Abstract

Fatty acid composition and moisture and oil content were determined for Montola-2001 and Centennial safflower varieties at three different harvest dates from flowering to maturity, which were grown as autumn and spring crops in two different locations in 2001–2002 and 2002–2003. The experiment was carried out using split–split plots in a randomized complete block design with three replicates. Sowing dates affected oil content and fatty acid compositions significantly (P < 0.01), whereas moisture content in both years was not significantly affected. Moisture content declined 15 days from flowering period to maturity, while oil content increased. The rate of the palmitic acid formation decreased in both varieties 15 days from flowering period to maturity, whereas formation rates of the oleic and linoleic acids increased in Montola-2001 and Centennial varieties, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Safflower (Carthamus tinctorius L.) is an annual herb belonging to the Compositae family. Safflower is a minor, underutilized oilseed crop. Safflower was cultivated in 795,118 ha in the world and 731,425 tonnes seed yield was obtained from this area during 2004 [1]. It has been cultivated locally for its oil, meal, and flower [2]. Safflower oil has long been used for industrial purposes, notably for preparing varnish, due to the high linoleic acid content of high linoleic varieties [3]. The resultant meal after oil extraction is used for animal feed, as it is rich in proteins [4]. The petals of the safflower flowers are intensely yellow, red, or orange in color and are used for dried-flower production [5, 6]. An additional product extracted from safflower flowers is carthamin, a dye used to color foods, beverages, and cosmetics [7].

The whole safflower seeds are white or cream in color, and their typical composition is 55–65% kernel and 33–45% hull. The whole seeds in normal-hull types contain 27–32% oil, 5–8% moisture, 14–15% protein, 2–7% ash, and 32–40% crude fiber [8, 9]. The whole seeds of the plant had an oil percentage of 25–37% in normal hull types; but in very thin hull types, this ratio was increased to 46–47% because the hull ratio was decreased and oil ratio was increased [10]. Safflower is one of the best examples of crops with variability for fatty acid composition in seed oil [11]. Standard safflower oil contains about 6–8% palmitic acid, 2–3% stearic acid, 16–20% oleic acid, and 71–75% linoleic acid [12]. A safflower from Israel with 5–10% stearic acid, compared with 1–3% of normal genotypes, was identified [13]. Very high levels of linoleic (87–89%) and very low oleic (3–7%) acid levels were found in safflower from Portugal [14]. Additionally, sources of variation for very high oleic acid content (> 85%) have been reported [15, 16].

The fatty acid composition of vegetable oil determines its best commercial uses [2]. High-oleic safflower oil, because of its great stability and bland flavor, makes a great frying oil [17]. It also has no linolenic fatty acid, which is readily oxidized in oils such as soybean and canola to cause rancidity and off-flavors during storage or frying [18]. High-linoleic safflower oil, in view of its reported role in reducing blood cholesterol levels, is being utilized as premium edible oil [10]. Genotype during oil formation exert the major effect on the proportions of oleic and linoleic acids. However, literature data are mainly for standard genotypes, while very little is known about high oleic genotypes.

Sowing date can be a major factor that affects oil quality and fatty acid composition. Information on how sowing date influences fatty acid composition is quite important. The ratio of oleic and linoleic acids in seed oils is to a large extent dependent upon environmental conditions, particularly moisture and temperature, during seed maturation [19, 20]. Thus, determining optimum sowing date is likely to be of critical importance in many areas.

Very limited research has been done on safflower in Turkey because of its low acreage and lesser economic importance [21]. Turkey has favorable climatic and agricultural conditions for the cultivation of a wide variety of oilseeds. Safflower is an oilseed that has been grown for centuries in the semiarid conditions of central Anatolia [2]. In fact, as a Mediterranean country, Turkey is one of the countries with wild species of safflower, and its soil and climatic conditions are very favorable for safflower production [22]. Presently, over 50% of vegetable oil consumed in Turkey is imported. Safflower has potential to become an alternate oilseed crop in the Trakya region of Turkey. Information on sowing and harvest dates for safflower is not available in this region.

In the near future, as oil resources are increasingly depleted, safflower oil, like other vegetable oil substances, could be used on a large scale to produce both biofuel and alcohol [3]. Future safflower will be hybrids, day length, neutral, and spineless, with seeds consisting of about 20% hull and 55% oil. Safflower oil will be modified to reduce the saturated fatty acid content and increase the oleic acid to 85% [23].

The objective of this research was to determine the effects of sowing and harvest dates on fatty acid composition and moisture and oil content of two safflower varieties with high oleic and high linoleic genotypes grown in the Trakya region of Turkey.

Experimental Procedures

Growing Location and Crop Management

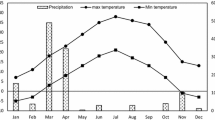

The study was conducted over two crop seasons, 2001–2002 and 2002–2003, in the experimental fields of the Agriculture Faculty of Trakya University (Tekirdag, 40°59′N, 27°31′E; 5 m elevation) and Trakya Agricultural Research Institute (Edirne, 41°40′N, 26°34′ E; 41 m elevation) located in the Trakya region in northwest Turkey. The soil of the experimental area in the Tekirdag location was clay loam, low in organic matter (0.87%), moderate in phosphorus (P) content (61.7 kg ha−1), but rich in potassium (K) content (600.1 kg ha−1) and a pH of 7.3. The soil of the experimental area in the Edirne location was sandy loam, with a pH of 5.75 and 1.42% organic matter. This soil contained phosphorus (P) (40.3 kg ha−1) and potassium (K) (504.1 kg ha−1). The experimental areas were suitable for safflower cultivation.

Two varieties of safflower were used: “Montola-2001,” an introduction from the USA, has oil with high levels of oleic acid and has a mutant genotype; Centennial, an open pollinated introduction from the USA, with traditional genotype, has high levels of linoleic acid. Seedings were made on 12 October (autumn) 2001, on 16 March (spring) 2002, on 18 October (autumn) 2002, and on 13 March (spring) 2003. In sowing, row width was 70 cm. Intrarow spacing was stabilized at 5 cm (100 plant/m2) by thinning. All treatments were fertilized with 10 kg nitrogen and 10 kg phosphorus per decare. Weed control was obtained by mechanical rotary tillage (21 May 2002–13 May 2003) in the interrow and by manual weeding in the row. Sowing was performed on nonirrigated seed beds.

Seed Harvesting

Individual heads of two safflower lines were tagged at the time of flowering in sufficient quantity to allow periodic harvest of individual heads until maturity. Since an individual safflower head “blooms” over a period of 4–5 days, flowering is herein used to mean that period when the earliest 50% of the florets of a head have completed pollination. A total of 150 individual heads per plot were tagged on the same day at random at the time of flowering. Fifty heads from each plot were sampled at each harvest date throughout the period of maturity (15th day after flowering, 30th day after flowering, and maturity) until all tagged heads were harvested. All plots were hand harvested. Temperature, rainfall, and relative humidity data during the crop growing period were collected from nearby weather stations in both locations and are presented in Table 1.

Moisture Content

The safflower seeds were analyzed for their moisture content according to the International Union of Pure and Applied Chemistry (IUPAC) methods no. 1.122 [24].

Lipid Extraction

The safflower seeds were dried before lipid extraction. Lipid extraction from the dry seeds was carried out by hexane extraction under the operating conditions specified in IUPAC methods no. 1.121. Total oil content of the samples is expressed as a percentage by mass of the product [24].

Preparation of FAME

Fatty acid methyl esters (FAME) were prepared from the safflower oils after alkaline hydrolysis, followed by methylating in methanol with 12.5% boron trifluoride (BF3) catalyst. The final concentration of the FAME was approximately 7 mg/ml in heptane [25]. FAME standards (99% purity) were purchased from Nu-Chek-Prep Inc. (Elysian, MN, USA).

Capillary Gas–Liquid Chromatography

Analyses of the FAME by capillary gas–liquid chromatography (GLC) were carried out on a Hewlett Packard 6890 chromatograph equipped with a flame-ionization detector (FID) on a split injector. A fused-silica capillary column (CP-Sil 88, 50 m × 0.25 mm i.d., 0.2 μm film; Chrompack, Middleburg, The Netherlands) was used for the FAME analysis. GLC operating conditions were a temperature program of 130°C for 5 min and then a 2°C/min increase to 177°C. The injector and detector temperatures were set at 250°C. Helium was used as the carrier gas at 1 ml/min.

Experimental Design and Statistical Analysis

The experiment was carried out using split–split plots in a randomized complete block design with three replicates and a subplot area of 10.5 m2. Sowing date (autumn–spring), varieties (Montola-2001; Centennial) and harvest date (15th day after flowering, 30th day after flowering, and maturity) were placed into the main, sub, and sub–sub plots, respectively. With random split–split plot experimental design, the analytical data collected with three replications of each treatment were subjected to analysis of variance (ANOVA) using MSTAT software program. The least significant difference (LSD) test was applied to the results using the same program [26]. Results for each location were analyzed separately and are presented by individual location. For statistical analysis, sowing date, harvest date, cultivar, and between-year effects were considered fixed.

Results and Discussion

Sowing and harvest date effects on moisture and oil content, and fatty acid composition of safflower varieties Montola-2001 and Centennial grown in different locations are presented in Tables 2 and 3, respectively.

Moisture Content

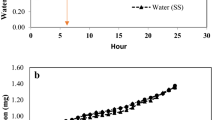

Moisture content in either location was not influenced by sowing date and between-year effects (P > 0.01) but was influenced by harvest date (P < 0.01). The difference of moisture content between both varieties was only significant in the Edirne location (P < 0.01). A significant year × variety × sowing date × harvest date interaction for moisture content was not observed. Moisture content declined from an average of 30.25–42.50% to 4.00–6.17% at 15 days from flowering period to maturity (Table 2). Except for spring sowing at the Tekirdag location, the moisture content for both varieties generally decreased to a maximum of between 15 and 30 days after flowering sampling period then declined slightly. A slower loss of moisture from the seeds of the Montola-2001 variety was observed compared with the Centennial variety. Similarly, numerous research studies have shown that the moisture content decreases during safflower seed development [27–29]. Our findings agree with the findings by Sims et al. [27], Bratcher and Kemmerer [30], and Dorrell [31]. However, moisture content of the seeds was higher than that of other reported safflower varieties [2, 32–34].

Oil Content

Oil content varied insignificantly with the study years (Table 2). In contrast, oil content in both locations was influenced by sowing date, harvest date, and variety (P < 0.01). A significant year × variety × sowing date × harvest date interaction for oil content was not observed. Oil content increased very rapidly from the 15th to the 30th day after the flowering sampling period and reached its maximum level in maturity in both varieties. Oil content during this period increased about twofold. During 30 days from the flowering period to maturity, the rate of oil accumulated in the seed slowed dramatically. Generally, the maximum oil content was found in the Centennial variety at maturity. At maturity, oil content for the Montola-2001 variety in both locations was higher in spring sowing than that observed in autumn sowing. However, oil content for the Centennial variety in both locations was usually higher in autumn sowing than that observed in spring sowing at maturity. Numerous research studies have shown that oil content increases during safflower seed development, and climatic factors during growing season, maturity, variety, and location influence oil concentration [27–29, 32, 35–37].

Fatty Acid Composition

Palmitic (C16:0), stearic (C18:0), oleic (C18:1), and linoleic (C18:2) acids were the principal fatty acids for all safflower seeds analyzed. The sum of lauric (C12:0), myristic (C14:0), palmitoleic (C16:1), linolenic (C18:3), and arachidic (C20:0) acids, given in Table 3, is below 0.8%.

When between-year effects on fatty acid composition of safflower seeds were compared, only the differences in the C18:2 content in the Tekirdag location were found to be significant (P < 0.05). Meanwhile, sowing and harvest dates effects, along with differences between the proportions of each of the four major fatty acids, were found to be significant (P < 0.01). The sum of five minor fatty acids was not influenced by sowing date, harvest date, variety, or between-year effects. In addition, a significant year × variety × sowing date × harvest date interaction for the four major fatty acids can be seen in Table 3.

The C16:0 content in both varieties decreased during seed development. Results shown in Table 3 revealed that the C16:0 content was higher in the Centennial variety at maturity. In addition, the C16:0 content in both varieties was higher in autumn sowing than that observed in spring sowing. The C16:0 content of the Centennial variety in spring sowing at the Tekirdag location decreased greatly, from 13.2% on the 15th day after the flowering period to 6.6–7.3% in fully ripened seeds. Hamrouni et al. [29], working with safflower seeds, found that C16:0 content decreased considerably, from 13.7% to 4.0%, during seed ripening. Hill and Knowles [38] revealed that the actual amount of C16:0 in their safflower varieties remained at about the same level until 10 days after flowering and then slowly increased until about 25 days after flowering, although the C16:0 percentage in relative amount decreased during seed development.

The C18:0 content decrease in autumn sowing of the Montola-2001 variety and increase in spring sowing of the Centennial variety were found in both locations 15 days from the flowering period to maturity. In addition, the C18:0 content decreased in spring sowing of the Montola-2001 variety and in autumn sowing of the Centennial variety in the Edirne location during seed development. Hamrouni et al. [29] reported that the C18:0 content decreased slightly, from 1.2% to 1.0% during seed ripening. At maturity, the C18:0 content in the Montola-2001 variety was very similar for both sowing dates (Table 3). In contrast, the C18:0 content for the Centennial variety were higher in spring sowing. The results also reveal that the C18:0 content were higher in the Centennial variety than in the Montola-2001 variety at maturity for both sowings. The safflowers reached their highest value (3.4–4.0%) following a large decrease in the C16:0 content in spring sowing of both locations. For their safflower varieties during seed development, Hill and Knowles [38] observed a similar relationship between C16:0 and C18:0 content. Similarly, our results for the Centennial variety are in accordance with Ladd and Knowles [13], who reported that their safflower varieties with high levels of C18:0 contained lower levels in C16:0. However, our results for the Montola-2001 variety are generally similar to those obtained by Hamrouni et al. [29], who demonstrated that rapid decreases in C16:0 were accompanied by slightly decreases in C18:0 at the end of ripeness. Comparing the effects of sowing dates in both locations, high levels of the C18:0 were associated with low levels of the C18:2 in the Centennial variety at maturity. The C18:0 and C18:2 content in spring sowing of this variety were in the range of 3.4–4.0% and 58.5–69.7%, respectively. However, amounts of these fatty acids in autumn sowing were in the range of 2.5–3.4% and 72.6–74.3 for C18:0 and C18:2, respectively. The results in the Centennial variety agree with the findings by Ladd and Knowles [13], who revealed that increases in C18:0 were accompanied by decreases in C18:1 or in C18:2 in some cases, and sometimes in both. The C18:1 content belonging to the Montola-2001 variety increased during seed development, while the C18:2 content decreased. In contrast, a decrease in the C18:1 content and an increase in the C18:2 content of the Centennial variety was observed during seed development, whereas C18:1 content increased in the Montola-2001 variety, from 22.5–31.7% to 40.8–55.2%, during seed development, with a subsequent reduction in the C18:2, from 55.2–67.3% to 35.3–49.1%. The C18:1 content of the Montola-2001 variety showed a rapid increase at 30 days from flowering period to maturity in autumn sowing at the Tekirdag location and at the 15th to the 30th day after the flowering period in spring sowing at the Edirne location. The C18:1 increased rapidly, mostly at the expense of the C18:2. A decrease in the C18:1, from 22.6–35.0% to 14.1–30.4%, and an increase in the C18:2, from 52.0–66.2% to 58.5–74.3%, was observed for the Centennial variety. There was an inverse relationship between the development of C18:1 and C18:2 acids in both varieties. The lowest content of C18:1 was found in the highest C18:2 content. This was constant for all safflower seeds analyzed. The C18:1 content increased in the Montola-2001 variety, as it was an oleic type, and the C18:2 content increased in the Centennial variety, as it was a linoleic type ,during seed development. Increases in these fatty acids of both varieties might be caused by their genotypic features. Important factors influencing fatty acid composition are the variety and genetics of the seed. Similar observations were made by Garces et al. [19], Lajara et al. [20], and Hill and Knowles [38]. However, Robertson et al. [39] reported that environmental conditions influence fatty acid composition much more than does the genotype of the variety. Garces et al. [19] revealed that in high C18:1 mutants, C18:1 and C18:2 content was less influenced by temperature than in standard genotypes.

At maturity, the C18:1 content of the Montola-2001 variety was higher in spring sowing at the Edirne location and in autumn sowing at the Tekirdag location. The C18:1 content of the Centennial variety in both locations was higher in spring sowing than that observed in autumn sowing. At maturity, the C18:2 content of the Montola-2001 variety was higher in autumn sowing at the Edirne location and in spring sowing at the Tekirdag location. The C18:2 content of the Centennial variety in both locations was higher in autumn sowing than that observed in spring sowing. Apparently, another important factor influencing fatty acid composition of the safflower seed is the sowing date in the location in which it is planted. The variation of fatty acid composition with climatic conditions, particularly moisture and temperature during the growing season, was indicated by several investigators [13, 19, 36, 40]. The literature supports a strong correlation between C18:1 and C18:2 content and temperature. Under low temperatures, C18:2 content increases, and under high temperatures, C18:1 content increases. Lajara et al. [20] concluded that temperature during the time elapsed between flowering and ripening is perhaps the most important factor influencing fatty acid composition. The mechanism involved appears to be the direct effect of temperature on the activity of desaturase enzymes converting C18:1 to C18:2 acids, and on the solubility of oxygen, which seems to play a regulatory function in that activity [41]. Sims et al. [27] reported the formation of unsaturated fatty acids increases in plants grown at low temperature. In fact, many authors, such as Hamrouni et al. [29], Browse and Slack [42], and Robertson et al. [43], have also indicated the existence of an inhibitory effect of high temperature on desaturases. The enzymes that convert C18:1 to C18:2 acid are inactivated at high temperature, which prevents extensive formation of C18:2.

As for C18:3 content, it is given in the sum of the minor fatty acids (Table 3). During the process of seed formation and ripening, minor fatty acids represented 0.1–0.8% of total fatty acids, of which C18:3 content was present in less than 0.3%. Also, the C18:3 was not found in some samples analyzed during seed development. According to Nagaraj [10], during seed development, C18:2 acid predominated in every lipid class, whereas C18:3 content decreased with increasing maturation and was absent in fully mature safflower seeds. This situation was confirmed in previous works [27, 38, 44]. McKillican and Sims [44] reported that low levels of C18:3 acids were contained in their safflower varieties as late as 30 days after flowering. Hill and Knowles [38] showed that this fatty acid was not found past 10 days after flowering in any variety. Sims et al. [27] also revealed that it was not found in the more mature safflower samples.

The results of the present study show that oil content and the four major fatty acids were affected by sowing and harvest dates. As expected, decreases in moisture content were accompanied by increases in oil content during seed development. The saturated fraction included mainly the C16:0 and C18:0 acids, and although the rates of C16:0 acid regularly decreased during seed development, the rates of C18:0 acid showed fluctuations. There was an inverse relationship between the development of the C18:1 and C18:2 acids. The C18:1 content increased in the high oleic variety, and the C18:2 content increased in the high linoleic variety during seed development. Besides, changes of fatty acid composition, especially the C18:1 and C18:2 acids, in regard to sowing date were largely attributed to seasonal weather differences, particularly moisture and temperature, during the growing season.

This detailed study has led to the conclusion that important factors influencing fatty acid composition are evidently seed genotype and sowing date. A correct decision on safflower sowing date should be based on a thorough understanding of the environmental factors influencing yield components, oil quality, fatty acid composition, and also its genotype-dependent characteristics. The information provided by this study may be helpful for recommending optimum sowing date in terms of the fatty acid synthesis pattern and oil accumulation in similar climates and soil conditions.

References

FAOSTAD Database. http://www.fao.org. (accessed June 2005)

Isigigur A, Karaosmanoglu F, Aksoy HA (1995) Characteristics of safflower seed oils of Turkish origin. J Am Oil Chem Soc 72:1223–1225

Corleto A, Alba E, Polignano GB, Vonghio G (1997) Safflower: a multipurpose species with unexploited potential and world adaptability. In: Corleto A, Mündel HH (eds) Proceedings of the IVth International Safflower Conference, Bari, Italy, pp 23–31

Pavlov DC, Todorov NA (1996) Safflower (Carthamus tinctorius L.). In: Nwokolo E, Smartt J (eds) Food and feed from legumes and oilseeds. Chapman and Hall, London, pp 245–257

Hofbauer J, Pelikan J (1997) Production of safflower in Czech Republic. In: Corleto A, Mündel HH (eds) Proceedings of the IVth International Safflower Conference. Bari, Italy, pp 43

Uher J (1997) Safflower in European Horticulture. In: Corleto A, Mündel HH (eds) Proceedings of the IVth International Safflower Conference, Bari, Italy, pp 41–42

Corleto A (2001) Safflower project: on-farm introduction of safflower as an alternative oil crop in Southern Italy. In: Bergman JW, Mündel HH (eds) Proceedings of the Vth International Safflower Conference. Williston, North Dakota and Sidney, Montana, USA, pp 179–184

Weiss EA (1983) Oilseed crops. Tropical agriculture series. Longmans, London pp 558

Lata TS, Prakash V (1984) Studies on the proteins from safflower seed (Carthamus tinctorius L.). J Agric Food Chem 32:1412–1416

Nagaraj G (1993) Safflower seed composition and oil quality—a review. In: Third International Safflower Conference. Beijing, pp 58–71

Knowles PF (1989) Safflower. In: Downey RK, Robbelen G, Ashri A (eds) Oil crops of the world. New York, pp 363–374

Velasco L, Fernandez-Martinez JM (2001) Breeding for oil quality in safflower. In: Bergman JW, Mündel HH (eds) Proceedings of the Vth International Safflower Conference. Williston, North Dakota and Sidney, Montana, USA, pp 133–137

Ladd SL, Knowles PF (1970) Inheritance of stearic acid in the seed oil of safflower (Carthamus tinctorius L.). Crop Sci 10:525–527

Futehally S, Knowles PF (1981) Inheritance of very high levels of linoleic acid in an introduction of safflower (Carthamus Tinctorius L.) from Portugal. In: First International Safflower Conference, Davis, California, pp 56–61

Fernandez-Martinez J, Rio M, Haro A (1993) Survey of safflower (Carthamus tinctorius L.) germplasm for variants in fatty acid composition and other seed characters. Euphytica 69:115–122

Dajue L (1993) Progress of safflower (Carthamus tinctorius L.) research and production in China. In: Third International Safflower Conference, Beijing, China, pp 35–46

Smith JR (1993) More than four decades of safflower development. In: Third International Safflower Conference, Beijing, China, pp 861–867

Bergman JW (1997) Safflower genetic improvement for yield and value-added traits for the United States Northern Great Plains. In: Bergman JW, Mündel HH (eds) Proceedings of the IVth International Safflower Conference. Bari, Italy, pp 229–231

Garces R, Garcia JM, Mancha M (1989) Lipid characterization in seeds of a high oleic acid sunflower mutant. Phytochem 28:2597–2600

Lajara JR, Diaz U, Diaz Q (1990) Definite influence of localization and climatic conditions on fatty acid composition of sunflower seed oil. J Am Oil Chem Soc 67:618–623

Esendal E (2001) Safflower production and research in Turkey. In: Bergman JW, Mündel HH (eds) Proceedings of the Vth International Safflower Conference. Williston, North Dakota and Sidney, Montana, USA, pp 203–206

Esendal E (2001) Global Adaptability and Future Potential of Safflower. In: Bergman JW, Mündel HH (eds) Proceedings of the Vth International Safflower Conference. Williston, North Dakota and Sidney, Montana, USA, pp XI–XII

Rubis DD (2001) Developing new characteristics during 50 years of safflower breeding. In: Bergman JW, Mündel HH (eds) Proceedings of the Vth International Safflower Conference. Williston, North Dakota and Sidney, Montana, USA, pp 109–111

IUPAC (1987) Standard methods for the analyses of oils, fats, and derivatives, 7th edn. Blackwell Jevent Publishers, Oxford

(1992) Official methods and recommended practices of the American Oil Chemists’ Society, 4th edn. American Oil Chemists’ Society, Champaign, Method Ce 2–66

Soysal I (1993) Principles of biometric analysis, vol 95. Trakya University, Tekirdag Agricultural Faculty, Tekirdag, pp 15–35

Sims RA, Mc Gregor WG, Plessers AG, Mes JC (1961) Lipid changes in maturing oil bearing plants. II. Changes in fatty acid composition of flax and safflower seed oils. J Am Oil Chem Soc 38:276–279

Leininger LN, Lee A (1964) Urie, development of safflower seed from flowering to maturity. Crop Sci 4:83–87

Hamrouni I, Touati S, Dhifi W, Chahed T, Ayachi S, Salah H, Marzouk B (2004) Glycerolipid evolution during safflower seed formation and ripening. J. Food Lipids 11:297–311

Bratcher SS, Kemmerer AR (1969) Oxidative stability of safflower oil. J Am Oil Chem Soc 46:173–175

Dorrell DG (1976) Chlorogenic acid content of sunflower seed flour as affected by seeding and harvest date. Can J Plant Sci 56:901–905

Abo-Hegazi AMT, Shalaby AR (1993) Characteristics of some mutants of safflower, (Carthamus Tinctorius. L). In: Third International Safflower Conference, Beijing, pp 102–111

Xuehai Z, Qingwei Z (1993) Studies on Development and Exploitation of Safflower. In: Third International Safflower Conference, Beijing, pp 897–901

Gambacorta G, Leone AM, Cazzato E (1997) Seed composition of some safflower cultivars tested in South Italy. In: Corleto A, Mündel HH (eds) Proceedings of the IVth International Safflower Conference. Bari, Italy, pp 353–356

Knowles PF (1968) Associations of high levels of oleic acid in the seed oil of safflower (Carthamus tinctorius L.) with other plant and seed characteristics. Econ Bot 22:195–200

Nagaraj G, Reddy PS (1997) Some factors influencing safflower seed and oil quality. In: Corleto A, Mündel HH (eds) Proceedings of the International Safflower Conference. Bari, Italy, pp 347–349

Esendal E, Tosun F (1972) Research on the yield, phonological, morphological and seed characteristics of some native and foreign varieties of safflower (Carthamus tinctorius L.) under Erzurum ecological conditions. Ataturk Univ J Agric Fac 3:93–115

Hill AB, Knowles PF (1968) Fatty acid composition of the oil of developing seeds of different varieties of safflower. Crop Sci 8:275–277

Robertson JA, Thomas JK, Burdick D (1971) Chemical composition of seed of sunflower hybrids and open pollinated varieties. J Food Sci 36:873

Nagao A, Yamazaki M (1984) Effect of temperature during maturation on fatty acid composition of sunflower seed. Agric Biol Chem 48:553–555

Harris P, James AT (1969) Effect of low temperature on fatty acid biosynthesis in seeds. Biochem Biophys Acta 187:13–18

Browse J, Slack CR (1983) The effects of temperature and oxygen on the rates of fatty acid synthesis and oleate desaturation in safflower (Carthamus tinctorius L.) seed. Biochem Biophys Acta 753:145–152

Robertson JA, Chapman GW, Wilson RL (1978) Relation of days after flowering to chemical composition and physiological maturity of sunflower seed. J Am Oil Chem Soc 55:266–269

McKillican ME, Sims RPA (1963) Lipid changes in maturing oil-bearing plants. III. Changes in lipid classes in flax and safflower oils. J Am Oil Chem Soc 40:108–113

Acknowledgments

The authors gratefully acknowledge the Trakya University Research Fund for providing funding for this work (TUBAP-479).

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Gecgel, U., Demirci, M., Esendal, E. et al. Fatty Acid Composition of the Oil from Developing Seeds of Different Varieties of Safflower (Carthamus tinctorius L.). J Amer Oil Chem Soc 84, 47–54 (2007). https://doi.org/10.1007/s11746-006-1007-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-006-1007-3