Abstract

The rheology of organogels developed by candelilla wax (CW) and a pure n-alkane (dotriacontane, C32) was evaluated with a rheometer equipped with a true-gap system and compared with the rheograms obtained with a fixed-gap system. The two systems used a cone and plate geometry. In contrast to the fixed-gap system, the true-gap system makes the corrections in the gap size associated with the expansion/shrinkage of the sample and/or the rheometer geometry when changing temperature conditions are used during measurements. The CW and C32 organogels were prepared using safflower oil high in triolein (SFO) as the liquid phase, and the treatments studied resulted from the factorial combinations of two levels of gelator concentration (1 and 3%) and two gel setting temperatures (T set; 5 and 25 °C) achieved using a cooling rate of 1 or 10 °C/min. The use of the true-gap system provided rheological parameters (i.e., G′ profiles) that agreed with the micro structure and the calorimetric (i.e., heat of melting, ΔH M) behavior of both the CW and the C32 organogels. The use of a fixed-gap system in the rheological characterization of organogels must be treated with caution, specially with time dependent G′ determinations involving the use of fast temperature ramps (i.e., 10 °C/min).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

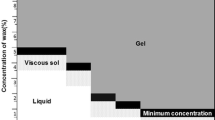

During recent years, organogels developed with low molecular weight compounds, such as fatty acids and n-alkanes, have received a great deal of attention mainly because these molecules require only a small concentration (≤2%) to achieve gelation [1–4]. However, very little is known about their rheological properties as affected by different time–temperature conditions. Rogers and Marangoni [5, 6] studied the effect of cooling rate and type of solvent on the non-isothermal nucleation and crystallization kinetics of organogels made with 12-hydroxystearic acid. These authors observed that cooling rates lower than 5 °C/min resulted in organogels with few crystal nuclei that grew large and showed very little branching. In comparison, the organogels developed at cooling rates higher than 5 °C/min showed higher nucleation and a highly branched fibrillar network [5]. Since crystal size, branching, and junction zones among fibers that form the three-dimensional network determine the gel rheological properties [7], Rogers and Marangoni [5] proposed that the organogel’s elasticity might be engineered through the control of variables that establish nucleation and its kinetics such as cooling rate. Unfortunately, Rogers and Marangoni [5, 6] did not evaluate the cooling rate effect on the rheological properties of the 12-hydroxystearic acid organogels.

Within this context, the rheological behavior of n-alkane based organogels was investigated recently using candelilla wax (CW) and dotriacontane (C32) as gelling agents and high-triolein safflower oil as the liquid phase [8]. C32 (C32H66) was used in its pure form (≈99.0%), while CW was a mixture of n-alkanes with uneven carbon number (C29H60, ≈4.2%; C33H68, ≈8.0%) and alcohols of penta-cyclic triterpenoids (≈7.4%) with hentriacontane (C31H64) as its main component (≈79%) [8]. The rheological profiles of CW and C32 organogels, developed at two gel setting temperatures (5 and 25 °C) achieved using a cooling rate of 1 or 10 °C/min, were determined with a mechanical spectrometer (Paar Physica UDS 200; Stuttgart, Germany) using a cone (50 mm, 1°; MK22) and plate geometry with a truncated fixed gap of 0.05 mm [8]. Under some time–temperature conditions G′ in both, the CW and C32 organogels, showed a steady and significant decrease as a function of time (i.e., 0–180 min), particularly in the organogels developed at 10 °C/min and a gel setting temperature of 25 °C [8]. This decrease in G′ was associated with the presence at the junction zones of less organized structures (i.e., alkanes in the rotator phase), that would result in the rupture of the bonds between the microplatelets of n-alkanes during G′ measurements. However, we could not fully explain this rheological behavior, mainly because the strain applied during G′ measurement (180 min) was always within the linear viscoelastic region of the system.

A possible explanation for the decrease in G′ observed in that study might be associated with the expansion/shrinkage suffered by the rheometer geometry and the organogel due to changing temperature conditions used during rheological measurements. These process ought to affect gap size and therefore the rheological measurements. Additionally, the expansion/shrinkage of the rheometer frame due to altering laboratory conditions might also modify the actual gap, particularly in long lasting experiments. Läuger et al. [9] detailed addressed the effect of these conditions on the viscosity of silicon oil. Within this framework, in an attempt to understand the rheological behavior of the CW and C32 organogels previously observed [8], in this investigation we determine the G′ profiles of these organogels using a mechanical spectrometer (Paar Physica MCR 301, Stuttgart, Germany) equipped with a true-gap system. This device makes the corrections in gap size associated with the expansion/shrinkage of the sample and/or the rheometer geometry due to changing temperature conditions used during measurements [9].

Materials and Methods

CW and C32 organogels were developed using the same experimental design, gelator concentrations and time–temperatures conditions reported by Morales-Rueda et al. [8]. In short, the treatment conditions investigated resulted from the factorial combination of gelator concentration (1 and 3%, w/w), gel setting temperatures (T set, 5 and 25 °C), and cooling rates (1 and 10 °C/min). The treatments were randomly distributed among aliquots of the CW or C32 dispersions in SFO. For each treatment two independent measurements were done (n = 2).

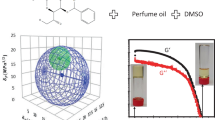

The main difference with our previous work [8] is that in the present investigation the elastic (G′) and loss (G″) moduli of the organogels were determined with a mechanical spectrometer (Paar Physica MCR 301, Stuttgart, Germany) using a steel cone-plate geometry (50 mm, 1°; CP50-1/TG, Anton Paar, Graz-Austria) equipped with a true-gap system. Temperature was controlled by a Peltier system located in both the base and top of the measurement geometry through a Peltier-controlled hood (H-PTD 200). The control of the equipment was made through the software Start Rheoplus US200/32 version 2.65 (Anton Paar, Graz-Austria). The gel dispersion at room temperature was applied on the base of the geometry and the cone was set using the true-gap function of the software. Any excess of the sample was removed from the borders of the rheometer geometry with the help of a spatula. After 20 min at 90 °C the system was cooled at the corresponding cooling rate until achieving a particular T set. At a given T set the G′ and G″ were determined as a function of time within 0 and 180 min, always within the linear viscoelastic region (LVR) of the system. For the systems at 1% CW and 1% C32 concentration the strain applied was between 0.01 and 0.05%. At 3% gelator concentration the strain used was between 0.05 and 0.1%. A frequency of 1 Hz was used in all cases.

The same SFO, CW, and C32 used in our previous investigation [8] were also utilized in the present work. Therefore, the calorimetric parameters (i.e., heat of melting, ΔH M), the solid phase content (SPC), and the microphotographs of the CW and C32 organogels determined in the original work [8] were also used in this investigation. All these parameters were measured as a function of time (0–180 min) after achieving a preestablished T set at a given cooling rate.

Results and Discussion

The composition of CW, C32, SFO have been previously reported [8]. In short, CW contained 78.9 ± 0.1% of hentriacontane (C31H64), while the C32 utilized had a purity of 99.50% (±0.01%). The microphotographs obtained by PLM (Figs. 1, 2, 3, 4) showed that, independent of gelator concentration and T set, C32 developed larger needle-like crystals, highly branched and with a higher extent of birefringence (Figs. 3, 4) than the crystals developed under the same conditions by CW (Figs. 1, 2). In our previous work [8] we showed that, independent of the gelator concentration and the cooling rate used, the gelation temperature for C32 was always higher than for CW. This indicated that for a given T set higher supercooling was achieved by C32 than by CW, independent of gelator concentration and cooling rate. Additionally, we observed that a higher concentration of CW than C32 was required to achieve the same gelation temperature (see Fig. 2b in [8]). All these results pointed to the fact that C32 has a higher self-assembly capability in the SFO than CW. However, it is important to point out that although hentriacontane was the major component in CW, nonacosane, tritriacontane, and triterpene alcohols were also present in CW [8]. This mixed composition might result in the development of mixed self-assembled structures with a lower extent of three-dimensional molecular structure (i.e., lower crystallinity and ΔH M) and smaller crystals than the ones achieved by pure C32. In organogels developed with stearic alcohol and stearic acid, Schaink et al. [10] and Gandolfo et al. [11] obtained smaller crystals at a 3:7 stearic acid to stearyl alcohol ratio than with the pure compounds.

Figure 5 shows some characteristics G′ profiles for 1% C32 and 3% CW organogels obtained under isothermal conditions once a particular T set (i.e., 5 or 25 °C) was achieved at a given cooling rate (i.e., 1 or 10 °C/min). The rheological profiles were obtained with the fixed and the true-gap systems. The corresponding SPC present in the organogels was independent of the type of system used (fixed gap vs. true gap) in the rheological measurements, and is also shown in Fig. 5. It is important to point out that for the same gelator type and cooling rate used the SPC in the organogels remained constant during the 180 min involved in the rheological measurements (i.e., once T set was achieved no additional CW or C32 crystallization occurred). For a given type of organogel developed at the same T set, cooling rate, and gelator concentration different G′ magnitudes and G′ profiles as a function of time were obtained with each type of system. Overall, with the true-gap system under all time temperature conditions investigated a constant G′ pattern as a function of time was observed in the C32 organogels developed at 1% (Fig. 5a, c) and 3% concentration (data not shown). Under the same time–temperature conditions, the use of the fixed-gap system showed a steady decrease in G′ at both the 1% (Fig. 5a, c) and the 3% (data not shown, see [8]) concentration until a plateau was achieved. Similar observations applied to the rheological measurements with CW (Fig. 5b, d). However, with the CW we observed a distinctive behavior at a cooling rate of 10 °C/min, particularly at the T set of 25 °C. Under these conditions the use of the fixed-gap system with 3% CW organogels, resulted in a concomitant decrease of G′ at the T set of 25 °C (Fig. 5d). This decrease was more evident at 1% concentration, and was also observed at the T set of 5 °C (data not shown, see [8]). However, with the true-gap system, the 3% CW organogels developed at both T set’s at a cooling rate of 10 °C/min, followed a G′ profile that initially increased slowly attaining a plateau (Fig. 5d). Similar behavior was observed with the 1% CW organogels (data not shown).

In high quality rheometers, like the one used by Morales-Rueda et al. [8] (i.e., Paar Physica UDS 200; Stuttgart, Germany), the gap position can be set accurately to within 1 µm [9]. However, such models use a compensating gap adjustment routine (i.e., auto gap control) during temperature dependent rheological measurements that rely on a constant thermal expansion coefficient (e.g., 1 µm/K). The software makes the appropriate gap adjustments based on empirically established temperature position functions using the expansion coefficient determined once the thermal expansion is completed [9]. It seems that when a temperature ramp was used during rheological measurements using a fixed-gap system, particularly a high cooling rate (i.e., 10 °C/min; Fig. 5c, d) the automatic gap adjustment was inaccurate since the equipment geometry and the organogel had not reached their final expansion/shrinkage. These results showed that the lack of an appropriate adjustment in gap size due to the expansion/shrinkage of both the rheometer geometry and the organogel affected our previous G′ measurements [8], particularly when a cooling rate of 10 °C/min was used to achieve the T set’s.

The true-gap system constantly measures the magnetic impedance and the voltage between the lower and the upper plate of the geometry using appropriate electronics. Both the magnetic impedance and the voltage have specific relationships with the gap size. Thus, during the rheological measurements the voltage between the lower and the upper plate of the geometry is measured by the rheometer’s electronics, and by taking into consideration the particular relationship between voltage and gap size, an electronic feedback mechanism constantly adjusts the gap to the desired constant value through the rheometer’s software [9]. Thus, in contrast with the fixed-gap system, the true gap provides a constant and real gap size during the organogels’ rheological measurements.

In general, the G′ profiles obtained with the true-gap system showed that, for the same type of gelator and independent of its concentration and the T set used, higher G′ profiles were obtained at 1 °C/min than at 10 °C/min (i.e., at 1 °C/min the organogels achieved a higher level of structural organization than at 10 °C/min). This was particularly evident with C32 organogels (i.e., Fig. 5a, c). When the G′ values after 180 min (G′180) at both cooling rates were plotted as a function of the corresponding SPC (Fig. 6), it was evident that for the same gelator concentration and time–temperature conditions higher G′180 were obtained with C32 than with CW organogels, particularly at 1 °C/min and at 3% of gelator concentration. This in spite of the higher SPC (P < 0.05) and smaller crystal sizes developed by CW organogels (Figs. 1, 2) in comparison with the ones developed by C32 organogels (Figs. 3, 4). This agreed with our previous conclusion [8] that indicated that with the exception of the 1% gelator concentration at T set of 25 °C at both cooling rates, C32 developed organogels at significantly lower SPC than CW. This is independent of the cooling rate and T set used [8] (i.e., at the T set investigated C32 observed higher solubility in SFO than CW). These results again pointed out that C32 has higher self-assembly capability in the SFO than CW.

Wang et al. [7] have shown that the topological structure of a three-dimensional fiber network in an organogel depends on the supersaturation of the system. Specifically, these authors showed that the development of transient (i.e., entanglement of fibers) and permanent (i.e., branching of fibers) junction zones in a gel network is supersaturation dependent [7]. In turn, both the transient and permanent junction zones determine the rheological properties of the self-assembled fibrillar network [7]. These authors concluded that organogels with fibrillar network structures with a high extent of transient junction zones, have higher elasticity than organogels with spherulitic network structures (i.e., a network with high extent of permanent junction zones). The microphotographs obtained by PLM showed that independent of T set, C32 organogels developed at 1 °C/min showed larger needle-like crystals with a higher extent of branching (Fig. 3) than the organogels developed at 10 °C (Fig. 4). As a result higher G′180 was observed in the C32 organogels developed at 1 °C/min than in the ones obtained at 10 °C/min (Fig. 6). A similar explanation might be applied to CW organogels. However, the magnification used in the PLM was not sufficient to appreciate the microscopic characteristics of CW crystals (Figs. 1, 2).

The rheograms obtained with the true-gap system showed that CW organogels were achieving a higher structural order as a function of time (i.e., G′ steadily increased as a function of time). This phenomenon was more evident when a cooling rate of 10 °C/min was used to achieve the T set’s (Fig. 5d). As discussed in our previous paper [8], during the cooling stage the thermodynamic driving force for gel formation (e.g., the difference between the temperature of the system and the gelation temperature, T g) increased faster at the higher cooling rate. Consequently, during the cooling stage the gelator molecules had less time to organize at 10 °C/min than at 1 °C/min, i.e., for a given T set, a less well organized molecular packing of the n-alkanes was achieved at 10 °C/min than at 1 °C/min. This was particularly evident at the higher T set (i.e., 25 °C) where the lower supercooling conditions prevailed (Fig. 5d). Once T set was achieved, the CW organogels evolved into a higher state order as a function of time through a solid → solid transition from a rotator phase developed by the n-alkanes. Rotator phases are commonly observed in n-alkanes and are characterized by a crystalline lattice of the molecular centers while molecules rotate about their chain axes (i.e., structural disorder) [12–14]. Thus, as noted in our original work [8], independent of the T set used, CW organogels developed at 1 °C/min observed higher ΔH M (i.e., higher level of structure and therefore higher G′) than the CW organogels developed at 10 °C/min (Fig. 7a). Additionally, in organogels developed at T set of 25 °C the ΔH M increased as a function of time, a process probably associated with the development of a more organized molecular packing from the one originally achieved (e.g., rotator phase) through an annealing process. These effects were more evident in 3% CW organogels than in 1% CW organogels (data not shown, see [8]), suggesting that a concentration effect is also involved in the development of a better structured three-dimensional network. Previously our group described a similar phenomenon also in CW organogels [15], which was observed later in 12-hydroxystearic acid organogels by Rogers et al. [16]. As pointed out in our previous reports [8, 15] the ΔH M increment observed in CW organogels as a function of time (Fig. 7a) could not be associated to changes in the SPC, mainly because the SPC achieved by the organogels right after attaining T set remained constant during the whole period of rheological and ΔH M measurements.

With the true-gap system, the C32 organogels showed a steady G′ profile at all time–temperature conditions investigated. Although SPC was statistically higher in the C32 organogels developed at 10 °C/min than in the ones developed at 1 °C/min (P < 0.05), as for CW, the G′ profiles of C32 organogels were always higher at 1 °C/min (Fig. 6). As previously mentioned, at this cooling rate larger C32 crystals with a greater extent of branching were obtained at all T set’s (Fig. 3) than at 10 °C/min (Fig. 4), a process that resulted in organogels with a higher level of three-dimensional organization (i.e., higher fractal dimension) than the one achieved at 10 °C/min (Fig. 6). With the C32 organogels although there was a tendency to obtain higher ΔH M at 1 °C/min than at 10 °C/min under all conditions investigated, the differences were not significant (Fig. 7b). Additionally, at all conditions investigated the ΔH M of C32 organogels remained constant as a function of time indicating the absence of a solid → solid transition. Given the T g values previously reported for C32 [8], at the T set investigated this gelator system achieved higher thermodynamic driving force for gelation during the isothermal stage than the CW system, and therefore, C32 organogels achieved a higher structural order (i.e., higher G′) than CW organogels. Thus, the development of a rotator phase would be less probable in the C32 organogels than in the CW organogels (i.e., development of a higher state order by C32 organogels as a function of time through a solid → solid transition from a rotator phase will not exist). Therefore, under the time–temperatures conditions investigated both the ΔH M (Fig. 7b) and the G′ for C32 organogels remained constant during the 180 min of experimentation (Fig. 5a, c).

In conclusion, contrary to the rheological results obtained with the fixed-gap system, the G′ results obtained with the true-gap system agreed with the ΔH M behavior (Fig. 7), crystal size, and three-dimensional organization of the crystal network observed by the C32 and CW organogels (Figs. 1, 2, 3, 4). Thus, we must use a fixed-gap system with caution specially with time dependent G′ determinations (i.e., creep and recovery measurements), and rheological measurements involving the use of fast temperature ramps (i.e., 10 °C/min).

References

Wright AJ, Marangoni AG (2007) Time, temperature, and concentration dependence of Ricinelaidic acid: canola oil organogelation. J Am Oil Chem Soc 84:3–9

Kumar R, Katare OP (2005) Lecithin organogels as a potential phospholipid-structured system for topical drug delivery: a review. AAPS PharmSciTech 6:E298–E310

Murdan S, Gregoriadis G, Florence AT (2000) Novel sorbitan monostearate organogels. J Pharm Sci 88:608–614

Abdallah DJ, Weiss RG (2000) n-Alkanes, Gel n-alkanes (and many other organic liquids). Langmuir 16:352–355

Rogers MA, Marangoni AG (2008) Non-isothermal nucleation and crystallization of 12-hydroxystearic acid in vegetable oils. Cryst Growth Des 8:4596–4601

Rogers MA, AG Marangoni (2009) Solvent-modulated nucleation and crystallization of 12-hydroxystearic acid: a nonisothermal approach. Langmuir ARTICLE ASAP DOI:10.1021/1a8035665

Wang R, Liu X, Xiong J, Li J (2006) Real-time observation of fiber network formation in molecular organogel: supersaturation dependent microstructure and its related rheological property. J Phys Chem B 110:7275–7280

Morales-Rueda JA, Dibildox-Alvarado E, Charó-Alonso M, Weiss RG, Toro-Vazquez JF (2009) Thermo-mechanical properties of candelilla wax and dotriacontane organogels in safflower oil. Eur J Lipid Sci Technol 111:207–215

Läuger J, Ziegler A, Raffer G (2004) True gap control: direct measurement of the real gap size during parallel-plate and cone and plate rheological experiments. Revista Mexicana de Ingeniería Química 3:307–310

Schaink HM, van Malssen KF, Morgado-Alves S, Kalnin D, Van der Linden E (2007) Crystal network for edible oil organogels: possibilities and limitations of the fatty acid and fatty alcohol systems. Food Res Intern 40:1185–1193

Gandolfo FG, Bot A, Flöter E (2004) Structuring of edible oils by long-chain FA, fatty alcohols, and their mixtures. J Am Oil Chem Soc 81:1–6

Espeau P, White JW (1997) Thermodynamic properties of n-alkanes in porous graphite. J Chem Soc Faraday Trans 93:3197–3200

Zgardzinska B, Pietrow M, Goworek T, Wawryszczuk J (2006) ortho-Positronium in some n-alkanes: influence of temperature and pressure. Acta Physica Pol A 110:747–753

Tozaki K, Inaba H, Hayashi H, Quan C, Nemoto N, Kimura T (2003) Phase transitions of n-C32H66 measured by means of high resolution and super-sensitive DSC. Therm Acta 397:155–161

Toro-Vazquez JF, Morales-Rueda A, Dibildox-Alvarado E, Charo-Alonso M, Alonzo-Macias M, Gonzalez-Chavez MM (2007) Thermal and textural properties of organogels developed by candelilla wax in safflower oil. J Am Oil Chem Soc 84:989–1000

Rogers M, Wright AJ, Marangoni AG (2008) Post-crystallization Increases in the mechanical strength of self/assembled fibrillar networks is due to an increase in network supramolecular ordering. J Phys D 41:215501

Acknowledgments

The investigation was supported by grant # 48273-Z/25706 from CONACYT. The technical support from Concepcion Maza-Moheno and Elizabeth Garcia-Leos is greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Morales-Rueda, J.A., Dibildox-Alvarado, E., Charó-Alonso, M.A. et al. Rheological Properties of Candelilla Wax and Dotriacontane Organogels Measured with a True-Gap System. J Am Oil Chem Soc 86, 765–772 (2009). https://doi.org/10.1007/s11746-009-1414-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-009-1414-3