Abstract

Among numerous mesophilic fungi screened for sterol esterase activity followed by the esterification reaction between plant β-sitosterol and lauric acid in organic solvent, six Aspergillus strains were selected as the most active producers. These fungi had not been studied previously for sterol esterase production. The fungi were cultivated under solid state fermentation (SSF) conditions. The gently dried SSF cultures as such were tested in the esterification reactions, without any special enzyme isolation and purification (downstream) processes. All the six Aspergillus SSF preparations were able to synthesize sterol esters. Sterol esterase activity of these GRAS cleared Aspergillus strains was inducible by sterol ester supplementation to the SSF medium and showed remarkably different moisture optimum during growth as compared to the production of lipase (determined by pNP-palmitate). Genome analysis revealed that sterol esterase production might be a common feature of many Aspergillus species. The synthetic usefulness of the best SSF preparations of A. oryzae NRRL 6270 and A. sojae NRRL 6271 was demonstrated by synthesis of esters of plant sterols with lauric acid resulting in 45–63% conversions (GC) and 27–38% isolated yields of steryl laurates. The isomer preference of A. oryzae NRRL 6270 towards the 10E,12Z isomer of conjugated linoleic acid (CLA) in the esterification reaction with plant sterols was also determined.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Phytosterols (referred to as sterols) and their fatty acid esters (steryl esters) are known to reduce blood cholesterol levels [1]. This physiological activity has led to the development of several neutraceutical foods, such as a salad oil with addition of sterols or steryl esters and a margarine blended with steryl esters [2]. In addition, sterols and sterol esters are useful compounds in cosmetics, for example in moisturizing ointments, or as gelling agents in antiperspirant deodorants [3].

Practical applications of free sterols in foods are limited due to their low solubility and high melting point. Therefore fatty esters of sterols are generally preferred in the food industry [4].

Sterols in plants exist as free alcohols, esters with fatty acids, glycosides, and acylated glycosides. In edible oils, sterols can be present in the free and/or esterified forms. Considerable variability in the proportion of free and esterified sterols was observed among different oils and fats, with free sterols ranging from 32 to 94% of the total sterols. Refining or hydrogenation tended to decrease total sterols and increase esterified sterols [5].

Sterol esterases (EC 3.1.1.13) hydrolyze fatty acid esters of sterols. They have been studied extensively from a number of mammalian tissues primarily because of their importance in the absorption and metabolism of cholesterol [6]. They have also been detected and characterized in microbes of different origins: fungal [7], bacterial [8], of yeast [9].

Solid state fermentation (SSF) offers numerous advantages for the production of several metabolites relevant for the food processing industry. SSF has also proved itself to be an economical way to produce various enzymes including lipases and esterases [10].

The above precedents prompted us to cultivate a series of filamentous fungi by solid state fermentation (SSF) and screen them for novel sterol esterase activities. Among these organisms, our aim was to find useful sterol esterase activity in strains being GRAS (Generally recognized as safe) cleared, which is advantageous in application of such biocatalysts in the food or cosmetic industries.

The goal was therefore to test such strains, which had not been investigated or not in detail as sterol esterase producers. Because the gently dried SSF preparations without any costly downstream processing can be considered as inexpensive, naturally immobilized biocatalysts, we tested these materials not only as sterol esterase producers but also evaluated their behavior in synthetic esterification reactions as well.

Experimental

Materials and Methods

GC analyses were carried out on HP 5890 or Agilent 4890D instruments equipped with a FID detector and Restek Rtx-65TG column (30 m × 0.25 mm, 0.10 μm film with 35% dimethyl–56% diphenyl polysiloxane; Restek) or HP- INNOWax column (30 m × 0.32 mm, 0.25 μm film with crosslinked polyethylene glycol; HP), or SGE BPX-70 column (60 m × 0.22 mm, 0.25 μm film with 70% cyanopropylpolysiloxane; SGE Pty, Australia) using H2 as the carrier gas. The experimental molar response factor for the lauryl ester of the plant β-sitosterol over unreacted β-sitosterol was 0.98.

The NMR spectra were recorded in CDCl3 on a Bruker DRX-500 spectrometer (at 500 MHz for 1H- and 125 MHz for 13C-spectra) and are reported in ppm on the δ scale.

TLC was carried out on Kieselgel 60 F254 (Merck) sheets. Spots were visualized by treatment with 5% ethanolic phosphomolybdic acid solution and heating of the dried plates.

All solvents were freshly distilled prior to their use. Lauric acid was obtained from Fluka (No 61620), plant β-sitosterol (65% purity) was purchased from Merck (No. 3741; this composition is referred to as plant β-sitosterol throughout this work). The sterol composition (55.6% β-sitosterol, 36.9% stigmasterol, 5.9% campesterol, 1.4% cholesterol) of this product was determined by GC according to ISO 12228 using a standard sample (Supelco 4-7150) containing different types of sterols. The conjugated linoleic acid (CLA) preparation having 79.7% CLA content [the two main isomers 9Z,11E (48.6 %) and 10E,12Z (48.5%) along with minor amounts of E,E-CLA isomers (2.1%) and Z,Z-CLA isomers (0.8%), all normalized to the total CLA content] was a kind gift from Loders and Croklaan Lipid Nutrition Co. (Wormer veer, Netherlands).

Lipase from Candida cylindracea was purchased from Fluka (No. 62316). The inorganic salts and materials for biomass production were the corresponding products of Sigma, Aldrich or Fluka.

Microorganisms

The filamentous fungi used in this study were as follows: Actinomucor elegans ATCC 6476; Aspergillus niger ATCC 10864; Aspergillus oryzae IFO 5238, NRRL 1808, NRRL 3485 and NRRL 6270; Aspergillus oryzae var. brunneus IFO 30102; Aspergillus sojae NRRL 6271; Aspergillus sp. TUB F-1755; Aspergillus terreus FRR 2532; Chaetomium cochliodes NRRL 2320; Chaetomium elatum UAMH 2672; Chaetomium funicola UAMH 3034; Chaetomium globosum NRRL 6296 and OKI 270; Chaetomium virescens ATCC 32319; Epicoccum nigrum BSUM; Fusarium oxysporum f. sp. dianthi HIPP; Gliocladium catenulatum NRRL 1093; Gliocladium roseum NRRL 1085; Gliocladium vermoesenii NRRL 1752; Mucor hiemalis NRRL 13.009; Myrothecium verrucaria NRRL 2003; Paecilomyces farinosus VKM F-816; Paecilomyces lilacinus NRRL 895; Paecilomyces marquandii NRRL 901; Paecilomyces varioti IFO 4855; Phanerochaete chrysosporium ATCC 24725; Rhizopus arrhizus ATCC 6204; Rhizopus sp. TUB F-1260; Scopulariopsis brevicaulis WFPL 248 A; Stemphylium botryosum DAOM 166.388, Thamnidium elegans ATCC 18.191, Thamnostylum piriforme ATCC 8686; Tolypocladium geodes CBS 723.70; Trichoderma asperellum TUB F-868; Trichoderma effusum TUB F-354; Trichoderma harzianum ATCC 56.678, TUB F-791, TUB F-886, TUB F-946, TUB F-947 and TUB F-963; Trichoderma virens TUB F-498 and Zygorchynchus moelleri ATCC 1208. The strains were obtained from American Type Culture Collection (ATCC), Manassas, VA; Botany School, University of Melbourne (BSUM), Parkville, Vic., Australia; Centraalbureau voor Schimmelcultures (CBS), Utrecht, The Netherlands; Department of Agriculture, Eastern Cereal and Oilseed Research Centre (DAOM), Ottawa, Canada; Institute for Fermentation (IFO), Osaka, Japan; Food Research Laboratory (FRR), CSIRO, North Ryde, NSW, Australia; Hungarian Institute for Plant Protection (HIPP), Budapest, Hungary; Northern Regional Research Center (NRRL), USDA, Peoria, IL, USA; National Institute for Public Health (OKI), Budapest, Hungary, Budapest University of Technology and Economics (TUB), Hungary; University of Alberta Mold Herbarium and Culture Collection (UAMH), Alberta, Canada; Russian Culture Collection of Microorganisms (VKM), Moscow, Russia and Western Forest Products Laboratory (WFPL), Vancouver, Canada. Many of these isolates were tested in our previous study for lipase production (13). Strains were stored as freeze-dried cultures and revitalized on potato-dextrose-agar (PDA) medium in Petri plates at 30 °C.

Solid State Fermentation (SSF)

Solid state fermentation was carried out in cotton-plugged 500 ml Erlenmeyer flasks on a solid wheat bran medium (10 g) containing a mixture of wheat bran (9 g) and olive oil (1 g), and wetted with a salt solution to a 60 and 70% moisture content. In a few experiments a mixture of sterol esters (1 g)—instead of olive oil—was used as an enzyme inducer. Composition of the salt solution (w/v) was 0.5% NH4NO3, 0.5% KH2PO4, 0.1% MgSO4·7H2O, 0.1% NaCl and 0.1% (v/v) trace element solution, pH 6.0. The composition of the trace element solution (w/v) was the following: 0.08% MnSO4, 0.17% ZnSO4·7H2O, 0.25% FeSO4·7H2O. In some experiments performed with the two best strains, Aspergillus oryzae NRRL 6270 and Aspergillus sojae NRRL 6271, wheat bran was also tested in a wider moisture content range, without adding any inducer.

The wet SSF media were routinely sterilized in an autoclave, inoculated from fully sporulating Petri plate cultures (PDA, 106 viable spores/g dry matter SSF medium) and incubated at 30 °C without shaking (still culture).

To avoid inhomogeneity during sampling from the SSF material the whole SSF material in one flask were taken as a sample. In addition, parallel/simultaneous Erlenmeyer flask SSF cultivations were performed in order to obtain an appropriate amount of material for sampling. After dewatering the SSF material (by drying at room temperature or removing water with acetone), the dried SSF samples were properly homogenized. For the organic chemical reactions several smaller portions from different part of the homogenized SSF sample were taken.

Lipase activity was determined from the culture extract of the SSF samples. The content of each Erlenmeyer flask was mixed thoroughly with an appropriate volume (to make a total volume of 150 ml) of 0.1% Tween-80 solution. The SSF material was extracted at room temperature for 2 h with occasional shaking, then centrifuged at 9,500g for 10 min and the supernatant was used for the assay.

In the sterol esterification tests, different types of dry SSF samples were used. The wet SSF material was dewatered by two different methods, namely (a) direct drying at room temperature (21 °C) for 24 h and/or (b), removing water with 3 v/w cold acetone and final drying at room temperature for 24 h (moisture content of dried SSF materials is approximately 6% after room temperature drying). For enzyme extraction studies, SSF material was extracted at room temperature with 0.1% Tween-80 solution (as for the lipase activity tests), and after 2 h, a second extraction step was performed. The extracted SSF material was dewatered with 3 v/w cold acetone and finally dried at room temperature for 24 h. For testing the ultrafiltered crude enzyme extracts, 10 ml of the crude supernatants (right after extraction and centrifugation) were filtered through a 0.22 μm filter (Millipore) and concentrated by ultrafiltration using a 5-kDa Amicon Ultra Centrifugal Filter Device (Millipore) at 3,500g for 45 min. The filtrate and the concentrated solution were lyophilized before use in the sterol esterification experiments.

Shake Flask/Submerged Fermentation (SmF)

Three different media were used for shake flask fermentation experiments: Med 1, containing 3% (w/v) of ground wheat bran, 0.3% (w/v) of NH4NO3, 0.3% (w/v) of KH2PO4, 0.05% (w/v) of NaCl, 0.05% (w/v) of MgSO4·7H2O, 0.1% (w/v) of trace element solution. Med 2, containing 3% (w/v) of ground wheat bran, 0.5% of (w/v) corn steep liquor (50%), 0.3% (w/v) of (NH4)2HPO4, 0.05% (w/v) of NaCl, 0.05% (w/v) MgSO4·7H2O, 0.1% (w/v) trace element solution. Med 3, containing 3% (w/v) of ground wheat bran, 0.5% (w/v) of soybean meal, defatted, 0.1% (w/v) of (NH4)2SO4, 0.1% (w/v) of KH2PO4, 0.1% (w/v) of CaCO3, 0.05% (w/v) of NaCl, 0.05% (w/v) of MgSO4·7H2O, 0.1% (w/v) of trace element solution.

The composition of the trace element solution is the same as the one used in SSF; 150 ml of each medium was added to a 750 ml flask and sterilized in an autoclave at 121 °C for 20 min. The sterile media were inoculated from fully sporulating Petri plate cultures (106 viable spores per ml) and incubated at 30 °C on a rotary shaker at 220 rpm. After 40 h of incubation the crude fermentation material was centrifuged at 9,500g for 10 min and the supernatant was used for the assay.

For the sterol esterification tests, dried (a) or ultrafiltered (b) SmF (submerged fermentation) samples were used.

-

(a)

The 40 h SmF material was filtered through a glass filter, washed with distilled water and dried at room temperature for 24 h (fungal biomass plus residual insoluble media components).

-

(b)

Ten milliliter of the centrifuged supernatant was filtered through a 0.22-μm filter (Millipore) and concentrated by ultrafiltration using a 10-kDa Amicon Ultra Centrifugal Filter Device (Millipore) at 3,500g for 45 min. The filtrate and the concentrated solution were lyophilized before use in sterol esterification experiments (extracellular enzymes).

Lipase Activity Test from SSF Preparations

Lipase activity was determined according to Vordelwülbecke et al. [11] using p-nitrophenyl-palmitate (pNPP, SIGMA) as a substrate. Solution A contained 90 mg of pNPP dissolved in 30 ml of propane-2-ol. Solution B contained 2 g Triton X-100 and 0.5 g gum arabic (SIGMA) dissolved in 450 ml buffer (Tris–HCl, 50 mM, pH 8.0). The assay solution was prepared by adding 1 ml of solution A to 9 ml of solution B to obtain an emulsion, which remained stable for 2 h. The assay mixture contained 2 ml of the emulsion and 0.5 ml of the appropriately diluted enzyme extract. After incubation at 45 °C for 30 min, the liberated p-nitrophenol (pNP) was measured at 410 nm.

Enzymatic Sterol Ester Formation Screen

Suspensions of the enzyme preparations (20 mg/5 mg in case of the concentrated enzymes) with a solution of β-sitosterol (20 mg) and lauric acid (20 mg) in toluene (0.5 ml) were shaken at 1,000 rpm in sealed glass vials at room temperature for the time indicated in Tables 1, 2 and 3. The conversions were checked by TLC (hexane-acetone 10:1, v/v). At the reaction time indicated in Tables 1, 2 and 3, the ratio of the product and residual substrate fractions were analyzed by GC.

Enzymatic Esterification of β-Sitosterol with Lauric Acid on Preparative Scale

The preparative scale conversions of β-sitosterol (200 mg, each) catalyzed by SSF preparation 229 and 231 (from Aspergillus oryzae NRRL 6270) or by 239 and 241 (from Aspergillus sojae NRRL 6271) (200 mg each) were also performed with lauric acid (200 mg) in toluene (5 ml). After shaking the reaction mixture at 1,000 rpm, 35 °C for 72 h, the enzyme preparation was removed by filtration. The solvent was distilled off from the filtrate by rotary evaporation and the residue was separated by column chromatography (silica gel, hexane-acetone 10:0.2, v/v) to give the sterol ester as a light yellow oil.

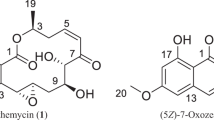

GC data of the purified lauric ester are shown in Fig. 1. GC retention times (Restek Rtx-65TG column, injector 350 °C, detector 350 °C, 290–322 °C, at 2 °C/min, 16 psi); Rt, min: for components of the plant β-sitosterol: 2.41 (cholesterol), 2.92 (stigmasterol), 3.03 (campesterol) and 3.26 (β-sitosterol, main); for components of the lauryl ester of the plant β-sitosterol: 11.65, 12.39, 12.76, 13.57 (main). Characteristic signals of the sterol esters (in addition to the aliphatic/alicyclic protons of the sterol moiety) in the 1H-NMR spectra: 0.9 ppm (3H, s, CH3), 1.25 ppm (18H, m, 9 × CH2), 2.23 ppm (2H, t, C3–CH2), 4.63 ppm (1H, m, CH–OAcyl).

GC data for the esterification reaction of plant β-sitosterol with lauric acid catalyzed by SSF-preparation 241 (Aspergillus sojae NRRL 6271). a GC chromatogram of the plant β-sitosterol used as starting compound (1: cholesterol, 1.4%; 2: stigmasterol, 36.9%; 3: campesterol, 5.9%; 4: β-sitosterol, 55.6%). b GC chromatogram of an esterification reaction mixture from β-sitosterol and lauric acid with an 85% conversion. c GC data for the purified product (lauryl ester of plant β-sitosterol: 5: cholesteryl laurate; 6: stigmasteryl laurate; 7: campesteryl laurate; 9: β-sitosteryl laurate)

Enzymatic Esterification of β-Sitosterol with Conjugated Linoleic Acid (CLA) on Preparative Scale

Esterification of β-sitosterol (400 mg, 0.97 mol) with conjugated linoleic acid (272 mg, 0.97 mol) in the presence of SSF-241 preparation (from Aspergillus sojae NRRL 6271) was performed in toluene (10 ml). After shaking the reaction mixture at 1,000 rpm, 35 °C for 168 h, the enzyme preparation was removed by filtration. The solvent was distilled off from the filtrate by rotary evaporation and the residue was separated by column chromatography (silica gel, hexane-acetone 10:0.2–10:1, v/v) to give sterol ester (410 mg, 61%), residual CLA (75 mg, 28%) and β-sitosterol (108 mg, 27%). Conversion was determined by 1H-NMR using the integral ratio of the two characteristic signals of the free sterols at 3.57 ppm (0.3 H, m, –CH–OH) and sterol esters at 4.63 ppm (0.7 H, m, CH–OAcyl).

GC-data for the residual conjugated linoleic acid is shown in Fig. 2. GC retention times (HP-INNOWax column, injector 250 °C, detector 250 °C, 100–250 °C, at 10 °C/min, 12 psi) for the main isomers of residual CLA; Rt, min: 17.18 (35.9%, minor, 10E,12Z-isomer) and 17.30 (64.1%, major, 9Z,11E-isomer).

GC data for the esterification reaction of plant β-sitosterol with CLA catalyzed by SSF-preparation 241 (Aspergillus sojae NRRL 6271). a GC chromatogram for the starting CLA (the two stereoisomers: 9Z,11E- and 10E,12Z-isomers). b GC chromatogram for the unreacted CLA fraction for the reaction mixture of the esterification reaction between plant β-sitosterol and CLA after 70% conversion

Identification of the CLA Isomers by Preparation of Conjugated Linoleic Acid Methyl Ester and its Partial Hydrolysis with Lipase from Candida cylindracea

To a solution of conjugated linoleic acid (5 g) in toluene (50 ml) and methanol (50 ml) was added dropwise 5 ml conc. sulfuric acid. After 12 h, the mixture was diluted with 100 ml hexane, washed with sat. Na2CO3 solution (2 × 50 ml) and brine (30 ml). After drying over MgSO4, the solvent was removed in vacuum to yield CLA methyl ester (88%) as a light yellow oil. GC analysis of CLA methyl ester was performed on HP-INNOWax column.

CLA methyl ester (200 mg) and lipase from Candida cylindracea (50 mg) were added to 0.1M sodium phosphate buffer (3 ml, pH = 7) and the mixture was shaken at room temperature for 0.5 h. The product was extracted with dichloromethane (5 ml) dried (MgSO4). GC analysis of the isolated reaction mixture revealed 18% conversion.

GC retention times (HP-INNOWax column, injector 250 °C, detector 250 °C, 100–250 °C, at 10 °C/min, 12 psi); Rt, min: for the CLA methyl ester fraction: 11.46 (26.37%, minor, 10E,12Z-isomer) and 11.57 (55.43%, major, 9Z,11E -isomer), for the CLA fraction: 17.18 (15.82%, major, 10E,12Z-isomer) and 17.30 (2.37%, minor, 9Z,11E-isomer).

Results and Discussion

There are several reports dealing with extracellular lipase production by fungi on different media under submerged (SmF) conditions. However, in recent years it was found that SSF is more appropriate in several cases for the production of enzymes and other thermolabile products, because higher yields can be obtained than in SmF [12]. Because a previous lipase/esterase activity screening of mesophilic fungi cultivated by solid state fermentation (SSF) resulted in biocatalysts exhibiting high productivity and enantioselectivity in synthetic biotransformation [13] and isolation of novel microbial sterol esterases—e.g., from ascomycete Melanocarpus albomyces [14]—have been published recently, we thought it worthwhile to screen several less characterized fungi for sterol esterase activities. Considering the SSF matrix as a natural immobilization carrier, we decided to test the gently dried SSF materials as biocatalysts without further downstream processing.

As in numerous cases, lipase preparations—e.g., from porcine pancreas (PPL, Amano), Pseudomonas sp. (Lipase PS, Amano), Chromobacterium viscosum (Lipase LP) and Candida rugosa (Lipase AY, Amano)—exhibited sterol esterase activities as well [15], whereas lipase preparations from Aspergillus sp. (Lipase A, Resinase A) exhibited no sterol esterase activity [16]—the lipase activity and the sterol ester production activity were tested in parallel.

First, we tested the sterol esterase activity of all the strains, which were screened for lipase activity previously [13] using esterification of β-sitosterol with lauric acid in an organic solvent. Because in this preliminary screen, only Aspergillus species exhibited measurable sterol esterase activity, the investigation was extended to other Aspergillus strains, which are GRAS (Table 1).

In this extended screen of sterol esterase activity, the SSF conditions (wheat bran of 60% moisture content as substrate, olive oil as inducer and air drying at RT) applied in our recent screen for lipase activity of fungal strains [13] were chosen as a starting point. In addition, the effect of water content during SSF (60 or 70% moisture contents) and the drying method of the biomass (simple air drying at R.T. or washing with acetone) on sterol esterase activity were also tested (Table 1).

Considering the highest rate of conversion in esterification of β-sitosterol and the simplicity of the final treatment of the biocatalyst, the SSF conditions using wheat bran having 60–70% moisture content in substrate, olive oil as inducer and air drying at RT were chosen as conditions for further screening. From the six Aspergillus oryzae/sojae SSF enzyme preparations tested, two strains (A. oryzae NRRL 6270 and A. sojae NRRL 6271) exhibiting good conversions at 240 h in the sterol esterification reaction were chosen for the further tests.

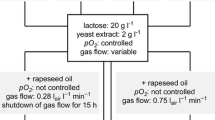

In several cases, the sterol ester activities of the SSF preparations were not in accordance with their lipase activities. To clarify this situation, these two strains (A. oryzae NRRL 6270 and A. sojae NRRL 6271) were further tested under SSF conditions, using different substrates and no inducer in a wider range of moisture contents (Table 2). It became clear that these conditions had a different effect on the lipase and sterol esterase activities. Interestingly, slightly higher lipase activities were observed for the non-induced SSF preparations as for the preparations induced with olive oil, with a maximum at 75% moisture content. In contrast, the sterol esterase activity was high at lower moisture content (60–67%) and decreased significantly when the moisture content was above 70%. Both lipase and sterol esterase activities of SSF preparations cultivated on sunflower seed waste or rapeseed were lower than that of SSF preparation cultivated on wheat bran under the same conditions. The best condition for sterol esterase production of the two selected Aspergillus species by SSF without inducer was found to be a cultivation on wheat bran containing 67% moisture.

Because inducing by olive oil had a positive impact on lipase activity [13], induction of the sterol esterase activity by sterol esters seemed to be a logical further step. Therefore, SSF preparations induced by a mixture of sterol esters were also tested in the esterification reaction of β-sitosterol with lauric acid (Table 3). As the forming steryl laurates are different (GC Rt: 11–14 min, see also Fig. 1) from the sterol esters used as inducer (GC: Restek Rtx-65TG column, 290–342 °C, 2 °C/min, 16 psi; 19–24 min), the residual inducer was expected not to influence the result of the activity test. In fact, analysis of the samples from the steryl laurate formation reactions catalyzed by the sterol ester induced SSF preparations (Table 3) revealed no significant amounts of the inducer sterol esters.

As expected, the sterol esterase activity of the Aspergillus SSF preparations increased significantly due to induction with sterol esters. The sterol ester induced SSF preparations reached the same conversion in the β-sitosteryl laurate formation much faster (45% conv. at 48 h: No. 239 in Table 3) then the corresponding olive oil induced preparations (43% conv. at 240 h: No. 188 in Table 1). Comparing the SSF preparations grown on the same substrate having similar moisture content, the final conversions were much higher even after 168 h with the sterol ester induced preparations (Table 3) than the conversions after 240 h with preparations induced with olive oil (Table 1) or without inducer (Table 2). Similarly to the non-induced cases (Table 2), the best moisture contents with respect to high sterol esterase/low lipase activity of the A. oryzae and A. sojae SSF preparations were in the range of 60–67% (Table 3). At the 70–75% moisture content range the sterol esterase activity dropped while lipase activity increased significantly. At higher moisture content (80%) both sterol esterase and lipase activities decreased significantly. This different activity optima for the sterol esterase and lipase activities of the A. oryzae and A. sojae SSF preparations clearly indicate that sterol esterase/lipase activities belong to distinct enzymes in these two strains.

As many fungal genomes—among them genomes for several Aspergillus strains—have been fully explored recently, we decided to identify these enzymes in these genomes as well. Thus, the known sterol esterase of Saccharomyces cerevisiae (SwissProt: P34163) [17, 18] was chosen as template for a BLAST search [19] within fungal genes in the SwissProt/TrEMBL sequence databases. Among the first 20 hits there were 7 genes from Aspergillus strains [A. terreus (Q0CIB3), A. fischerianus (A1DET8), A. nidulans (Q5B446), A. fumigatus (Q4WUM3), A. niger (A2QN29), A. clavatus (A1CAG4), A. oryzae (Q2U453)]. As the sequence of the A. oryzae gene [20] (TrEMBL: Q2U453) shares high sequence identity (42%)/homology (60%) with the S. cerevisiae sterol esterase (SwissProt: P34163) [17, 18] and our data clearly indicate the independence of lipase and sterol esterase activities in A. oryzae, we assume that this sequence (TrEMBL: Q2U453) belongs to the sterol esterase activity which we found in this strain. Furthermore, the other homologous sequences in the TrEMBL database with “putative assignment” of their functions as “triglyceride lipase-cholesterol esterase” imply that the presence of sterol esterase is a common feature of many Aspergillus strains.

For testing the extra- or intracellular nature of the sterol esterases and increasing the specific activity of the preparations, extraction experiments were performed with both Aspergillus oryzae NRRL 6270 and Aspergillus sojae NRRL 6271 SSF preparations (wheat bran, 67% moisture, no inducer). After extraction of the SSF material and ultrafiltration of the extract, the residual dried SSF material and the lyophilized concentrated extract and filtrate were analyzed in the test reaction between β-sitosterol and lauric acid. In this test, only the residual SSF material exhibited sterol esterase activity after 240 h (A. oryzae NRRL 6270: 53% conversion; 55% conversion with the non-extracted control SSF preparation) indicating the intracellular or cell wall bound nature of the enzyme. Worth to mention here that the signal-anchor motif for type III membrane proteins of the S. cerevise sterol esterase (14–34: YIIVVLVYIESIISSVLKLIP) which is a known membrane-anchored protein [18] shows a high degree of sequence identity (30%)/homology (65%) to the 15–39 sequence portion of A. oryzae sterol esterase (TrEMBL: Q2U453).

For comparing the two fermentation methods, we also performed submerged/shake flask fermentation (SmF) with both target strains (A. oryzae NRRL 6270 and A. sojae NRRL 6271). Similarly to the SSF extraction experiments, the dried cell mass and the ultrafiltered supernatant samples were tested for sterol esterification. In agreement with the SSF results, only the gently dried cell mass was effective in the esterification test (A. oryzae NRRL 6270: 37% conversion after 240 h), confirming the intracellular or cell wall-bound nature of the sterol esterase activity. This experiment also indicated the efficiency of SSF over SmF as lower conversion was achieved with the dried SmF cell mass (37%) as with the same amount of SSF preparation, which contains, in addition to the cell mass, the substrate matrix as well (55%).

To demonstrate the synthetic usefulness of the SSF biocatalysts, the esterification between lauric acid and the plant β-sitosterol was investigated on preparative scale (starting from 200 mg of plant β-sitosterol) with the four best SSF preparations (Table 4). All the four selected SSF biocatalysts were succesfully applied in the preparative scale sterol esterification reactions resulting in 45–63% conversions (GC) and 27–38% isolated yields of steryl laurates (Table 4), which were unambiguously characterized by GC and 1H-NMR spectroscopy (Fig. 1).

Finally, the esterification reaction between conjugated linoleic acid (CLA; containing the two main isomers 9Z,11E- and 10E,12Z- in equal amounts) and plant β-sitosterol was investigated with the A. oryzae NRRL 6271 SSF preparation (sample No 241 in Table 3). The efficiency of this SSF preparation in the esterification reaction between plant β-sitosterol and CLA proved to be comparable (70% conv. at 120 h) as between plant β-sitosterol and lauric acid (85% conv. at 168 h, Table 3). In addition, a slight preference towards one of the major isomers of CLA was observed. The positional isomer-preference of the sterol esterase catalyzed process was determined by comparison of the residual CLA fraction from the sterol esterification reaction to the CLA fraction obtained after hydrolysis of CLA methyl ester by Candida cylindracea lipase. As the isomer preference of the lipase from Candida cylindracea for 9Z,11E-CLA over the 10E,12Z-isomer is known [21], we were able to determine that A. oryzae NRRL 6271 SSF preparation exhibits selectivity towards the 10E,12Z-CLA in the esterification reaction with plant β-sitosterol.

In conclusion, food-grade Aspergillus oryzae and Aspergillus sojae strains cultivated under SSF conditions were successfully applied to produce biocatalysts with useful sterol esterase activity for the first time. Genome analysis revealed that sterol esterase activity is a common feature of many Aspergillus species. It was demonstrated, that lipase and sterol esterase activities belong to distinct enzymes. Finally, the synthetic usefulness of these SSF preparations was proven by production of esters of plant sterols with lauric acid and conjugated linoleic acid. In the latter case isomeric preference of A. oryzae NRRL 6270 towards the 10E,12Z-CLA was also determined.

References

Plat J, Mensink RP (2005) Plant stanol and sterol esters in the control of blood cholesterol levels: mechanism and safety aspects. Am J Cardiol 96(1A):15D–22D

Thompson GR, Grundy SM (2005) History and development of plant sterol and stanol esters for cholesterol-lowering purposes. Am J Cardiol 96(1A):1D–9D

Panitch MM (1997) Antiperspirant deodorant compositions. PCT Int Appl WO 9711678

Villeneuve P, Turon F, Caro Y, Escoffier R, Baréa B, Barouh B, Lago R, Piombo G, Pina M (2005) Lipase-catalysed synthesis of canola phytosterols oleate esters as cholesterol lowering agents. Enzyme Microb Technol 37:150–155

Phillips KM, Ruggio DM, Toivo JI, Swank MA, Simpkins AH (2002) Free and esterified sterol composition of edible oils and fats. J Food Comp Anal 15:123–142

Moreau RA, Hicks KB (2004) The in vitro hydrolysis of phytosterol conjugates in food matrices by mammalian digestive enzymes. Lipids 39:769–776

Leone R, Breuil C (1999) Biodegradation of aspen sterol esters and waxes by two filamentous fungi with or without other carbon sources. World J Microbiol Biotechnol 15:723–727

Brahimi-Horn MC, Mickelson CA, Guglielmino ML, Gaal AM, Sparrow LG (1991) Identification of lipolytic activity in a multitrophic population grown in wool-scour effluent. J Ind Microbiol 8:53–58

Taketani S, Osumi T, Katsuki H (1978) Characterisation of sterol-ester hydrolase in Saccharomyces cerevisiae. Biochim Biophys Acta 525:87–92

Rodriguez Couto S, Sanromán Á (2006) Application of solid-state fermentation to food industry—a review. J Food Eng 76:291–302

Vorderwülbecke T, Kieslich K, Erdmann H (1992) Comparison of lipases by different assays. Enzyme Microbiol Technol 14:631–639

Viniegra-Gonzáles G, Favela-Torres E, Aguilar CN, Rómero-Gomez SJ, Díaz-Godínez G, Augur C (2003) Advantages of fungal enzyme production in solid state over liquid fermentation systems. Biochem Eng J 13:157–167

Nagy V, Tőke ER, Keong LC, Szatzker G, Ibrahim D, Che Omar I, Szakács G, Poppe L (2006) Production of novel, highly enantioselective fungal lipases by solid state fermentation. J Mol Catal B Enzym 39:141–148

Kontkanen H, Tenkanen M, Reinikainen T (2006) Purification and characterisation of a novel steryl esterase from Melanocarpus albomyces. Enzyme Microb Technol 39:265–273

Kontkanen H, Tenkanen M, Fagerström R, Reinikainen T (2004) Characterisation of sterol esterase activities in commercial lipase preparations. J Biotechnol 108:51–59

Miller A, Majauskaite L, Engel K-H (2004) Enzyme-catalyzed hydrolysis of γ-oryzanol. Eur Food Res Technol 218:349–354

Jandrositz A, Petschnigg J, Zimmermann R, Natter K, Scholze H, Hermetter A, Kohlwein SD, Leber R (2005) The lipid droplet enzyme Tgl1p hydrolyzes both steryl esters and triglycerides in the yeast, Saccharomyces cerevisiae. Biochim Biophys Acta 1735:50–58

Koeffel R, Tiwari R, Falquet L, Schneiter R (2005) The Saccharomyces cerevisiae YLL012/YEH1, YLR020/YEH2, and TGL1 genes encode a novel family of membrane-anchored lipases that are required for steryl ester hydrolysis. Mol Cell Biol 25:1655–1668

Altschul SF, Gish W, Miller W, Myers EW, Lipman DJ (1990) Basic local alignment search tool. J Mol Biol 215(3):403–410

Machida M, Asai K, Sano M, Tanaka T, Kumagai T, Terai G, Kusumoto K, Arima T, Akita O, Kashiwagi Y, Abe K, Gomi K, Horiuchi H, Kitamoto K, Kobayashi T, Takeuchi M, Denning DW, Galagan JE, Nierman WC, Yu J, Archer DB, Bennett JW, Bhatnagar D, Cleveland TE, Fedorova ND, Gotoh O, Horikawa H, Hosoyama A, Ichinomiya M, Igarashi R, Iwashita K, Juvvadi PR, Kato M, Kato Y, Kin T, Kokubun A, Maeda H, Maeyama N, Maruyama J, Nagasaki H, Nakajima T, Oda K, Okada K, Paulsen I, Sakamoto K, Sawano T, Takahashi M, Takase K, Terabayashi Y, Wortman JR, Yamada O, Yamagata Y, Anazawa H, Hata Y, Koide Y, Komori T, Koyama Y, Minetoki T, Suharnan S, Tanaka A, Isono K, Kuhara S, Ogasawara N, Kikuchi H (2005) Genome sequencing and analysis of Aspergillus oryzae. Nature 438:1157–1161

Warwel S, Borgdorf R (2000) Substrate selectivity of lipases in the esterification of cis/trans-isomers and positional isomers of conjugated linoleic acid (CLA). Biotechnol Lett 22:1151–1156

Acknowledgments

The financial support from the Hungarian Scientific Research Fund (OTKA, T-48854) is gratefully acknowledged. Thanks are due to Dr. Pál Kolonits for the NMR spectroscopic measurements and Dr. Sándor Tömösközi for lyophilization facilities. Professor Robert P. Tengerdy (Colorado State University) is thankfully acknowledged for his valuable comments and advice.

Author information

Authors and Affiliations

Corresponding authors

About this article

Cite this article

Tőke, E.R., Nagy, V., Recseg, K. et al. Production and Application of Novel Sterol Esterases from Aspergillus Strains by Solid State Fermentation. J Am Oil Chem Soc 84, 907–915 (2007). https://doi.org/10.1007/s11746-007-1127-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-007-1127-4