Abstract

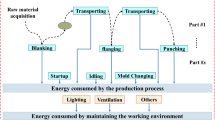

Whereas in the past the sustainable use of resources and the reduction of waste have mainly been looked at from an ecological point of view, resource efficiency recently becomes more and more an issue of cost saving as well. In manufacturing engineering especially the reduction of power consumption of machine tools and production facilities is in the focus of industry, politics and research. Before power consumption in machining processes can be reduced it is necessary to quantify the amount of energy needed, to identify energy consumers and to determine the available degrees of freedom for an optimization. Simulation can be an adequate alternative to the measurement of power consumption during machining operation. However, many of the available simulation methods are not suitable for this task. This paper describes an approach based on the discrete-event simulation, which is known mainly from the simulation of logistical systems. It has been adapted to model machining operations and to generate workpiece-specific power consumption profiles and energy footprints. Two-axis turning in a CNC machining centre is shown exemplary. The aim is to provide a basis for further applications such as the simulation, comparison and optimization of power consumption in process chains and production systems in combination with logistical models.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

It is substantial to know and to understand the power consumption of a manufacturing system before efforts aimed on reduction can be successful. Measurement of the power input of a machine tool during machining operation is easy to realize, but in terms of the evaluation of a large set of machining parameters and even different machine tool configurations this is not very efficient. Therefore, several authors propose the development of predictive methods, based on simulation [1–3]. The available mainly continuous modeling techniques used for the simulation of machining operations, such as FEM or multi body simulation, focus on mechanical behavior, e.g. oscillations, loads and forces [4–6]. They are of limited use for the calculation of the power consumption in an overall machining process. Another disadvantage is their missing compatibility to logistics simulation. This is of interest for a number of reasons:

-

A long term goal is the minimization of power consumption in manufacturing process chains and overall production systems during the manufacturing of a product. Therefore it is essential to consider the performance and consumption of previous and subsequent manufacturing steps in optimization efforts.

-

The energy efficiency of a machine tool is strongly depending on the individual usage. Use case scenarios must be incorporated in the evaluation of the efficiency of machine tools and production systems [7]. They are strongly linked to the product portfolio, the order situation and the utilization of all facilities.

-

The power consumption of machine tools caused during idle times is substantial; therefore it is necessary to include the capacity utilization as well as the production program in investigations for the optimization of power consumption in machining operations. Scheduled automatic machine shut-down and power-up procedures could be introduced on the basis of the actual order situation.

2 Model design

The modeling approach described in this paper is based on the assumption that each relevant component of the machine tool at a certain time has either the status ‘off’ or ‘on’, the latter with a given level of power consumption. This is equivalent to the status ‘available’ or ‘blocked’ of a server, as facilities are called in discrete-event systems. In opposition to continuous modeling, the status of each subsystem is determined only when major changes occur. The status can change multiple times during the simulation but consequently oscillations and other continuous behavior within one status are ignored.

The model includes representations of all relevant machine tool components and subsystems which are contributing to the overall power consumption. During the simulation they are simultaneously set in their respective statuses with the corresponding level of power consumption and for the respective time by a discrete-event system. Loads on spindle and axes are calculated depending on the actual operation.

In the example described in this article the simulation system reads and evaluates NC-program files to generate this information. Machine tool, workpiece as well as the cutting tool specific data is incorporated. A data model of the actual work piece geometry is used to calculate the relevant engagement parameters. The collected data is used to visualize power consumption profiles and calculate the energy balance of the simulated machining process.

In the following exemplary the implementation of two-axis turning in a CNC machining centre with a Siemens Sinumerik 840D control will be described. The Matlab SimEvents toolbox for discrete-event simulation has been used; the Matlab environment acts as an experimental frame for the model parameterization, simulation execution and data collection. This allows running extensive simulation experiments and multi-parameter studies automatically.

2.1 Machine tool model

The top-level structure of the discrete-event machine tool model is shown in Fig. 1. It consists of the following subsystems:

-

Machine tool component representations for X- and Z-axis, spindle drive, coolant system and base load

-

Load calculation subsystem

-

Event management subsystem

-

Signal analysis subsystem

In this example the base load is merging the power consumption of several consumers, such as the control unit, fans, axes closed loop control etc. As the model is meant to prove the concept, an adequate level of abstraction was chosen.

All of the component representation subsystems are identical regarding their principle function. They feature three input ports “_d”, “_p” and “_Call” as well as one output port “_P” and are designed to generate a signal on the output port of the height “_p” and the duration “_d” after being called by the trigger signal on port “_Call” in a discrete-event manner. If the signal on port “_d” equals zero the duration of the output signal is assumed as infinite. The signals “_d”, “_p” and “_Call” are generated by the load calculation subsystem. It reads and interprets the NC-code line by line. If the actual line includes commands that lead to a change in the status of one or more components, typically G or M-codes, the new level of power consumption and its duration are calculated and the related trigger signals are set to activate the relevant component representations. With this design it is possible to generate a load signal (representing power consumption in Watt) of a given height and length, as it would be typical for axes and spindle operations performing a single cut with given dimensions and feed rate v f . It is further possible to keep the load signal on a certain level until the next relevant change occurs based on a command line in the NC-code. The latter is used to generate the load signal for components that feature statuses which are not directly linked to a machining operation, for example the cutting fluid supply system. It is being switched ‘on’ in the early phase of the NC-program by a M8 code and switched ‘off’ later on after all machining has been finished by a M9 code. The duration of the status “cutting fluid supply on” cannot be calculated directly when the first M8 command is read in the NC-program. Possible statuses for the components, considered in this example, are shown in Table 1.

Loads on spindle and axes are calculated using the formula for linear motion and rotation. For statuses including tool engagement in addition cutting force and feed force are calculated using the Kienzle equations [8]. Consequently, a calculated mean height is assumed during the actual status. The engagement parameters are considered constant during one cut but not necessarily during one working feed travel. In case the tool plunges into the workpiece during one working feed travel, two different statuses of spindle drive and axes are considered; either calculated with and without tool engagement. Load peaks, as they typically occur for example during the change of spindle speed, are not considered in the simulation.

Machine tool-, tool- and workpiece-specific values, such as efficiency factors and correction values, are treated as constants for one simulation experiment but can be altered automatically by the experimental framework for each new experiment. This is used to perform automatic parameter studies.

The role of the event management subsystem is to initiate every simulation step at the correct point in time. In opposition to continuous modeling, where changes in the status of the system are being calculated in small increments and often with a fixed step size, in discrete-event modeling only those points in time are of interest, where major changes in the status of the system occur. Those events are comparable to an entity (representing the workpiece) entering or leaving a server (representing a machine tool or facility) or a queue (representing a material buffer) in a logistical model. In case of the discussed machine tool model every change in the status of one of the components as described in Table 1 represents such an event. The event management subsystem initiates the evaluation of the next line in the actual NC-program based on the calculated duration of the actual operations. This is a legitimate approach, since the machine control reads and executes the NC-code line by line as well.

The signal analysis subsystem collects the data for further analysis. For all consumers, power consumption profiles are generated as well as the cumulated power consumption of the overall process.

2.2 Workpiece model

To calculate the process forces during each cut it is necessary to determine the actual engagement parameters of the tool. In case of two axes-turning especially the depth of cut a p , which is calculated from the perpendicular distance of the tool tip to the actual outer shape of the workpiece, is used to calculate the load on spindle and axes. Furthermore, if the load on spindle and axes changes during feed travel due to the tool plunging into the workpiece, it is necessary to calculate the duration of the two different statuses of spindle and axes. Therefore a model of the actual workpiece shape is needed as well.

The workpiece model for 2-axis turning can be limited to a vector of the coordinates of the vertices representing the outer workpiece shape. The workpiece itself is considered as a two-dimensional polygon. Its contour is updated after each cut. Whenever a feed travel is being carried out, it must be checked first, whether the tool path leads into the workpiece. If so, the coordinate of the point where the tool plunges into the workpiece is being calculated. The tool path is then divided into two parts, leading to two different component statuses; with and without tool engagement. For both cases the duration and the respective load on axes and spindle drive is being calculated.

In the next step the workpiece model must be updated. The coordinate where the tool plunges into the workpiece as well as the coordinate where the tool leaves the material and any vertices of movements inside the ‘old’ contour are being added to the vector describing the workpiece outer shape. Remaining vertices outside of the new polygon contour are skipped.

3 Model validation

As described above, the simulation model calculates cutting forces and then generates power consumption profiles of machining operations over time. To validate this model a number of experiments with different cutting parameters and workpiece materials have been performed. During all machining experiments the power consumption of axes and spindle has been logged using the inherent trace function of the machine control unit. The overall load on the machine main input has been measured using an external AV Power PA4400A Power Analyzer.

Figure 2 shows an overview of the total power consumption of all consumers in a typical machining task, calculated with the simulation model. It becomes obvious that in this case the base load and the main spindle are the major energy consumers. The contribution of the axes is comparably small due to the small and simple design of the test workpiece.

The load profile over time caused by the overall machining process is of interest as well. It can be used for example to balance the consumption of different machine tools to avoid load peaks. Figure 3 shows the simulated versus the measured power consumption profile for the reference machining experiment. The machining process consists of one leveling cut, four roughing cycles and one finishing cut.

The comparison of the simulated load signals with the measured data shows a good accordance of both, length and height of the load signals. Only minor deviations occur in the height of the signal, compared to the mean height of the measured load. They are caused by the calculation of cutting forces using the typical correction values within the Kienzle equation. As it is common understanding they represent a generalization of experimental data and are therefore connected with a small error.

The oscillations that are visible in the measured load signals are caused by a number of dynamic effects within the tool/workpiece interaction, the machine tool and even the measuring equipment. For the calculation of power consumption in machining processes they are of minor importance and are therefore ignored in this modeling approach.

4 Conclusions and outlook

The simulation model described in this paper is intended to be used for the estimation of the power consumption in machining operations and to study the influence of machine tool components and process parameters as well as to generate the energy footprint of a given workpiece.

Depending on the aim of a simulation, it is certainly possible to extend the model with any other relevant components. To simulate more sophisticated machine tools it could be useful to incorporate representations of spindle cooling, closed loop control of axes and subcomponents of the coolant supply system separately. Further detailing will therefore be done in the future to examine more sophisticated machine tools and especially more complex procedures, such as scheduled shut-down and warm-up procedures of machine tools, which will become of more importance in production scheduling.

The introduced discrete-event modeling approach is straightforward to implement, but a number of effects are not taken into account, especially dynamic mechanical behavior of tool and machine tool or the influence of varying engagement parameters during one cut. The engagement parameters are considered constant during one cut and minor changes in the height of power consumption during one operation are ignored. This is relevant for example if the depth of cut a p in a turning operation changes continuously because of a tilted tool path and a cylindrical workpiece or in case of a conical workpiece. However, corresponding machining experiments have shown that the resulting inaccuracy is only of a minor influence on the simulation results because the influence of such effects is much smaller than the investigated level of power consumption of major consumers. The achieved accuracy of power consumption profiles is adequate to be used to optimize cost and environmental impact.

Due to the general flexibility of the modeling approach it can be easily transferred to other manufacturing processes as well, such as grinding, grind-hardening or heat treatment. This enables the simulation of the power consumption of process chains in the future. The aim is to determine the most cost- and energy-efficient way for production, taking into account alternative process chains as well as batch sizes and other parameters. Since the Matlab environment allows the automatic execution of simulation models, the evaluation of alternative process chains and large sets of process parameters can be done automatically. All model parameters and model structures of interest can be varied automatically, enabling the deployment of numerical optimization as well (Fig. 4).

The efficiency of new manufacturing processes that incorporate surface hardening within the machining process and therefore avoid heat treatment can be determined for example in relation to the actual batch size. Whole process chains for the production of surface hardened components such as grind hardening [9, 10] and cold surface hardening [11–13], both avoiding an energy consuming heat treatment step, could be assessed regarding their overall power consumption.

References

Müller E, Engelmann J, Strauch J (2008) Energieeffizienz als Zielgröße in der Fabrikplanung. wt Werkstattstechnik online 7/8

Neugebauer R (2008) Energieeffizienz in der Produktion, Untersuchung zum Handlungs- und Forschungsbedarf

Dietmair A, Verl A, Wosnik M (2008) Zustandsbasierte Energieverbrauchsprofile. wt Werkstattstechnik online 7/8

Zäh MF, Schwarz F (2009) Implementation of a process and structure model for turning operations. Prod Eng Res Dev 3:197–205

Aurich JC, Biermann D, Blum H, Brecher C, Carstensen C, Denkena B, Klocke F, Kröger M, Steinmann P, Weinert K (2009) Modelling and simulation of process: machine interaction in grinding. Prod Eng Res Dev 3:111–120

Fleischer J, Munziger M, Tröndle M (2008) Simulation and optimization of complete mechanical behavior of machine tools. Prod Eng Res Dev 2:85–90

Kuhrke B (2009) Ansätze zur Optimierung und Bewertung des Energieverbrauchs von Werkzeugmaschinen. Proc. of „Die energieeffiziente Werkzeugmaschine“ Düsseldorf

Kienzle O (1952) Die Bestimmung von Kräften und Leistungen an spanenden Werkzeugen und Werkzeugmaschinen. Z.VDI 94:299–305

Brockhoff T, Brinksmeier E (1999) Grind-hardening: A comprehensive view. Ann CIRP 48(1):255–260

Zäh MF, Brinksmeier E, Heinzel C, Huntemann J-W, Föckerer T (2009) Experimental and numerical identification of process parameters of grind-hardening and resulting part distortions. Prod Eng Res Dev 3:271–279

Brinksmeier E, Garbrecht M, Meyer D (2008) Cold surface hardening. Ann CIRP 57(1):541–544

Brinksmeier E, Garbrecht M, Meyer D, Dong J (2008) Surface hardening by strain induced martensitic transformation. Prod Eng Res Dev 2:109–116

Meyer D, Dong J, Garbrecht M, Hoffmann F, Brinksmeier E, Zoch H-W (2010) Mechanisch induziertes Härten. J Heat Treat Mater 65(1):37–45

Acknowledgments

The authors gratefully acknowledge the support of the German Research Foundation (DFG) for this ongoing research project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Larek, R., Brinksmeier, E., Meyer, D. et al. A discrete-event simulation approach to predict power consumption in machining processes. Prod. Eng. Res. Devel. 5, 575–579 (2011). https://doi.org/10.1007/s11740-011-0333-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-011-0333-y