Abstract

This paper describes an investigation into the usefulness of some instrumental methods (GC, NMR, and DSC) in the detection of adulteration of olive oil with soybean, sunflower, and canola oils (that are relatively cheap oils mixed as adulterants with olive oil). These seed oils were compared with genuine and commercial olive oils, two of which appeared to have been adulterated. It was observed that from among physical and chemical indices, the iodine value and the refractive index in the two olive oil samples (named A and B) were significantly higher (P < 0.01) than in the reference (genuine) olive oil, both values being above standard limits established for olive oil. On the other hand, fatty acid (FA) profiles in these two samples exhibited higher amounts of linolenic and linoleic acids (5.34 and 39.92%, 6.38 and 54.42%, 0.79 and 12.88% for A, B and genuine olive oils respectively) but significantly lower amounts of oleic acid (30.07, 21.72 and 67.86%, respectively). The number and intensity of signals observed using 1H NMR indicated that the peaks numbered 2 and 7 were useful in the determination of olive oil purity. Because of higher linolenic and linoleic acid contents in samples A and B, the intensity and integrated areas for these two signals were higher than those for other olive oil samples in which signal 2 was not observed and signal 7 had a very low intensity. Satisfactory results were achieved from quantitation of DSC parameters. The results show that due to increased unsaturated FAs in samples A and B and the consequent changes in triacylglycerol profiles, offset crystallization temperature and onset melting temperature in these two olive oils differed from those of the reference and clearly shifted to lower values. Crystallization and melting curves were similar to the corresponding curves observed for soybean and sunflower oils in terms of shape and number of peaks.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Virgin olive oil represents the main source of fat production in the Mediterranean countries where olive oil production is common [1]. According to the trade standard of International Olive Oil Council for Olive Oils and Olive Pomace Oils, virgin olive oil is the oil obtained from the fruit of the olive tree solely by mechanical or other physical means under conditions, particularly thermal, that do not lead to alterations in the oil, and which has not undergone any treatment other than washing, decanting, centrifuging, or filtration [2]. Virgin olive oil is a foodstuff rich in natural antioxidants (phenols and tocopherol) and oleic acid. This FA is more resistant to the free radical oxidation processes compared to the polyunsaturated FAs. It is also known to be responsible for increasing plasma HDL and apoprotein A levels and for decreasing LDL and apoprotein B levels. For this reason, it plays an important role in preventing cardiovascular diseases [3]. The growing demand for olive oil over the past few years can be attributed not only to flavor but also to reports of potential health benefits, causing its rising price on the market. The higher price of olive oil compared to other edible oils may encourage cheaper oils to be mixed with virgin olive oil for greater profitability. Authentication of purity is, therefore, desirable [4, 5]. Edible oil characterization is a very important task, which has been classically undertaken by different chemical methods to determine acidity, peroxide value, iodine value, etc., or combined with chromatographic methods to determine the proportion of different acyl groups, minor components, etc. Many of these methods are cumbersome and require a great deal of time and expense with inaccurate results in certain cases. In recent years, many studies have been directed toward the characterization, classification, and purity detection of olive oils using different techniques [3–9]. Nuclear magnetic resonance (NMR) is an important tool in the study of food lipids, oils, and fats, which has gained growing applications, particularly because of the great amount of information it provides that allows discrimination between oils of different composition in a very short time [10]. Thermo-analytical techniques, such as differential scanning calorimetry (DSC), have also been used in oil and fat characterization to determine melting and crystallization profiles, heat of transition, phase diagrams, solid fat content, and adulterants in animal fats and butter. This technique can provide very useful information on the basis of FA and TAG profiles in oils and fats [11].

The present study investigates the effectiveness of physicochemical indices along with FA profiles in characterizing some Iranian olive oils and in detecting their purity. The usefulness of the information obtained from the number and intensity of signals in 1H NMR employed for a simple and rapid characterization of these oils will be discussed. Also the crystallization and melting behavior of soybean, sunflower, canola, and genuine olive oils will be investigated to explore the relationship between the thermal response of oil samples and their FA composition. The information obtained will be used to identify the likelihood of mixing these seed oils with olive oils as adulterants.

Materials and Methods

Chemical Reagents and Samples

All solvents/chemicals used were of analytical grade and obtained from Merck (Darmstadt, Germany). Pure FAs including palmitic acid, stearic acid, oleic acid, linoleic acid, and linolenic acid were purchased from the Sigma Chemical Co. (St Louis, MO). Six olive oils labeled A, B, C, D, F (virgin olive oils) and E (refined olive oil) were purchased from local markets. Genuine olive oil (G), soybean oil, sunflower oil, and canola oil were obtained from manufacturers. To avoid changes in the chemical composition of samples, they were frozen and stored at −18 °C immediately after their arrival in the laboratory.

Chemical Analysis

The AOCS official method (AOCS 2003) was employed for determination of some chemical and physical indices of the oil samples [12].

FA Analysis by GLC

The gas chromatographic analysis of FAME was performed on a chroma-pack CP 9002 gas chromatograph (Middelburg, The Netherlands) equipped with a flame-ionization detector. The column used was a CP-FFAP-CB fused silica WCOT (25 m × 0.32 mm i.d., 0.3 μm film thickness). The temperature program consisted of increasing the temperature first from 40 °C to 100 °C at a rate of 25 °C/min and holding for 0.2 min and then increasing to 200 °C at a rate of 10 °C/min and holding for 17 min. Temperatures of injector and detector were 240 and 280 °C. Ultra-high-purity helium was used as the carrier at 75 kPa. Samples were methylated before injection into GC by Ortega et al. [13] method. Injection (1 μl) was performed in the split mode at a split ratio of 100:1.

NMR Spectroscopy

NMR spectroscopy was performed on a Bruker instrument at 400 MHz. The first 0.2 g of the sample was dissolved in 400 μl of CDCl3 and the resulting solution was placed in a 5-mm diameter NMR tube. The acquisition parameters were: spectral width, 8,278.14 Hz; relaxation delay, 2 s; number of scans, 16; pulse width, 90°; and temperature of the sample in the probe was set at 300 K.

Thermal Analysis by DSC

For DSC analysis, a Metller TA4000 differential scanning calorimeter was used. Nitrogen (99.999% purity) was the purge gas flowing at ~20 ml/min. The DSC instrument was calibrated with indium (m.p. 156.6 °C, ΔH = 28.45 j/g). Samples of ca. 6–9 mg were weighed into aluminum pans and covers were hermetically sealed into place. An empty, hermetically sealed aluminum pan was used as reference. Samples were subjected to the following temperature program: sample was melted at 50 °C and held for 5 min before cooling to −100 °C at a rate of 5 °C/min. The samples were again held at this temperature for 5 min before being heated to 25 °C at a rate of 5 °C/min.

Statistical Analysis

Data were statistically analyzed by one way analysis of variance (ANOVA) with the SAS software package. Duncan’s multiple range test was applied to determine significant differences between means, at a level of P < 0.01.

Results and Discussion

Chemical and Physical Indices

Higher iodine values and a higher refractive indices were obtained for soybean, canola, and sunflower oils than for genuine olive oil as a result of higher amounts of polyunsaturated FAs in the former. These two indices can, therefore, be used for the detection of adulteration in olive oil mixed with these seed oils. As observed in Table 1, for olive oil samples (except for samples A and B), different iodine values and refractive indices were obtained obviously due to the natural differences in oil compositions albeit within standard limits; therefore, absence of common vegetable oils in samples C, D, E, and F is logically true. It is also seen in Table 1 that the iodine values and the refractive indices for samples A and B were significantly higher (P < 0.01) than those for genuine olive oil (G) and other olive oil samples and this increase was so considerable that showed unusual increase in degree of unsaturation in the oils. The increased refractive index can be explained by the higher iodine value of samples A and B, indicating possible impurity of these two oils. Saponification values in soybean, sunflower, canola and olive oils were all in the same range and there was no significant differences among them (P < 0.01) therefore, it did not change quite as expected even after partial replacement of olive oil with these vegetable oils.

FAs Composition

Table 1 presents the results of oil analyses. The FA composition is the first characteristic used for determining the purity of virgin olive oil. Every oil or fat has its own characteristic FA and TAG profiles although there are similarities among FAs in different oils. The principal variation in FA composition of oils and fats is the chain length and degree of unsaturation of the component FA. In fact, virgin olive oil contains a high amount of oleic acid (55–83% according to IOOC), a low level of linoleic acid (3.5–21%), and a very low level (≤1%) of linolenic acid [14]. Higher levels of linolenic acid are regarded as an index of seed oil addition; this parameter is included in EEC regulation 2568/91 on olive oil classification [15]. Table 1 shows only the values of those parameters which are essential for the aims of this study. Soybean and canola oils exhibited considerably high linoleic and linolenic acid contents far beyond the normal values encountered in the olive oil. Thus, these two FAs, especially linolenic acid, could be used as a parameter for the detection of fraud mixing of these oils in olive oil. The measurements of FA composition indicated the values normally observed in olive oil samples C, D, E, F and within official limits (IOOC) established for olive oil. Samples A and B however, exhibited higher amounts of linolenic and linoleic acids and significantly reduced oleic acid (P < 0.01) that can not be related to the variety. These evidences were used to refute the likelihood addition of sunflower and canola oil because canola oil contains high amounts of oleic acid just as olive oil does while the amount of linolenic acid in sunflower oil was less than 1%; hence, it was concluded that soybean oil had been mixed with samples A and B. In this study, analysis of FAs produced satisfactory results with regard to the levels of adulteration. It must be mentioned, however, that methods using the analysis of FAs or TAGs may also be inadequate for low amounts of incorporation. Christopoulou et al. [16] showed that adulteration of olive oil with certain vegetable oils up to a level of 5% could be detected using FA analyses. Tsimidou et al. [5] showed that for incorporation at a level of 20% (higher than 10%) principal component analysis of TAG and FA profiles could be satisfactorily used to show clearly the presence of foreign oil.

NMR Results

Figure 1 shows the 1H-NMR spectra of pure olive oil (G), soybean, canola and sunflower oils while Fig. 2 shows the 1H-NMR spectra of other samples of olive oils. The 1H-NMR spectrum of any oil sample shows at least 9 or, in some cases, even 10 signals of significant intensity. These signals are due to protons of the main components, i.e. triglycerides. The protons which are related to each signal have been shown in Fig. 1. Some of the signals are produced due to the resonance of protons which are common among different FAs and signals 1, 3, 4, 5, 6, 8, 9, 10 are typical in this regard. However, signal 2 is particularly related to the protons of methyl group of linolenic acid while signal 7 belongs to bis-allylic protons (methylenic protons in position α in relation to the two double bonds). The only FAs considerably present in these oils that have this group of protons are linolenic and linoleic acids. The chemical shift observed in the signals in this study was slightly different from those in previous studies reported [6, 10]. This difference can be related to the kind of solvent and some other conditions. The determination of the proportions of the different acyl groups in the oil sample by 1H NMR is a valuable indicator of whether the sample falls within the acyl group pattern of genuine olive oil. From an authenticity point of view, the most interesting 1H-NMR signals are likely to be signals 2 and 7. Figure 1 illustrates how the methyl groups of the linolenic acyl chains (signal 2) appear as slightly different from the methyl groups of the other FA chains (signal 1). The different amounts of linolenic acid in vegetable oils make it possible to use this information to identify these oils. The only n-3 FA present in soybean, canola, sunflower, and olive oil is linolenic acid. If the proportion of this acyl group is high enough, its methylic proton signals can be observed in 1H-NMR spectra Therefore, n-3 acids measured on the basis of the characteristic signal 2 in Fig. 1 determines the level of linolenic acid directly, allowing direct detection of common seed oil addition in olive oil. As observed in FAs profiles, soybean and canola oils contain significant proportions of linolenic acyl groups. Thus, this signal can be observed clearly in 1H-NMR spectra of soybean and canola oils with a considerable integrated area. On the other hand, the presence of a very small proportion of linolenic acid and the methylic protons of this FA in pure virgin olive oil (G) and sunflower oil allows us to distinguish these oils from soybean and canola oils because signal 2 is absent in the 1H-NMR spectra of sunflower and pure olive oils. In Samples A and B, signal 2 can be observed clearly, which is in agreement with high quantities of linolenic acid in their FA profiles while in other olive oils (C, D, E, F) containing normal amounts of linolenic acid (about 1%), this peak was absent. From these results, it is evident that linolenic acyl groups were clearly observable in higher proportions than normal in the 1H-NMR spectra of olive oil, which can be an indicator of adulteration with seed oils having a high linolenic content. The integrated areas of signal 2 for soybean oil, canola oil, and samples A and B were 0.24, 0.23, 0.15, and 0.2, respectively. The usefulness of signal 7 in establishing the relative proportion of linoleic and linolenic acyl groups is known. The 1H-NMR spectra of olive oil and sunflower oil that have very low proportions of linolenic acyl groups only showed a typical signal of bis-allylic protons of linoleic acyl groups; this signal was quite small for pure olive oil. Given the high quantities of these two fatty acids (FAs) in soybean and canola oils and the high quantity of linoleic acid in sunflower oil, the intensity of signal 7 for these oils was significantly higher than that for genuine olive oil. The integrated areas of signal 7 for soybean, canola, sunflower, and pure virgin olive oil were 0.97, 0.53, 0.78, and 0.15, respectively. Also for samples A and B, the intensity of signal 7 was clearly higher than that for pure olive oil (G) and other olive oil samples (0.87 and 0.91 for samples A and B, 0.06–0.16 for other olive oil samples). This was due to large amounts of linoleic and linolenic acids in these two oils. According to these observations and on the basis of the magnitude of peaks 2 and 7 in samples A and B, the adulterant was likely to be soybean oil (which would agree with FA profiles, refractive index, and iodine value data).

Thermal Analysis

DSC Crystallization Behavior

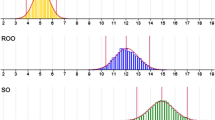

Crystallization is a commonly used physical event to characterize the thermal behavior of oil samples requiring the release of thermal enthalpy. Oils and fats can be crystallized in several polymorphic forms, especially α, β and β′ [11]. In this study, the cooling curve of vegetable oils were subdivided into different exothermic regions corresponding to different FAs and TAGs in order to use this technique to qualify and quantify certain parameters of the oil samples. The rate of cooling or heating has been reported in a number of studies to be effective on shape and number of thermal curve peaks [9, 11]. Since all experiments in the present study were performed at the same rate using the DSC instrument, the influence of this factor could be neglected and, thus, the discussion can be focused on the differentiation between oil samples in terms of their FA and TAG composition. According to Fig. 3, three exothermic peaks can be detected in the cooling curves of canola and pure olive oils. In general, the lowest exothermic peak was sharper and taller than the two smaller exothermic peaks at higher temperatures. The major exothermic peak at −55.2 °C in canola oil and at −45.5 °C in pure olive oil might correspond to the co-crystallization of highly unsaturated (UUU) TAGs such as LLnLn, LLLn, OLnLn, LLL and OOO, POO, OOL, respectively. At 5 °C/min, the cooling curves of soybean and sunflower oils revealed three exothermic peaks, too. The lower temperature peak at −75.5 °C in soybean and at −73.5 °C in sunflower oil could have been caused by the co-crystallization of UUU groups such as LLLn, LLL, OLL, OOL and LLL, OLL, OOL, respectively. The two higher temperature peaks in the samples were due to the crystallization of higher saturation levels of TAG [11, 17]. In Fig. 4, the sequence of curves clearly shows the pronounced influence of the degree of unsaturation in FA and TAG profiles on peak temperatures. As the polyunsaturated FA increased, the peaks of crystallization shifted to lower temperatures and became broader. The results of this study showed that transition temperatures and peak shapes in samples C, D, E, and F were similar in their DSC cooling curves because of the similarity of FA profiles in both olive oil samples (except A and B) and pure olive oil. The major peak corresponding to the co-crystallization of major TAG groups in pure virgin olive oil can be seen in these oils in the same temperature ranges. In samples A and B, cooling curves were clearly different from those of olive oils but similar to those of the sunflower and soybean oils. According to the results of GC, the proportion of major TAGs in pure olive oil (i.e. OOO, POO and OOL which are the most important factors responsible for the main peak in the crystallization curve) is expected to reduce in A and B samples, whose FA profiles were different from those of other olive oils. In contrast, the proportion of TAGs containing higher unsaturated FAs (LLL, LLLn, OLL) should increase. So TAG profiles of A and B oils were similar to those of soybean and sunflower oils and the major peak, therefore, became broader and shifted to lower temperatures. It can be observed in Table 2 that in these two samples, transition temperature shifted to lower temperatures, too, which can be explained by the highly unsaturated FA in their composition. The key point is that higher oleic oils like olive and canola display a large peak near −50 °C, whereas more polyunsaturated oils like soybean and sunflower display peaks at −70 to −80 °C; as a result, the addition of soybean or sunflower oil to olive oil can be detected from DSC crystallization data.

DSC Melting Behavior

Figures 5 and 6 illustrate the melting curves of samples and Table 3 lists their respective endothermic temperatures. In canola oil, a large peak was observed at −16.0 °C which was assumed to be the melting peak of all the TAG in canola oil, especially the major three unsaturated triacylglycerols (TAGs) such as OOL and OOO. In soybean oil, four endotherms were observed. The major endotherms at lower temperatures were due to the melting of LLL, LLLn, LLnLn and OLL, PLL, POL/SLL, and the two tailing shoulder endothermic peaks at the high temperature side were due to the minor SSU groups. Sunflower oil showed two overlapping peaks. Therefore, it was apparent that all the TAG in the sunflower melted in this wide endotherm region. The lower temperature peak was assumed to be the melting peak of highly unsaturated TAG groups, especially LLL, OLL and OOL, while the higher temperature endotherm was assumed to be the melting peak of SUU and SSU groups. Pure olive oil showed triple melting peaks. The main endothermic transition at −6.0 °C most likely corresponded to the melting peak of the major TAG groups.

An exothermic peak before the melting onset was observed in oil samples that could be associated with the solid-to-solid transformation known as polymorphism phenomenon. Due to the presence of highly unsaturated TAG, the first peak was larger in soybean and sunflower oils and onset melting temperature was significantly lower than in pure olive oil. Because of the lower proportion of this group of TAGs in pure olive oil, the first peak was completely small looking like a shoulder. On the basis of number and shape, all olive oil samples (except for samples A and B) showed endothermic peaks that were similar to those of pure olive oil and the main endothermic transition was near −5 °C. It is observed in Table 3 that the temperature of peaks in these oils was almost in the same range as that for pure olive oil. But in samples A and B, triple endothermic peaks were observed that were thoroughly different from that for pure olive oil but similar to the melting curves in soybean and sunflower oils. It was clearly seen that in samples A and B, the first peak became larger because of the increased highly unsaturated TAGs and that they had different and significantly lower onset melting temperature values than those of pure or other olive oils. The key point is that more polyunsaturated oils like soybean and sunflower oils display main peaks near −15 to −25 °C, whereas pure olive oils display main peaks at −4 to −6 °C while for canola oil, it was near −16 °C. As a result, the addition of soybean or sunflower oils to olive oil can be detected from DSC melting data.

Conclusion

The development of new and increasingly sophisticated techniques for the authentication of oil products continues apace along with increasing consumer awareness of its safety. There is increasing evidence showing olive oil available on the Iranian market to be unreliable; i.e., they may be adulterated by adding cheaper oils and, therefore, a kind of advanced quality control might be necessary. The use of instrumental methods such as GC, NMR, and DSC as demonstrated here offers suitable methods for detection of mixing soybean and sunflower oils with pure olive oil. In this study, it was shown that, with regard to the levels of adulteration, the gas chromatography technique can be complemented, or substituted by other modern techniques, such as NMR or DSC that can provide fingerprints whose simple observation with the naked eye will be sufficient to distinguish oils of different compositions. These techniques promise to offer a sensitive, rapid, and reproducible fingerprint for quality control purposes.

References

Angerosa F, Servili M, Selvaggini R, Taticchi A, Esposto S, Montedoro G (2004) Volatile compounds in virgin olive oils occurrence and their relationship with the quality. J Chromatogr A 1054:17–31

Wesley IJ, Barnes RJ, McGill AEJ (1995) Measurement of adulteration of olive oils by near-infrared spectroscopy. J Am Oil Chem Soc 72:289–292

Ranalli A, Ferrante ML, De-Mattia G, Costantini N (1999) Analytical evaluation of virgin olive oil of first and second extraction. J Agric Food Chem 47:417–424

Aparicio R, Aparicio-Ruiz R (2000) Authentication of vegetable oils by chromatographic techniques. J Chromatogr A 881:93–104

Tsimidou M, Macrae R (1984) Authentication of virgin olive oils using principal component analysis of triglyceride and fatty acid profiles: part 2: detection of adulteration with other vegetable oils. Food Chem 25:251–258

Guillen MD, Ruiz A (2003) Edible oils: discrimination by 1H nuclear magnetic resonance. J Sci Food Agric 83:338–346

Lai YW, Kemsley EK, Wilson RH (1994) Potential of Fourier transforms infrared spectroscopy for the authentication of vegetable oils. J Agric Food Chem 42:1154–1159

Lopez-Diez EC, Bianchi G, Goodacre R (2001) Rapid quantitative assessment of the adulteration of virgin olive oils with hazelnut oils using Raman spectroscopy and chemometrics. J Agric Food Chem 51:6145–6150

Tan CP, Che Man YB (2002) Comparative differential scanning calorimetric analysis of vegetable oils: I. Effect of heating rate variation. J Am Oil Chem Soc 13:129–141

Guillen MD, Ruiz A (2001) High resolution 1H nuclear magnetic resonance in the study of edible oils and fats. Trends Food Sci Technol 12:328–338

Che Man YB, Tan CP (2002) Comparative differential scanning calorimetric analysis of vegetable oils: II. Effect of cooling rate variation. Phytochem Anal 13:142–151

AOCS (2003) Official method and recommended practices of the American Oil Chemists Society. In: Firestone D (eds) 5th edn. AOCS Press, Champaign

Ortega J, Lopez-Hernandez A, Garcia HS, Hill CG Jr (2004) Lipase-mediated acidolysis of fully hydrogenated soybean oil with conjugated linoleic acid. J Food Sci 69:FEP1–FEP6

International olive oil council. Trade standard applying to olive oil and olive pomace oil. Coi/T. 15/NC no. 2/Rev, 1997

Sacchi R, Patumi M, Fontanazza G, Barone P, Fiordiponti P, Mannina L, Rossi E, Segre AL (1996) A high-field 1H nuclear magnetic resonance study of the minor components in virgin olive oils. J Am Oil Chem Soc 73:747–758

Christopoulou E, Lazaraki M, Komaitis M, Kaselimis K (2004) Effectiveness of determination of fatty acids and triglycerides for the detection of adulteration of olive oils with vegetable oils. Food Chem 84:463–474

Tan CP, Che Man YB (2000) Differential scanning calorimetric analysis of edible oils: comparison of thermal properties and chemical composition. J Am Oil Chem Soc 77:143–155

Acknowledgments

The authors would like to acknowledge the Isfahan University of Technology for their financial support and B. Bahrami for his technical assistance.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Jafari, M., Kadivar, M. & Keramat, J. Detection of Adulteration in Iranian Olive Oils Using Instrumental (GC, NMR, DSC) Methods. J Am Oil Chem Soc 86, 103–110 (2009). https://doi.org/10.1007/s11746-008-1333-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-008-1333-8