). Since each spherulite is connected only to adjacent spherulites, the number of junction zones between microstructural elements is presumably small whereas long fibrillar strands that interpenetrate will form more junction zones with other fibrillar strands [36].

The observed decrease in G′ with spherulization is consistent with the findings of Wang and others. However, the authors noted that the critical strain of a gel with spherulites was higher than the critical strain of a fibrillar gel. It was suggested that the junction zones in spherulitic gels, despite being relatively less in number (and thus contributing to a lower elasticity) were stronger than junction zones formed in fibrillar networks. Though no explanation was given as to why these junction zones were stronger, it is possible that the presumably greater contact surface of the junction zones between the spherulites may be responsible for the observed increase in the critical strain.

The trends reported by Wang and others is not consistent with that previously reported for 12-HSA/canola oil organogels. It was reported by Rogers and others [37] that the critical or yield stress for a gel developed at a high supersaturation was lower than the yield stress of a gel developed at a low supersaturation (higher crystallization/storage temperature). A similar decrease in the critical stress with cooling rate is observed in Fig. 8b.

The observed trends (high yield stresses and elastic moduli for materials cooled at slow cooling rates and low yield stresses and elastic moduli for materials cooled at high cooling rates) are also observed even when oscillatory shear is applied. Given the same oscillatory treatment during crystallization, material crystallized at the low cooling rate generally had a higher yield stress and elastic modulus than a material crystallized at the high cooling rate (Fig. 9). In certain instances (G′ of material crystallized at 1,500 % Strain and 1 Hz and 500 % and 10 Hz and yield stress of material crystallized at 500 % and 10 Hz), the data does not agree with these trends. However, the difference observed in these data sets can be attributed to the large error inherent in mechanical testing, especially of materials that have undergone fracture.

The G′ (a, b) and yield stress (c, d) of a 2.5 % 12-HSA/canola oil gel crystallized under oscillatory shear strains of 1,500 % (a, c) and 500 % (b, d) at frequencies of 1 Hz and 10 Hz and cooling rates of 1 °C/min and 30 °C/min. Values with different letters (applicable only to values with the same cooling regime and oscillatory shear strain) have significantly different means (p ≤ 0.05). Values with different numbers (applicable only to values crystallized under the same mechanical treatment, i.e., identical shear strain and frequency) have significantly difference means (p ≤ 0.05)

Mechanical Properties—Oscillatory Shear

The effect of an oscillatory shear on the material properties of a 12-hydroxystearic acid/canola oil gel is of particular interest as it was shown previously that the application of an oscillatory shear resulted in the formation of novel microstructures. It is of great interest to see whether or not the modification of these microstructures will affect the macroscopic performance of the material.

The effect of applying an oscillatory shear (at two shear strains of 500 and 1,500 % and two cooling rates and two frequencies) on the material properties (storage modulus G′ and yield stress) of a crystallizing solution of 2.5 % 12-hydroxystearic acid/canola oil is given in Fig. 9. Statistical testing (One-way ANOVA) was conducted only within each oscillatory shear strain regime, i.e., samples with shear strains of 500 and 1,500 % were not compared.

The data shows that the application of oscillatory shear during the crystallization of a 12-HSA/canola oil gel resulted in a deterioration of the mechanical properties. The applied oscillatory shear treatments resulted in a fluid dispersion. Of the six treatments, three treatments (1 °C/min-1,500 %-10 Hz, 30 °C/min-1,500 %-1 Hz and 30 °C/min-1,500 %-10 Hz) did not result in a material that exhibited a linear viscoelastic region at stresses above 1 Pa. No yield stress was provided for these treatments as the lack of an LVR prevented the determination of the critical stress.

Figure 9a shows that the application of an oscillatory shear (strain 1,500 %) at 1 Hz to a crystallizing 12-HSA/canola oil solution at either cooling rates resulted in a decrease in the storage modulus G′ of the material by about 1 order of magnitude relative to the gels crystallized under static conditions. These results suggest that the application of shear during crystallization is detrimental to the elasticity of the material. It is interesting to note that increasing the frequency of the oscillation, at either cooling rates, to 10 from 1 Hz resulted in a further deterioration of the material properties even though the G′ for the sample crystallized at 10 Hz was not significantly different from the G′ of the sample crystallized at 1 Hz.

Figure 9b shows the G′ of gels crystallized under a reduced oscillatory strain of 500 % at various frequencies and cooling rates. Overall, the results suggest that reducing the applied oscillatory strain during crystallization will mitigate the loss of mechanical strength in the gel. Figure 9b shows that for both 1 and 30 °C/min, at 1 Hz, the reduction of the oscillatory strain to 500 % results in a gel with a storage modulus that is comparable (p > 0.05) to a gel that is crystallized statically. However, it must be noted that the gel crystallized under an oscillatory strain of 500 % at 10 Hz resulted in a gel with a lower G′ that is significantly different (p ≤ 0.05) from the statically crystallized gels at either cooling rate. This suggests that the rate at which mechanical energy is applied to the system is detrimental to the formation of a gel structure.

Figure 9c shows the yield stress for the statically-crystallized gels at either cooling rates and the gel crystallized at 1 °C/min-1,500 %-1 Hz. No yield stress was available for the other samples as the materials did not exhibit a linear viscoelastic region. The data shows that the sample crystallized statically at 1 °C/min showed the highest yield stress. As well, the yield stress obtained for the sample statically-crystallized at 30 °C/min was not significantly different from the yield stress obtained for the gel crystallized at 1 °C/min-1,500 %-1 Hz. It must be noted that despite having the visual appearance of a liquid, the gel crystallized at 1 °C/min-1,500 %-1 Hz exhibited a linear viscoelastic region. This suggested that the material retained some interconnected structure that allowed it to exhibit elasticity.

Figure 9d shows the obtained yield stresses for gels crystallized under an oscillatory shear strain of 500 % at various oscillatory frequencies and cooling rates. At a cooling rate of 1 °C/min, the data shows that decreasing the oscillatory shear strain applied during crystallization to 500 % resulted in yield stress that was comparable to that exhibited by the statically-crystallized sample. Observing a similar trend to that observed in the storage modulus data, the sample crystallized under an oscillatory strain of 500 % and frequency of 10 Hz exhibited a low yield stress compared to the statically-crystallized sample. Interestingly, for the gel crystallized at a cooling rate of 30 °C/min, the sample crystallized at a strain of 500 % and 1 Hz displayed a higher, if not comparable, yield stress than the statically crystallized sample. However, the difference appears slight and may be attributable to the inherently high variability in such measurements. Like the sample cooled at 1 °C/min, the 30 °C/min gel crystallized under a strain of 500 % and frequency of 10 Hz, displayed a lower yield stress than the gel crystallized statically at the same cooling rate.

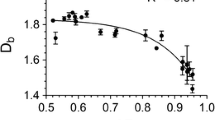

A microstructural explanation for the decreased mechanical strength of fast-cooled (1 °C/min) shear-crystallized gels which takes into account modifications (thickening) to the fibrillar microstructure of the gel can be made by developing the work of Burkhardt and others on 12-hydroxystearic acid gels. If the amount of crystalline material is taken to be constant between the statically-crystallized sample and the shear-crystallized sample, the concentration of the crystalline matter into a few thick fibers will reduce the number of contact points between fibers as there will be fewer fibers. Burkhardt and others [23] suggested a simple scaling relationship to this effect. Using a simple network theory obtained from polymer physics, it was suggested that the shear modulus G 0 for a cubic lattice of interconnected cylindrical rods can be approximated as the number density of network junction zones multiplied by kT. This is, however, inaccurate as the strength of interactions in an enthalpic network such as 12-HSA SAFiNs is several orders of magnitude greater than kT. However, if kT can be replaced with the appropriate energy of interaction for the system, the relation can still be considered to be valid. The number density of network junction zones is a function of the volume fraction and the radius of the fibers as given by:

where R is the radius of the cylindrical rods and Φ is the volume fraction of the structurant. It can be seen from this relationship that as the radius of the fibers increases, the number density of the network junction zones decreases and, correspondingly, the shear modulus G 0 will decrease.

The yield stress of the material crystallized at 1 °C/min decreases with progressively increasing oscillatory stresses applied during crystallization. A simplified power law for the yield stress similar to that given above was described by Terech and others [22] in studies of 12-HSA gels in organic solvents.

where σ* is the yield stress, D is the diameter of the fiber and γ c is the critical strain (strain beyond which a material exits the linear viscoelastic region). As can be seen in this relation, an increase in the cross-sectional diameter of the fibers in a 12-HSA gel will result in a concomitant decrease in the yield stress. As the application of an oscillatory shear results in thickened fibers, it is not unlikely that the decrease in yield stress associated with increasing the applied oscillatory shear strain is due to the thickening of fibers.

Shi and others formulated a relationship between the elasticity of a spherulitic network and the number of junction zones formed by a network of spherulites. Using simulation of a network of spherulites, these workers found that increasing the number of spherulitic domains resulted in a decrease in the elastic modulus [38]. The results show that the G′ for gels crystallized at 30 °C/min at an oscillatory strain of 500 % and oscillatory frequency of 1 Hz is comparable to the G′ for gels crystallized quiescently. Given that the micrograph of the gel crystallized under these conditions show increased nucleation, the results do not agree with the findings of Shi and others. This may be explained by assuming that, in a thin sample as was the case in this study, the number of junction zones a given spherulite may form with other spherulites can be assumed to remain relatively constant as the number of contacts formed between spherulites can be considered to be largely a matter of geometry and proximity to other spherulites. In other words, the number of spherulites immediately adjoining a given spherulite can be assumed to remain relatively constant regardless of the size and number of spherulites in the network.

As the application of an oscillatory shear results in an increase in the nucleation rate, it is possible that a reduction in the spherulite size is responsible for the decrease in the yield stress. While the number of contact points a given spherulite may form with adjacent spherulites can be assumed to remain largely constant, the reduction in spherulite size will increase the overall contact area between spherulites. According to Shi and others, the strength of interactions between the spherulitic domains of a molecular gel is weaker than the interactions within a given spherulite. Assuming this weak-link regime, it can be surmised that the point of yield is at the boundary between two spherulites. Given that reducing the size of spherulites will increase the total contact area between spherulitic domains, it is reasonable to suppose that the decrease in the yield stress may be due to the fact that there were more yield points in a system with more small spherulites than in a system with a few big spherulites.

Oil-Binding—Cooling Rate and Oscillatory Shear

The difference in the oil-binding capacity expressed as the percentage of oil lost after centrifugation is given in Fig. 10. The gel cooled at 30 °C/min displayed a higher oil-binding capacity than the gel crystallized at 1 °C/min. This higher oil-binding capacity may be due to the fact that a rapidly cooled gel exhibits a high degree of branching and thus a smaller pore/mesh size. As the solvent is held via capillary forces, a decrease in the pore size will increase the oil-binding capacity of a gel. The results are consistent with those suggested by Rogers and others [39], who noted that 12-HSA/canola oil gels crystallized under a higher supersaturation exhibited less oil syneresis and thus displayed a greater ability to bind oil.

The oil-binding capacity of a 2.5 % 12-HSA/canola oil gel crystallized under an oscillatory shear strain of 1,500 % (a) and 500 % (b) at various frequencies and cooling rates. Values with different letters (applicable only to values with the same cooling regime and oscillatory shear strain) have significantly different means (p ≤ 0.05). Values with different numbers (applicable only to values crystallized under the same mechanical treatment, i.e., identical shear strain and frequency) have significantly difference means (p ≤ 0.05)

The same trend (high oil-binding capacity for rapidly-cooled gels and relatively low oil-binding capacity for slow-cooled gels) can be observed even with the application of oscillatory shear, given that the oscillatory shear treatment is kept constant.

The oil-binding capacity of the gels crystallized under the various oscillatory shear conditions are also given in Fig. 10. The statistical testing was limited to samples with the same oscillatory shear strain, i.e., samples with different oscillatory shear strains were not compared.

Figure 10a shows that the application of an oscillatory shear strain of 1,500 % to a crystallizing solution of 12-HSA/canola oil results in a material with a very poor oil-binding capacity. As well, an increase in the frequency of oscillation from 1 to 10 Hz resulted in a material with a significantly lower (p ≤ 0.05) oil binding capacity. As the main mode of oil-binding in gels is presumably physical entrapment (as opposed to adsorption of the oil to solid surfaces), the low oil-binding capacity observed in the sheared samples may be due to the destruction of the fibrillar network structure as evidenced by the decrease in the storage modulus when shear is applied.

Figure 10b shows the oil-binding capacity of the gels crystallized under an oscillatory strain of 500 % at various cooling rates and oscillatory frequencies. The results show that for both cooling rates, the application of an oscillatory shear at 10 Hz and a strain of 500 % resulted in a gel that exhibited a lower oil-binding capacity compared to the statically crystallized gels and the gels solidified under an oscillatory shear of strain 500 % and frequency of 1 Hz. Relative to the sample crystallized under a shear strain of 1,500 %, these results suggest that lowering the oscillatory shear strain resulted in a material with a stronger oil-binding capacity. It must be noted that the samples with poor oil-binding capacity (strain 500 % and frequency of 10 Hz) also have a significantly lower (p ≤ 0.05) storage modulus and yield stress. This suggests that the mechanism of oil-binding is via physical entrapment.

Oil-Binding and Microstructure

At this point, a salient question must be posed: Why are organogels particularly sensitive to shear when compared to triglyceride-structured fats? The shear sensitivity of organogels may be attributed to the nature of the interactions responsible for structuring the organogel materials as well as the low volume fraction of crystalline material. Organogels are predominantly composed of liquid oil (at least 85 % wt/wt composition) and contain small amounts of crystalline material. The solids content of a fat, however, is relatively high. A fat material may contain anywhere from 40 to 70 % SFC. A fat can be considered to be structured by a network of fat spherulites interacting via van der Waals forces. The application of shear may cause the dislocation of fat spherulites and may even modify the morphology of the fat spherulites. However, since the fat spherulites are not “interconnected permanently”, dislocation of a fat spherulite from its position will not negatively impact the elasticity as much, as it is likely (because of the high volume fraction) it will interact with another fat spherulite. The elastic properties of an organogel are very dependent on the permanent network junction zones formed by the microstructural elements. Once the “interconnectedness” of an organogel system is lost, it is unlikely that it can be recovered due to the low volume fraction and the permanent (as opposed to transient) nature of the interactions in an organogel system. In short, the elastic properties of an organogel are very much dependent on the interconnection of the fibrillar or platelet morphologies. The elastic properties of a fat, however, are not dependent so much on the interconnectedness of the fat spherulites but rather on the volume fraction of the crystalline material and the transient interactions between these crystalline particles. As shear inevitably results in the destruction of interactions between the crystalline matter, the ability to recover interactions between microstructural elements will determine the sensitivity of a material to shear.

The mechanical properties and oil-binding results obtained are all in agreement with those reported by other workers. In sum, the common finding of these workers is that the application of shear to an organogel system resulted in the destruction of the gel such that oil-binding capacity and mechanical strength were negatively impacted.

Conclusion

This study shows that it is possible to engineer the microstructure of edible oil organogels via control of the cooling rate and the application of shear. The variation in the cooling rate (and supersaturation) significantly affected the resulting microstructure. At a low cooling rate, fibrillar structures were obtained; at a high cooling rate, spherulitic microstructures indicative of a high extent of branching were observed. Similarly, the application of oscillatory shear also resulted in the modification of the microstructures in a cooling rate-dependent fashion. The application of an oscillatory shear at the low cooling regime resulted in the aggregation and thickening of the fibrillar microstructures. Application of an oscillatory shear at the high cooling regime resulted in an increased incidence of nucleation.

The study also shows that the morphological changes to the gel affected the macroscopic properties of the material. A high cooling rate resulted in a higher oil-binding capacity and a lower elastic storage modulus and yield stress. A low cooling rate resulted in a relatively lower oil-binding capacity and a higher elastic storage modulus and yield stress. It was found that the application of an oscillatory shear with relatively high amplitude (1,500 %) resulted in the formation of a liquid dispersion rather than a gel. This material had poor mechanical and oil-binding properties. Reduction of the oscillatory strain alleviated the negative effect of the application of oscillatory shear to a certain extent.

The material properties of these shear-crystallized gels were different from the material properties of gels developed quiescently. This suggests that shear-crystallization can be used to tailor the macroscopic properties of an edible oil organogel.

References

Brandt M, Moss J, Ferguson M (2009) The 2006–2007 food label and package survey (FLAPS): nutrition labelling, trans fat labelling. J Food Compos Anal 225:S74–S77

LeGault L, Brandt MB, McCabe N, Adler C, Brown AM, Brecher S (2004) 2000–2001 food label and package survey: an update on prevalence of nutrition labeling and claims on processed, packaged foods. J Am Diet Assoc 104:952–958

Mensink RP, Zock PL, Kester ADM, Katan MB (2003) Effects of dietary fatty acids and carbohydrates on the ratio of serum total to HDL cholesterol and on serum lipids and apolipoproteins: a meta-analysis of 60 controlled trials. Am J Clin Nutr 77:1146–1155

Keys A (1957) Diet and the epidemiology of coronary heart disease. J Am Med Assoc 164:1912–1919

Mozaffarian D, Katan MB, Ascherio A, Stampfer MJ, Willett WC (2006) Trans fatty acids and cardiovascular disease. N Engl J Med 354:1601–1613

Ascherio A, Katan MB, Zock PL, Stampfer MJ, Willett WC (1999) Trans fatty acids and coronary heart disease. N Engl J Med 340:1994–1998

Bot A, Veldhuizen YSJ, den Adel R, Roijers EC (2009) Non-TAG structuring of edible oils and emulsions. Food Hydrocolloids 23:1184–1189

Pernetti M, van Malssen KF, Flöter E, Bot A (2007) Structuring of edible oils by alternatives to crystalline fat. Curr Opin Colloid Interface Sci 12:221–231

Rogers MA (2009) Novel structuring strategies for unsaturated fats—Meeting the zero-trans, zero-saturated fat challenge: a review. Food Res Int 42:747–753

Térech P, Weiss RG (1997) Low molecular mass gelators of organic liquids and the properties of their gels. Chem Rev 97:3133–3159

Abdallah DJ, Weiss RG (2000) Organogels and low molecular mass organic gelators. Adv Mater 2000:1237–1247

Weiss RG, Térech P (2006) Introduction. In: Weiss RG, Térech P (eds) Molecular gels: materials with self-assembled fibrillar networks. Springer, Dordrecht, pp 1–16

Co ED, Marangoni AG (2012) Organogels: an alternative edible oil-structuring method. J Am Oil Chem Soc 89:749–780

Binder RG, Applewhite TH, Kohler GO, Goldblatt LA (1962) Chromatographic analysis of seed oils. Fatty acid composition of castor oil. J Am Oil Chem Soc 39:513–517

Babu S, Sudershan RV, Sharma RK, Ramesh VB (1996) A simple and rapid polarimetric method for quantitative determination of castor oil. J American Oil Chem Soc 73:397–398

Masri MD, Goldblatt LA, DeEDS F, Kohler GO (1962) Relation of cathartic activity to structural modifications of ricinoleic acid of castor oil. J Pharm Sci 510:999–1002

Hughes NE, Marangoni AG, Wright AJ, Rogers MA, Rush JWE (2009) Potential food applications of edible oil organogels. Trends Food Sci Technol 20:470–480

Tamura T, Ichikawa M (1997) Effect of lecithin on organogel formation of 12-hydroxystearic acid. J Am Oil Chem Soc 74:491–495

Lescanne M, Colin A, Mondain-Monval O, Heuz K, Fages F, Pozzo JL (2002) Flow-induced alignment of fiberlike supramolecular self-assemblies during organogel formation with various low molecular mass organogelator-solvent systems. Langmuir 18:7151–7153

Xiong Y, Liu Q, Wang H, Yang Y (2008) Self-assembly of a dialkylurea gelator in organic solvents in the presence of centrifugal and shearing forces. J Colloid Interface Sci 318:496–500

Bot A, Agterof WGM (2006) Structuring of edible oils by mixtures of γ-oryzanol with β-sitosterol or related phytosterols. J Am Oil Chem Soc 83:513–521

Térech P, Pasquier D, Bordas V, Rossat C (2000) Rheological properties and structural correlations in molecular organogels. Langmuir 16:4485–4494

Burkhardt M, Kinzel S, Gradzielski M (2009) Macroscopic properties and microstructure of HSA based organogels: sensitivity to polar additives. J Colloid Interface Sci 331:514–521

Jahaniaval F, Kakuda Y, Abraham V (2002) Oil-binding capacity of plastic fats: effects of intermediate melting point TAG. J Am Oil Chem Soc 79:389–394

Liu XY (2005) Gelation with small molecules: from formation mechanism to network architecture. In: Fages F (ed) Topics in Current Chemistry 256: Low Molecular Mass Organogelators. Springer-Verlag, Berlin, pp 1–37

Li JL, Liu XY, Wang RY, Xiong JY (2005) Architecture of a biocompatible supramolecular material by supersaturation-driven fabrication of its fiber network. J Phys Chem B 109:24231–24235

Da Pieve S, Calligaris S, Co E, Nicoli MC, Marangoni AG (2010) Shear nanostructuring of monoglyceride organogels. Food Biophys 5:211–217

Wang RY, Liu XY, Xiong JY, Li JL (2006) Real-time observation of fiber network formation in molecular organogel: supersaturation-dependent microstructure and its related rheological property. J Phys Chem B 110:7275–7280

Wang RY, Liu XY, Narayanan J, Xiong JY, Li JL (2006) Architecture of fiber network: from understanding to engineering of molecular gels. J Phys Chem B 110:25797–25802

Lam R, Quaroni L, Pedersen T, Rogers MA (2010) A molecular insight into the nature of crystallographic mismatches in self-assembled fibrillar networks under non-isothermal crystallization conditions. Soft Matter 6:404–408

Rogers MA, Marangoni AG (2008) Non-isothermal nucleation and crystallization of 12-hydroxystearic acid in vegetable oils. Cryst Growth Des 8:4596–4601

Keith HD, Padden FJ (1963) A phenomenological theory of spherulitic crystallization. J Appl Phys 34:2409–2421

Ziegleder G (1993) Vorkristallisation von Schokoladen: Einflüsse durch Produkt und Maschine. Süßwaren 37:54–58

Campos JR (2006) Effects of Processing Conditions on the Crystallization of Cocoa Butter. Ph.D. Thesis, University of Guelph, Guelph, Canada

Liu XY, Sawant PD (2002) Mechanism of the formation of self-organized microstructures in soft functional materials. Adv Mater 14:412–426

Li JL, Yuan B, Liu XY, Xu HY (2010) Microengineering of supramolecular soft materials by design of the crystalline fiber networks. Cryst Growth Des 10:2699–2706

Rogers MA, Wright AJ, Marangoni AG (2009) Nanostructuring fiber morphology and solvent inclusions in 12-hydroxystearic acid/canola oil organogels. Curr Opin Colloid Interface Sci 14:33–42

Shi JH, Liu XY, Li JL, Strom CS, Xu HY (2009) Spherulitic networks: from structure to rheological property. J Phys Chem B 113:4549–4554

Rogers MA, Wright AJ, Marangoni AG (2008) Engineering the oil binding capacity and crystallinity of self-assembled fibrillar networks of 12-hydroxystearic acid in edible oils. Soft Matter 4:1483–1490

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

12-HSA crystallized statically in canola oil at 1 K/min (WMV 5.14 mb)

12-HSA crystallized under oscillatory shear in canola oil at a cooling rate of 1 K/min (WMV 7.07 mb)

About this article

Cite this article

Co, E., Marangoni, A.G. The Formation of a 12-Hydroxystearic Acid/Vegetable Oil Organogel Under Shear and Thermal Fields. J Am Oil Chem Soc 90, 529–544 (2013). https://doi.org/10.1007/s11746-012-2196-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-012-2196-6