Abstract

Garden cress (Lepidium sativum L.) is an edible, underutilised herb, grown mainly for its seeds in India. Physicochemical properties, minor components (unsaponifiable matter, tocopherols, carotenoids), fatty acid composition and storage stability of garden cress seed oil (GCO) were studied. Cold press, solvent and supercritical CO2 extraction methods were employed to extract the oil. The total oil content of garden cress (GC) seeds was 21.54, 18.15 and 12.60% respectively by solvent, supercritical CO2 and cold press methods. The physical properties of GCO extracted by the above methods were similar in terms of refractive index, specific gravity and viscosity. However, cold pressed oil showed low PV and FFA compared to the oil extracted by other methods. α-Linolenic acid (34%) was the major fatty acid in GCO followed by oleic (22%), linoleic (11.8%), eicosanoic (12%), palmitic (10.1%) erucic (4.4%), arachidic (3.4%) and stearic acids (2.9%). Oleic acid (39.9%) and α-linolenic acid (42.1%) were the predominant fatty acids at the sn-2 position. The total tocopherol and carotenoid content of GCO was 327.42 and 1.0 μmol/100 g oil, respectively. The oil was stable up to 4 months at 4 °C. Tocopherol and BHT offered the least protection, while ascorbyl palmitate (200 ppm) offered the maximum protection to the oil, when subjected to the accelerated oxidative stability test. Thus GCO can be considered as a fairly stable oil with a high content of α-linolenic acid.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Lepidium sativum L. is an edible herb and a member of the Cruciferae (Brassicaceae) family [1]. Garden cress (GC) is an annual, glabrous, erect herb cultivated as a culinary vegetable all over Asia and Europe [1, 2]. It is commonly cultivated throughout the temperate regions of India and Pakistan [1]. The GC plant is cultivated in Ethiopia for the edible oil from its seeds [3]. Egyptians used GCO mixed with wild mustard seed oil to stabilise unstable linseed oil [4]. Medieval Indian medical texts record the medicinal properties of the GC plant [1, 2]. Since ancient times, the seeds have been used in local traditional medicine [5]. The GC seeds are bitter, thermogenic, depurative, rubefacient, galactogogue, tonic, aphrodisiac, ophthalmic, antiscorbutic, antihistaminic and diuretic. They are useful in the treatment of asthma, coughs with expectoration, poultices for sprains, leprosy, skin disease, dysentery, diarrhoea, splenomegaly, dyspepsia, lumbago, leucorrhoea, scurvy and seminal weakness [2]. The seedlings are consumed as a spice and are a rich source of glucosinolates [6]. Seeds, leaves and roots of GC are of economic importance too. In India, GC is mainly cultivated for its seeds. Fresh leaves are mainly used in salad and have antibacterial, diuretic and stimulant properties. The juice of eight-day-old, whole GC plants has been shown to be chemoprotective against IQ (2-amino-3-methylimidazo [4.5-f]quinoline)-induced genotoxic effects and colonic neoplastic lesions in rats [7]. GC seeds have been shown to reduce the symptoms of asthma and improve lung function in asthmatics [8]. The seeds have been reported as possessing a hypoglycemic property [9] and the seed mucilage is used as a substitute for gum arabic and tragacanth.

Agronomic attributes show that GC plants grow well in semi-arid regions and low fertility soils. It is cultivated thoughout India, especially in the central and northern states [10]. GC seeds exhibit the morphological characteristics of oil seeds and can be used for extracting oil. The challenge is to obtain a stable oil as it is prone to oxidative rancidity. Therefore, in the present study, the physicochemical properties of GCO obtained using different extraction methods (solvent extraction, cold expression and supercritical fluid extraction) and its storage stability were investigated.

Materials and Methods

Materials

GC seeds were purchased from a local market in Mysore. The seeds were identified and authenticated at the Department of Horticultural Sciences, University of Agriculture sciences, Bangalore. Seeds were air dried, powdered in a plate mill (Glenmills Inc. NJ) or flaked in a roller flaker (Kvarnmaskiner, Malmo, Germany) and stored in plastic containers. Oil from the seeds was extracted by different extraction methods. All the chemicals used were of analytical grade. The fatty acid methyl ester standards, tocopherol isomers and carotenoids were obtained from the Sigma Chemical Company, USA.

Methodology

Cold Press Extraction of Oil from Garden Cress Seeds

Flaked GC seeds (800 g) were pressed with a hydraulic press (B Sen Barry & Co., New Delhi, India) at a pressure of 10 tons for 10 min at room temperature. The oil obtained from the seeds was collected in a clean vessel, flushed with nitrogen and the weight of the oil was recorded. The oil was stored in polyethylene terephthalate (PET) bottles at −20 °C until further analysis.

Soxhlet Extraction (SOX) of GCO

Soxhlet extraction of the powdered GC seeds (100 g) was carried out in a Soxhlet apparatus using petroleum ether (60–80 °C) as solvent for 6 h. The extract was concentrated in a rotary evaporator (Buchi, Donau, Switzerland). The oil was flushed with nitrogen, weighed and stored at −20 °C until further analysis.

Supercritical Carbon Dioxide Extraction (SCE) of GCO

Supercritical CO2 extraction was performed using CO2 in a supercritical fluid extractor (Novaswiss, Switzerland). The system was operated in CO2 recycling mode. GC seed powder (1,000 g) was loaded into the 2-l capacity extractor vessel and extracted at 50 °C and at 250 bar using CO2 with a flow rate of 1 kg/min. The oil thus separated from CO2 was collected in a reduced-pressure receiver (50 bar and 40 °C). The collected oil was flushed with nitrogen, weighed and stored at −20 °C until further analysis.

Physical Properties of GCO

Colour

The oil colour was evaluated using a Hunter Lab Labscan XE spectrophotometer (Hunter Associates Laboratory Inc, Reston Virginia). Oils extracted by different methods (15 ml) were pipetted into a sample cup and the colour values were obtained using a 2°/C (2oobserver/illuminant C) [11].

Viscosity

Viscosity (η) was measured in a cone-and-plate geometry viscometer (Rheology International Model R: 3M). The instrument is calibrated with silicon oil to torque of 512 mPa. The shear stress (Γ) was obtained at a shear rate (γ) of 50 rpm. The η was calculated by determining the slope of the linear regression of Γ on γ utilising the statistical package STATISTICA v 5.1 (Statsoft, Tulsa, OK). The viscosity was reported in mPa s-1 at a temperature of 25 ± 2 °C.

Refractive Index

The refractive index was determined according to the AOCS official method [12] using an Abbe type refractometer (American Optical Corporation, Buffalo, NY) at 25 °C.

Specific Gravity

The specific gravity was measured in a 25-ml capacity specific gravity bottle at room temperature of 25 + 2 °C [13].

Chemical Properties of GCO

Free Fatty Acids

The free fatty acid content (FFA%) in GCO was determined according to the AOCS official method [14]. A 3–10 g amount of GCO was dissolved in 50 ml of ethanol and diethyl ether (1:1) mixture neutralised with 0.1 N KOH. This mixture was titrated against a 0.1-N NaOH solution using phenolphthalein (1%) as the indicator.

Peroxide Value (PV)

The peroxide value was determined according to the method described by the International Dairy Federation Standard Method [15]. GCO (0.1 g) was mixed with 9.8 ml of chloroform/methanol (70:30 v/v) mixture followed by the addition of 0.05 ml of ammonium thiocyanate solution (30 g/100 ml) and 0.05 ml of an iron (II) chloride solution. The iron (II) chloride solution was prepared by adding 0.4 g of barium chloride dihydrate and 0.5 g of iron sulphate solution in 50 ml distilled water. After 5 min of incubation at room temperature (25 ± 2 °C) in the dark, the absorbance of the sample was measured at 500 nm against a blank containing all the reagents except the oil sample in a UV visible spectrophotometer (Shimadzu Corporation, Japan). Hydroperoxides present in the oil oxidised Fe2+ to Fe3+ and the formed Fe3+ ions were quantified using a calibration curve of FeCl3 (2–20 μg).

The peroxide value was expressed as mequiv of peroxides/kg oil.

Saponification Value

The saponification value of GCO was determined according to the AOCS official method [16]. A known quantity of oil was saponified with alcoholic KOH for 1 h in a water bath. This solution was titrated against 0.1 N HCl using 1% phenolphthalein as the indicator.

Where B is the volume in ml required to titrate the blank; Sis the titer value of the sample; N is the normality of HCl; w is the weight of the sample in g.

Conjugated Dienes (CD)

The amount of conjugated dienes (CD) in GCO was determined according to the method of the IUPAC [17]. Oil samples (0.02–0.04 g) were weighed and dissolved in 25 ml of iso-octane (2,2,4-trimethylpentane), in volumetric flasks. The contents were mixed thoroughly and the absorbance was read at 234 nm using a UV–visible spectrophotometer (Shimadzu Corporation, Japan). Pure iso-octane was used as a blank. The amount of CD was calculated according to the following equation: CD = A/(C × d), where A = absorbance of the solution at 234 nm, C = concentration of the solution in g/100 ml solution, and d = length of the cell in cm.

Unsaponifiable Matter of GCO

The unsaponifiable matter content in GCO was measured according to the AOCS official method [18]. An oil sample (5 g) in 30 ml of absolute ethanol and 5 ml of 60% aqueous KOH was refluxed for 1 h followed by extraction of unsaponifiable matter using diethyl ether. The solvent was evaporated to dryness and the residue was desiccated and weighed.

Estimation of Fatty Acids in GCO

Fatty acid analysis of GCO was carried out by gas liquid chromatography method. Fatty acid methyl esters (FAME) were prepared according to the method of Morrison and Smith [19]. A GCO sample (10–20 mg) was saponified for 1 h with 1 ml of methanolic KOH (0.7 N) at 60 °C, followed by neutralisation with 1 ml of methanolic HCl (0.7 N). The resulting free fatty acids were extracted in hexane and evaporated to dryness. The fatty acids were methylated using boron trifluoride (14% in methanol) and 0.2 ml benzene. The FAME were extracted in hexane, washed with water and evaporated to dryness. Fatty acid analysis was performed using a gas–liquid chromatograph (Shimadzu, GC-14B, Shimadzu Corporation, Japan) fitted with a fused silica capillary column (BP 21: 30 m length, 0.30 mm i.d., 0.50 µm film thickness). The GC was equipped with a flame ionisation detector and Clarity Lite 420 integrator. The above mentioned analysis was carried out using isothermal conditions. The column temperature was set at 220 °C, the injector temperature at 230 °C and the detector temperature at 240 °C. Nitrogen was used as the carrier gas with a flow rate of 1 ml/min. Individual fatty acids in the sample were identified by comparison with the retention times of standard fatty acid methyl esters. The determinations were carried out in triplicate (n = 3).

Estimation of Tocopherols in GCO

GCO (1.0 g) was saponified with 4 ml of 5% ethanolic pyrogallol (w/v), 1 ml KOH (100%) and boiled in a water bath for 3 min. Samples were then cooled, 30 ml distilled water was added and the mixture was extracted three times with diethyl ether. The combined extracts were washed with water to neutralise and remove fatty acid soaps. The extract was dried with anhydrous sodium sulphate and evaporated to dryness under a vacuum at 40 °C. The residue was dissolved in 1.0 ml ethanol and 4.0 ml of benzene and dried under a stream of nitrogen. The residue was dissolved in 1.0 ml of ethanol and used for identification and quantification of tocopherol isomers by an HPLC method [20] using a Shimadzu LC 10AVP-HPLC system equipped with a fluorescence detector and Phenominix C18, column (250 × 4.60 mm, 5 µm). The excitation wavelength used was 290 nm and the emission wavelength was 330 nm. An isocratic elution program was employed using a mobile phase containing methanol: water (95:5, v/v). The flow rate was 1.0 ml/min. The individual tocopherol homologues were calculated based on the calibration curve of standards of α, γ and δ tocopherols. The determinations were carried out in triplicate (n = 3).

Estimation of Carotenoids in GCO

The major carotenoids in the oil samples (β-carotene, lutein and zeaxanthin) were measured according to the method described by Raju et al. [21]. A GCO sample (5.0 g) was refluxed with 25 ml ethanol and 5 ml of saturated KOH solution for 1 h. The mixture was extracted three times with hexane and diethyl ether (1:1). The pooled organic layer was washed with distilled water and dried with anhydrous sodium sulphate. The organic solvent was evaporated to dryness in a flash evaporator (Buchi, Switzerland). The unsaponifiable matter was suspended in ethyl acetate and the carotenoids were separated by an HPLC method using a Shimadzu HPLC system (LC-10) equipped with a PDA detector, a reverse phase Nucleosil ODS C18 column (250 × 4.6 mm, 5 μm particle size). The mobile phase consisted of mixtures of acetonitrile:water (9:1, v/v) with 0.25% triethylamine (A) and ethyl acetate with 0.25% triethylamine (B). The gradient was set at 90% of A at 0 min to 50% of A at 10 min. The percentage of A decreased from 50% at 10 min to 10% A at 20 min. The flow rate was 1 ml/min and the chromatogram was monitored at 450 nm. Identification of carotenoids was based on co-chromatography using standards and characteristics of UV–VIS spectra recorded by the PDA detector. The determinations were carried out in triplicate (n = 3).

Positional Distribution of the Fatty Acids in GCO

Hydrolysis of GCO oil by pancreatic lipase was performed according to the method described by Fayaz and Fereidoon (2005) [22]. GCO (0.025 g) was added to 5.0 ml of 1.0 M Tris HCl buffer (pH 8.0) containing 0.5 ml of calcium chloride (2.2%) and 1.25 ml of sodium taurocholate (0.05%) and heated at 40 °C for 1 min followed by the addition of 5 mg of porcine pancreatic lipase. The reaction mixture was incubated under nitrogen for 15 min at 40 °C in a shaking water bath. Ethanol (5.0 ml) was then added to the reaction mixture to stop the enzymatic reaction, followed by an addition 5 ml of 6 M HCl. The hydrolytic products in the mixture were extracted in hexane (50 ml) and washed two times with distilled water. Hexane was passed through a bed of anhydrous sodium sulphate and evaporated to dryness under stream of nitrogen. The hydrolytic products were separated by the TLC method. TLC plates were prepared by coating silica Gel G matrix over 20 × 20 glass TLC plates using automatic TLC plate coater (CAMAG, Switzerland). The thickness of the coating was 500 μm. The TLC plates were activated at 120 °C for 1 h prior to use. The hydrolytic products were spotted onto the TLC plates and developed using a solvent system of hexane/diethyl ether/acetic acid (70:30:1). TLC resolved the mixture of hydrolytic products into four major spots namely monoglycerides, diglycerides, free fatty acids and triglycerides. These spots were scraped and the lipids were extracted into methanol/chloroform (1:1 v/v). The FA profile of the lipids was analysed by gas liquid chromatography as described in the fatty acid analysis section. The monoglyceride spot was used to determine the sn-2 fatty acid composition and the free fatty acid spot was used to assess the fatty acid composition of sn-1 and sn-3 positions.

Oxidative Stability of GCO

GCO obtained by the cold press method was stored in screw-capped bottles in the dark, at room temperature (25 ± 2 °C) and at 4 °C. The progress of lipid peroxidation of the oil was assessed by measuring PV and CD as described above by drawing an aliquot of the sample and testing it every month for a period of 5 months.

Accelerated oxidative stability was carried out according to the method of Joyner et al. [23]. GCO extracted by the cold press method was subjected to accelerated oxidative stability studies in the presence and absence of 200 ppm of synthetic antioxidants viz., α-tocopherol, ascorbyl palmitate and BHT. Glass beakers containing duplicate samples of GCO (60 ml) covered with a petri dish were placed in an oven maintained at 60 ± 2 °C. The progress of lipid peroxidation of the GCO was assessed by measuring PV and CD as described above by drawing an aliquot of sample and testing it daily for 8 days.

Statistical Analysis

The results were analysed by using SPSS-10 software. Statistical differences between means were determined by ANOVA and Duncan’s test. P values of <0.05 were considered significantly different.

Results and Discussion

Colour is an important characteristic for determining the visual acceptance of the oil. The L, a, and b values of GCO are shown in Table 1. The negative ‘a’ value indicates the intensity of green colour, the positive ‘b’ value indicates yellow colour, while ‘L’ value is a measure of lightness of the oil. Soxhlet extracted oil was dark yellowish, while cold pressed oil showed a light yellowish colour. The seeds of the cruciferous family are known to contain chlorophyll and its derivatives [24] which could be extracted with the oil [25]. A linear correlation between the ‘a’ value and the total chlorophyll content of the oil has been reported [25]. Hence, the dark colour of solvent extracted oil in comparison to the cold pressed GCO, could be due to the pigments extracted along with the oil.

GCO was obtained by cold pressing (hydraulic pressing), solvent (soxhlet) extraction and supercritical CO2 extraction methods. The physicochemical properties of GCO extracted by the different methods are summarised in Table 2. The total oil content of solvent extracted GCO was 21.54%, supercritical CO2 extraction was 18.15% and cold expression was 12.60%. Maximum oil extraction was obtained by soxhlet method (21.54%). The oil content in GC seeds is relatively less compared to other edible oil seeds such as mustard (25–40%), rapeseed (40–45%) and camelina or false flax (40–45%) of Cruciferae family [26]. GCO has a typical smell of mustard oil but less pungent than mustard oil.

The PV and FFA values of the cold pressed GCO was lowest compared to the oils extracted by solvent and supercritical CO2 extraction (Table 2). The refractive index shows the degree of unsaturation and presence of unusual components such as hydroxyl groups [27]. The refractive index of GCO is within the range of edible oils (Table 2).

Supercritical CO2 extracted GCO showed the highest FFA value while cold pressed and soxhlet extracted oil showed lower FFA values. The acid value of GCO (Table 2) is in conformity with the specifications of edible oils (1–7% of oleic acid). The acid value depends on the extraction method adopted. A low acidity value characterises stability of an oil at room temperature (25 ± 2 °C).

The PV of GCO extracted by different methods is presented in Table 2. Cold pressed oil showed a low PV, while solvent extracted oil showed the highest PV. The high PV in soxhlet extracted oil could be due to the exposure of the oil to high temperature (60–80 °C) during extraction. The low PV of cold pressed GCO indicates that it is less prone to oxidative rancidity at room temperature. The viscosity of the oils obtained by the three methods varied from 53.8 to 64.3, respectively (Table 2). The cold pressed GCO was more viscous than the oil extracted by the other two methods.

The saponification value indicates the amount of saponifiable units (acyl groups) per unit weight of oil. A high saponification value indicates a higher proportion of low molecular weight fatty acids in the oil or vice versa. GCO showed a saponification value of 174.00–182.23 indicating that the oil contained high molecular weight mass fatty acids (Table 2). The saponification value of GCO (178.36) was lower than that of palm oil (196–205), olive oil (188–196), sunflower oil (186–196), soybean oil (188–195) and safflower oil (186–198) [28]. Unsaponifiable matter of GCO extracted by different methods varied between 1.16 and 1.65 g/100 g (Table 2).

The unsaponifiable matter content was higher in GCO compared to other oils such as sesame (1.2%), white melon (1.1%), corn (0.92%), cotton (0.52), palm (0.34%), peanut (0.33), palm kernel (0.22) and coco kernel (0.09) [29]. The high unsaponifiable matter in the cold pressed oil could be due to the presence of lignans (29.4%), crude fibre (16.5%), protein (24.3%) and minerals (5.4%) in GC seeds [30].

The iodine value (IV) is a measure of average unsaturation of an oil or fat. It depends on all unsaturated components in the oil. The IV of solvent extracted oil was relatively higher than cold pressed and supercritical fluid extracted GCO (Table 2). The unsaponifiable matter contains many olefinic compounds including carotenoids and squalenes having long chain of unsaturation.

The presence of these unsaturated components in oil affects its IV [31]. In our study, the solvent extracted oil contained a significantly higher amount of total carotenoids in comparison with the cold pressed oil. Thus, the higher carotenoid content might be responsible for a high IV in solvent extracted GCO.

The fatty acid profile of GCO is presented in Table 3. GCO showed a presence of eight major fatty acids namely palmitic acid, stearic acid, oleic acid, linoleic acid, linolenic acid, arachidic acid, eicosenoic acid and erucic acid (3.6–4.4%) (Table 3). The fatty acid composition of GCO reported in this study is in agreement with data reported earlier [32]. The saturated fatty acids (SFA) content was as low as 15.6% and the unsaturated fatty acids (UFA) content was as high as 84.4% in GCO. The PUFA/SFA (P/S) ratio ranged from 2.8 to 3.0 with an average value of 2.86. The n-6/n-3 ratio of the oil was found to be 0.31 and 0.34.

GCO contained 15.6% SFA, 37.6% MUFA and 46.8% PUFA unlike flax seed oil [28] which contains predominantly ω-3 PUFA (52.7%). Hence, flax seed oil is highly unstable and categorised as a drying oil. Camelina is another ω-3 rich oil seed having MUFA (32.8%) and PUFA (54.1%) [26] comparable to GCO. Camelina oil contains 30–40% of α-linolenic acid similar to GCO and has relatively high MUFA compared to flax seed oil. Erucic acid content in GCO was less than 5% and conforms to the WHO norms for erucic acid content in edible oils.

Fatty acids at stereo specific position on the glycerol backbone of GCO triglycerides are summarised in Table 4. α-Linolenic acid was the major fatty acid esterified at the sn-2 position, followed by oleic acid, linoleic acid, palmitic acid and arachidic acid in GCO. An increased bio-availability of α-linolenic acid and oleic acid can be expected since the sn-2 fatty acids are favored for absorption in the intestine [33]. An earlier study of ours showed that a dietary supplementation of GCO at 10% increased the tissue level of α-linolenic acid, EPA and DHA [34]. The distribution of palmitic acid at the sn-1 and sn-3 positions in GCO is in accordance with conventional edible oils. Erucic acid and arachidic acid in GCO were mainly esterified at the sn-1 and sn-3 positions along with other fatty acids. Low erucic acid content in GCO and its distribution mainly at sn-1 and sn-3 positions indicates that it is not readily absorbed. Our earlier study substantiated poor/no absorption of erucic acid in serum, liver, brain, heart and kidney when fed at the highest dose of GCO (10%) to experimental animals [34].

The total tocopherol content in cold pressed and Soxhlet extracted oil is presented in Table 5. The total tocopherol content was 268.06 μmol/100 g in cold pressed oil and 327.42 μmol/100 g in solvent extracted oil, respectively. A qualitative estimation of tocopherols in GCO by the HPLC method showed the presence of α, δ and γ-tocopherol, respectively (Table 5). Among them, γ-tocopherol is found to be the predominant tocopherol in GCO. γ-tocopherol content in vegetable oil is positively correlated with the amount of α-linolenic present in it [35].

The carotenoids contents of GCO samples extracted by different methods are summarised in Table 6. The total carotenoid content in GCO samples varied between 0.76 and 1.0 μmol/100 g. Solvent extracted GCO had the highest amount of total carotenoids and β-carotene was found to be the major carotenoid in GCO.

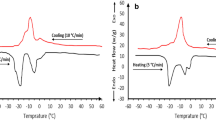

The storage stability of cold pressed GCO stored at room temperature (25 ± 2 °C) and at 4 °C is presented in Figs. 1 and 2. A steady increase in PV and percentage CD levels was noticed in GCO stored at room temperature. However, the PV and percent CD levels were maintained at low level at 4 °C compared to that stored at room temperature. At 4 °C, the PV and percentage CD levels were 4 times lower than that of oil stored at room temperature indicating that GCO is relatively stable at refrigerated temperatures.

The effect of individual synthetic antioxidants viz., α-tocopherol, ascorbyl palmitate, BHT at 200 ppm and a combination of α-tocopherol and ascorbyl palmitate at 200 ppm on PV and CD levels were measured by heating the oil continuously for 7 days at 60 ± 2 °C in an oven. As shown in Figs. 3 and 4, among the antioxidants tested, ascorbyl palmitate gave the maximum protection against oxidation of the oil followed by the combination of α-tocopherol and ascorbyl palmitate (Figs. 3, 4). Individually, both BHT and α-tocopherol did not protect GCO against lipid peroxidation.

This is the first report on the physicochemical properties of GCO. Our studies have shown that GCO is rich in α-linolenic acid (34.5%) which is esterified at the sn-2 position of triglyceride. GCO has a good amount of PUFA and MUFA. The oil is fairly stable at refrigerated temperatures and the natural antioxidants tocopherol and carotenoids present in it protect the oil from rancidity. GCO can be considered as a potential, alternate and non-conventional seed oil for ω-3 fatty acids and can be blended with suitable edible oils or in the form of a supplement to increase ω-3 fatty acids in functional foods.

References

Nadkarni AK (1954) Indian Meteria Medica, with ayurvedic, unani-tibbi, siddha, allopathic, homeopathic, naturopathic and home remedies, appendices and indexes. 3rd edn. Dhootapeshwar Prakashan Ltd. Panvel pp 736–737

Kirthikar KR (1952) Lepidium sativum L. In: Kirthikar KR, Basu BD (eds), In: Indian Medicinal Plants 1: Lalith Mohan Basu. India pp 174–175

Uphof JCT (1959) Dictionary of economic plants, 2nd edn. Hafner Publishing, New York, p 308

Lotfy M, Aref H, Hussein AA (1957) The antioxidant properties of garden cress (Lepidium sativum) and wild mustard (Sinapsis arvensis) Oils. J Am Oil Chem Soc 34:96–100

Anonymous (1972) The Wealth of Indian Raw Materials Publication and information Directorate, vol 9. CSIR, New Delhi pp 71–72

Gil V, MacLeod AJ (1980) Studies on glucosinolate degradation in Lepidium sativum L. seed extracts. Phytochem 19:1369–1374

Kassie F, Rabot S, Uhl M, Huber W, Qin HM, Helma C, Hermann RS, Knasmüller S (2002) Chemoprotective effects of garden cress (Lepidium sativum) and its constituents towards 2-amino-3-methyl-imidazo[4, 5-f]quinoline (IQ)-induced genotoxic effects and colonic preneoplastic lesions. Carcinogenesis 23:1155–1161

Archana NP, Anita AM (2006) A study on clinical efficacy of Lepidium sativum seeds in treatment of bronchial asthma. Iran J Pharmacol Ther 5:55–59

Eddouks M, Maghrani M, Zeggwagh NA, Michel JB (2005) Study of the hypoglycaemic activity of Lepidium sativum L. aqueous extract in normal and diabetic rats. J Ethnopharmacol 97:391–395

Gupta S (2007) Effect of nutrients and plant density on growth and yield of garden cress (Lepidium sativum L.) M.Sc., Dissertation, University of Agricultural Sciences, Bangalore

Khan MI, Asha MR, Bhat KK, Khatoon S (2008) Studies on quality of coconut oil blends after frying potato chips. J Am Oil Chem Soc 85:1165–1172

AOCS (1998) Refractive index. Official methods and recommended practices of the American Oil Chemists’ Society, 5th edn. AOCS Press Champaign, Illinois

AOCS (1998) Specific gravity, refractive index. Official methods and recommended practices of the American Oil Chemists’ Society, 5th edn. AOCS Press Champaign, Illinois

AOCS (1998)Free fatty acids, refractive index. Official methods and recommended practices of the American Oil Chemists’ Society, 5th edn. AOCS Press Champaign, Illinois

International IDF standards International Dairy Federation, IDF-Square Vergote 41, Brussels, Sec. 74A: 1991

AOCS (1998) Saponification value. Official methods and recommended practices of the American Oil Chemists’ Society, 5th edn. AOCS Press Champaign, Illinois

Paquot C, Hanfenne A (1987) IUPAC standard methods for analysis of oils, fats and derivatives, 7th edn. International Union of Pure and Applied Chemistry, Blackwell Scientific, Oxford, pp 210–211

AOCS (1998) Unsaponifiable matter. Official methods and recommended practices of the American Oil Chemists’ Society, 5th edn. AOCS Press Champaign, Illinois

Morisson WR, Smith LM (1964) Preparation of fatty acid methyl esters and dimethylacetals from lipids with boron fluoride methanol. J Lipid Res 5:600–608

Hatman LJ, Kayden HJ (1979) A high performance liquid chromatographic method for the determination of tocopherol in plasma and cellular elements of the blood. J Lipid Res 20:639–645

Raju M, Varakumar S, Lakshminarayana R, Krishnakantha TP, Bhaskaran V (2007) Carotenoid composition and vitamin A activity of medicinally important green leafy vegetables. Food Chem 101:1598–1605

Fayaz H, Fereidoon S (2005) Structured lipids from high laurate canola oil and long chain omega-3 fatty acids. J Am Oil Chem Soc 82:731–736

Joyner NT, McIntyre JE (1938) The oven test as an index of keeping quality. Oil Soap 15:184–186

Appelquist LA (1971) Composition of seeds of Cruciferae oil crops. J Am Oil Chem Soc 48:851–859

Sinnecker P, Gomes MSO, Jose AGA, Lanfer-Marquez UM (2002) Relationship between color (instrumental and visual) and chlorophyll contents in soybean seeds during ripening. J Agric Food Chem 50:3961–3966

Budin JT, Breene WM, Putnam DH (1995) Some compositional properties of Camelina (Camelina sativa L. Crantz) seeds and oils. J Am Oil Chem Soc 72:309–315

Pearson D (1981) The chemical analysis of foods, 7th edn. Churchill Livingstone, Edinburgh, pp 504–530

White PJ (2007) Fatty acids in oils and seeds (vegetable oils). In: Chow CK (ed) Fatty acids in food and their health implications, 3rd edn. CRC Press, Florida, pp 228–229

Kapseu C, Parmentier M (1997) Fatty acid composition of some vegetable oils from Cameroon. Sci Aliments 17:325–331

Mathews S, Singhal RS, Kulakrni PR (1993) Some physicochemical characteristics of Lepidium sativum (haliv) seeds. Nahrung 1:69–71

Knothe G (2002) Structure indices in FA chemistry. How relevant is the iodine value? J Am Oil Chem Soc 79:847–854

Sumangala SG, Malleshi NG, GUO M (2004) Chemical composition of garden cress (Lepidium sativum) seeds and its fractions and use of bran as a functional ingredient. Plant Foods Hum Nutr 59:105–111

Aoyama T, Fukui K, Taniguchi K, Nagaoka S, Yamamoto T, Hashimoto Y (1996) Absorption and metabolism of lipids in rats depend on fatty acid isomeric position. J Nutr 126:225–231

Diwakar BT, Dutta PK, Lokesh BR, Naidu KA (2008) Bio-availability and metabolism of n-3 fatty acid rich garden cress (Lepidium sativum) seed oil in albino rats. Prostaglandins Leukot Essent Fatty Acids 78:123–130

Kamal-Eldin A, Anderson R (1997) A multivariate study of the correlation between tocopherol content and fatty acid composition in vegetable oils. J Am Oil Chem 74:375–380

Acknowledgements

The authors thank Dr. V. Prakash, Director, CFTRI, and Dr. P.V. Salimath, Head of the Department of Biochemistry and Nutrition, for their encouragement and support. Dr. K. Uday Shankar, Food Engineering Department, CFTRI, is acknowledged for his technical help in conducting supercritical CO2 extraction experiments. KAN gratefully acknowledges the financial assistance in the form of a project from the Indian Council of Medical research (ICMR), New Delhi. Financial support to Mr. B.T. Diwakar through Senior Research Fellowship from Council for scientific and Industrial Research (CSIR), New Delhi, India is also gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Diwakar, B.T., Dutta, P.K., Lokesh, B.R. et al. Physicochemical Properties of Garden Cress (Lepidium sativum L.) Seed Oil. J Am Oil Chem Soc 87, 539–548 (2010). https://doi.org/10.1007/s11746-009-1523-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-009-1523-z