Abstract

Partial hydrogenation of vegetable oils is carried out to improve the chemical stability and raise the melting point to produce semi-solid products such as margarine. Trans fatty acids formed during traditional hydrogenation have come under intense scrutiny with regard to human health. Here we report partial hydrogenation of soybean oil using a high performance integral-asymmetric polyetherimide membrane sputtered with platinum to deliver hydrogen directly to or near the catalytic sites. Oil flows past the platinum-coated “skin” side of the membrane while dissolved molecular and some atomic hydrogen is supplied from the highly porous substructure of the membrane. The membrane has a high hydrogen flux but is essentially impermeable to soybean oil. Hydrogenation using our metal/polymer catalytic composite membrane produced oil with only 4 wt.% total trans fatty acids and 14.5 wt.% C18:0 saturates at IV of 95 while the conventional Pt/C slurry reactor produced more than 10 wt.% TFA and the same amount of C18:0 saturates under similar conditions of temperature and pressure. Our concept requires hydrogen pressures of only about 65 psi and temperatures near 70 °C. The polymeric base membranes used here have been mass produced and can be packaged in spiral wound modules. The relatively mild reaction conditions and the direct pathway to produce useful membrane modules combine to make our concept promising for near-term application.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The partial hydrogenation of vegetable oil to improve its oxidative stability and increase its solid fat content has been practiced since the early nineteenth century. Improved oxidative stability increases the shelf life of the product and the solid fat content makes it more suitable for margarines, shortenings, and baking applications. Recent health concerns regarding trans fatty acids (TFAs) formed during partial hydrogenation of oil have led to a renewed interest in hydrogenation technologies and process modifications that minimize TFAs. Ideally, the technology being considered should be easy to commercialize and be compatible with the existing hydrogenation facilities. Processing temperatures and hydrogen pressures compatible with existing capital equipment are especially important.

The vegetable oil hydrogenation process can be described by the Horiuti-Polanyi mechanism in which hydrogen dissociates on the catalyst surface and forms an unstable half-hydrogenated intermediate complex with the adsorbed fatty acid molecule. The half-hydrogenated intermediate formed can isomerize, or add or lose additional hydrogen, depending on the concentration of hydrogen at the surface of the catalyst. A high concentration of hydrogen at the surface of the catalyst would favor hydrogenation while a lower concentration of hydrogen at the surface of the catalyst would favor isomerization and thus the formation of TFAs [1].

Industrial hydrogenation of vegetable oil is a three-phase (gas–solid–liquid) process generally carried out in a batch autoclave over nickel based catalyst as a slurry at 110–190 °C, 30–70 psi hydrogen pressure, with 0.01–0.15 wt.% Ni [2]. Due to the low solubility of hydrogen in oils, the conventional industrial hydrogenation slurry reactors suffer from significant gas–liquid mass transfer limitations. This may often lead to the surface of the catalyst being hydrogen starved and result in an increased amount of TFAs. The relatively high temperature used in these reactors also promotes the formation of TFAs by increasing the hydrogen consumption rate which exacerbates hydrogen starvation of the catalyst surface. TFA formation can be minimized by increasing pressure, decreasing temperature, and increasing agitation to address mass transfer limitations [3]. These changes increase the hydrogen availability at the surface of the catalyst and lead to lower TFAs. However, there are practical limits to which pressure and agitation can be increased and thereby TFAs reduced in conventional industrial reactors.

Precious metal catalysts are active at considerably lower temperatures and can thus produce less TFA as compared to conventional Ni catalysts. The order of catalytic activity of precious metal catalysts is Pd > Rh > Pt > Ru. The cis–trans isomerization follows the order Pd > Rh > Ru > Pt [1]. Due to the low selectivity of Pt towards cis–trans isomerization, it may be the most interesting metal for future hydrogenation catalysts [2]. Several studies focus on the use of precious metal catalysts for partial hydrogenation of vegetable oil [4]. A disadvantage of using metal catalysts in slurry systems is the difficult recovery of the catalyst particles from the reaction mixture which results in loss of precious metal catalyst.

Other modifications which have been reported to lead to low TFA include using a solvent to increase hydrogen solubility in oil under supercritical conditions [5], using novel reactors like electrochemical hydrogenation cell [6], or other novel reactor configurations [7–9].

Here we demonstrate the hydrogenation of soybean oil over metal/polymer composite asymmetric membrane with platinum catalyst deposited on the “skin” side of an integral-asymmetric polymeric membrane and hydrogen being supplied directly at or near the surface of the catalyst. The concept of supplying hydrogen at the catalyst surface was studied by Gryaznov et al. [10] for the hydrogenation of cyclopentadiene. A polydimethylsiloxane film was covered with a dense layer of Pd-Ru alloy which supplied atomic hydrogen at the surface of the catalyst for the hydrogenation reaction. The very low hydrogen permeability of metals, however, does limit the efficiency of this process. The Pt catalyst layer in our case is imperfect and has defects which are beneficial to the process as is discussed below. The hydrogenation results obtained are compared with conventional slurry system and other developing technologies.

Concept

The metal/polymer composite catalytic membrane used here consists of an integral asymmetric membrane with high flux and selectivity for hydrogen and negligible permeability to vegetable oil. The polymeric membrane consists of a highly porous substructure with a thin (approximately 0.2 μ) dense and defect-free layer known as the membrane skin which results in high hydrogen selectivity and flux for defect-free membranes. Gases permeate through the thin skin by the well-known solution/diffusion mechanism while the porous substructure allows convection. These solution diffusion polymeric membranes have no continuous passages but rely on the thermally agitated motion of chain segments comprising the polymer matrix to generate penetrant scale transient gaps in the matrix, thereby allowing diffusion through the membrane [11]. The membrane skin is coated with a very thin layer of platinum using a magnetron sputter. Hydrogen would emerge only as atomic hydrogen at the oil side of the metal coating if the platinum layer was defect free. This would result in quite low hydrogen fluxes [12]. The platinum layer on the membrane used in our case has defects which results in significant hydrogen fluxes with our sputtered membranes (see below). This, however, is neither unexpected nor detrimental to our concept.

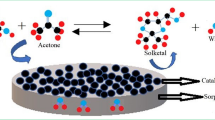

Figure 1 shows a proposed schematic of our vegetable oil hydrogenation process. In the concept studied, hydrogen is supplied from the porous side of the membrane and oil is pumped across the skin/platinum side of the membrane where it comes in contact with the catalytic metal. A positive hydrostatic pressure is maintained on the oil side to prevent the membrane from being mechanically destroyed. We assume that the hydrogen diffuses mainly through the defect-free polymeric skin under the driving force of a hydrogen partial pressure difference maintained by consumption of hydrogen by hydrogenation reaction near the membrane surface. Since the hydrogen is supplied near or at the catalytic sites and in part as atomic hydrogen permeating metal-coated portions of the membrane we expect that TFAs will be reduced since hydrogen starvation of the catalytic surface can be avoided. If hydrogen builds up in the oil then the driving force for hydrogen permeation will diminish which represents a type of self-limiting mechanism for hydrogen transport through the membrane to the oil phase.

Thus, we propose to minimize TFA formation by avoiding hydrogen starvation of the catalyst surface by directly supplying hydrogen to the catalytic sites via “reverse permeation” (from substructure to skin) of a high-flux thin film asymmetric metal/polymer composite membrane with a perfect polymer skin and a “defective” metal coating.

Experimental Procedure

Materials

Soybean oil (Iodine Value IV = 129–131) was obtained from MP Biomedicals (Solon, OH). Table 1 gives the fatty acid profile of soybean oil as measured by us. PEI to cast asymmetric membranes was obtained from General Electric (Huntersville, NC, Ultem-1000). Acetic acid (HPLC grade), acetone (99.5%), p-xylene (99.9%), and dichloromethane (99.9%), used in membrane casting were obtained from Fisher Scientific (Rochester, NY), 1,1,2,2-tetrachloroethane (98%), and, a 5 wt.% Platinum on activated carbon catalyst used hydrogenation experiments were from Sigma Aldrich (St. Louis, MO). Platinum target (99.95 wt.% platinum) for membrane sputtering was from Ted Pella Inc. (Redding, CA).

Membrane Preparation

The integral asymmetric PEI membranes used in this study were fabricated using the phase inversion process as described by Peinemann [13]. About 170 ml of a solution containing 15.9 wt.% polyetherimide, 54.6 wt.% dichloromethane, 4.8 wt.% 1,1,2,2-tetrachloroethane, 17.6 wt.% xylene (swelling/pore forming agent) and 7.1 wt.% acetic acid (swelling/pore forming agent) was prepared. The polymer solution was cast onto a pre-cooled glass plate (11 × 8.5 in., 16–18 °C) as a film of approximately 350 μm thickness using a Gardner knife. After 3–4 s evaporation in air by free convection the nascent membrane is submerged in an acetone bath at 12–16 °C for 30 min. The nascent membranes are then air dried overnight. Circular stamps (4.6 cm diameter) are cut and tested in a filter holder (see below) for their gas flux using a constant-volume variable-pressure apparatus similar to the one described elsewhere [14]. All evaluations were completed at 25 °C with a feed pressure of 65 psi. The normalized gas flux and the ideal gas selectivity (H2/N2) are calculated as a quality control. The ideal gas selectivity αH2/N2 is the ratio of the normalized gas fluxes for gas H2 and N2 at a given temperature and feed pressure.

The hydrogen flux of these membranes can be as high as 100 GPU (one gas permeation unit or GPU equals 10−6 cm 3(STP) cm−2 s−1cmHg−1) and ideal gas selectivities measured by single gas permeation of αH2/N2 up to 179 at 35 °C(ideal αH2/N2 for PEI) [15]. Any defects in the membrane skin result in ideal gas selectivities that are lower than 179. Membranes were deemed acceptable with a hydrogen flux of at least 20 GPU before sputtering and αH2/N2 of at least 40 before sputtering with platinum.

Acceptable membranes were stored in air. Before their use in hydrogenation experiments, the membranes were sputtered on the skin side with platinum using a DESK II magnetron sputterer (Denton Vacuum, Moorestown, NJ, 3 s at 45 mA, 100 mtorr) and were re-tested for their gas transport properties. The gas flux of the membranes is reduced by on the order of four to fivefold after sputtering as can be expected from coverage of the membrane with a metal layer containing defects. Gas selectivities after sputtering also change and the change depends on factors such as initial αH2/N2, and the defects on the platinum sputtered layer.

The loading of the platinum on the membrane was determined by sputtering platinum on a quartz crystal under the same sputtering conditions as used for sputtering the membrane and measuring the weight of the deposited (μg cm−2) platinum using a quartz crystal microbalance.

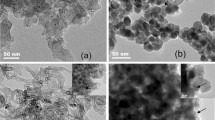

Figure 1a shows an SEM image of an integral asymmetric PEI membrane manufactured in our laboratory using the method [13] discussed above. As shown in Fig. 1a, the membrane consists of a highly porous substructure with a thin dense layer known as a membrane skin. Figure 1b shows SEM of the membrane surface after sputtering with platinum. As shown in Fig. 1b, the platinum layer has defects which result in high hydrogen fluxes through the sputtered membrane. Table 2 gives the properties of the catalytic membrane used in the hydrogenation experiment. The high value of αH2/N2 means that the membrane skin was defect-free but the platinum layer was not. The final flux of the membrane used in hydrogenation experiment was 15 GPU with a Pt catalyst loading of 0.86 μg cm−2 (Fig. 2).

Experimental Setup and Procedures

The platinum sputtered membrane was installed in a stainless steel 47 mm filter holder (model XX4404700, Millipore Corp., Billerica. MA). Figure 3 shows the schematic of the experimental setup used for hydrogenation with catalytic membrane. Before the start of the hydrogenation reaction, the Pt catalyst on the membrane was reduced using hydrogen at 60 °C for 15 h applied to the platinum (skin) side of the membrane with the permeate side open to the atmosphere. About 13.7–13.8 g of oil were added to the system. To avoid oil oxidation, air was removed from the system with a nitrogen purge before heating the oil. The oil was circulated with a flow rate of about 25 g/min across the platinum-sputtered side of the membrane using a gear pump (series GA, Micropump Inc., Vancouver, WA). The oil side pressure was maintained at 75 psi using ultra high purity (UHP) nitrogen applied to the headspace of the reactor. UHP hydrogen was supplied from the porous substructure side of the membrane at 65 psi after the reaction temperature of 70 °C was attained. The hydrogenation reaction was allowed to proceed for 8 h with an oil sample taken every 2 h and analyzed. The conventional slurry reactor run was performed in a Parr Reactor (model number 4565) using 50 g of soybean oil and 0.05 g of 5 wt.% Pt on activated carbon as catalyst. The reaction was performed at 70 °C, 65 psi hydrogen pressure with a stirring speed of 300 rpm (standard four blade turbine type impeller).

Analysis

Oil samples were converted to their corresponding fatty acid methyl esters (FAMEs) following the alternate method in AOCS official method Ce 2–66. FAMEs thus obtained were analyzed by gas chromatography (GC) using a 100 m CP-Sil 88 column in a Hewlett-Packard 6890 series gas chromatograph. AOCS official method Ce 1 h-05 was followed for the analysis of fatty acids. Injection port and column were maintained at 250 and 181 °C, respectively, helium carrier gas at 1 ml/min and split injection (split ratio 1:100) was used. The IV of hydrogenated oil was calculated from the composition obtained by GC analysis using Eq. 1, [16].

Hydrogenation Selectivity Calculation

If the hydrogenation of soybean oil is represented by the first-order irreversible reaction scheme as shown in Eq. 2 then it is possible to calculate hydrogenation selectivities using the experimental composition data from our experiments [17].

where k 1, k 2, k 3 are pseudo-first-order rate constants. The linolenate (SLn), Linoleate (SL), and, oleate (SO) fatty acid selectivities are defined as

Integrating the appropriate rate equations based on Eq. 2 for the mol% of linolenate [Ln], linoleate [L], and oleate [O] fatty acids and rearranging yields [17]

The selectivities reported here were calculated using our experimentally determined oil composition and then solving Eqs. (6)–(8) to obtain k 1, k 2, and k 3 using a computer code as described in AOCS official method Tz 1b-79. The code was rewritten in java with a convergence criterion of 0.01%.

Results and Discussion

An improved soybean oil hydrogenation process not only must reduce the formation of TFA significantly at comparable levels of hydrogenation as represented by the target IV number but the process must also ideally do so at hydrogen pressures, operating temperatures, and stirring speeds that do not require major modifications to existing facilities. The need for costly catalyst materials must be minimized and a long catalyst life is desirable. Below we show a comparison of the metal/polymer catalytic integral-asymmetric membrane process with conventional and other novel approaches.

Figure 4 compares the TFA versus IV profile obtained for hydrogenation experiments using a platinum membrane, a Pt/C slurry reactor, a Pt/TiO2 slurry reactor [18] and a conventional Ni slurry reactor [19]. It should be kept in mind that for the same catalyst hydrogen starvation of the catalyst surface results in increased TFA formation. As expected, the conventional Ni slurry reactor produced the most TFA, 24.5 wt.% at an IV of 95 [19]. The extremely high amount of TFA produced using the Ni slurry reactor is due to the high selectivity of Ni catalysts for TFA formation as compared to Pt catalysts and also due to higher reaction temperatures used that result in the catalyst surface being hydrogen starved. The hydrogenation run using platinum membrane (70 °C, 65 psi H2, membrane H2 flux = 15 GPU, membrane αH2/N2 = 200) produced the least amount TFA, 3.5 wt.% at an IV of 95. Hydrogenation run under similar conditions of temperature and pressure with the Pt/C slurry reactor produced significantly higher TFA as compared to the catalytic membrane reactor (more than 8 wt.% TFA at an Iodine Value of 95). Conventional slurry hydrogenation run reported with Pt/TiO2 [18] (100 °C, 60 psi H2) produced much higher TFA, 12.5 wt.% at an IV of 95, possibly due to the higher temperature used for the reaction. We hypothesize that our concept of supplying hydrogen from the substructure of the metal/polymer composite membrane directly at or near the catalytic sites reduces TFA formation due to alleviating hydrogen starvation of the catalyst surface when compared to supplying hydrogen by diffusion from the bulk oil phase.

Trans fatty acid content as a function of Iodine Value during hydrogenation of vegetable oil. Pt catalytic membrane (filled squares, secondary x-axis gives the time for corresponding iodine values, only for Pt catalytic membrane), Pt/C slurry reactor (open squares) at 70 °C, 65 psi, Pt/TiO2 slurry reactor at 100 °C, 60 psi (open circles) [18], and Ni slurry reactor at 140 °C, 15 psi (open triangles) [19]

Due to the different metal/oil ratios, metal dispersion, and type of reactors used it may be inappropriate to directly compare the reaction rates for all the above cases. However, in order to provide an insight into the hydrogenation rates obtained in thecatalytic membrane reactor, the secondary x-axis in Fig. 4 gives the time corresponding to the iodine values for the catalytic membrane reactor.

Figure 5 compares the composition profiles (C18:0, C18:1, C18:2, C18:3) of hydrogenation using a Pt catalytic membrane, a Pt/C catalyst as a slurry at 70 °C, 65 psi, and a conventional Ni/Si catalyst at 140° [19]. The Ni slurry reactor produced significantly higher C18:1 and lower C18:0 as compared to the platinum catalysts. The SLN, SL, SO fatty acid selectivities were 2.0, 18.5, and 37.4, respectively. The significant differences in composition profiles with increasing hydrogenation for the conventional Ni catalysts are characteristics of Ni catalysts and are consistent with the literature. The platinum membrane produced very similar composition profile for all the components as compared to the conventional Pt/C slurry reactor. The SLN, SL, SO fatty acid selectivities were 1.5, 2.6, and 3.8, for the platinum membrane reactor and 1.6, 2.4, 3.9 for Pt/C slurry reactor. Although an increase in hydrogen concentration at the catalyst surface is also generally accompanied by a decrease in hydrogenation selectivities, they are also affected by the physical characteristics of the catalyst as it controls the diffusion of reactants in and out of the catalyst pores. Selectivities are higher when triglyceride molecules can move freely in and out of the catalyst pores [20]. Conventional slurry reactors use a catalyst supported on a porous support, which increases diffusion limitation of triglyceride molecules and decreases the hydrogenation selectivity. Due to the non-porous and structured nature of the platinum catalyst on the membranes, higher selectivities may have been expected but because of the high hydrogen concentration at the catalyst surface the selectivities were ultimately very similar to Pt/C slurry reactors with lower TFAs being produced while using a platinum membrane reactor.

Fatty acid composition as a function of IV during hydrogenation of soybean oil using Pt catalytic membrane (solid line), Pt/C slurry reactor (dashed line), and Ni slurry reactor (gray dashed line) [19]. Reaction conditions: temperature = 70 °C (140 °C for Ni slurry reactor [19]), hydrogen pressure = 65 psi (15 psi for Ni slurry reactor [19])

Several authors have studied novel reactor configurations for the partial hydrogenation of vegetable oil. Figure 6 compares TFA and C18:0 saturates (at IV = 90 except where specified) from some of these reports with those obtained in the present study. Schmidt et al. [8] hydrogenated sunflower oil using a membrane reactor in the pore-flow-through mode where the reaction mixture was pumped through catalytic active porous membranes (using both Pt and Pd catalyst). The aim was to prevent TFA formation by eliminating mass transfer limitations. However hydrogen scarcity at the catalyst surface promoted the isomerization to TFA as compared to the conventional process. The amount of TFAs formed using these membranes with a platinum catalyst was 15 wt.% at an IV of around 98 (80 °C, 290 psi H2). Fritsch et al. [7] developed microporous polymer membranes with very high oil fluxes (1,000–2,000 L m−2 h−1 bar−1) and the membranes were activated with platinum. The membranes were then used for hydrogenation of sunflower oil at 100 °C and 58 psi. The amount of TFA and C18:0 saturates formed at an IV of 90 were 22 and 12.5 wt.%, respectively, which is very high and may not satisfy the specifications established.

Piqueras et al. [18] reported the hydrogenation of sunflower oil on a Pt/TiO2 catalyst using supercritical propane to eliminate the gas–liquid interface and increase the hydrogen solubility in oil by creating a homogeneous phase. This led to an increase in hydrogen concentration at the surface of the catalyst as compared to the conventional process and thus resulted in very low TFA formation. At an IV of 90 the TFA formed were 4 wt.% as compared to 13 wt.% formed in the conventional slurry process under similar conditions. The decrease in TFA was also accompanied by an increase in C18:0 saturates from around 10 wt.% in a conventional reactor to 20 wt.% when using supercritical propane. However the pressure used to achieve the homogeneous phase is extremely high (2,300 psi) which would require special equipment designed to handle high pressures. Pintauro et al. [6] reported the hydrogenation of soybean oil using a solid polymer electrolyte reactor where hydrogen is generated in situ by the electro-reduction of protons at the anode and migrate through the ion exchange membrane to Pt-black cathode where the reaction takes place. The low amount of TFAs and high saturates obtained (3 wt.% total TFA, 21 wt.% saturates at IV 92) using a solid polymer electrolyte electrochemical cell also indicates hydrogenation being carried out at high hydrogen concentration. The membranes studied in this work produced the same low amount of TFA (4 wt.% at IV of 90) and less saturates (14.5 wt.% at an IV of 90) and that also at temperature and pressure which are compatible with the existing equipment and the process is much simpler than operating the reactor as an electrochemical cell.

This study demonstrates a novel integral-asymmetric metal-polymer composite catalytic membrane approach for low TFA hydrogenation of soybean oil. Hydrogen is supplied directly at or near the surface of an integral-asymmetric polymeric membrane sputtered with platinum by pressurizing the porous substructure of the membrane with hydrogen. The oil flows over the platinum-sputtered feed (skin) side of the membrane. The process is simpler than some of the alternatives being studied and no catalyst recovery from the oil is needed since the catalyst is immobilized on the membrane. The system is compatible with existing commercial hydrogenation facilities as far as temperatures (~70 °C) and hydrogen pressure (~65 psi). Our approach shows significantly lower TFA values at comparable hydrogenation levels. We hypothesize that this is due to avoiding hydrogen starvation of the catalyst surface by rapid hydrogen permeation through a high performance asymmetric membrane.

References

Dijkstra AJ (2006) Revisiting the formation of trans isomers during partial hydrogenation of triacylglycerol oils. Eur J Lipid Sci Technol 108:249–264

Veldsink JWB, Martin J, Schoon, Nils-H, Beenackers, Antonie ACM (1997) Heterogeneous hydrogenation of vegetable oils: a literature review. Catal Rev Sci Eng 39:253–318

Musavi A, Cizmeci M, Tekin A, Kayahan M (2008) Effects of hydrogenation parameters on trans isomer formation, selectivity and melting properties of fat. Eur J Lipid Sci Technol 110:254–260

Nohair B, Especel C, Marecot P, Montassier C, Hoang LC, Barbier J (2004) Selective hydrogenation of sunflower oil over supported precious metals. Comptes Rendus Chimie 7:113–118

King JW, Holliday RL, List GR, Snyder JM (2001) Hydrogenation of vegetable oils using mixtures of supercritical carbon dioxide and hydrogen. J Am Oil Chem Soc 78:107–113

Pintauro PN (2001) Synthesis of a low-trans content edible oil, non-edible oil, or fatty acid in a solid polymer electrolyte reactor, US Patent 6218556 B1

Fritsch D, Bengtson G (2006) Catalytic polymer membranes for high temperature hydrogenation of viscous liquids. Adv Eng Mater 8:386–389

Schmidt A, Schomacker R (2007) Partial hydrogenation of sunflower oil in a membrane reactor. J Mol Catal A Chem 271:192–199

Veldsink JW (2001) Selective hydrogenation of sunflower seed oil in a three-phase catalytic membrane reactor. J Am Oil Chem Soc 78:443–446

Gryaznov VM, Ermilova MM, Orekhova NV (2001) Membrane-catalyst systems for selectivity improvement in dehydrogenation and hydrogenation reactions. Catal Today 67:185–188

Baker RW (2004) Membrane technology and applications, Wiley, London

Baker RW, Louie J, Pfromm PH, Wijmans JG (1989) Ultrathin metal composite membranes for gas separation, US Patent 4,857,080

Peinemann KV (1987) Method for producing an integral, asymmetric membrane and the resultant membrane, US Patent 4,673,418

Obrien KC, Koros WJ, Barbari TA, Sanders ES (1986) A new technique for the measurement of multicomponent gas-transport through polymeric films. J Memb Sci 29:229–238

Barbari TA, Koros WJ, Paul DR (1989) Polymeric membranes based on bisphenol-a for gas separations. J Memb Sci 42:69–86

Petursson S (2002) Clarification and expansion of formulas in AOCS recommended practice Cd 1c-85 for the calculation of iodine value from FA composition. J Am Oil Chem Soc 79:737–738

Albright LF (1965) Quantitative measure of selectivity of hydrogenation of triglycerides. J Am Oil Chem Soc 42:250–253

Piqueras CA, Tonetto G, Bottini S, Damiani DE (2008) Sunflower oil hydrogenation on Pt catalysts: comparison between conventional process and homogeneous phase operation using supercritical propane. Catal Today 133:836–841

Dejonge A, Coenen JWE, Okkerse C (1965) Selective hydrogenation of linolenate groups in soya-bean oil. Nature 206:573–574

Patterson HBW (1983) Hydrogenation of fats and oils, Applied Science Publishers Ltd., London

Acknowledgments

The project was supported by the national Research Initiative of the USDA Cooperative State Research, Education and Extension Service, grant number 2005-35503-15398.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Singh, D., Rezac, M.E. & Pfromm, P.H. Partial Hydrogenation of Soybean Oil with Minimal Trans Fat Production Using a Pt-Decorated Polymeric Membrane Reactor. J Am Oil Chem Soc 86, 93–101 (2009). https://doi.org/10.1007/s11746-008-1321-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-008-1321-z