Abstract

This paper concerns the primary biodegradation of different commercial fatty-alcohol ethoxylate surfactants (FAEs), applying the OECD 301 E test for ready biodegradability. Changes were made both in the carbon-chain length of the surfactants as well as in the number of units of ethylene oxide (EO) in its molecule. The biodegradation were monitored, analysing the colony-forming units (CFU) formed during this process. From the biodegradation profiles drawn for the FAEs, parameters characteristic of the biodegradation process were defined: latency time (t L), biodegradability at 50 h of assay (B), half-life (t 1/2), mean biodegradation rate until reaching biodegradability of 85% (V M), and the residual concentration of the surfactant (S R). The analysis of these parameters enabled the establishment of the influence of surfactant concentration and structure during the biodegradation process. The increase in the surfactant concentration lowered the rate of the biodegradation process and the biodegradability of the surfactant in addition to the half-life and residual concentration of the surfactant. The mean biodegradation rate, V M, for fatty-alcohol ethoxylates increased with the number of EO units and molecular weight of the surfactant. At low initial test concentrations (less than 25 mg/L), the concentration of the residual surfactant rapidly diminished with biodegradation time. For higher concentrations, after an adaptation period of the microorganisms, the surfactant concentration declined exponentially and the biodegradation rate became far slower for all the surfactants. The parameters characteristic of the growth curves: specific growth-rate, k, and the yield of biomass production per gram of surfactant, Y ap, made possible the quantification and corroboration of the results during the biodegradation process.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Surfactants are widely used in household cleaning detergents, personal-care products, textiles, paints, polymers, pesticide formulations, pharmaceuticals, mining, oil recovery, and the pulp and paper industries. The world production of synthetic surfactants amounts to 7.2 million tonnes annually [2]. After use, surfactants as well as their products are mainly discharged into sewage-treatment plants and then dispersed into the environment by releasing effluents into surface waters and by sludge disposal on land. Surfactants have different behaviors and fates in the environment.

FAEs make up the second highest volume group of surfactant after LAS and the leading group within the family of non-ionic ethoxylate surfactants [3]. In Europe, 5 × 105 tonnes of these surfactants are sold yearly [4] representing some 40% of the total production of FAEs [5], most of these being used in detergent formulas. FAEs are easily biodegraded [3, 6, 7], although the massive dumping of these surfactants into sewage waters requires strict control to prevent the pollution of the aquatic environment, and generally waters are controlled by determining only the anionic surfactants. One key element in this process is the evaluation of the biodegradability and toxicity for guaranteeing the use of these surfactants in domestic and industrial formulations.

The FAEs used in this work belong to those called oleochemical—that is, they are from natural, renewable sources. FAEs are not pure as they are mixtures of molecules that differ in the size of the hydrocarbon and ethoxylate chain. The mixture of oligomers has mean lengths between 1 and 20 ethoxylate units and homologs with a number of carbon atoms in the alkyl chain between 12 and 18.

Due to the enormous economic importance of surfactants and their contribution to the deterioration of the environment when these persist in nature, numerous studies have sought to establish the structural characteristics that govern the susceptibility of these molecules to be degraded.

The factor that strongly affects the biodegradability of FAEs is the hydrophobic structure and in particular the linearity of the carbon backbone, which has a heavier influence than other factors such as length of the alkyl chain, the type of bond to the ethoxylate chain, and its length. The search for relationships between parameters in the biodegradation process and the structural properties of these surfactants would serve to characterize them with respect to an environmental standpoint.

The present work analyses the biodegradation of linear FAEs in relation to microorganism growth during this process. The study includes different FAEs in which the length of the carbon chain and the number of units of ethylene oxide has been modified, and the influence of the surfactant concentration has been analysed both in the biodegradation process as well as in the growth of the microorganisms.

Experimental Procedures

Surfactants

The following commercial surfactants, fatty-alcohol ethoxylates with the general formula R(–O–CH 2 –CH 2 ) n –OH, were used in this study: FINDET 10/15, FINDET 10/18, FINDET 1214N/16, FINDET 1214N/23, FINDET 1618A/18 and FINDET 1618A/23 supplied by KAO CORPORATION S.A. (Tokyo, Japan). Table 1 shows the main characteristics of the surfactants analysed in this research.

Static-Biodegradation Assay

The static biodegradation tests were carried out according to the OECD 301 E test for ready biodegradability [1]. A solution of the surfactant, representing the sole carbon source for the microorganisms, was tested in a mineral medium, inoculated and incubated under aerobic conditions in the dark. The procedure consists of introducing 1.2 L of surfactant solution (for which the biodegradability is to be determined) into a 2 L Erlenmeyer flask and inoculating the solution with 0.5 mL of water from a secondary treatment of a sewage-treatment plant (STP) that operates with active sludges. The Erlenmeyer flask is plugged with a cotton stopper and left in darkness in a thermostatically controlled chamber at 25 °C. The constant rotary speed of the orbital shaker (125 sweep/min) provides the necessary aeration. The surfactant solution is prepared by dissolving the desired quantity of surfactant in the nutrient solution.

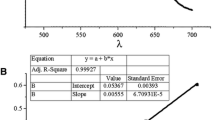

The biodegradation process was monitored by measuring the residual-surfactant concentration over time. The FAEs were determined by the iodine-iodide colorimetric method [11]. For the absorbance measurements, a double-beam spectrophotometer SPECTRONIC UNICAM UV-V was used. The absorbance was directly proportional to the surfactant concentration.

Reference assays were made with an easily biodegradable surfactant (LAS) in order to determine the activity of the microbial population present in the test medium. The initial concentration of the reference assay was 5 mg/L in all cases, and the mean biodegradability at 5 days was 97.28% ±1.54. According to the OECD [1], for the validity of the assay to be accepted, the percentage of the biodegradation of the soft standard after 5 days should be greater than 90%. It is known that sorption may significantly influence the resulting environmental effects of surfactants [12] and it has been studied by some authors [13] who have proposed expressions to predict the sorption onto activated sludge particles for alcohol ethoxylates. In the biodegradation assays presented here, the sorption can be considered negligible, given the scant biomass formation. To confirm this fact, abiotic assays were made in the presence of HgCl2, observing that the values of the residual surfactant remained around 100% over the biodegradation period. These results indicate that the contribution of abiotic processes in the degradation of the FAEs in the biodegradation tests made can be dismissed.

The biodegradation was studied at different initial concentrations varying from 5 to 50 mg/L: surfactant C12–14E11 was studied at concentrations of 5, 15, 20, 25, and 50 mg/L; the FAEs C12–14E4 and C16–18E6 at 5, 25, and 50 mg/L; while the surfactants C10E3, C10E6 and C16–18E11 were studied at an initial concentration of 5 mg/L.

Biomass Growth During the Biodegradation Process

During the biodegradation assays, the number of viable microorganisms was measured by counting the heterotrophic microbes in a dish [14], expressing the result as colony-forming units (CFU) per mL. The culture medium, nutrient agar, enables the detection of a broad variety of microorganisms. With a sterile pipette, 1 mL of sample is taken from the culture, and a series of 1:10 dilutions are taken in ClNa at 0.9% until reaching a suspension of microorganisms of between 30 and 80 viable cells per mL of test solution.

Each dilution was analysed in duplicate: 1 mL of sample to be analysed was placed on a 10-cm dish. Then 20 mL of previously sterilized culture medium was poured onto the dish, sterilized, melted and tempered at 60 °C, and gently stirred to complete the homogenization. The mixture was left to cool until complete solidification and then incubated at 25 °C for 72 h in darkness. The total number of microorganisms was determined by multiplying the number of CFU by the corresponding dilution factor.

Results and Discussion

The effect of the concentration of the FAEs on the primary biodegradation was studied for the commercial surfactants C12–14E4, C12–14E11 and C16–18E6. The biodegradation of surfactants C10E3, C10E6 and C16–18E11 at 5 mg/L were also studied. Figure 1 presents the results of the primary biodegradation of these surfactants. The concentration is expressed as a percentage of residual surfactant and each point of the graphs represents the mean value of the two replicates.

In light of legislation demanding a minimum level of 80% of the primary biodegradation after 19 days, when the surfactants are subjected to the OECD test [1] all the surfactants can be considered biodegradable, as shown in Fig. 1. Biodegradation exceeds 90% in less than 13 days (most in 4 days) except for C12–14E4 at 50 mg/L, which did not surpass 60% in this time period.

In a preliminary analysis of the primary-biodegradation profiles (Fig. 1), it was found that for the three surfactants for which the concentration had been modified, the concentration of the residual surfactant rapidly diminished with biodegradation time. For higher concentrations, after an adaptation period of the microorganisms, the surfactant concentration declined exponentially and the biodegradation rate became far slower for all the surfactants, this effect being more pronounced for the surfactant with the least number of ethylene oxide units, C12–14E4.

The biodegradation curves found for 50 mg/L significantly differed from the rest of the concentrations studied, the shape of the curve was exponential, and, although the concentration did not significantly affect the latency time, the biodegradation process became slower.

Parameters Characteristic of the Biodegradation Process

For the comparison and quantification of the different biodegradation assays, a number of parameters characteristic of the biodegradation profiles were defined and evaluated.

Latency time (t L) is the time needed for the non-adapted microorganisms to acclimatize themselves to the new substrate. The latency or acclimation period prior to the biodegradation process of organic compounds in the aquatic environment can have several causes, such as a lack of nutrients, enzymatic induction, predation by protozoa, mutation of species, growth of a microbial population capable of metabolising the substrate, or simply the adaptation to the presence of toxic agents [15–17]. This time corresponds to the period during which a mild change occurs in the residual concentration. For each biodegradation assay, it was calculated by drawing two tangents to the adaptation and biodegradation stages (Fig. 2). The latency term was the cut-off point of both straight lines.

Half-life time (t 1/2) is the time for which the substrate concentration diminishes to half from the beginning of the biodegradation process. Therefore, the latency time was also counted. As with the latency time, the half-life is calculated by graphic methods on the biodegradation curve (Fig. 2).

Mean biodegradation rate (V M) has been defined as the mean velocity of biodegradation until achieving 85% biodegradation of the surfactant, and it has been calculated as the quotient between the percentage of biodegradation reached and the time needed to reach this biodegradation value. This parameter provides the speed of the biodegradation process.

Residual-surfactant concentration (S R) is the concentration which has not been degraded by the microorganisms and represents the concentration of the surfactant that is not metabolisable. It is calculated as the mean value of the surfactant concentration at the end of the assay when the surfactant remains practically constant over the biodegradation time.

Surfactant biodegradability (B) is defined as the percentage of surfactant that is biodegraded after 50 h of assay.

Table 2 shows the parameters characteristic of the biodegradation profiles for all the surfactants and all the concentrations assayed. S 0 is the initial concentration of the biodegradation assay in mg/L while tT is the total duration of the assay in hours.

Figure 3 lists the characteristic parameters (t 1/2, V M, B and S R) of the biodegradation profiles as a function of the initial assay concentration for the surfactants C12–14E4, C12–14E11, and C16–18E6.

For the parameters t 1/2 and V M, which are related to the rate of the biodegradation process, it is noteworthy firstly that t 1/2 slightly increased with the surfactant concentration to 25 mg/L, fundamentally for the surfactants with the highest number of ethylene oxide units, increasing notably for concentrations of 50 mg/L. Secondly, in a similar way, the mean biodegradation rate slowed with the initial surfactant concentration. This indicates that, as the concentration increased, biodegradation slowed down. This slowing in the mean biodegradation rate may have been due to an auto-inhibition triggered by a bacteriostatic effect of the substrate.

In the case of the parameters S R and B, as the initial surfactant concentration increased in the assay, the residual concentration rose and the surfactant biodegradability increased, as might be expected (Fig. 3).

In an effort to establish relationships between the parameters found in the biodegradation process on the one hand, and the structural characteristics of the surfactants on the other, Fig. 4 presents the mean biodegradation rate against the number of EO units of the different surfactants assayed. It was found that for high assay concentrations the biodegradation rate increased with the size of the ethoxylate chain. For 5 mg/L, the effect of the number of EO units on the mean biodegradation rate was less pronounced (Fig. 4).

Several authors [5] have demonstrated that the primary degradation step is a central fission mechanism for which the intermediates are polyethylenglycol (PEG) and fatty alcohols (Fig. 5). Steber and Wierich [18] have also studied the ultimate biodegradation of PEG.

The biodegradation rate appears to be greater the higher number of EO units of the ethoxylate chain (Fig. 4) for surfactant concentrations above 5 mg/L. Furthermore, this effect is more pronounced the higher the initial surfactant concentration. The results suggest that the longer the ethoxylate chains released in the biodegradation process, the less acute is the inhibitory effect exerted on the microorganisms responsible for the biodegradation process.

The biodegradability of surfactants is influenced simultaneously by several parameters: HLB, CMC, carbon chainlength (Fig. 6), etc., and it is difficult to find a prominent parameter. However, there seems to be a positive correlation between the biodegradation and the HLB (Table 3).

The FAE C12–14E11, the surfactant with the greatest HLB, presents the greatest biodegradability. For the set of the surfactant tested, the FAEs which show a greater HLB have a lower CMC (Table 1). For the same surfactant concentration lower CMC surfactants have less free surfactant. Thus we can relate the high biodegradability to the lower presence of free surfactant which have an inhibitory effect in the medium.

In general, for all the concentrations assayed, the results appear to confirm that the biodegradation was preferential towards the surfactant with the longest alkyl chain (Fig. 6) and the greatest degree of ethoxylation (Fig. 4), this effect may be due to the lower CMC of these FAEs. If the biodegradation rate is considered as the slope of the biodegradation curve, the rate can be seen to be greater (at the three concentrations studied) for the surfactant with the longest carbon chain, C16–18E6; that is, the surfactant with the longest carbon and ethoxylate chain degraded to a greater extent and more rapidly than did the rest of the surfactants tested. This fact was more discernible when high surfactant concentrations were assayed (Fig. 1).

The literature provides examples of increase, decrease, and random values in the biodegradation rate in relation to the longest alkyl chain lengths [19]. For biodegradation assays in river water, it was found that the biodegradation rate increased for C8–C12 chain lengths and decreased for C12–C18. In other assays, the biodegradation rate diminished on going from the C18 to C8 chain length, but with different ethoxylate chain lengths. However, when only the hydrophobic part of the surfactant was taken into account, there was evidence of higher rates of primary biodegradation for homologs with longer alkyl chains [20]. A possible explanation to this fact may be that the CMC of the surfactant depends on its hydrophilic group (type and size) and on its lipophilic group (length and branching). In an aqueous medium, the CMC decreases when the number of C atoms in the alkyl chain of the surfactant increases and the surfactant can exert a minor inhibitory effect.

Microbial Growth During Primary Biodegradation

During the biodegradation process, microorganisms consume the surfactant, which was the only carbon source present in the medium, and they transform it according to the following reaction:

That is, the microorganisms consume the surfactant molecule, break it down and transform it into biomass and into subproducts of degradation with the release of CO2. Growth curves of the microorganisms constitute an alternative method to evaluate the total or final biodegradability of the surfactants when these are the only carbon source in the culture medium.

Figure 7 presents, as an example, the growth curves together with the corresponding primary-biodegradation profiles for the surfactant C12–14E4. It can be seen that the biodegradation curves were adjusted by the growth curves of the microorganisms. During the exponential growth phase of the microorganisms, a linear decline occurred in the residual concentration of the surfactant, and, when the surfactant concentration remained constant, the microorganisms registered no growth. Finally, for substrate concentrations greater than 5 mg/L, the bimodal growth curves resulted (two peaks), suggesting the inhibition of the microorganisms existing initially in the assay and the growth of new populations due to the biodegradation of the metabolites. This may be due to the mechanism of biodegradation of FAEs with fission of the central ether bond to yield the corresponding fatty alcohol (FA) and the (poly)ethylene oxide chain (PEO) which may be better substrates for the culture as compared to the original surfactant.

Microbial growth during the primary phase of the exponential growth can be described by Monod’s equation [21] according to the expression

or in its integrated form

where k represents the specific growth rate in h−1, X the biomass concentration at each time expressed as CFU/mL, and X 0 the biomass at the beginning of the assay.

For a comparison of the different assays of microorganism growth, the parameters characteristic of these curves were determined. By non-linear regression to Eq. (2), the specific growth rate was determined for the FAEs assayed (k); X 0, is the initial value of CFU/mL found in the assay. Table 4 shows the parameters characteristic of the growth curves during the biodegradation process.

For each surfactant, k diminishes with the initial concentration of the assay, though for C12–14E4 there was no increase in growth rate when 25 was changed to 50 mg/L. These results indicate a possible inhibition of the microorganisms with concentration. Table 4 shows that at the two concentrations studied, the surfactant C16–18E6 (with lower CMC) had the lower growth rate. Also, the parameter Y ap has been calculated, this representing the yield of the biomass production—that is, the proportion of the original substrate converted into biomass, which is assumed to be constant over the biodegradation process. Y ap was calculated as ΔX/ΔS quotient, where ΔX is the quantity of microorganisms formed during the exponential growth phase and ΔS the substrate consumed during the same time period.

When the test concentration is higher than the CMC, (for the surfactant C12–14E4) a decrease in the yield (Y ap) can be seen, possibly due to the formation of micelles and to the lower presence of free surfactant in the medium.

For the same concentration of surfactant (5 mg/L), the yield of the biomass production is lower for the surfactant with lower CMC (C16–18E6) because of the formation of micelles, hence to the lower presence of free surfactant in the test medium.

The results of this study demonstrate that the biodegradation process is strongly related to the concentration of the initial surfactant and to the CMC of the surfactant. The concentration of the surfactant can exert an inhibitory effect whereas the quantity of the free surfactant present in the medium (C source for the microorganisms responsible for the process) depends on the CMC.

References

OECD (1993b) Guideline for testing of chemicals, “Ready Biodegradability”. OECD, Paris, France

Di Corcia A (1998) Characterisation of surfactants and their biointermediates by liquid chromatography-mass spectrometry. J Chromatogr A 794:165–185

Szymanski A, Wyras B, Zbigniew S, Jaroszynski T, Lukaszeqski Z (2000) Biodegradation of fatty alcohol ethoxylates in the continuous flow activated sludge test. Water Res 34:4101–4109

Karsa DR, Porter MR (1995) Biodegradability of surfactants. Blackie Academic & Professional, Glasgow

Marcomini A, Zanette M, Pojana G, Suter MJ (2000) Behavior of aliphatic alcohol polyethoxylates and their metabolites under standardized aerobic biodegradation conditions. Environ Toxicol Chem 19:549–554

Salanitro JP, Díaz LA, Kravetz L (1995) Aerobic biodegradability of surfactants at low concentrations using an automated pressure transducer system. Chemosphere 31:2827–2837

Reznickova I, Hoffmann J, Komarek K (2002) Biodegradation of technical mixtures of oxyethylenated aliphatic alcohols in aqueous environment. Chemosphere 48:83–87

Griffin WC (1949) Classification of surface active agents by HLB. J Soc Cosmet Chem 1:311–326

Bravo V, Jurado-Alameda E, Reyes A, García-López A, Bailón R, Cuevas M (2005) Determination of average molecular weight of commercial surfactants: Alkylpolyglucosides and Fatty-Alcohol Ethoxylates. J Surfact Deterg 8:341–346

Van Os NM, Haak JR, Rupert LAM (1993) Physico-chemical properties of selected anionic, cationic and nonionic surfactants. Elsevier, Amsterdam

Jurado E, Fernández-Serrano M, Núñez-Olea J, Luzón G, Lechuga M (2002) Comparison and use of methods for the determination of non-ionic surfactants in biodegradation processes. Tenside Surfact Det 39:154–159

Belanger SE, Dorn PB, Toy R, Boeije G, Marshall SJ, Wind T, Van Compernolle R, Zeller D (2006) Aquatic risk assessment of alcohol ethoxylates in North America and Europe. Ecotox Environ Safe 64:85–99

Van Compernolle R, McAvoy DC, Sherren A, Wind T, Cano ML, Belanger SE, Dorn PB, Kerr KM (2006) Predicting the sorption of fatty alcohols and alcohol ethoxylates to effluent and receiving water solids. Ecotox Environ Safe 64:61–74

APHA, AWWA, WPCF (1992) Standard methods for the examination of water and wastewater, American Public Health Association

Wiggins B, Jones S, Alexander M (1987) Explanations for the acclimation period preceding the mineralization of organic chemicals in aquatic environments. Appl Environ Microbiol 53:791–796

Wiggins B, Alexander M (1988a) Role of chemical concentration and second carbon sources in acclimation of microbial communities for biodegradation. Appl Environ Microbiol 54:2803–2807

Wiggins B, Alexander M (1988b) Role of protozoa in microbial acclimation for mineralization of organic chemicals in sewage. Appl Environ Microbiol 34:661–666

Steber J, Wierich P (1985) Metabolites and biodegradation pathways of fatty alcohol ethoxylates in microbial biocenoses of sewage treatment plants. Appl Environ Microbiol 49:530–537

Patterson SJ, Scott CC, Tucker BE (1970) Nonionic detergent degradation: III initial mechanism of the degradation. J Am Oil Chem Soc 47:37–41

Swisher RD (1987) Surfactant biodegradation Marcel-Dekker, New York

Monod J (1949) The growth of bacterial cultures. Annu Rev Microbiol 3:371–394

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Jurado, E., Fernández-Serrano, M., Núñez-Olea, J. et al. Primary Biodegradation of Commercial Fatty-Alcohol Ethoxylate Surfactants: Characteristic Parameters. J Surfact Deterg 10, 145–153 (2007). https://doi.org/10.1007/s11743-007-1027-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11743-007-1027-5