Abstract

A total of 15 walnut (Juglans regia L.) samples from 15 cultivars from different geographical areas (Villaviciosa, Colunga, Ribadesella, Llanes, Nava, Peñamellera and Sariego) from Asturias, Spain were studied. Samples of virgin walnut oil were obtained from dehusked ground walnuts by extraction at a pressure of 160 kg cm−2 and temperature below 40 °C for 3 min. The oil obtained by pressure was filtered for analysis. Fatty acid, sterol and tocopherol compositions as determined by capillary column gas chromatography (GC) and triacylglycerols composition as determined by high performance liquid chromatography (HPLC) are reported. The overall composition (percentages of husk, oil and moisture) was also determined. The higher percentages of fatty acids, as determined by capillary GC, corresponded to palmitic (6.11 ± 0.06–7.49 ± 0.04%), oleic (11.70 ± 1.10–18.90 ± 1.19%), linoleic (59.81 ± 1.03–64.77 ± 1.25%) and linolenic (11.11 ± 0.05–15.65 ± 1.09%). γ-Tocopherol was the major component of the total tocopherols in the sample under study (289.01 ± 6.02–676.52 ± 5.98 mg kg−1 oil). β-Sitosterol was the major sterol found (78.61 ± 1.45–86.50 ± 1.35%) followed by Δ5-avenasterol (5.54 ± 0.92–13.81 ± 1.06%). The main triacylglycerides were LLL (24.67 ± 1.31–29.20 ± 1.22%), followed by LLLn (14.63 ± 1.01–17.06 ± 1.13%), OLL + PoLO (13.81 ± 1.01–16.14 ± 1.16%) and PLL + LnOO (11.83 ± 1.09–14.10 ± 1.10%).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The European Union is the third largest walnut-producing region in the world after Turkey and the United States, with an annual production of 104,000 tonnes. France is one of the major producers in the European Union, producing 28,000 tonnes per year, followed by Greece, Germany and Austria. Spain produces 12,000 tonnes per year from a planted area of 5,500 ha, generating a turnover of more 25 million dollars. Furthermore, it has 280,000 dispersed trees which do not form part of intensive plantations. Despite increasing production, Spain must import three times what it produces to satisfy internal consumption [1]. At the same time, the beneficial effects on human health of walnut oil have increased interest in walnut cultivation [2]. Asturias (Spain) produces 70 tonnes per year from 30,000 autochthonous cultivars which are difficult to catalogue and which are disseminated irregularly all around the region [3]. Several authors have studied the physical–chemical characteristics of walnut oils obtained by supercritical fluid extraction [4, 5] or by solvent [6, 7], each sample being obtained from different fruits originating from diverse plantations in several countries.

Much of the existing literature attribute the beneficial health effects of walnuts oils to the their high oleic acid content; however, little research has been conducted on lipid class compositions of walnuts oils. The objective of this research was to evaluate the lipid composition data of walnut oil obtained from 15 walnut cultivars from different geographical areas in Asturias, Spain.

Materials and Methods

Samples and Extraction of Oils

Fifteen walnut (Juglans regia L.) cultivars were collected from different geographical areas from Asturias province, Spain. Table 1 shows the geographical locations of each cultivar plants were grown under natural rainfall. The study was carried out during 2007. During the crop year, three samples (2 kg each) of fruits at full maturity from each variety were picked. After harvesting, the walnuts were dried in an oven at 40 °C for 3 days and were then dehusked by hand and ground in an electric grinder. The walnut powder was subsequently maintained at 40 °C during the pressing between ten vertically stacked cylindrical steel plates, each of 12 cm internal diameter and 1 cm thickness. All the plates were pressed together at a maximum pressure of 160 kg cm−2 for 3 min in order to prevent the oil from coming into contact with the oxygen in the air. The extracted oil was separated and filtered at 40 °C through filter paper and stored in darkness at 4 °C until its analysis.

Solvent Oil Extraction and Water Content

Walnut samples were blanched and ground in an electrical grinder. Oil was extracted in a Soxhlet glass apparatus using hexane as the solvent [8]. Moisture was determined by weight loss after heating in an oven at 105 °C in accordance with IUPAC methods [9].

Fatty Acids Analysis

Fatty acid methyl-esters (FAME) were analyzed by gas chromatography (GC). FAME were extracted with n-heptane after cold methylation with 2 N KOH in methanol [10]. FAME analysis was performed on an HP-5890-II apparatus (Hewlett-Packard, Palo Alto, CA) using a fused silica capillary SP-2380 column (60 m × 0.25 mm, 0.2 μm film thickness). The oven temperature was kept at 160 °C for 13 min and was then raised to 190 °C at a rate of 1.5 °C min−1 and held isothermally for 20 min. The injector temperature was kept at 225 °C, while the detector temperature was 250 °C. Hydrogen (19 psi inlet pressure) was used as the carrier gas, while the make-up gas was nitrogen.

Standards of each fatty acid were used to identify the fatty acids. These were purchased from Sigma–Aldrich (St. Louis, MO): palmitic (P = C16:0), palmitoleic (Po = C16:1), stearic (S = C18:0), oleic (O = C18:1 ω9 cis), linoleic (L = C18:2), and linolenic (Lo = C18:3) acids. Fatty acids were identified in the samples by comparing retention times for standards and samples. The area was expressed as percentages.

Tocopherol Analysis

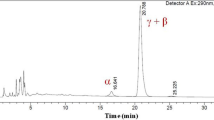

Tocopherols were quantified by HPLC. The HPLC system consisted of a low press quaternary pump HP-1050, a Rheodyne injection valve (20 μL loop), a thermostatic furnace and a fluorescence detector RF-235 (Shimadzu, Kyoto, Japan). Separation was performed in a 250 × 4 mm particle size 5 μm Lichrospher Si-60 (Merck, Darmstadt, Germany) column. The column and detector were kept at a temperature of 40 °C. The mobile phase was n-hexane/2-propanol 99/1 (v/v). The flow rate was supported at 1.00 mL min−1 isocratic elution. Quantification was carried out by a calibration system based on standards [11].

Sterols Analysis

The unsaponifiable fraction was extracted as described [12]. A 0.5-mL 5-α-cholestanol (Fluka, Buchs, Switzerland) solution in chloroform was added to 5 g of oil as an internal standard. The mixture was saponified for 0.5 h with 50 mL of 2 N ethanolic potassium hydroxide. The solution was then passed to a 500-mL decanting funnel, 100 mL distilled water was added and the mixture was extracted twice with three 80-mL portions of diethyl ether. The diethyl ether extracts were combined in another funnel and were washed several times with 100-mL portions of water, until the wash reached neutral pH. The diethyl ether solution was dried over anhydrous sodium sulphate and evaporated to dryness in a rotary evaporator at 30 °C under reduced pressure. After purification by thin-layer chromatography [13], the sterols fraction was analyzed and quantified by gas chromatography in an HP 5890-II apparatus equipped with a split-splitless injector and a flame ionization detector. An HP-5 fused silica capillary column (30 m × 0.32 mm i.d., 0.25 μm film thickness) was used, hydrogen (7 psi inlet pressure) being the carrier gas and nitrogen the make-up gas. The oven temperature was maintained isothermally at 265 °C for 30 min. The injector temperature was 280 °C, while the detector was kept at 300 °C. Previously, the sterols fraction was derivatized as trimethylsilyl ethers (TMS) according to the method proposed in [12]. Sterols were identified by comparison of the mass spectral data with those of authentic reference compounds and by comparing their retention times with sterols from olive, sunflower and soybean oils [13].

Triacylglycerides Analysis

Triacylglycerides were analyzed by high performance liquid chromatography (HPLC) as proposed by the International Union Pure and Applied Chemistry [14]. The HPLC system consisted of a Hewlett-Packard (Palo Alto, CA, USA) 1,050 liquid chromatograph, with a low pressure quaternary pump, a Rheodyne (Cotati, CA, USA) injection valve (20 μL loop), a thermostatic furnace and a refractive index detector HP-1074. An HP chemical station was used to control and monitor the system. The separation was performed in a 250 × 4 mm particle size 4 μm Lichrospher 100 RP-18 Merck (Darmstadt, Germany) column. The column and detector were maintained at a temperature of 40 °C. The mobile phase was acetonitrile/acetone 50/50 (v/v). The flow rate was 1.15 mL min−1 isocratic elution for 45 min.

The assignment of the chromatographic peaks was carried out by means of standards purchased from Sigma–Aldrich (St. Louis, MO): trilinolein (LLL), the most important, and triolein (OOO). This method allowed the carbon number of the components associated with each peak group to be deduced, as well as the difference between the retention times of the triacylglycerols. The area was reported as a percentage.

Statistics Analysis

Data are presented as mean values ± standard deviation of three samples of each cultivar, analyzed individually in duplicate. Data were treated by analysis of variance (ANOVA) using statistical software SAS (version 8.02, SAS Institute Inc., Cary, NC, USA). Differences among treatments were determined by statistical analysis using a Student t test where (p < 0.05) was considered statistically significant.

Results and Discussion

Table 1, shows the overall composition (percentages of husk, moisture and oil) of walnuts from different cultivars in Asturias. Variations in the percentages of oil obtained among the different cultivars (56.50 ± 2.65–67.62 ± 1.38%) and moisture (3.87 ± 0.07–6.77 ± 0.26%) was observed. The fat values are similar to those described previously by others authors, although the lowest value was lower than previous reports [15–17]. This may be due to the different origins and their different geographical locations.

The fatty acids composition (Table 2), included palmitic (6.11 ± 0.06–7.49 ± 0.04%), oleic (11.70 ± 1.10–18.90 ± 1.19%), linoleic (59.81 ± 1.03–64.77 ± 1.25%) and linolenic (11.11 ± 0.05–15.65 ± 1.09%). These averages were similar to varieties such as Criolla, Chandler and Franqueta [18]. In general terms, the obtained results were in agreement with fatty acid composition observed in Portuguese samples [19] and other geographical origins such as Italy [20], Canada [21] and New Zealand [22]. Other minor fatty acids have been identified, such as C14:0, C17:0, C17:1, C20:0 and C20:1 were less than or equal to 0.01%, which is consistent with literature [15–17] and no significant differences among the samples analyzed. Due to the composition in linoleic and linolenic acids, the oils are susceptible to oxidation. Tocopherols are well-known natural antioxidants. They are relatively abundant in seeds with high amounts of unsaturated fatty acids, as is the case of walnut oils. γ-Tocopherol was the major component of total tocopherols in the samples under study. This level varied from 289.01 ± 6.02 to 676.52 ± 5.98 mg kg−1 oil (Table 3). It is worth noting that α-tocopherol content was very low (5.90 ± 1.32 and 26.29 ± 1.10 mg kg−1 oil). These results are in according with those reported by [4, 18], although the γ-tocopherol content was lower than that of the present study. β-Tocopherol was not detected and δ-tocopherol values ranged from 19.63 ± 1.16 to 106.70 ± 1.67 mg kg−1.

Table 4 shows the individual sterols content of the different cultivars studied. β-Sitosterol was the major sterol found ranging between 78.61 ± 1.45 and 86.50 ± 1.35%. The next major component was Δ5-avenasterol, constituting between 5.54 ± 0.92 and 13.81 ± 1.06% followed by campesterol (4.35 ± 0.17–5.79 ± 0.24%). Other components such as clerosterol, sitostanol and Δ5-stigmastadienol were present at small amounts. The major ones (i.e., β-sitosterol, Δ5-avenasterol and campesterol) were already reported to occur in walnuts and in similar amounts [21, 23]. Triacylglycerides analysis with critical pairs is defined as those structures that have the same equivalent carbon number (ECN), which is formulated as ECN = CN−2n, where CN is the carbon number and n is the number of ethylenic double bounds of the triacylglycerides. We identified and quantified twelve triacylglycerides: LLnLn, LLLn, LLL, OLLn, PLnL, OLL + PoLO, PLL + LnOO, PLO, PPL, OOO, SOL + POO, PLS + POP. Peaks were identified by comparison of logarithms of selectives (log α) relative to the triolein in relation to the corresponding values of standard homogeneous triacylglycerides and standard oils such as olive, sunflower and soybean [18]. The values for each variety are shown as percentages in Table 5. The main triacylglycerides were LLL (24.67 ± 1.31–29.20 ± 1.22%), followed by LLLn (14.63 ± 1.01–17.06 ± 1.13%), OLL + PoLO (13.81 ± 1.01–16.14 ± 1.16%) and PLL + LnOO (11.83 ± 1.09–14.10 ± 1.10%). Other triacylglycerides present in small amounts were PPL (5.73 ± 1.06–7.70 ± 1.08%), PLO (4.36 ± 0.04–6.66 ± 0.07%) and OLLn (4.60 ± 0.06–5.59 ± 0.06%). Triacylglycerides that have three unsaturated acid presented the biggest proportions, followed by those that have two unsaturated acids. These compositions are in a similar range to those reported by [25].

Conclusion

Results of the present study confirm that walnut oil from Asturias is a very good source of polyunsaturated fatty acids, basically linoleic and linolenic fatty acids and sterols, mainly β-sitosterol. The beneficial health effects of phytosterols indicate that this oil can function as a nutraceutical oil. It is also a good source of vitamin E (γ-tocopherol and δ-tocopherol) and may be used a as virgin oil for food.

References

Ministerio de Agricultura (2008) Pesca y Alimentación. Anuario de Estadística

Gebauer SK, Psota TL, Harris WS, Kris-Etherton PM (2006) N-3 Fatty acid dietary recommendations and food sources to achieve essentiality and cardiovascular benefits. Am J Clin Nutr 83:15265–15355

Servicio Regional de Investigación y Desarrollo Agroalimentario (2008) Consejería de Medio Rural y Pesca. Principado de Asturias

Oliveira R, Rodríguez MF, Bernardo-Gil G (2002) Characterization and supercritical carbon dioxide extraction of walnut oil. J Am Oil Chem Soc 79:225–230

Salgin S, Salgin U (2006) Supercritical fluid extraction of walnut kernel oil. Eur J Lipid Sci Technol 108:577–582

Dogan M, Akgul A (2005) Fatty acid composition of some walnut (Juglans regia L.) cultivars from east Anatolia. Grasas Aceites 56:328–331

Ozkan G, Koyuncu MA (2005) Physical and chemical composition of some walnut (Juglans regia L.) genotypes grown Turkey. Grasas Aceites 56:41–146

International Union of Pure and Applied Chemistry (IUPAC) (1987) Standard methods for the analysis of oils, fats and derivatives: method 1122. In: Paquot C, Haufenne A (eds) Determination of oil content (extraction method), 7th edn. Blackwell, Oxford, pp 14–16

International Union Pure and Applied Chemistry (IUPAC) (1987) Standard methods for the analysis of oils, fats and derivatives: method 1121. In: Paquot C, Haufenne A (eds) Determination of moisture and volatiles matter content, 7th edn. Blackwell, Oxford, pp 13–16

International Union Pure and Applied Chemistry (1987) Standards methods for the analysis of oils, fats and derivatives: methods 2301. In: Paquot C, Haufenne A (eds) Preparation of the fatty acid methyl esters, 7th edn. Blackwell, Oxford, pp 123–129

Identification and determination of tocopherols (1987) Standard methods for the analysis of oils, fats and derivatives: method 2411. In: Paquot C, Haufenne A (eds) Identification and determination of tocopherols, 7th edn. Blackwell, Oxford, pp 174–219

Official Journal of the Commission of the European Communities (1991) Regulation No 2568/91, L248, September 9

León-Camacho M, Morales MT (2000) Gas and liquid chromatography: methodology applied to olive oil. In: Harwood JL, Aparicio R (eds) Handbook of olive oil: analysis and properties. Aspen, Gaithersburg, pp 159–208

International Union Pure and Applied Chemistry (1987) Standard methods for the analysis of oils, fats and derivatives: method 2324. In: Paquot C, Haufenne A (eds) Determination of the composition of triglycerides in vegetable oils in terms of their partition number by high performance liquid chromatography (HPLC), 7th edn. Blackwell, Oxford, pp 1–6

Savage GP (2001) Chemical composition of walnuts (Juglans regia L.) grown in New Zealand. Plant Food Hum Nutr 56:75–82

Amaral JS, Casal S, Pereira JA, Seabra RM, Oliveira BP (2003) Determination of sterol and fatty acid compositions, oxidative stability, and nutritional value of six walnut (Juglans regia L.) cultivars grown in Portugal. J Agric Food Chem 51:7698–7702

Crews C, Hough P, Godward J, Brereton P, Lees M, Guiet S, Winkelman W (2005) Study of the main constituents of same authentic walnut oils. J Agric Food Chem 53:4853–4860

Martinez ML, Mattea MA, Maestri D (2006) Varietals and crop year effects on lipid composition of walnut (Juglans regia L.) genotypes. J Am Oil Chem Soc 83:791–796

Amaral JS, Casal S, Pereira JA, Seabra RM, Oliveira PP (2003) Determination of sterol, fatty acid compositions, oxidative stability, nutritional value of six walnut (Juglans regia L.) cultivars grown in Portugal. J Agric Food Chem 51:7698–7702

Rugeri S, Cappelloni L, Carnovale E (1998) Chemical composition and nutritive value of nuts grown in Italy. Ital J Food Sci 3:243–252

Li L, Tsao R, Yang R, Krammer JKG, Hernández M (2007) Fatty acid profiles, tocopherol contents, and antioxidant activities of heartnut (Juglans ailanthifolia var. cordiformis) and Persian walnut (Juglans regia L.). J Agric Food Chem 55:1164–1169

Zwarts L, Savage GP, McNeil DL (1999) Fatty acid content of New Zealand grown walnuts (Juglans regia L.). Int J Food Sci Nut 50:189–194

Kamm W, Dionisi F, Hischenhuber C, Engel K (2001) Food Rev Int 17:249–290

Tubaileh RM (1999) Variación en el contenido en ceras y alcoholes grasos en el aceite de oliva durante la desodorización. Doctoral thesis. University of Córdoba, Spain

Amaral JS, Cunha SC, Rui Alves M, Pereira JA, Seabra RM, Oliveira BP (2004) Triacylglycerol composition of walnut (Juglans regia L.) cultivars: characterization by HPLC-ELSD and chemometrics. J Agric Food Chem 52:7964–7969

Acknowledgments

The authors are grateful for funding via the Plan Regional de Investigación from the Principado de Asturias (PCTI, project: PC-CIS01-01). We also wish to thank the company Valle, Ballina y Fernández (Villaviciosa, Asturias, Spain) for financing this project and M. Ciordia from SERIDA (Principado de Asturias) for her valuable collaboration.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Bada, J.C., León-Camacho, M., Prieto, M. et al. Characterization of Walnut Oils (Juglans regia L.) from Asturias, Spain. J Am Oil Chem Soc 87, 1469–1474 (2010). https://doi.org/10.1007/s11746-010-1629-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-010-1629-3