Abstract

Coconut (Cocos nucifera) contains 55–65% oil, having C12:0 as the major fatty acid. Coconut oil has >90% saturates and is deficient in monounsaturates (6%), polyunsaturates (1%), and total tocopherols (29 mg/kg). However, coconut oil contains medium chain fatty acids (58%), which are easily absorbed into the body. Therefore, blends of coconut oil (20–80% incorporation of coconut oil) with other vegetable oils (i.e. palm, rice bran, sesame, mustard, sunflower, groundnut, safflower, and soybean) were prepared. Consequently, seven blends prepared for coconut oil consumers contained improved amounts of monounsaturates (8–36%, p < 0.03), polyunsaturates (4–35%, p < 0.03), total tocopherols (111–582 mg/kg, p < 0.02), and 5–33% (p < 0.02) of DPPH (2,2-diphenyl-1-picrylhydrazyl free radicals) scavenging activity. In addition, seven blends prepared for non-coconut oil consumers contained 11–13% of medium chain fatty acids. Coconut oil + sunflower oil and coconut oil + rice bran oil blends also exhibited 36.7–89.7% (p < 0.0005) and 66.4–80.5% (p < 0.0313) reductions in peroxide formation in comparison to the individual sunflower oil and rice bran oil, respectively. It was concluded that blending coconut oil with other vegetable oils provides medium chain fatty acids and oxidative stability to the blends, while coconut oil will be enriched with polyunsaturates, monounsaturates, natural antioxidants, and a greater radical scavenging activity.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Coconut oil is a clear edible oil with a characteristic sweet smell and has been consumed in tropical places for thousands of years [1]. Coconut oil, because of its long shelf life and melting point of 24.4 °C, was frequently used in the baking industry in western countries as well. However, a negative campaign against saturated fats and tropical oils resulted in the replacement of coconut oil with hydrogenated fats [1]. Coconut oil is rich in saturated fatty acids (SFA) (≈93%). However, coconut oil also contains medium chain fatty acids (MCFA) (≈60%), especially C12:0 (≈50%). MCFAs (C6:0, C8:0, C10:0, C12:0) are smaller than the standard storage unit of fat (C14), and hence are burnt for energy rather than stored in the body [2]. Consumption of a diet rich in medium chain triglycerides (MCT) improves upper body adiposity in overweight men, hence MCT may be considered as a potential tool in the prevention of weight gain and obesity [3]. C12:0 (≈ 50%) and C10:0 (≈ 6%), which are found in coconut oil in major amounts, are known for their unique antiviral, antibacterial,, and antiprotozoal properties. Lauric acid in coconut oil becomes 2-mono-laurin in the gut and dissolves the lipid envelope that protects most pathogenic bacteria and viruses. It also attacks pathogenic yeast and parasites [4]. Research has also shown that natural coconut oil in the diet leads to a normalization of body lipids, protects against alcohol damage to the liver,, and improves the immune system’s anti-inflammatory response [5].

Coconut oil is mainly consumed by the people of the coastal regions of India. Coconut oil is very stable against oxidation and hence not prone to peroxide formation. Therefore, the incorporation of coconut oil to other oxidation susceptible vegetable oils increases the stability of the blends. The prolonged use of coconut oil for cooking by coconut oil consumers make their diets deficient in polyunsaturates (PUFA), monounsaturates (MUFA), and natural antioxidants which are present in other vegetable oils. On the other hand, the non-coconut oil consumers are deprived of the health benefits as well as the oxidative stability of the MCFA present in coconut oil. In addition, coconut oil is an expensive oil and blending it with other lower cost vegetable oils will produce lower cost coconut oil blends. The objective of this work was to prepare healthier and lower cost blends of coconut oil for both coconut oil and non-coconut oil consumers and also to study the composition, stability, and antioxidant activity of these blends having coconut oil as the major, equal or minor component.

Experimental Procedures

Materials

Three different batches of all the commercial oil samples of raw coconut oil (expelled from dry coconut)/copra oil (CNO), refined, bleached, and deodorized coconut oil (RCNO), refined sunflower oil (SFO), refined safflower oil (SAFO), refined soybean oil (SBO), refined palm oil (PO), refined rice bran oil (RBO), raw groundnut oil (GNO), raw mustard oil (MO), and raw sesame oil (SESO) were procured from a local supermarket in Mysore. tert-Butyl hydro quinone (TBHQ) was procured from Loba Chemie, Mumbai, India. 2,2-diphenyl-1-picryl hydrazyl free radicals (DPPH) and sesamin were procured from the Sigma Chemical Co., St. Louis, USA. Sesamol was procured from Spectrochem Pvt. Ltd., Mumbai, India. The other chemicals and reagents used for analysis were of analytical reagent grade.

Methods

Preparation of Blends

A 100 g mixture of CNO and other vegetable oil were placed in 250-ml beakers in duplicate for each blend and were mixed by using a mechanical stirrer at 180 rpm for 15 min. The temperature during mixing was 65 °C. Sixty different blends having various proportions of CNO and other vegetable oils were prepared in this manner and the coconut oil aroma for each blend was evaluated on a five-point hedonic scale by a panel of ten judges and monitored by the same panel for a period of 8 months.

Blends for coconut oil consumers: Coconut oil consumers prefer a strong coconut oil aroma in their food. Therefore, the blends for them were prepared by using CNO. The basis of selection of seven blends for coconut oil consumers was a combination of three factors: (1) presence of strong coconut oil aroma, (2) presence of adequate amounts of MUFA, PUFA, and natural antioxidants, (3) lower cost of the blend when compared to CNO only. The seven blends selected for coconut oil consumers were 20% CNO + 80% SFO, 50% CNO + 50% RBO, 80% CNO + 20% SAFO, 80% CNO + 20% SESO, 50% CNO + 50% GNO, 50% CNO + 50% PO, 20% CNO + 80% PO. These blends were analyzed for fatty acid composition, natural antioxidants content, and radical scavenging activity.

Blends for non-coconut oil consumers: Non-coconut oil consumers are generally averse to the coconut oil aroma in their food. Therefore, the blends for them were prepared by using refined, bleached, and deodorized coconut oil (RCNO). The minimum level of incorporation of an oil is 20% in an oil blend as per the rules of Prevention of Food Adulteration Act (PFA) in India. Also, the incorporation of RCNO (to an extent of 20%) to another lower cost vegetable oil would minimally increase the cost of the oil blend but still provide the health benefits of MCFA and its oxidative stability. The seven blends prepared for non-coconut oil consumers were 20% RCNO + 80% SAFO, 20% RCNO + 80% SFO, 20% RCNO + 80% RBO, 20% RCNO + 80% SBO, 20% RCNO + 80% GNO, 20% RCNO + 80% SESO, 20% RCNO + 80% MO. These blends were analyzed for fatty acid composition, natural antioxidants content, and radical scavenging activity.

Fatty Acid Composition by Gas Chromatography

Fatty acid methyl esters (FAME) of the oil samples were prepared by transesterification, according to AOCS Method No: Ce 1-62, 1998 [6]. FAMEs were analyzed on a Fisons 8000 series gas chromatograph (Fisons Co., Italy), equipped with a hydrogen flame ionization detector (FID) and a fused silica capillary column (100 m × 0.25 mm i.d.), coated with 0.20 μm SP2560 (Supelco Inc., Bellefonte, PA) as the stationary phase. The oven temperature was programmed from 140 to 240 °C at 4 °C/min with an initial hold at 140 °C for 5 min. The injector and FID were at 260 °C. A reference standard FAME mix (Supelco Inc.) was analyzed under the same operating conditions to determine the peak identity. The FAMEs were expressed as relative area percentage.

Oxidative Stability Measurement

Blends of CNO with SFO in the ratio of 80:20, 50:50, 40:60, 30:70, and 20:80, respectively, and CNO with RBO in the ratio of 40:60, 30:70, and 20:80, respectively, were prepared in 100 g × 2 batches as described under “Methods”. Each blend (40 g × 2) along with individual samples (40 g × 2) of CNO, SFO,, and RBO was placed in beakers (50-ml capacity) and incubated at 37 °C and 55% RH in a lab incubator to study the oxidative stability of the blends over a period of 6 weeks (42 days). Also, GNO and SFO + 200 ppm TBHQ, as two positive controls, were also incubated simultaneously under similar conditions. Samples (2 g × 2) were withdrawn at weekly intervals and analyzed for their peroxide value as per AOCS Method No: Cd 8-53, 1997 [7].

Natural Antioxidants in the Oil Blends

The total tocopherol content was determined by using IUPAC Method No. 2.301, 1987 [8]. Oryzanol content in RBO and its blends was determined by a spectrophotometric method [9] by dissolving 0.01 g of the sample in 10 ml of hexane and reading the absorbance at 314 nm in a 1-cm cell (double beam UV–visible recording spectrophotometer model UV-1601, Shimadzu corporation, Kyoto, Japan). The oryzanol content was calculated by using the formula:

where A is the absorbance of the sample, W is the weight of the sample in gram/100 ml, 358.9 is E 1%1cm for oryzanol.

Analysis of lignans in SESO and its blends was performed by HPLC (model LC-10A VP Shimadzu corporation, Kyoto, Japan) equipped with a UV-detector (290 nm) on a C18 phenomenex column (250 mm length × 4.6 mm i.d.) using 70% methanol as the mobile phase according to Kamal Eldin and Appelqvist [10]. Standard sesamol and sesamin were used for the quantitation of lignans in the sample.

Radical Scavenging Activity (RSA) toward DPPH Radicals

RSA and the presence of hydrogen donors in the prepared oil blends were examined by reduction of DPPH radicals in toluene. A toluenic solution of DPPH radicals was freshly prepared at a concentration of 10−4 M according to Ramadan et al. [11] with minor modifications. The oil samples (50 ± 1 mg) were placed in test tubes and a 4-ml aliquot of DPPH toluenic solution was added and vortexed for 20 s at ambient temperature. Against a blank of pure toluene without DPPH radicals, the decrease in the absorption at 515 nm was measured in a 1-cm quartz cell after 1, 30, and 60 min of mixing, using a UV-visible spectrophotometer (model UV-1601, Shimadzu corporation, Kyoto, Japan). RSA toward DPPH radicals was estimated from the differences in absorbance of toluenic DPPH solution with or without sample (control) and the inhibition percent was calculated using the following equation:

Statistical Analysis

All the determinations were carried out in triplicate and the results are given as means ± standard deviation. The mean, standard deviation, correlation coefficient values, and ANOVA (two-tailed P value) were calculated by using the statistical package, GraphPad Instat Demo [DATASET1.ISD] [12].

Results and Discussion

Fatty Acid Composition

The fatty acid composition of CNO and other vegetable oils is given in Table 1. CNO is rich in MCFA (59.7%) while other vegetable oils are deficient in MCFA (0%). On the other hand, CNO is deficient in PUFA (1.2%) and MUFA (6.1%) while other vegetable oils are rich in MUFA (18.7–65.8%) and PUFA (7.8–71.1%).

The fatty acid composition of the blends for coconut oil consumers is given in Table 2. The data indicated that these blends were significantly enriched with MUFA and PUFA (from 6.1 and 1.2% in coconut oil) to the extent of 7.9–36.3% (P value < 0.03) and 4.4–35.6% (P value < 0.03), respectively. The benefits derived through blending of CNO for the coconut oil consumer were the improved amounts of natural antioxidants, cholesterol-lowering substances like oryzanol [13, 14], lignans [15] as well as PUFA and MUFA incorporated in the blend which were absent in CNO. These blends may help in reducing low-density lipoprotein cholesterol in the body [16].

The fatty acid composition of the blends for non-coconut oil consumers is given in Table 3. These blends were enriched with MCFA from RCNO and thus the MCFA content (0% in other vegetable oils) increased to 11.3–13.2% in the blends. P value < 0.0025 indicated a significant improvement in SFA content [containing MCFA (30–48% of total SFA content)] after the treatment (blending) in the blends for non-coconut oil consumers, in comparison to control (corresponding constituent vegetable oil other than RCNO). Although there was a marginal decrease (18–20%) in MUFA and PUFA, the blends contained good amounts of MUFA (16.0–49.6%) and PUFA (22.7–55.1%). The benefits derived through blending vegetable oils with RCNO for the non-coconut oil consumer were incorporation of the MCFA and improved oxidative stability, without imparting any coconut oil flavor/aroma to the blends. These blends might also show 13% of the fat not being deposited in the body (due to the presence of 20% of coconut oil) [2, 3, 17–19].

Oxidative Stability

Earlier reports on the oxidative stability of individual oils and oil blends indicated that apart from inherent natural antioxidants in oil, PUFA content is an important factor influencing their oxidative stability. Oxidative stability index (OSI) is inversely proportional to PUFA content and the oxidative stability of high PUFA oil can be increased by blending with high MUFA oil [20, 21]. In other words, if the PUFA content of oil is reduced through blending with MUFA, MCFA or SFA, the oxidative stability of the blend would increase and the same has been attempted by incorporation of CNO to other vegetable oils. Figures 1 and 2 illustrate the oxidative stability of the CNO and its blends. CNO was less prone to peroxide formation, while SFO, GNO, and RBO had greater rates of peroxide formation in the order of RBO < GNO < SFO. On the other hand, peroxide values of the SFO + CNO and RBO + CNO blends decreased with increase in CNO concentration of the blends thus indicating that CNO provided oxidative stability to its blends (Figs. 1, 2). CNO, to a certain extent inhibited peroxide formation in the oil blends. The SFO + CNO blends had significant reduction (P value < 0.0005) in peroxide formation by 36.7–89.7% over a period of 42 days in comparison to the individual SFO, while RBO + CNO blends had significant reduction (P value < 0.0313) in peroxide formation by 66.4–80.5% over a period of 42 days in comparison to the individual RBO.

TBHQ had a greater inhibitory effect against peroxide formation than CNO (Fig. 1). In RBO + CNO blends, it was observed that there was a slight increase in the peroxide values while 100% RBO had a markedly high peroxide value during the same period (Fig. 2). Therefore, it can be concluded that the presence of CNO in the oil blends was responsible for the decrease in the rate of peroxide formation (Figs. 1, 2).

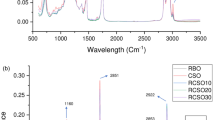

Natural Antioxidants and Their Radical Scavenging Activity

The term “natural antioxidants” collectively refers to total tocopherols (in all vegetable oils), oryzanol (in RBO), and lignans (in SESO). The natural antioxidans content and radical scavenging activity (RSA) of CNO and other vegetable oils is given in Table 4. CNO had a very low content of natural antioxidants (29 mg/kg) and hence a very low RSA (2.8%) while other vegetable oils had high amounts of natural antioxidants (467–1169 mg/kg) and hence had high RSA (24.1–54.4%). The total tocopherols content and DPPH scavenging activity of CNO and other vegetable oils correlated well (r = 0.97). Moreover, RBO and SESO also contained unique antioxidant substances i.e., oryzanol (2,800 mg/kg) and lignans (10,688 mg/kg), respectively, but the role of oryzanol in RBO and lignans in SESO in scavenging DPPH radicals could not be understood clearly.

The total tocopherols content and RSA of blends for coconut oil consumers and non-coconut oil consumers is also given in Table 4. The total tocopherols content in blends for coconut oil consumers significantly increased (P value < 0.02) from 29 (in CNO) to 111–582 mg/kg (in the blends) and hence there was an significant increase (P value < 0.02) in the DPPH scavenging activity of the blends by 5.5–33.4%, far better than a meager 2.8% activity showed by 100% CNO. The CNO + RBO blend apart from containing 387 mg/kg total tocopherols also contained 1,300 mg/kg oryzanol which might have also contributed to the scavenging of DPPH radicals to an extent of 28%. Similarly, CNO + SESO blend apart from containing 111 mg/kg total tocopherols also contained 2,137 mg/kg lignans which might not have contributed to the scavenging of DPPH radicals, since the activity was only 5.5%. The DPPH scavenging activity of the blends was found to increase with the increase in total tocopherols content in the blend and the total tocopherols content and DPPH scavenging activity correlated well (r = 0.96). The total tocopherols contents of the blends (367–929 mg/kg) for non-coconut oil consumers decreased (P value < 0.0025) by 20–25% when compared with those of individual vegetable oils (497–1,169 mg/kg), but still these blends exhibited good DPPH scavenging activity (19.9–48.9%). The CNO + RBO and CNO + SESO blends, apart from containing 626 and 451 mg/kg total tocopherols, respectively, also contained oryzanol (2,250 mg/kg) and lignans (8,550 mg/kg), respectively. However, the contribution by oryzanol and lignan in scavenging DPPH radicals to the extent of 43.3 and 23.2%, respectively, is still to be explored. The DPPH scavenging activity of the blends was found to increase with the total tocopherols content in the blends and correlated very well (r = 0.97).

The DPPH radical quenching ability of individual oils was found to be in the order RBO > SFO > GNO > CNO. RSA of SFO + CNO blends and RBO + CNO blends significantly increased to 7.2–27.4% (P value < 0.03) and 39.5–49.4% (P value < 0.0005), respectively, in comparison to 100% coconut oil which showed a RSA of only 2.9% (Figs. 3, 4). The DPPH scavenging activity of the SFO + CNO blends increased with the successive decrease in CNO concentration which suggested that addition of SFO to CNO results in a greater RSA than 100% CNO (Fig. 3).

The DPPH scavenging activity of the RBO + CNO blends increased with the successive decrease in CNO concentration which suggested that addition of RBO to CNO resulted in a greater RSA than 100% CNO. The RBO + CNO blend even having 40% CNO had greater DPPH scavenging activity (39.5%) than 100% GNO (24.3%) (Fig. 4).

It was found that the oxidative stability of oil blends depended upon the PUFA and MUFA content of the oil blends. The higher the PUFA and MUFA content, the lower would be the oxidative stability, while the radical scavenging activity of oil blends depended upon the total tocopherols content. The higher the total tocopherols content the higher the DPPH scavenging activity would be.

PO, SFO, and RBO are lower cost oils, therefore blending them with CNO produced lower cost blends (i.e. 50% CNO + 50% PO; 20% CNO + 80% PO; 20% CNO + 80% SFO; 50% CNO + 50% RBO). RBO and SESO contained oryzanol and lignans, respectively, while SFO and SAFO contained large amounts of MUFA and PUFA, respectively, therefore blending them with CNO produced MUFA-, PUFA-, and antioxidants enriched blends (i.e. 50% CNO + 50% RBO; 80% CNO + 20% SESO; 20% CNO + 80% SFO; 80% CNO + 20% SAFO). CNO is rich in MCFA and is a very stable oil with a long shelf life. Therefore, even minor incorporation (20%) of RCNO to other vegetable oils produced blends having moderate amounts of MCFA (11–13%) and greater oxidative stability without interfering with the flavor of other vegetable oils. Therefore, blends for coconut oil consumers contained more natural antioxidants, PUFA, MUFA and were able to scavenge DPPH radicals to a greater extent. These blends were also lower cost than CNO. The blends for non-coconut oil consumers had balanced fatty acid composition of SFA, MCFA, MUFA, and PUFA and were more stable against oxidation than the corresponding individual vegetable oils.

References

Enig MG, Atal S, Sampugna J, Keeney M (1990) Isomeric trans fatty acids in the US diet. J Am Coll Nutr 9:471–486

Kiyasu JY, Bloom B, Chaikoff IL (1952) The portal transport of absorbed fatty acids. J Biol Chem 199:415–419

St-Onge MP, Ross R, Parsons WD, Jones PJ (2003) Medium-chain triglycerides increase energy expenditure and decrease adiposity in overweight men. Obes Res 11:395–402

Enig MG (1998) Lauric oils as antimicrobial agents: theory of effect, scientific rationale, and dietary applications as adjunct nutritional support for HIV-infected individuals. In: Watson RR (ed) Nutrients and foods in AIDS. CRC Press, Boca Raton, pp 81–97

Enig MG (1993) Diet, serum cholesterol and coronary heart disease. In: Mann GV (ed) Coronary heart disease: the dietary sense and nonsense. Janus Publishing, London, pp 36–60

Firestone D (ed) (1998) Method no: Ce1-62. Official methods and recommended practices of the American Oil Chemists Society, 5th edn, AOCS press, USA

Firestone D (ed) (1997) Method no: Cd 8-53. Official methods and recommended practices of the American Oil Chemists Society, 5th edn, AOCS press, USA

Paquot C, Havtfenne A (eds) (1987) IUPAC method no. 2.301. Standard methods for analysis of oils, fats and derivatives. International Union of Pure and Applied Chemistry, 7th edn. Blackwell, Oxford, pp 174–182

Gopala Krishna AG, Hemakumar KH, Khatoon Sakina (2006) Study on the composition of rice bran oil and its higher free fatty acids value. J Am Oil Chem Soc 83:117–120

Kamal-Eldin A, Appelqvist LA (1994) Variations in the composition of sterols, tocopherols and lignans in seed oils from four Sesamum species. J Am Oil Chem Soc 71:149–156

Ramadan MF, Kroh LW, Morsel JT (2003) RSA of black cumin (Nigella sativa L.), coriander (Coriandrum sativum L.) and niger (Guizotia abyssinica Cass.) crude seed oils and oil fractions. J Agric Food Chem 51:6961–6969

GraphPad Instat Demo: [DATASET1.ISD]. http://www.graphpad.com, GraphPad Software Inc., USA

Seetharamaiah GS, Chandrashekara N (1988) Hypocholesterolemic activity of oryzanol in rats. Nutr Reports Intern 38:927–935

Seetharamaiah GS, Chandrashekara N (1989) Studies on hypocholesterolemic activity of rice bran oil. Atherosclerosis 78:219–223

Namiki M (2007) Nutraceutical functions of sesame: a review. Crit Revs Food Sci Nutr 47:651–673

Wahida Karmally RD (2005) Balancing unsaturated fatty acids: what’s the evidence for cholesterol lowering. J Am Diet Assoc 105:1068–1070

Ruppin DC, Middleton WRJ (1980) Clinical use of medium chain triglycerides. Drugs 20:216–224

Kabara JJ (1975) Fatty acids and derivatives as antimicrobial agents. US patent No. 4002775, 21 May 1975

Bourque C, St-Onge MP, Papamandjaris AA, Cohn JS, Jones PJ (2003) Consumption of an oil composed of medium chain triacyglycerols, phytosterols, and N-3 fatty acids improves cardiovascular risk profile in overweight women. Metabolism 52:771–777

Chu Yan-Hwa, Kung Yu-Lang (1998) A study on vegetable oil blends. Food Chem 62:191–195

Frankel EN, Huang SW (1994) Improving the oxidative stability of polyunsaturated vegetable oils by blending with high-oleic sunflower oil. J Am Oil Chem Soc 71:255–259

Acknowledgments

Authors are thankful to Dr. V. Prakash, Director, CFTRI, Mysore, for providing infrastructural facilities, Coconut Development Board, Kochi, for funding the project and Dr. B.R. Lokesh, Head, LSTF Dept., for useful discussions on nutritional aspects of coconut oil.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Bhatnagar, A.S., Prasanth Kumar, P.K., Hemavathy, J. et al. Fatty Acid Composition, Oxidative Stability, and Radical Scavenging Activity of Vegetable Oil Blends with Coconut Oil. J Am Oil Chem Soc 86, 991–999 (2009). https://doi.org/10.1007/s11746-009-1435-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-009-1435-y