Abstract

Aqueous extraction using subcritical water is an environmentally friendly alternative to extracting oil and protein from oilseeds with flammable organic solvents. The effects of solids-to-liquid ratio (1:3.3–1:11.7), temperature (66–234 °C), and extraction time (13–47 min) were evaluated on the extraction of oil and protein from soybean flakes and from extruded soybeans flakes with subcritical water. A central composite design (23) with three center points and six axial points was used. Subcritical water extractions were carried out in a 1-L high-pressure batch reactor with constant stirring (300 rpm) at 0.03–3.86 MPa. In general, oil extraction was greater for extruded soybean flakes than with soybean flakes. More complete oil extraction for extruded soybean flakes was achieved at around 150 °C and extraction was not affected by solids-to-liquid ratios over the range tested, while oil extraction from soybean flakes was more complete at 66 °C and low solids-to-liquid ratio (1:11.7). Protein extraction yields from flakes were generally greater than from extruded flakes. Protein extraction yields from extruded flakes increased as temperature increased and solids-to-liquid ratio decreased, while greater protein extraction yields from soybean flakes were achieved when using low temperatures and low solids-to-liquid ratio.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Increasing worldwide soybean production is being driven by growing demand for high quality protein to feed livestock (primarily swine and poultry) and for vegetable oils to supply food and fuel sectors [1]. Countercurrent hexane extraction has long been used to extract most soybean oil [2]; however, increasing environmental regulations and safety concerns regarding hexane use in oilseed-crushing units [3] are driving extensive research toward environmentally friendly extraction technologies [4].

Among the emerging technologies to extract oil and protein from oilseeds, enzyme-assisted aqueous extraction processing (EAEP) has been considered to be an effective and environmentally friendly process in which oil and protein are simultaneously extracted from soybeans [4, 5]. This water and enzyme-based technology along with mechanical treatments, such as flaking and extruding (expanding), has achieved similar levels of oil extraction as conventional hexane extraction (>97%) [6]. Despite achieving high oil extraction yields (removal from solids), however, overall free oil recovery in EAEP of soybeans ranges from 79 to 83% due to unrecovered emulsified oil in the skim (primarily sugar- and protein-rich) and small residual amounts of unextracted oil in the insolubles (fiber-rich fraction) [7, 8]. The mild operating conditions used in EAEP of soybeans enables production of oil with good quality and protein with similar nutritional compositions as proteins produced by conventional extraction procedures such as soy protein concentrate (SPC) or isolate (SPI) [9, 10].

Over the past decade, there has been increasing interest in using subcritical water for extraction where hot water (100 °C < T < 374 °C) under sufficient pressure (1–8 MPa) to maintain water in the condensed phase has been used to extract protein, essential oils, and bioactive components from a wide variety of matrices [11–17]. At subcritical conditions, the density, dielectric constant, dissociation constant, viscosity, diffusivity, electrical conductance, and solvency change [18]. At subcritical conditions, water polarity decreases thereby favoring extraction of organic bioactive components. The water ionization constant (Kw) increases with increasing temperature, making subcritical water a suitable media for catalyzing hydrolytic reactions [12, 14, 16]. Changes in the dielectric constant of water, the outstanding feature of sub- and supercritical water extraction, depends primarily on temperature (changes from 90 to 20 in dielectric constant can be achieved by increasing the temperature from ambient to 300 °C) and much less on pressure. Increasing pressure causes small increases in the dielectric constant, which could impair the extraction of low-polar components. The most significant change in extraction conditions due to pressure is related to water density, determining whether the extraction is performed with liquid or with steam. Although pressure has little effect on extraction efficiency, lower recovery of extracted components has been observed when using steam instead of liquid water [17]. In addition to extracting organic components, subcritical water has been used to hydrolyze triacylglycerols into free fatty acids [19, 20] and to convert organic waste (cellulose) into valuable products (glucose) [18].

The use of subcritical water to simultaneously extract oil and protein from oilseeds has not been extensively evaluated. Most research has focused on extraction of oil and/or protein from rice bran and to a lesser extent on extracting protein from defatted soybean meal and full-fat soy flour [12–16]. Protein extraction yields from deoiled rice bran were greater when using subcritical water conditions compared with the alkali extraction [12]. The effects of temperature (200–220 °C), reaction time (10–30 min), and solids-to-liquid ratio (1:5–2:5) were evaluated when using subcritical water to extract protein from defatted soybean meal and full-fat soy flour [14]. About 50% protein recovery was achieved relative to starting material when extractions were performed at 200–210 °C and 1:5 solids-to-liquid ratio for 30 min. Although full-fat soy flour has been used, no oil extraction data were reported.

Oil and protein extraction yields from soybeans when using aqueous extraction systems are greatly affected by the extent of cell wall disruption, the solids-to-liquid ratio, the presence or lack of enzyme during extraction, and the extraction time and temperature [5, 21–24]. The present study was undertaken to gain a better understanding of how these parameters affect oil and protein extractions from soybeans under subcritical extraction conditions.

Materials and Methods

Soybeans

Full-fat soybean flakes were prepared from variety 92M91-N201 soybeans (Pioneer, a DuPont Business, Johnston, IA, USA) harvested in 2008.

Processing Methods

Soybean Flaking

The soybeans were cracked into 4–6 pieces by using a corrugated roller mill (model 10X12SGL, Ferrell-Ross, Oklahoma City, OK, USA) and the hulls were removed from the meats (cotyledons) by aspirating with a multi-aspirator (Kice, Wichita, KS, USA). The meats were conditioned at 60 °C to make them plastic for flaking by using a triple-deck seed conditioner (French Oil Mill Machinery Co., Piqua, OH, USA) and were flaked to approximately 0.25 mm thickness by using a smooth-surface roller mill (Roskamp Mfg, Inc., Waterloo, IA, USA). The soybean flakes contained 20.3% oil (wet-basis), 35.9% protein (wet-basis), and 7.6% moisture.

Extruding Full-Fat Soybean Flakes

The moisture content of the flakes was increased to 15% by spraying water onto the flakes while mixing in a Gilson mixer (model 59016A, St. Joseph, MO, USA). The moistened full-fat soybean flakes were extruded/expanded by using a twin-screw extruder (ZSE 27 mm diameter; American Leistritz Extruders, Somerville, NJ, USA). High-shear geometry screws were used in co-rotational orientation at 90-rpm screw speed. The extruder barrel (1,080 mm length) was composed of ten heating blocks that were set for the temperature profile 30-70-100-100-100-100-100-100-100-100 °C. The extruder was manually fed to achieve a 10.5-kg/h output rate of extruded flakes. The collets were cooled to room temperature, placed in polyethylene bags, and stored in a cold room at 4 °C until extracted. The extruded soybean flakes contained 22.7% oil (wet-basis), 88.7% solids (wet-basis), 35.3% protein (wet-basis), and 11.3% moisture.

Subcritical Water Extraction

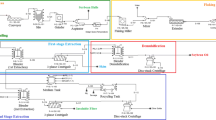

Oil and protein extractions from flakes and extruded soybean flakes were carried out in a high-pressure, 316 stainless-steel, batch reactor as shown in Fig. 1 (High-Pressure Equipment Co., Erie, PA, USA). The reactor, pressure rated for 241 MPa, consisted of 1 L internal volume (7.6 cm internal diameter and 23.1 cm length) heated by an electrical jacket, two J thermocouples (TC1 and TC2), an analog pressure gauge (Pa), digital pressure gauge (Pb), and a MagneDrive stirring assembly (Autoclave Engineers, Supercritical Fluid Technologies Inc., Newark, DE, USA).

Soybean flakes and extruded soybeans flakes were dispersed into deionized water to achieve solids-to-liquid ratios ranging from 1:3.3 to 1:11.7 (Table 1). The amount of solids per 100 g of slurry for solids-to-liquid ratios of 1:3.3, 1:5, 1:7.5, 1:10, and 1:11.7 were 22.6, 16.3, 12.3, 8.9, and 7.8 g, respectively. The amount of slurry loaded into the reactor was determined based on the minimum amount needed to achieve adequate stirring (400 g) and the maximum amount that would fit into the reactor without plugging the vent lines located just above the slurry level. Slurries of approximately 675 g for soybean flakes and 775 g for extruded soybean flakes were loaded into the reactor at room temperature (extruded flakes are denser than flakes). A leak test was performed with helium at 0.69 MPa. In order to degas the mixture prior to starting the experiments, the reactor was purged with helium at 0.69 MPa and maintained for 6 min at 0.69 MPa after which it was vented. The degassing cycle was repeated five times while stirring the slurry at 300 rpm. Extraction experiments were performed at temperatures ranging from 66 to 234 °C and extraction times ranging from 13.2 to 46.8 min (Table 1). The slurries were stirred at 300 rpm and the resulting pressure varied from 0.14 to 3.96 MPa. The reactor heating cycle ranged from 40 min (66 °C) to 240 min (234 °C) while the cooling time from the target temperature to 70 °C ranged from 120 min (100 °C) to 480 min (234 °C). The system was cooled to 70 °C to ensure safe handling of the product before opening the reactor to remove the slurry.

Following extraction, the slurry was centrifuged at 3,000g (20 min at 25 °C) to separate insolubles from the liquid phase (Fig. 2). Three phase layers were observed after centrifuging: an insoluble fraction (fiber-rich fraction), a skim fraction (protein- and sugar-rich fraction), and a cream fraction (oil-rich emulsion). After removing the insoluble fraction, the liquid phase was placed into a separatory funnel (2 L) and allowed to settle overnight at 4 °C. During settling, the liquid phase separated into two fractions (skim fraction and cream + free oil fraction). Since oil and protein extractabilities were the focus of this study, only the insoluble fraction was analyzed to determine mass balances for oil and protein.

Oil, Protein, and Solids Recoveries

Oil and protein analyses were carried out on the insoluble and starting materials (soybean flakes and extruded soybean flakes). Total oil content was determined by using the Mojonnier acid hydrolysis method (AOCS method 922.06) and protein content was determined by using the Dumas combustion method and the N conversion factor of 6.25 (vario MAXCN Elementary Analyses system Gmbh, Hanau, Germany). Extraction yields were expressed as percentages of each component in the insoluble fraction relative to the initial amount in the starting material. All chemical analyses were performed in duplicate.

Experimental Design and Statistical Analysis

In order to optimize for the best combination of solids-to-liquid ratio, temperature and reaction time for oil and protein extraction, a complete 23 factorial design of the central rotational type was established, with three central points and six axial points, based on Response Surface Methodology [22]. The effects of solids-to-liquid ratio (1:3.3–1:11.7), temperature (66–234 °C), and extraction time (13.2–46.8 min) on the extraction of oil and protein from soybean flakes and extruded soybeans flakes by using subcritical water treatment were evaluated. Pressures were a consequence of temperature and slurry composition, not being one of the independent variables in the experiment. The independent variables (solids-to-liquid ratio, temperature, and extraction time) were evaluated according to coded levels (α, −1, 0, 1, +α). The variable levels used in the experimental design were selected in order to achieve slightly lower and/or higher values than the common range of values reported in the literature. Central points are the average of levels −1 and +1, while axial points were determined by interpolation (α = ±1.68). Coded and uncoded levels and their corresponding independent variables are shown in Table 1. Dependent variables (i.e., evaluated responses) were oil and protein extraction yields for soybean flakes and extruded soybean flakes. Data were analyzed by using Statistica version 8.0 software. The significance of each model was tested by Analysis of Variance (ANOVA).

Results and Discussion

Oil and Protein Extraction Yields

Oil and protein extractabilities from soybeans are significantly affected by mechanical treatments such as grinding, flaking, extruding, and combinations of these treatments [21–24]. The combination of flaking and extrusion is more effective in extracting oil when using aqueous extraction of soybeans due to more complete cell disruption that facilitates water penetration into the matrix, releasing soluble and insoluble components into the external environment [21–24]. In Table 2, the effects of extent of cell wall disruption on oil and protein extraction from soybean flakes and extruded soybean flakes under different subcritical water extraction conditions are presented. Regardless of treatment applied, oil extraction yields were significantly improved when using extruded soybean flakes (38–84%) compared with soybean flakes (4–50%).

Campbell and Glatz [24] reported that nearly complete cellular disruption of soybeans cotyledons was achieved when comminuted by extrusion, in relation to milling, flaking, and flaking followed by milling. Our results are in agreement with those of Lamsal et al. [20] in which oil extractability improved from 46 to 71% when combining flaking and extruding of soybeans compared to flaking alone.

Higher oil extraction yields from soybean flakes (50%) and from extruded soybean flakes (84%) were achieved when extracting at 1:10 solids-to-liquid ratio and 100 °C for 20 min and at 1:11.7 solids-to-liquid ratio and 150 °C for 30 min, respectively. Lower oil extraction yields for both soybean flakes (4%) and extruded soybean flakes (38%) were observed at 1:7.5 solids-to-liquid ratio and 234 °C for 30 min. Absolute pressures and water densities are presented in Table 3 as functions of extraction temperature. Water density was slightly reduced when moving from 66 to 150 °C extraction temperature (from 980 to 917 kg/m3), being more pronounced from 150 to 234 °C (from 917 to 823 kg/m3). In all cases, however, water was present in the liquid phase. Although no water was observed to change from liquid to vapor, which would affect the recovery of extracted components [17], the increase in pressure from 0.14 to 3.96 MPa when moving from 66 to 234 °C extraction temperature could have reduced extractability of oil from both extruded soybean flakes and soybean flakes at 234 °C. A slight increase in the dielectric constant due to increasing pressure could affect extraction of low polar components [17].

Temperature can affect extraction due to enhanced solute solubility and diffusion into the solvent bulk [25]. In some cases, however, temperature has been associated with reduced oil and protein extraction during aqueous extraction of soybeans [14]. Reduced extractability is likely a consequence of protein thermal denaturation [26], which affects both oil and protein extraction to different extents. Heating favors protein-lipid interactions in which denatured protein is likely to sequester oil by exposing hydrophobic amino acids [22]. Since soybean flakes and extruded soybean flakes contain proteins with different solubilities [27] due to protein denaturation during extrusion, one would expect lower protein extractability when using extruded soybean flakes compared with soybean flakes. Protein extraction yields from soybean flakes and from extruded soybean flakes ranged from 31 to 72 and 27 to 73%, respectively. In general, extruded soybeans flakes had similar or slightly higher protein extractability when using water temperatures >150 °C. However, an opposite effect was observed when using temperatures <100 °C, where protein denaturation reduced protein solubility adversely affecting extraction yields. These results suggested that using temperatures >150 °C likely compensated for the reduced protein solubility due to extrusion. High protein extraction yields of 68 and 73% were achieved when extracting soybean flakes and extruded soybean flakes at 234 °C, respectively, which was the highest temperature evaluated and produced the lowest oil extraction yields for both soybean flakes and extruded soybean flakes. Although parameters that favor protein extractability also usually favor oil extraction, an opposite trend was observed at the highest temperature, which suggested some oil binding by unextracted protein and/or reduced oil extractability due to pressure increase at 234 °C (Table 3). The use of subcritical water to extract protein from raw and deoiled soybean meal was previously reported by Watchararuji et al. [14]. In that study, 50% protein recovery was achieved when extracting at 210 °C, 1:5 solids-to-liquid ratio, and 30 min residence time although oil extractability was not reported.

Statistical Analysis

Estimated regression models and coefficients of determination for oil and protein extractions from soybean flakes and extruded soybean flakes are shown in Table 4. Only parameters significant at P < 0.05 were used in the regression models. Coefficients of determination (R 2) for models of oil extraction from soybean flakes and extruded soybean flakes were 0.27 and 0.38, respectively; while coefficients for models of protein extraction from soybean flakes and extruded soybean flakes were 0.63 and 0.96, respectively. While satisfactory coefficients of determination were achieved for the models predicting protein extraction, low coefficients for oil extraction suggested that other sources of variation were not accounted for.

The effects of soybean moisture content before flaking and storage time of the beans and flakes before extruding have been associated with phospholipase D activity [7, 28–30], which could increase emulsion stability and affect the separation of extracted material before and after centrifugation. Our material was prepared and used over a 2- to 3-month period, which might have allowed phospholipase D activity, a factor not accounted for by the models.

Another source of variation that may have impacted the oil extraction models was the heating/cooling system of the reactor. Typically, fast heating and fast cooling are preferred for these types of experiments under subcritical conditions to avoid thermal degradation of the reactants and for better evaluation of reaction time necessary to achieve the desired extraction yields. In order to follow our experimental design parameters (reaction time and temperature), heating the reactor required 0.67 h (25−66 °C) to 4 h (25−234 °C) followed by cooling 2 h (100−70 °C) to 8 h (234−70 °C), which could have confounded measuring effects of reaction time on extraction yields. In some cases, the long cooling times surpassed the time to conduct the extraction. Reaction time was not statistically significant, likely a consequence of the long residence time due to the heating/cooling system that was used. These challenges with heating and cooling could be eliminated when transitioning from the current batch system to a continuous reactor. Although the real effect of residence time was not determined, the remaining parameters (temperature and solids-to-liquid ratio) provided useful information on their effects on extraction yields.

Table 5 shows the ANOVAs of the models. For all cases, regression was significant (F calculated/F table). Significance of the results was determined by comparing the F calculated (verifying the equality of the means) with the theoretical value (F table). Except for the models for oil and protein extraction from soybean flakes, the F tests for the lack of fit were not statistically significant (F calculated/F table) indicating that the models do not show lack of fit and thus can be used for prediction in the range of the parameters evaluated. The F test for lack of fit was statistically significant for oil and protein extraction from soybean flakes (F calculated > F table), which was associated with the pure error (extremely low) due to the low degrees of freedom (2). Based on the estimated regression models, response surfaces were built to express oil and protein extractions from soybean flakes and extruded soybean flakes (Figs. 3, 4).

According to the estimated regression model and Fig. 3a regardless of the solids-to-liquid ratio used, oil extraction from extruded soybean flakes decreases when temperature gets further away from the center point (150 °C) with lower extraction values at the axial points (±1.68). According to the estimated regression model and Fig. 3b, highest oil extraction yields from soybean flakes are achieved at high temperature values (+1.68, 234 °C) and high solids to liquid ratio (−1.68, 1:3.3) and at low temperature values (−1.68, 66 °C) and low solids-to-liquid ratio (+1.68, 1:11.7). Based on the estimated regression model and Fig. 4a, protein extraction from extruded soybean flakes is favored by increased temperature and low solids-to-liquid ratio, with higher extraction values at +1.68 for both variables (234 °C and 1:11.7 solids-to-liquid ratio). Although protein extraction yields from extruded flakes increased as temperature increased, the nutritional quality of the extracted protein might be adversely affected by thermal degradation. An opposite trend was observed for protein extraction from soybean flakes. According to the estimated regression model and Fig. 4b, highest protein extraction can also be achieved at low temperature (66 °C) and low solids-to-liquid ratio (1:11.7). The possibility of achieving high extractability of protein from soybean flakes at low temperature indicates the higher solubility of protein in soybean flakes compared with protein in extruded soybean flakes.

Conclusions

The temperature and the solids-to-liquid ratio significantly affected oil and protein extraction yields with subcritical water from soybean flakes and extruded soybean flakes. The economical viability of aqueous extraction of soybeans depends on both oil and protein extractabilities, therefore, conditions that favor both oil and protein extractions must be considered. Although oil extraction yields from extruded soybean flakes was not significantly affected by the solids-to-liquid ratio, conditions which favor both oil and protein extraction yields are: temperature around 150 °C and low solids-to-liquid ratio (1:11.7). For soybean flakes, low temperature (66 °C) and low solids-to-liquid ratio (1:11.7) favored both oil and protein extraction yields.

References

USDA-FAS (2007) Oilseeds: World Markets and Trade. Circular Series FOP 8-07, FOP 10-07 http://www.fas.usda.gov/oilseeds/circular/2007/October/oilseedsfull1007.pdf, http://www.fas.usda.gov/oilseeds/circular/2007/August/oilseedsfinal0807.pdf

Johnson LA (2008) Oil recovery from soybeans. In: Johnson LA, White PJ, Galloway R (eds) Soybeans: chemistry, production processing and utilization. AOCS Press, Urbana, pp 331–375

Galvin JB (1997) Toxicity data for commercial hexane and hexane isomers. In: Wan PJ, Wakelyn PJ (eds) Technology and solvents for extracting oilseeds and nonpetroleum oils. AOCS Press, Champaign, pp 75–85

de Moura JMLN, Campbell K, Mahfuz A, Jung S, Glatz CE, Johnson LA (2008) Enzyme-assisted aqueous extraction of oil and protein from soybeans and cream de-emulsification. J Am Oil Chem Soc 85:985–995

de Moura JMLN, Johnson LA (2009) Two-stage countercurrent enzyme-assisted aqueous extraction processing of oil and protein from soybeans. J Am Oil Chem Soc 86:283–289

de Moura JMLN, Almeida NM, de Johnson LA (2009) Scale-up of enzyme-assisted aqueous extraction processing of soybeans. J Am Oil Chem Soc 86:809–815

de Moura JMLN, Almeida NM, de Jung S, Johnson LA (2010) Flaking as a pretreatment for enzyme-assisted aqueous extraction processing of soybeans. J Am Oil Chem Soc 87:1507–1515

de Moura JMLN, Maurer D, Jung S, Johnson LA. Proof-of-concept of countercurrent two-stage enzyme-assisted aqueous extraction processing of soybeans. J Am Oil Chem Soc 88:1649–1658

Maurer D, Mahfuz A, Johnson LA, Jung S (2008) Enzymatic destabilization of natural occurring soy emulsion and oil quality. 99th AOCS Annual Meeting & Expo. Seattle, Washington, USA, p 124

de Almeida, NM, de Moura JMLN, and Johnson LA (2010) Functional properties of protein produced by two-stage aqueous countercurrent enzyme-assisted aqueous extraction. Abstracts pp 130. 101st Annual Meeting and Exposition of the American Oil Chemists Society, May 16–19, Phoenix, AZ

Teo CC, Tan SN, Yong JWH, Hew CS, Ong ES (2010) Pressurized hot water extraction (PHWE). J Chromatography A 1217:2484–2494

Sereewatthanawut I, Prapintip S, Watchiraruji K, Goto M, Sasaki M, Shotipruk A (2008) Extraction of protein and amino acids from deoiled rice bran by subcritical water hydrolysis. Bioresour Tech 99:555–561

Pourali O, Asghri FS, Yoshida H (2009) Simultaneous rice bran oil stabilization and extraction using sub-critical water medium. J Food Eng 95:510–516

Watchararuji K, Goto M, Sasaki M, Shotipruck A (2008) Value-added subcritical water hydrolysate from rice bran and soybean meal. Bioresource Tech 99:6207–6213

Pourali O, Asghari FS, Yoshida H (2009) Sub-critical water treatment of rice bran to produce valuable materials. Food Chem 115:1–7

Basile A, Jimenez-Carmona MM, Clifford AA (1998) Extraction of rosemary by superheated water. J Agric Food Chem 46:5205–5209

Hawthorne SB, Yang Y, Miller DJ (1994) Extraction of organic pollutants from environmental solids with sub- and supercritical water. Analytical Chem 66:2912–2920

Goto M, Obuchi R, Hirose T, Sakaki T, Shibata M (2004) Hydrothermal conversion of municipal organic waste into resources. Bioresource Tech 93:279–284

Holliday RL, King JW, List GR (1997) Hydrolysis of vegetable oils in sub- and supercritical water. Ind Eng Chem Res 36:932–935

King JW, Holliday RL, List GR (1997) Hydrolysis of soybean oil in subcritical water flow reactor. Green Chem 1(6):261–264

Rosenthal A, Pyle DL, Niranjan K (1996) Aqueous and enzymatic process for edible oil extraction. Enz Microb Tech 19:402–420

Lamsal BP, Murphy PA, Johnson LA (2006) Flaking and extrusion as mechanical treatments for enzyme-assisted aqueous extraction of oil from soybeans. J Am Oil Chem Soc 83:973–979

Rodrigues MI, Iemma AF (2005) Planejamento de experimentos e otimizacao de processos: uma estrategia sequencial de planejamentos. Casa do Pao, Campinas, Brazil, pp 95–123

Campbell KA, Glatz CE (2009) Mechanisms of aqueous extraction of soybean oil. J Ag Food Chem 57:10904–10912

Takeuchi TM, Pereira CG, Braga MEM, Marostica MR, Leal PF, Meireles MAA (2009) Low-pressure solvent extraction (solid-liquid extraction, microwave assisted, and ultrasound assisted) from condimentary plants. In: Meireles MAA (ed) Extracting bioactive compounds for food products: theory and applications. CRC Press, Boca Raton

Kinsella JE (1979) Functional properties of soy proteins. J Am Oil Chem Soc 56:242–258

de Almeida NM, JMLN Moura, L Johnson (2010) Functional properties of protein produced by two-stage aqueous countercurrent enzyme-assisted aqueous extraction. Abstracts pp 130. 101st Annual Meeting and Exposition of the American Oil Chemists Society, May 16-19, Phoenix, AZ

Yao L, Jung S (2010) 31P NMR phospholipids profiling of soybean emulsion recovered from aqueous extraction. J Agric Food Chem 58:4866–4872

List RG, Mounts TL, Lanser AC, Holloway RK (1990) Effect of moisture, microwave heating, and live steam treatment on phospholipase D activity in soybeans and soy flakes. J Am Oil Chem Soc 67:867–871

Jung S, Maurer D, Johnson LA (2009) Factors affecting emulsion stability and quality of oil recovered from enzyme-assisted aqueous extraction of soybeans. Bioresource Tech 100:5340–5534

Acknowledgments

This work was supported by funds provided by the U.S. Department of Agriculture, Cooperative Research, Education, and Extension Service, Grant #2009-34432-20057; and the U.S. Department of Energy, Grant DE-FG3606GO86014.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Ndlela, S.C., de Moura, J.M.L.N., Olson, N.K. et al. Aqueous Extraction of Oil and Protein from Soybeans with Subcritical Water. J Am Oil Chem Soc 89, 1145–1153 (2012). https://doi.org/10.1007/s11746-011-1993-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-011-1993-7

high pressure valve (414 MPa)

high pressure valve (414 MPa)