Abstract

Several diesters were prepared from commercially available oleic acid and common organic acids. The key step in the three step synthesis of oleochemical diesters entails a ring opening esterification of alkyl 9,10-epoxyoctadecanoates (alkyl: propyl, isopropyl, octyl, 2-ethylhexyl) using propionic and octanoic acids without the need for either solvent or catalyst. Each synthetic diester was evaluated for both low temperature operability and oxidation stability through measurement of cloud point, pour point, oxidation onset temperature, and signal maximum temperature. It was discovered that increasing chain length of the mid-chain ester and branching in the end-chain ester had a positive influence on the low temperature properties of diesters. Improved oxidation stability is achieved when the chain length of the mid-chain ester is decreased. Additionally, the mid-chain ester plays a larger role in oxidation stability than the end-chain ester. These products may prove useful in the search for bio-based industrial materials, such as lubricants, surfactants, and fuel additives.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Vegetable oils and derivatives thereof are attractive alternatives to petroleum-based products because they exhibit enhanced biodegradability and reduced toxicity and are of a domestic and renewable origin. Furthermore, vegetable oil based products have become more cost competitive with their petroleum derived counterparts as crude petroleum oil prices have increased dramatically in recent years due to a number of geopolitical factors.

Soybean oil (SBO, see Table 1 for list of abbreviations) is currently the major source of vegetable oil in the United States for both food and industrial applications. In 2004 the United States produced about one billion pounds of SBO in excess of commercial demand, which resulted in lower prices for both SBO and other agricultural commodities [1]. At present, the rapid increase in biodiesel (BD) production in the United States and elsewhere has reversed the downward trend in SBO prices. Nevertheless, the development of new economically feasible industrial products from SBO that replace petroleum-derived materials is a highly desirable goal. The advantages of using SBO and other oleochemical feedstocks as lubricants are well known. The superior lubricity of BD over that of petrodiesel, for instance, is one of the major advantages of the biofuel [2, 3]. However, vegetable oil based materials, including BD, have inferior oxidation stability [4, 5] and low temperature operability [6, 7] when compared to petroleum products. Chemical modification at sites of unsaturation along the fatty acid backbone of SBO, and other oleochemicals, can provide materials with improved oxidation stability and/or low temperature properties. Examples from the literature, though certainly not exhaustive, include hydrogenation [8], epoxidation [9], metathesis [10], and alkylation and acylation [11–13]. The reader is directed elsewhere [14] for a more comprehensive treatise on the synthesis of fatty acid derivatives.

We report the synthesis and evaluation of a series of diesters (10–17) derived from oleic acid. Addition of propionic and octanoic acids to the oxirane moieties of alkyl 9,10-epoxyoctadecanoates (alkyl: propyl, isopropyl, octyl, 2-ethylhexyl) at elevated temperature (100 °C) is the key step (Fig. 1) in a three-step sequence that includes esterification and epoxidation. Subsequent evaluation of diesters (10–17 ) for low temperature operability through cloud point (CP) and pour point (PP) determination and oxidation stability through oxidation onset temperature (OT) and signal maximum temperature (SMT) measurement are also reported (Table 2). This study may aid in the continued development of bio-based materials for use as alternatives to petroleum products in industry and elsewhere.

Materials and Methods

Materials

Formic acid (88%) was obtained from Fisher Scientific (Pittsburgh, PA) and oleic acid (99%) from Nu-Chek Prep, Inc. (Elysian, MN). All other chemicals and reagents were obtained from Aldrich Chemical (Milwaukee, WI). All materials were used without further purification. All organic extracts were dried using anhydrous magnesium sulfate (Aldrich Chemical).

Characterization

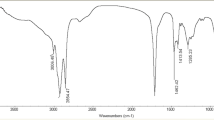

1H- and 13C-NMR spectra were recorded using a Bruker AV-500 spectrometer (Rheinstetten, Germany) operating at a frequency of 500.13 and 125.77 MHz, respectively, using a 5-mm broadband inverse Z-gradient probe in CDCl3 (Cambridge Isotope Laboratories, Andover, MA) as solvent. Each spectrum was Fourier-transformed, phase-corrected, and integrated using MestRe-C 2.3a (Magnetic Resonance Companion, Santiago de Compostela, Spain) software. FT-IR spectra were recorded neat on a Thermo Nicolet Nexus 470 FTIR system (Madison, WI) with a Smart ARK accessory containing a 45 ZeSe trough in a scanning range of 650–4,000 cm−1 for 32 scans at a spectral resolution of 4 cm−1.

Reactions were monitored by GC-MS using a Hewlett Packard (Loveland, CO) 5870 series II GC equipped with a 6890 series injector and a 5970 series MSD in EI mode. A Supelco (Bellefonte, PA) SPB-35 (30 m × 320 μm) column was used with a He flow rate of 0.9 mL/min. The temperature program started at 150 °C and increased to 290 °C at 10 °C min−1, which was followed by a hold time of 10 min. The inlet and detector temperatures were set to 250 and 280 °C, respectively, and an injection volume of 1 μL was used with a split ratio of 70:1.

Low Temperature Operability

Cloud point (CP) and pour point (PP) determinations were made in agreement with ASTM D 5773 [16] and ASTM D 5949 [17], respectively, using a Phase Technology Analyzer Model PSA-70S (Richmond, BC, Canada). Each sample was run in triplicate and average values rounded to the nearest whole degree are reported in Table 2. For a greater degree of accuracy, PP measurements were done with a resolution of 1 °C instead of the specified 3 °C increment. Generally, materials with lower CP and PP exhibit improved fluidity at low temperatures than those with higher CP and PP.

Oxidation Stability

Pressurized DSC (PDSC) experiments were accomplished using a DSC 2910 thermal analyzer from TA Instruments (Newcastle, DE). Typically, a 2-μL sample, resulting in a film thickness of <1 mm, was placed in an aluminum pan hermetically sealed with a pinhole lid and oxidized in the presence of dry air (Gateway Airgas, St Louis, MO), which was pressurized in the module at a constant pressure of 1,378.95 kPa (200 psi). A 10 °C min−1 heating rate from 50 to 350 °C was used during each experiment. The oxidation onset (OT, °C) and signal maximum temperatures (SMT, °C) were calculated from a plot of heat flow (W/g) versus temperature for each experiment. Each sample was run in duplicate and average values rounded to the nearest whole degree are reported (Table 2).

Fischer Esterification of Oleic Acid

To a stirred solution of oleic acid (99%, 1, 10.0 g, 35.4 mmol) in ROH (15.0 mL, R = propyl, isopropyl, octyl, 2-ethylhexyl) was added at rt H2SO4 (conc. 0.10 mL, 5.1 mol%), and the combined reaction was heated at reflux for 4 h. Upon cooling to rt the alcohol was removed in vacuo and the resultant oil dissolved in hexanes (10 mL). After washing with NaHCO3 (sat. aq. 2 × 1 mL) and brine (2 × 1 mL), the organic phase was dried, filtered, concentrated in vacuo, and placed for 6 h under high vacuum to afford alkyl oleates (2–5) as clear oils (97 + % typical yield). Esterifications employing C8 alcohols (2-ethylhexanol and octanol) were further dried by Kugelrohr (Buchi Model B-585, Flawil, Switzerland) distillation at 100–120 °C and 0.1–0.5 mm Hg to remove excess alcohol. No further purification was performed. 1H NMR (500 MHz, CDCl3): δ~5.4 (2H, –CH=CH–), ~2.3 (2H,–CH 2CO2R), ~2.0 (4H, –CH 2CH=CHCH 2–), ~1.6 (2H, –CH 2CH2CO2R), ~1.3 (20H, –CH 2–), ~0.9 (3H, –CH 3), 13C NMR (126 MHz, CDCl3): δ ~174 (–CO2R), ~130 (–CH=CH–), ~35 (–CH2CO2R), ~34 (CH2CH=CHCH2–), ~14 (–CH3). Additional signals in the 1H and 13C -NMR spectra vary with head group. FT-IR (neat): ~3,004, ~2,923, ~2,853 cm−1 (CH2 str), ~1,733 (C=O str), ~1,667 (olefin str), ~1,466 (CH2 bending vib), ~1,374 (CH3 sym bending vib), ~1,249, ~1,179, ~1,108 (C–O str), ~965 (vinyl C–H out of plane bend), ~723 (CH2 rocking vib).

Epoxidation of Alkyl Oleates

To a stirred solution of alkyl oleate (2–5, 10.0 g) and formic acid (88%, 5.0 mL, 117 mmol) at 4 °C was slowly added H2O2 (30% in H2O, 8.0 mL, 78 mmol). The reaction proceeded at rt with vigorous stirring (900+ rpm) until GC-MS analysis indicated consumption of 2–5 (14–16 h). After removal of the lower aqueous phase, hexanes (20 mL) were added to the upper oily phase, which was washed with NaHCO3 (sat. aq. 2 × 5 mL) and brine (2 × 5 mL), dried, filtered, concentrated in vacuo, and placed for 6 h under high vacuum to provide alkyl 9,10-epoxyoctadecanoates (6–9) as clear oils (95+% overall yield, typically). GC-MS analysis generally indicated the presence of <5% alkyl 9,10-dihydroxyoctadecanoate. No further purification was performed. 1H NMR (500 MHz, CDCl3): δ ~2.9 (2H, –CH(O)CH–), ~2.3 (2H, –CH 2CO2R), ~1.6 (2H, –CH 2CH2CO2R), ~1.5 (4H, –CH 2CH(O)CHCH 2–), ~1.3 (20H, –CH 2–), ~0.9 (3H, –CH 3); 13C NMR (126 MHz, CDCl3): δ ~174 (–CO2R), ~51 (–CH(O)CH–), ~35 (–CH2CO2R), ~14 (–CH3). Additional signals in the 1H and 13C-NMR spectra vary with head group. FT-IR (neat): ~2,923, ~2,853 cm−1 (CH2 str), ~1,733 (C=O str), ~1,466 (CH2 bending vib), ~1,374 (CH3 sym bending vib), ~1249, ~1,179, ~1108 (C–O str), ~723 (CH2 rocking vib), ~1,145 (ether C–O–C sym str), ~896 (C–C asym ring str), ~824 (“12 micron band”, ref. 15), and a small peak at ~3,500 (OH str) indicative of over-reaction to form alkyl 9,10-dihydroxyoctadecanoate in small (<5%) amount.

Synthesis of Diesters

To a solution of alkyl 9,10-epoxyoctadecanoate (6–9, 5.0 g) in a 7.4-mL (2 dram) vial was added 12 g of either propionic acid (12.1 mL, 0.16 mol) or octanoic acid (13.2 mL, 0.083 mol). The vial was purged with N2 and sealed with a septum and was then placed in a Pierce Reacti-vap Model 19780 (Rockford, IL) heating/stirring module with stirring at 100 °C. Aliquots (20 μL) of each reaction were removed, diluted in acetone (1 mL), and analyzed by GC-MS until complete. The reactions were allowed to proceed for 8 h in the cases of 6 and 7, and 9 h when 8 and 9 were used. The products resulting from propionic acid (10,12,14,16) were purified by washing with H2O (3 × 100 mL); however, 11, 13, 15, and 17 were not washed with water due to the low solubility of octanoic acid. Acid was removed first by rotary evaporation at 40 °C and then by Kugelrohr distillation at 70 °C and 0.1–0.5 mm Hg to afford diesters 10–17 (70–93% yield, Table 2), which were stored over molecular sieves to mitigate potential hydrolysis. 1H NMR (500 MHz, CDCl3): δ ~4.8 (1H, –CH(O2CR′)-), ~3.6 (1H, –OH), ~2.4 (2H, –CH(O2CCH 2 –), ~2.3 (2H, –CH 2 CO2R), ~1.6 (2H, –CH 2 CH2CO2R), ~1.5 (2H, –CH 2 CH(OH)–), ~1.4 (2H, –CH 2 CH(CO2R′)–), ~1.3 (20H, –CH 2 –), ~0.9 (3H, –CH 3 ); 13C NMR (126 MHz, CDCl3): δ ~174–173 (2C, –CO2R, –CO2R′), 76–72 (4C, –C9–O × 2, –C10–O × 2), ~35 (1C, –CH2CO2R), ~14 (–CH3). Additional signals in the 1H- and 13C -NMR spectra vary with ester groups. FT-IR (neat): ~3,500 cm−1 (OH str), ~2,925, ~2,855 (CH2 str), ~1,735 (C=O str), ~1,463 (CH2 bending vib), ~1,371 (CH3 sym bending vib), ~1,246, ~1,174, ~1,104 (C–O str), ~723 (CH2 rocking vib).

Results and Discussion

Synthesis

After the straightforward Fischer esterification [18] of oleic acid (1) to alkyl oleates 2–5, a modified epoxidation protocol [12, 13, 19] originally developed by Swern [9] and later modified for oleochemical use by Bunker and Wool [20] was employed to provide alkyl 9,10-epoxyoctadecanoates (6–9, Fig. 1). The reactions were monitored by GC-MS and terminated when >95% of starting material was consumed (14–15 h). Further analysis by GC-MS generally indicated the presence of a small amount (<5%) of alkyl 9,10-dihydroxyoctadecanoate, demonstrating the importance of monitoring the epoxidation closely to avoid unwanted over-reaction. The end-chain esters (R = propyl, isopropyl, octyl, 2-ethylhexyl) employed here were selected such that relatively short (R = propyl, 2) and long chain (R = octyl, 4) esters could be compared. Additionally, the effect of branching on low temperature and oxidation properties was also of interest, so isopropyl (3) and 2-ethylhexyl (5) end-chain esters were chosen for comparison as well.

The addition of carboxylic acids to oxiranes 6–9 to afford diesters 10–17 by ring opening esterification [21, 22] was accomplished at elevated temperature (100 °C) without need for either catalyst or solvent, as shown in Fig. 2. The reactant, in this case either propionic or octanoic acid, served as both reactant and solvent, thus eliminating the need for a separate solvent. Catalysts were also unnecessary since the reaction proceeded to completion at 100 °C. At reduced temperatures, such as rt, the use of catalyst may become necessary to avoid either extended reaction times or no reaction. Ambient temperature reactions were not investigated here since: (a) use of catalyst would add to material costs; (b) catalyst removal would complicate purification; (c) elevated temperature readily provided the desired products. The reactions were monitored by GC-MS and terminated when >95% of starting material was consumed (8–9 h). Table 2 contains both yield and time of reaction data for diesters 10–17.

When carboxylic acids add to oxirane moieties in the manner described above, diesters result. The additional mid-chain ester group serves as a point of branching along an otherwise linear fatty acid backbone. Propionic and octanoic acids were selected such that a variety of materials of varying chain length would allow for the study of branch size on low temperature and oxidation stability properties discussed below.

No effort to distinguish the regiochemistry (Fig. 2; alkyl 9-alkanoate-10-hydroxy-octadecanoate versus the equally likely alkyl 10-alkanoate-9-hydroxyoctadecanoate regioisomer) or the stereochemistry (R or S at C9 and C10) of the diesters obtained here was made, due to the laborious chromatography required and the economics involved at potentially larger commercial scales. If such materials are eventually adopted for commercial use, then production costs relating to synthesis and purification are of paramount importance. Therefore, the diesters prepared here were tested for low temperature operability and oxidation stability behavior without further purification.

Low Temperature Operability

The ability of a substance to remain liquid at low temperatures is an important attribute for a number of industrial materials, such as lubricants, surfactants, and fuels. Therefore, diesters 10–17 were screened for cold flow performance through determination of both CP and PP. An improvement in the cold flow behavior of diesters 10–17 (Table 2) was obtained over that of alkyl 9,10-epoxyoctadecanoate precursors (6–9), SBO, and soybean oil methyl esters (SME, Table 3). Not surprisingly, as the chain length of the mid-chain ester is increased, a corresponding improvement in low temperature behavior was observed. We hypothesize this is due to the greater ability of the longer chain esters to more effectively disrupt crystalline formation at reduced temperatures. For example, comparison of diesters where R (Fig. 1) is held constant reveals an improvement in CP and PP as the mid-chain ester length (R′) was increased, as shown by diester 10 (CP −8 °C; PP −15 °C, R′ = propyl; R = propyl) and diester 11 (CP −11 °C; PP −20 °C, R′ = octyl; R = propyl). A similar trend was exhibited when comparing 12 to 13, 14 to 15, and 16 to 17 (Table 2), which can be expressed as R′: propyl > octyl (lower CP and PP) where R is equal. Furthermore, the nature of the end-chain ester group also plays a role in the cold flow behavior of diesters. Three trends are apparent from the data where R′ is held constant: (a) branching in the end-chain ester lowers CP and PP; (b) octyl esters exhibit increased CP and PP in comparison to propyl esters; (c) 2-ethylhexyl esters have the most favorable CP and PP. These observations can be expressed as R: octyl > propyl > isopropyl > 2-ethylhexyl (lower CP and PP) where R′ is held constant. Therefore, based on the trends mentioned above, a material with R = 2-ethylhexyl and R′ = octyl should provide the best low temperature behavior, which is evidenced by 17 (CP −39 °C; PP −42 °C). Conversely, a material with R = octyl and R′ = propyl should correspondingly provide the least favorable CP and PP, as shown by 14 (CP 6 °C; PP -11 °C).

Oxidation Stability

The ability of a substance to resist oxidative degradation is another important attribute for a number of industrial materials, such as lubricants, surfactants, and fuels. Therefore, diesters 10–17 were screened for oxidation stability using PDSC through determination of both OT and SMT. PDSC is an effective method for measuring oxidation stability of oleochemicals in an accelerated mode [5, 23, 24]. The OT is the temperature at which a rapid increase in the rate of oxidation is observed at a constant, high pressure (200 psi). A high OT would suggest high oxidation stability of the material. The SMT is the temperature at which maximum heat output is noted from the sample during oxidative degradation. A higher SMT does not necessarily correlate with improved oxidation stability. Both OT and SMT were calculated from a plot of heat flow (W/g) versus temperature that was generated by the sample upon degradation and, by definition, SMT > OT.

In the present study, as the chain length of the mid-chain ester is decreased, a corresponding improvement in oxidation stability was observed, which is because longer chains are more susceptible to oxidative cleavage than shorter chains. These results are in agreement with other studies on chemically modified vegetable oils [11] and synthetic esters [25]. For example, when comparing diesters where R is held constant, an improvement in OT was noticed as the mid-chain ester length (R’) was decreased, as shown by diester 10 (OT 176 °C, R′ = propyl; R = propyl) and diester 11 (OT 156 °C, R′ = octyl; R = propyl). A similar trend was exhibited when comparing 12 to 13, 14 to 15, and 16 to 17 (Table 2), which can be expressed as R′: propyl > octyl (higher OT) where R is held constant. The effect of the end-chain ester is less pronounced. One would gather that, based on the above conclusions regarding the relationship between mid-chain ester length and OT, the same trend would apply to the end-chain ester group. However, R = propyl provided the highest OT (10) while R = isopropyl (13) gave the lowest. If the abovementioned trend was still applicable when considering end-chain ester groups, it would stand to reason that R = octyl (14 or 15) would afford the lowest OT. The results of 10 and 13 would suggest that branching has a detrimental effect on OT; however, comparison of R = octyl (14,15) and R = 2-ethylhexyl (16,17) reveals the opposite trend, i.e., branching improves OT. It is clear, based on these results, that the mid-chain ester has a significantly higher impact on oxidation stability than the end-chain ester. Also of note, the trends for CP and PP run counter to that of OT, i.e., increasing chain length is a benefit to CP and PP, but a detriment to OT. Future study will aim to strike a balance between these two opposing properties through investigation of a greater variety of mid-chain esters and, potentially, end-chain ester groups.

Abbreviations

- rt:

-

Room temperature

- str:

-

Stretch

- vib:

-

Vibration

- sym:

-

Symmetrical

- asym:

-

Asymmetrical

References

Gawrilow I (2004) Vegetable oil usage in lubricants. Inform 15:702–705

Knothe G, Van Gerpen JH, Krahl J. (eds.) 2005 The biodiesel handbook, AOCS Press, Champaign, IL

Van Gerpen JH, Soylu S, Tat ME (1996) Evaluation of the lubricity of soybean oil-based additives in diesel fuel, proceedings, annual international meeting of the ASAE, American Society of Agricultural Engineers, St Joseph, MI, paper no. 996134

Coscione AR, Artz WE (2005) Vegetable oil stability at elevated temperatures in the presence of ferric stearate and ferrous octanoate. J Agric Food Chem 53:2088–2094

Dunn RO (2006) Effect of antioxidants on the oxidative stability of methyl soyate (Biodiesel). Fuel Pro Technol 86:1071–1085

Hwang HS, Erhan SZ (2001) Modification of epoxidized soybean oil for lubricant formulations with improved oxidative stability and low pour point. J. Am Oil Chem Soc 78:1179–1184

Li S, Blackmon J, Demange A, Jao TC (2004) Linear sulphonate detergents as pour point depressants. Lub Sci 16:127–137

King JW, Holliday RL, List GR, Snyder JM (2001) Hydrogenation of vegetable oils using mixtures of supercritical carbon dioxide and hydrogen. J Am Oil Chem Soc 78:107–113

Findley TW, Swern D, Scanlan JT (1945) Epoxidation of unsaturated fatty materials with peracetic acid in glacial acetic acid solution. J Am Chem Soc 67:412–414

Holser RA, Doll KM, Erhan SZ (2006) Metathesis of methyl soyate with ruthenium catalysts. Fuel 85:393–395

Sharma BK, Adhvaryu A, Liu Z, Erhan SZ (2006) Chemical modification of vegetable oils for lubricant applications. J Am Oil Chem Soc 83:129–136

Moser BR, Erhan SZ (2006) Synthesis and evaluation of a series of α-hydroxy ethers derived from isopropyl oleate. J Am Oil Chem Soc 83:959–963

Moser BR, Erhan SZ (2007) Preparation and evaluation of a series of α-hydroxy ethers from 9,10-epoxystearates. Eur J Lip Sci Technol 109:206–213

Knothe G, Derksen JTP (eds.) (1999) Recent developments in the synthesis of fatty acid derivatives. AOCS Press, Champaign

Silverstein RM, Webster FX (1998) Spectrometric Identification of Organic Compounds, 6th Ed. Wiley, New York, p 92

ATSM D5773: Standard test method for cloud point of petroleum products (Constant Cooling Rate Method), in annual book of ASTM standards, vol 05.03, American Society for Testing and Materials, Philadelphia, 2003

ASTM D5949: Standard test method for pour point of petroleum products (Automatic Pressure Pulsing Method), in annual book of ASTM standards, vol 05.03, American Society for Testing and Materials, Philadelphia, PA, 2003

Fischer E, Speier A (1895) Darstellung der Ester. Ber Dtsch Chem Ges 28:3252–3255

Doll KM, Erhan SZ (2005) Synthesis of carbonated fatty methyl esters using supercritical carbon dioxide. J Agric Food Chem 53:9608–9614

Bunker SP, Wool RP (2002) Synthesis and characterization of monomers and polymers for adhesives from methyl oleate. J Polym Sci. Part A: Polym Chem 40:451–458

Campanella A, Baltanas MA (2006) Degradation of the oxirane ring of epoxidized vegetable oils in liquid-liquid heterogeneous reaction systems. Chem Eng J 118:141–152

Campanella A, Baltanás MA (2004) Degradation of the oxirane ring of epoxidized vegetable oils with solvated acetic acid using cation-exchange resins. Eur J Lipid Sci Technol 106:524–5301

Zhang YY, Ren TH, Wang HD, Yi MR (2004) A comparative study of phenol-type antioxidants in methyl oleate with quantum calculations and experiments. Lub Sci 16:385–392

Adhvaryu A, Sharma BK, Hwang HS, Erhan SZ (2006) Development of biobased synthetic fluids: application of molecular modeling to structure-physical property relationship. Ind Eng Chem Res 45:928–933

Randals SJ (1999) Esters, in synthetic lubricants and high-performance functional fluids. In: Rudnick LR and Shubkin RL (eds) Marcel Dekker, New York, pp 63–102

Acknowledgments

The authors acknowledge Mrs. Donna I. Thomas for excellent technical assistance.

Author information

Authors and Affiliations

Corresponding author

Additional information

Product names are necessary to report factually on available data; however, the USDA neither guarantees nor warrants the standard of the product, and the use of the name by USDA implies no approval of the product to the exclusion of others that may also be suitable.

About this article

Cite this article

Moser, B.R., Sharma, B.K., Doll, K.M. et al. Diesters from Oleic Acid: Synthesis, Low Temperature Properties, and Oxidation Stability. J Amer Oil Chem Soc 84, 675–680 (2007). https://doi.org/10.1007/s11746-007-1083-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-007-1083-z