Abstract

One of the problems of using surfactant-modified adsorbents in a surfactant-based adsorption process is loss of surfactant because of desorption. Recently, polymerizable surfactants have been used to minimize surfactant losses by polymerization of the surfactant admicellar structure to help secure it to the solid oxide surface. In this study, adsorption of polymerizable cationic gemini surfactant was used to form polymerized bilayers on silica. UV light was used to irradiate and initiate the polymerization process. Surfactant adsorption and desorption were evaluated to compare the efficiency of polymerized and non-polymerized surfactants using gemini and conventional surfactants, respectively. Results demonstrate that the increased stability of the polymerized surfactant-modified surface can reduce the desorption of surfactant from the surface, thereby improving operating characteristics of the surfactant-modified media (e.g., maintaining adsolubilization potential, dispersion stability, etc.).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Surfactant-modified adsorbents have been investigated for a number of applications. Various surfactant systems have been evaluated for surface modification including mixed anionic and cationic surfactants [1–3], and linker-based and extended surfactants [4]. Surfactant losses from the surface because of desorption negatively affects the stability of surfactant-modified surfaces [5, 6]. The hypothesis of this research is that fixing an admicellar structure to the surface by polymerization will reduce surfactant losses.

Gemini surfactants have received increased attention in recent years. Bis(quaternary ammonium) is a gemini surfactant containing two quaternary ammonium moieties which has been evaluated [7]. Gemini surfactants have very low CMC values compared with the corresponding monomeric and conventional surfactant, thereby requiring less raw materials for upscale production [8]. Previous studies have reported on the fact that gemini surfactants can assemble into various phases depending on their structure when dissolved in water [7]. The desirable properties of gemini surfactants can be modified by changing their alkyl tail length and their spacer length and flexibility [9]. Based on the effectiveness of gemini surfactants, cationic polymerizable gemini surfactants are expected to be strongly adsorbed on the silica surface with minimal desorption of surfactant from the surface, thereby improving the operating characteristics of the surfactant-modified media.

Background

Polymerization of Surfactants

Polymerization of amphiphile molecules has been evaluated for a variety of purposes. For example, polymerizable amphiphiles with fluorocarbon chains were studied as early as 1984 [10], with hydrocarbon and fluorocarbon amphiphiles evaluated in Langmuir–Blodgett multilayers [11]. Two years later, the monolayer microstructure of amphiphilic copolymers consisting of two-chain surfactant was also investigated [12]. Polymerization of admicelles is a process whereby adsorbed surfactant bilayers are polymerized after admicelle formation [13]. In 1989, Esumi et al. [14] studied the polymerization of the surfactant bilayer of sodium 10-undecenoate on alumina surface using UV irradiation. Further, research demonstrated that the dispersion stability of alumina with a polystyrene layer was increased with UV irradiation time and somewhat enhanced compared with that of alumina without the polystyrene layer, probably because of the increased electric repulsion force between alumina particles [15, 16].

Gemini and Polymerizable Gemini Surfactant

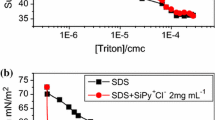

Gemini surfactants contain two hydrophobic tails and hydrophilic heads. Such molecules may be regarded as equivalent to the dimers of the mono-quaternary ammonium bromide surfactants C m H2m+1–(CS/2HS + 1)–N+–(CH3)2Br− [17]. These compounds have much lower CMC values and much higher surface activity (produces lower surface tension) than the corresponding monomeric surfactant. Adsorption of the gemini surfactant 12–2–12, was found to increase as the size of spacer group increased, resulting in a decrease of the maximum surface excess of surfactant [18]. The tighter packing of the hydrophilic groups of gemini surfactants results in a more cohesive and stable interfacial film, and double-tailed and doubly charged gemini surfactants interact more prominently with neutral and oppositely charged surfactants [8]. Once the gemini surfactant is adsorbed at the surface, the second charged head-group is brought into close proximity with the surface, an effect which becomes more pronounced as the spacer length is reduced [19].

Polymerizable gemini surfactants have also been investigated as novel pseudo-stationary phases in micellar electrokinetic chromatography [20]; one such example is sodium di(undecenyl) tartrate [21]. Various properties of these polymerizable gemini surfactants have been reported, for example designation of the nanostructures of the lyotropic liquid–crystalline phase behavior of the cross-linkable and polymerizable gemini surfactants, bis(alkyl-1,3-dine)-based phosphonium amphiphiles [22]. Synthesis of a polymerizable cationic gemini surfactant with a polymerizable group at the terminus of each hydrophobic group was achieved by Abe et al. [23] to investigate its basic interfacial properties in water and in the presence of 0.05 M NaBr. For comparison, the properties of the corresponding monomeric surfactant were also studied. In this research, we hypothesized that by using polymerizable surfactants we could stabilize surfactant-modified silica and reduce surfactant desorption from the silica surface [14–16].

Hypotheses

The major objective of this research was to demonstrate that polymerizable gemini surfactants lead to desirable stability of surfactant-modified silica surfaces (reduced decomposition) compared with single-head-group polymerizable and non-polymerized surfactants. It was hypothesized that strong interaction of dimeric surfactant head groups with the solid oxide surface would increase adsorption and that the crosslinking of adsorbed surfactant after polymerization would minimize desorption of surfactant from the surface, thereby reducing surfactant losses from the surface and improving the operating characteristics of the surfactant-modified media.

Materials and Analytical Section

Materials

Surfactants used in this study were divided into two types: polymerizable and non-polymerizable. For polymerizable surfactants, polymerizable cationic gemini surfactant (PG) and polymerizable monomeric surfactant (PM) were kindly supplied by the Faculty of Science and Technology, and the Institute of Colloid and Interface Science, of Tokyo University of Science, Japan. For non-polymerizable surfactant, dodecyl trimethylammonium bromide (DTAB) was purchased from S.M. Chemical Supplies, Thailand. The properties of these surfactants and their surface properties are shown in Table 1. The CMC of the gemini surfactant (PG) is reported as 5 × 10−4 M and PM and DTAB have reported CMC values of 1.8 × 10−2 M and 1.6 × 10−2 M, respectively. Furthermore, the PG surfactant has been reported to produce lower surface tension values than PM and DTAB (γ cmc for PG, PM and, DTAB are 32.1, 42.1 and, 39 mN/m, respectively) [8, 9, 23, 24].

Silica (SiO2), 15-nm particle size, was purchased from S.M. Chemical Supplies, and was used as received. The specific surface reported by the manufacturer product is 160 m2/g. The electrolyte concentration was controlled by use of 1 mM sodium bromide (NaBr). Solution pH was adjusted by use of NaOH and HCl. All chemicals were used as received and are ACS analytical reagent grade. Water used in this work was purified and had a resistance of 18.2 MΩ cm. Plastic and glassware were rinsed well with double-distilled water three times prior to use.

Analytical Method

Surfactant concentrations were analyzed by ion chromatography (Agilent) and UV–visible spectrophotometry (Shimadzu UV 1601). In addition, the zeta potentials of surfactant suspensions were measured by means of an electrophoretic apparatus (Zeta-Meter System 3.0) to examine the effect of polymerization on the dispersion stability of silica and also to confirm the presence of a surfactant bilayer before and after desorption studies. The UV lamp used as the source (initiator) in the polymerization process was purchased from Cole Parmer, USA.

Determination of the Adsorption Isotherm

The adsorption isotherms of all surfactant system were obtained by use of batch experiments. Different concentrations of surfactant covering the regions below and above the CMC were added into several vials containing 0.01 g silica. All solutions were then shaken for at least 48 h until they reached equilibrium. The pH of the solutions was periodically measured and adjusted to 7 ± 0.5. After being equilibrated, the solutions were centrifuged to remove the silica. The concentrations of DTAB and polymerizable surfactants in the supernatants were then determined by ion chromatography (ECD) and UV–visible spectrophotometry at the wavelengths 245 and 255 nm for PG and PM, respectively.

Determination of the Surfactant Polymerization

In this research, admicellar polymerization consisted of two steps; first, adsorption of surfactant on to the silica surface, and, second, polymerization of the admicelles by use of UV light and initiator. The solutions contained 0.1 g sodium persulfate after purging with nitrogen gas to remove dissolved oxygen. Polymerization of the surfactant was performed by irradiation with the UV lamp (30 W power supply) at 254 nm wavelength with the average operating temperature 25 ± 2°C. The lamp was placed 10 cm from samples. During this time, surfactant suspensions were shaken at 150 rpm for 18 h. Heat released during polymerization was observed by measuring the temperature before and after irradiation. To determine the extent of polymerization, the supernatant concentrations of the polymerizable surfactants PG and PM were analyzed by UV–visible spectroscopy at the wavelengths 245 and 255 nm, respectively. The concentration of non-polymerizable surfactant, DTAB was determined by ion chromatography with ECD detector. Zeta potential measurements were also evaluated after polymerization at various times on the basis of UV–visible spectroscopy results.

Determination of the Effect of Polymerization on the Dispersion Stability of Silica

Surfactant concentrations were varied to represent surfactant formation from monolayer through bilayer above the CMC concentration. After the adsorbed surfactant suspension samples were equilibrated/washed, the surface chemistry was characterized before and after polymerization/desorption by using zeta potential measurement. Each surfactant sample was placed into an electrophoretic cell before applying 50–75 mV to the apparatus. Zeta potential values were read and recorded for the silica particles in the electric field. The measurement was repeated ten times per sample, with the average value reported as the zeta potential for each condition.

Determination of Surfactant Desorption

Surfactant suspensions before and after polymerization were allowed to settle for one day before removal of the supernatant from the solution. Silica media were allowed to dry in a desiccator for several days to ensure that they were completely dry. The silica was then transferred to a new test tube and rinsed three to five times to remove excess surfactant. DI water was then added to in the new test tube as a blank solution for silica before shaking at 150 rpm for 48 h for the washing (desorption) study. Finally, the clear liquid was kept for further analysis.

Results

Adsorption Studies

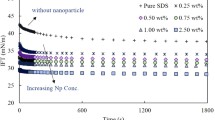

The adsorption isotherms were obtained by analysis of aqueous surfactant before and after adsorption on silica surface and then plotted in terms of surfactant adsorption (mM/g) versus equilibrium surfactant concentration (mM). Figure 1 shows the adsorption isotherm of polymerizable cationic gemini surfactant (PG), the corresponding monomeric polymerizable surfactant (PM), and the conventional cationic surfactant (DTAB) on silica. For all systems, the amount of surfactant adsorbed increased with increasing equilibrium surfactant concentration prior to plateau adsorption. The plateau adsorption levels, which are related to CMC values, are higher for the polmerizable monomer and gemini surfactants than for DTAB (Fig. 1; Table 2). To confirm the absence of micelles below the plateau adsorption transition point, pinacyanol chloride was added into each vial of surfactant, as an indicator. At concentrations slightly below the CMC and when the transition point (plateau adsorption) was reached and exceeded, the solutions were red and blue, respectively, indicating the absence and presence of micelles, respectively [25].

Polymerization of Surfactants

Zeta potential measurement and UV irradiation of 80% CMC for polymerizable gemini surfactant were carried out as a function of polymerization time, as shown in Fig. 2. The absorbance results indicate that complete polymerization is achieved when the samples have been irradiated for 12 h. In addition, polymerized silica coated with surfactant retained a positively charged surface, albeit reduced in charge after irradiation with UV light. System temperature was measured during polymerization in order to examine the heat released by UV irradiation. It was found that temperature rose by 3°C during the 18 h polymerization time (pre and post-polymerization temperatures were 24°C and 27°C, respectively). This finding shows there is no significant heat effect (temperature change) during irradiation by the UV lamp in this study.

Effects of Polymerization on the Dispersion Stability of Silica

In order to determine the silica surface charge as a function of surfactant coverage and polymerization, the zeta potential of silica dispersed in water was measured at different pH. It was found that the zeta potential of unmodified silica was negative (of the order of −40 mV) in the pH ranges studied (6.5–7.5), which is consistent with the point of zero charge (pzc) of silica (pH 2–3) [26]. At low surfactant loading, the surfactant-modified silica is expected to remain negative; however, bilayer sorption of surfactant is expected to result in positively charged surface because of the head of the cationic surfactant extending into the solution.

Before polymerization, comparison of zeta potential after adsorption for PG, PM, and DTAB are shown in Fig. 3. As can be seen, the zeta potential of surfactant-modified silica increases from negative to positive consistent with increased adsorption of the three surfactants studied, going from −40 to +40 mV.

Figure 4 shows the comparison of zeta potential with adsorption for PG, PM, and DTAB after polymerization. The results demonstrate that, as before, with increasing surfactant concentrations the zeta potential increases from negative to positive as the surfactant concentration approaches and exceeds the transition point/plateau adsorption. It is apparent that polymerization alters the zeta potential profile and that the zeta potential approaches a maximum of +20 mV after polymerization, compared with +40 mV before polymerization (Fig. 3). Thus, while charge reversal is still achieved, the polymerized admicelle surface is less positive than before, suggesting alteration of the nature of the surface aggregates.

Surfactant Desorption Studies

Indirect evaluation of the performance of polymerization for fixing the bilayer on to the silica surface was achieved by zeta potential measurement before and after desorption studies. The objective was to evaluate whether admicelle polymerization would reduce surfactant losses after desorption, compared with systems without polymerization, indicating the presence of a more fixed bilayer. If this is true, then the zeta potential values should indicate retention of more of its positive charge after washing (desorption) of the admicellar system. As discussed in the section “Determination of Surfactant Desorption” the systems were washed (desorbed) by decanting the aqueous phase and replacing with surfactant-free deionized water and allowing to equilibrate (desorb) for 48 h.

Results from zeta potential measurement in desorption studies without polymerization of surfactant PG, PM, and DTAB are shown in Fig. 5. After washing, the zeta potentials of PG, PM, and DTAB decreased, with the most dramatic decrease for the higher surfactant concentration (compare with Fig. 3). For most of the higher surfactant concentration, the zeta potential of the non-polymerized system changed from positive to negative which indicates significant desorption. For the highest surfactant concentrations, the zeta potential decreased from >40 mV for all systems (Fig. 3) to 20 mV for PG, <10 mV for PM and −40 mV for DTAB (Fig. 5). With additional washing steps it is expected that PG and PM would likewise become negatively charged, because the admicelles have not been polymerized and fixed to the surface.

After polymerization, surfactant desorption results for PG, PM, and DTAB are shown in Fig. 6. Comparing Figs. 5 and 6, we see that the polymerizable surfactants (PG and PM) retain their cationic zeta potential after washing much better after polymerization (Fig. 6) than prior to polymerization (Fig. 5). For PG and PM, zeta potentials remained positive, demonstrating that surfactant bilayers still exist on the surface, although the reduced charge suggests some reconfiguration in the nature of the surface aggregates (Fig. 6). In contrast, after desorption, the DTAB, surfactant bilayer was not observed, because the surface charge returned to the negative zeta potential value of the original silica, indicating that the DTAB had been “washed off” (desorbed from) the surface. Thus, the results in Fig. 6 demonstrate the improved stability of the adsorbed surfactant bilayer when the surfactant admicelles are capable of polymerization and have been polymerized.

The final results for percentage desorption, surfactant retention, and zeta potential values for each surfactant system before and after polymerization at bilayer concentrations is shown in Table 3. The percentage desorption is quantified by mass balance of surfactant in decanted water in the washing (desorption) study. The results in Table 3 show a similar trend to the zeta potential measurements above and are consistent with the polymerizable surfactants reported by Attaphong [27].

Discussion

It is interesting to note that the surface charge goes from −40 mV at very low surfactant coverage to +40 mV at plateau adsorption, indicating complete charge reversal of the surfactant admicelles (i.e., cationic head groups facing out into solution causing a net cationic surface charge). Granted, at intermediate surfactant coverage it is likely that patchy “islands” of bilayer coverage occur, without necessarily yet having complete monolayer coverage as reported by others [19, 28, 29]. The zeta potential values are slightly lower after polymerization, indicating that the adsorbed surfactant is altered somewhat during polymerization. Nonetheless, the zeta potential is still sufficient to maintain the electrostatic nature of the modified silica (i.e., stable dispersion), which is important for numerous applications. In addition, consistent with the main objective of this work, the polymerization process reduced desorption of the surfactant from the surface during washing, as demonstrated both by surfactant in the decanted water and the zeta potential of the washed surfaces. These results thus support the lower desorption of gemini over non-gemini surfactant, and the increased stability of polymerized admicelles (gemini or not) as reflected by their resistance to desorption. For the conventional surfactant, DTAB, it was apparent that the surfactant bilayer is readily desorbed during washing, further demonstrating the improved stability and performance of the adsorbed polymerizable gemini surfactant in the surface modification.

References

Fuangsawasdi A, Charoensaeng A, Sabatini DA, Scamehorn JF, Acosta JE, Osathaphan K, Khaodhiar S (2006) Mixtures of anionic and cationic surfactants with single and twin head groups: adsorption and precipitation studies. J Surfactants Deterg 9:21

Fuangsawasdi A, Charoensaeng A, Sabatini DA, Scamehorn JF, Acosta JE, Osathaphan K, Khaodhiar S (2006) Mixtures of anionic and cationic surfactants with single and twin head groups: solubilization and adsolubilization of styrene and ethylcyclohexane. J Surfactants Deterg 9:21

Fuangsawasdi A, Krajangpan S, Sabatini DA, Acosta JE, Osathaphan K, Tongcumpou C (2007) Effect of admicellar properties on adsolubilization: column studies and solute transport. Water Res 41:1343

Charoensaeng A, Sabatini DA, Khaodhiar S (2008) Styrene solubilization and adsolubilization on an aluminum oxide surface using linker molecules and extended surfactants. J Surfactants Deterg 11:61

Rouse JD, Sabatini DA, Harwell JH (1993) Minimizing surfactant losses using twin-head anionic surfactants in subsurface remediation. Environ Sci Technol 27:2072

Krajangpan S (2004) Enhanced adsolubilization in silica-packed column by mixture of cationic and anionic surfactants. Master thesis, Graduate School, Chulalongkorn University

Oda R, Huc I, Candan SJ (1997) Gemini surfactants, the effect of hydrophobic chain length and dissymmetry. Chem Commun 2105

Hait SK, Moulik SP (2002) Gemini surfactants: a distinct class of self-assembling molecules. Curr Sci 82:1101

Zana R (2002) Dimeric and oligomeric surfactants behavior at interfaces and in aqueous solution: a review. J Colloid and Interf Sci 97:205

Elbert R, Folda T, Ringsdorf H (1984) Saturated and polymerizable amphiphiles with fluorocarbon chains. Investigation in monolayers and liposomes. J Am Chem Soc 106:7687

Laschewsky A, Ringsdorf H, Schmidt G (1985) Polymerization of hydrocarbon and fluorocarbon amphiphiles in Langmuir–Blodgett multilayers. Thin solid film 134:153

Frey W, Schneider J, Ringsdorf H, Sackmann E (1987) Preparation, microstructure, and thermodynamic properties of homogeneous compound monolayers of polymerized and monomeric surfactants on the air/water interface and on solid substrates. Macromolecules 20:1312

Grady BP, O’Rear EA, Penn LS, Pedicini A (1989) Polymerization of styrene-isoprene on glass cloth for use in composite manufacture. Polym Compos 19:597

Esumi K, Watanabe N, Meguro K (1989) Polymerization of surfactant bilayer on alumina using a polymerizable surfactant. Langmuir 5:1420

Esumi K, Watanabe N, Meguro K (1991) Polymerization of styrene adsolubilized in polymerizable surfactant bilayer on alumina. Langmuir 7:1775

Esumi K, Nakao T, Ito S (1993) Fixation of polymerizable surfactant on alumina by uv irradiation. J Colloid and Interf Sci 156:256

Zana R, Yiv S, Kale KM (1980) Chemical relaxation and equilibrium studies of association in aqueous solutions of bolaform detergents. 3. docosane-1,22-bis(trimethylammonium bromide). J Colloid and Interf Sci 77:456

Alami E, Beinert G, Marie P, Zana R (1993) Alkanediyl-α,ω-bis(dimethylalkylammonium bromide) surfactants. 3. behavior at the air–water interface. Langmuir 9:1465

Atkin R, Craig VSJ, Wanless EJ, Biggs S (2003) Mechanism of cationic surfactant adsorption at the solid–aqueous interface. Adv Colloid Interf Sci 103:219

Akbey C, Gill N, Powe A, Warner IM (2005) Monomeric and polymeric anionic gemini surfactants and mixed surfactant systems in micellar electrokinetic chromatography, Part I: Characterization and application as novel pseudostationary phases. Electrophoresis 26:415

Kunitake T, Nagai M, Yanagi H, Takarabe K, Nakashima N (1984) Bilayer formation by aggregation of polymeric amphiphiles. Macromol Sci Chem A21:1237

Pindzola BA, Jin J, Gin D (2003) Cross-linked normal hexagonal and bicontinuous cubic assemblies via polymerizable gemini amphiphiles. J Am Chem Soc 125:2940

Abe M, Tsubone K, Koike T, Tsuchiya K, Ohkubo T, Sakai H (2006) Polymerizable cationic gemini surfactant. Langmuir 22:8923

Rosen MJ, Mathias JH, Davenport L (1999) Aberrant aggregation behavior in cationic Gemini surfactants investigated by surface tension, interfacial tension, and fluorescence methods. Langmuir 15:7340

Pongprayoon T, Yanumet N, O’Rear EA (2002) Admicellar polymerization of styrene on cotton. J Colloid and Interf Sci 249:227

Kosmulski M (2000) Surface charge and zeta potential of silica in mixtures of organic solvents and water. In: Papirer E (ed) Adsorption on silica surfaces. Surfactant Science Series, vol 90. Dekker, New York

Attaphong C (2006) Adsorption and adsolubilization of polymerizable surfactant onto aluminum oxide surface. Master thesis, Graduate School, Chulalongkorn University

Paria S, Khilar KC (2004) A review on experimental studies of surfactant adsorption at the hydrophilic solid–water interface. Adv Colloid Interf Sci 110:75

Schemehorn JF, Schechter RS, Wade WH (1981) Adsorption of surfactants on mineral oxide surfaces from aqueous solutions: isometrically pure anionic surfactants. J Colloid and Interf Sci 85:463

Acknowledgments

Financial support for this work was provided by National Center of Excellence for Environmental and Hazardous Waste Management (NCE-EHWM), Chulalongkorn University, Thailand. In addition, financial support for this research was received from The 90th Year Anniversary of Chulalongkorn University (Ratchadaphiseksomphot Endowment Fund), Chulalongkorn University, Thailand. Financial support was also received from the industrial sponsors of the Institute for Applied Surfactant Research (IASR), University of Oklahoma, USA, including Akzo Noble, Clorox, Conoco/Phillips, Church & Dwight, Ecolab, Halliburton, Huntsman, Oxiteno, Proctor & Gamble, Sasol, Shell, and Unilever. In addition, funds from the Sun Oil Company Chair (DAS) at the University of Oklahoma helped support this research. Finally, many thanks are extended to Dr. Kazuyuki Tsubone and Dr. Abe Mazahiko from Tokyo University of Science, Tokyo, Japan who supplied the samples of polymerizable surfactants used in this research.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Asnachinda, E., Khaodhiar, S. & Sabatini, D.A. Effect of Ionic Head Group on Admicelle Formation by Polymerizable Surfactants. J Surfact Deterg 12, 379–386 (2009). https://doi.org/10.1007/s11743-009-1125-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11743-009-1125-7