Abstract

Carbon nanotube is one of the important topics of interest in the nanotechnology science. Many scientists have been interested in surface-modified nanotubes for decades. In this study, multi-walled carbon nanotubes (MWCNTs) were functionalized with polyethylene glycol and dithiols in esterification reactions. The MWNTs were first carboxylate-functionalized. The carboxylated MWCNTs were acyl chlorite substituted. The functionalized MWNTs were used as the precursor to esterification of polyethylene glycols and thiols. The reactions were performed catalysts or non-catalysts, solvent-free and solvent media, using microwave-assisted and classical methods. The synthesized compounds were characterized by FTIR, TGA, TEM and NMR techniques. We investigate the advantage of microwave synthesis method in terms of time and solvent in Green Chemistry. The obtained compounds exhibit very interesting results in their complexes with metals due to containing free hydroxyl and thiol groups.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Carbon nanotubes have been the subject of considerable interest in the discovery of the fullerene. Carbon nanotubes (CNTs) find use in many areas, such as hydrogen storage, molecular electronics, biological sensors, high-resistant cables, metal sensors, gas sensors, and nanosensitive hand tools as quantum cables, emission imaging techniques, catalyst, information storage, intelligent sensors, protein-drug storage (Avilés-Barreto and Suleiman 2015; Lim et al. 2003; Jiang et al. 2005; Afrin et al. 2013; Hong et al. 2005; Dai et al. 2012; Hadavifar et al. 2014; Zang et al. 2009; Pandurangappa and Raghu 2008). With the modifications on CNTs with the functional groups, many features have changed with the interest on covalent modification of CNTs (Avilés-Barreto and Suleiman 2015; Jiang et al. 2005; Hong et al. 2005; Lin et al. 2003; Chen et al. 1998; Hamon et al. 1999). Chemically modified CNTs provide specificity and selectivity (Pandurangappa and Raghu 2008). These chemical modifications are carried out by oxidations from the side surfaces of the carbon nanotubes, from the deformed portions on the surfaces, and generally from the more reactive end portions. These modifications are performed in colloidal forms due to their low solubility (Lim et al. 2003). Oxidants such as nitric acid, sulfuric acid/potassium dichromate, nitric acid/sulfuric acid, sulfuric acid/potassium permanganate, per chloric acid, hydrogen peroxide, and osmium tetroxide are used to form functional groups on CNTs such as –COOH, OH, etc. (Dillon et al. 1999; Dujardin et al. 1998; Nagasawa et al. 2000; Ng et al. 2002; Pan et al. 2006). Through these groups, CNTs are provided with functional groups via various reactions such as acylation, amidization, esterification, thioesterification, etherification (Zang et al. 2009; Li et al. 2011; Kim et al. 2012). Amidization derivatives synthesized by different groups are functionalized with amino, thiol groups (Te et al. 2010; Banerjee et al. 2005; Gabriel et al. 2006). Some of the synthesized amide derivatives have been used in the synthesis of compounds containing noble metals (Xing and Imae 2007). Santhosh et al. used long diamines such as 1,7-diaminoheptane, 1, 10-diaminodecane, and 1,2-diaminododecane to explain that one side of the diamine was covalently attached to the glassy carbon surface and the other amine side not to bond with surface They synthesized amines having free ends by binding to many polymers to obtain modified materials and identified that they interact with and adsorb the simple anions, metal ions and small organic compounds (Santhosh et al. 2007). Some functionalized MWCNTs have been used in metal enrichment of ions such as vanadium, copper, arsenic, gold, and lead due to complexes between MWCNTs containing free amine, thiol, and hydroxide groups and metal ions (Dai et al. 2012; Mormann et al. 2008; Xu et al. 2008; Wang et al. 2005; Tsai et al. 2005; Profumo et al. 2006; Xiao et al. 2008). With these modifications, Smally et al. were synthesized MWCNTs containing SH groups in tip dots and long-alkyl chains and tried to bind to metal surfaces. For this purpose, MWCNTs compounds containing 2-mercaptoethyl amine have been synthesized by amidation because of their large surface-to-surface distance between MWCNTs (Lim et al. 2003). Synthesis of dentric structures with chitosan-containing Schiff bases was carried out with esterification (Jiang et al. 2005; Dai et al. 2012). Application of microwave technology in chemical syntheses has been popular in recent years. This is because microwave reactions are faster and more efficient than conventional reactions. In addition, microwave synthesis is quite advantageous with the instant adjustment function of pressure and temperature. Such reactions have become important in recent years due to the decrease in the volume of the solvent, the completeness of the reaction, high and well-increasing selectivity, reduced amount of reagent use, and increase the yield (Calisir and Çiçek 2017; Caddick and Fitzmaurice 2009; Cutress et al. 2009).

In this study, modified MWCNT derivatives containing free hydroxyl (–OH) and thiol (–SH) groups were synthesized under both classical and microwave-assisted reaction conditions using MWCNTs (D1–D7). The MWCNTs, which were purified from metal impurities, were subjected to oxidation and acylation, respectively. The targeted compounds were also reached by esterification and thioesterification reactions. Microwave-assisted reactions with classical methods have been compared in many respects. The products were characterized by FTIR, NMR techniques, TGA, and TEM.

Experimental

The MWCNTs used in this study were purchased commercially from Nanografi and Sigma Aldrich Company (product specifications, purity: 92%, outside diameter: 8–10 nm, average length: 1–3 µm). All other chemicals including HPLC grade solvents and reagents, were purchased from Merck and Sigma-Aldrich. Milestone StartSYNTH-Microwave Synthesis Labstation system was used to perform some reactions. All reactions were sonicated with Bandelin Sonorex ultrasonic bath and were mixed and heated with IKA C-MAG HS 7 and Heidolph MR Hei-Standard FTIR magnetic stirrers. All reactions were performed in a fume hood. Vacuum-filter system was used to filtrate some products with 0.45-µm nylons net filter (HNWP). In some of the experiments, Thermo Scientific Heraeus Megafuge 16R centrifuge system was used to separate solid product (15 °C, 5500 rpm and 15 min). While in workup studies, Stuart Vorteks Mixer SA8 was used to mix vigorously. To wash some products, ultrapure water (conductivity: < 0.2 µS/cm) was used produced from Thermo Scientific Smartpure2 pure water system. FTIR spectra were recorded on a Perkin Elmer BX 2 FTIR. 1H-NMR (400 MHz) and 13C-NMR (100 MHz) spectra were obtained in CDCl3 or DMSO-d6 solvents using NMR spectrometer. TGA spectra were recorded on EXSTAR 6000 TG/DTA 6300 thermogravimetry/differential thermal analyzer. TEM images were recorded with Hitachi HT7700. The images were taken at 120 kV and in high-resolution mode.

Synthesis of MWCNTs–COOH

MWCNT were purified with 10% HCl for 20 h to remove the metal and other impurities such as amorphous carbon in an ultrasonic bath. MWCNTs were washed with ultrapure water and dried in the oven at 60 °C for 48 h. Then 1.00 g MWCNTs were added to a 100 mL round bottom flask containing 20 mL mixture of concentrated H2SO4:HNO3 (3:1, v/v). The mixture was sonicated in an ultrasonic bath 30 min and then refluxed 24 h in an oil bath with stirrer, then cooled to room temperature. After that ultrapure water was added, mixed with vortex mixer and centrifuged until pH of solution was neutral value (7.0). The product was dried in the oven 65 °C for 48 h (Lim et al. 2003; Jiang et al. 2005; Li et al. 2011; Xu et al. 2008; Jeong et al. 2006; Qiu et al. 2013).

Synthesis of MWCNTs–COCl

MWCNTs–COOH (0.60 g) was added in a 50-ml flask containing 20.0 mL thionyl chloride. The reaction mixture was stirred and refluxed 24 h at 65 °C. Excess thionyl chloride was removed by evaporation under vacuum in an ice-water trapped system at low temperature. And washed three times with anhydrous THF to remove impurities. Dried in the oven 12 h at 60 °C. Synthesized acyl-modified MWCNTs were used directly in the next reaction without waiting (Avilés-Barreto and Suleiman 2015; Dai et al. 2012; Jeong et al. 2006; Qiu et al. 2013).

Synthesis of thiol-functionalized MWCNTs, D1–D3

General procedure-1 (classic)

MWCNTs–COCl (0.10 g) was added in a reaction bottle with cap (100 mL) containing 50.0 mL ethanol absolute and dispersed 30 min in an ultrasonic bath. Pyridine (5.0 mL) and a dithiol (10.0 mL) were added into the reaction bottle. The reaction mixture was sonicated 20 h in an ultrasonic bath at 55 °C. Then left to cool to room temperature.

General procedure-2 (microwave-assisted)

MWCNTs–COCl (0.10 g), pyridine (5.0 mL), and a dithiol (5.0 mL) were added in a microwave glass reactor (30 mL) and closed with reactors cap. The reaction mixture was refluxed in microwave synthesis system (E = 1000 W) for 2 h at 150 °C and 1 h at 120 °C. Then left to cool to room temperature.

General workup procedure

The resultant mixture was suspended with ethanol, mixed with vortex, and filtered by 0.45-µm HNWP filter under vacuum. Washed three times ethanol and diethyl ether. Dried in an oven at 65 °C.

Synthesis of MWCNT–CO–S–CH2CH2SH (D1)

Synthesized from 1,2-ethanedithiol to the general procedure-1 and general procedure-2. Purified by general workup procedure. FTIR (γ cm−1) 1721 (O=C–S stretch), 2920–2850 (asymmetric and symmetric stretch of CH2 groups), 2614 (–SH stretch), 1534–1243 (S–C(O)–C stretching), 1058 (CH2–CH2–O– bending); 1H NMR (DMSO-d6, 400 MHz) δ 1.53 (H), 3.35 (2H), 4.64 (2H); 13C{1H} NMR (DMSO-d6, 100 MHz) δ 36.00, 44.00, 170.88; TGA (TG %) MWCNT–COCl: 70.64 (595 °C) and D1: 85.20 (575 °C).

Synthesis of MWCNT–CO–S–CH2CH2–O–CH2CH2SH (D2)

Synthesized from diethylene glycol dithiol to the general procedure-1 and general procedure-2. Purified by general workup procedure. FTIR (γ cm−1) 1716 (O=C–S stretch), 2915–2848 (asymmetric and symmetric stretch of CH2 groups), 2616 (–SH stretch), 1535–1241 (S–C(O)–C stretching), 1052 (C–O–C bending); 1H NMR (DMSO-d6, 400 MHz) δ 1.51 (H), 3.36 (2H), 3.66 (2H), 4.00 (2H), 4.67 (2H); 13C{1H} NMR (DMSO-d6, 100 MHz) δ 30.61, 36.14, 69.99, 74.55, 168.8; TGA (TG %) MWCNT–COCl: 70.64 (595 °C) and D2: 83.90 (577 °C).

Synthesis of MWCNT–CO–S–CH2CH2–O–CH2CH2–O–CH2CH2SH (D3)

Synthesized from triethylene glycol dithiol to the general procedure and general procedure-2. Purified by general workup procedure. FTIR (γ cm−1) 1719 (O=C–S stretch), 2920–2845 (asymmetric and symmetric stretch of CH2 groups), 2616 (–SH stretch), 1535–1263 (S–C(O)–C stretching), 1070 (C–O–C bending), 1052 (S–C(O)–C bending); 1H NMR (CDCl3, 400 MHz) δ 1.27 (H), 1.58(2H), 2.65 (2H), 3.64 (2H); 13C{1H} NMR (CDCl3, 100 MHz) δ 22.00, 27.14, 29.99, 31.25, 69.25 168.75; TGA (TG %) MWCNT–COCl: 70.64 (595 °C) and D3: 82.61 (595 °C).

Synthesis of glycol-functionalized MWCNTs, D4–D7

General procedure-A (classic)

MWCNTs–COCl (0.10 g) and glycol (5–10 mL) were added in a reaction flask (100 mL) containing 30.0 mL toluene and dispersed 15 min in an ultrasonic bath. The black suspension was refluxed 42 h at 110 °C. Then left to cool to room temperature.

General procedure-B (microwave-assisted)

MWCNTs–COCl (0.10 g), and a glycol (5.0 mL) were added in a flask (100 mL) containing 30.0 mL toluene and linked a condenser. The reaction mixture was refluxed in microwave synthesis system (E = 1000 W) for 2 h at 120 °C. Then left to cool to room temperature.

Synthesis of MWCNT–CO–O–CH2CH2OH (D4)

Synthesized from ethylene glycol to the general procedure-A and general procedure-B. Purified by general workup procedure. FTIR (γ cm−1) 3200 (–OH stretch), 1704 (O=C–O stretch), 2918–2845 (asymmetric and symmetric stretch of CH2 groups), 1536–1242 (O–C(O)–C stretching), 1142 (O–C(O)–C bending); 1H NMR (DMSO-d6, 400 MHz) δ 2.56 (2H), 3.44 (2H); 13C{1H} NMR (DMSO-d6, 100 MHz) δ 61.72, 65.23, 167.17; TGA (TG %) MWCNT–COCl: 70.64 (595 °C) and D4: 81.73 (574 °C).

Synthesis of MWCNT–CO–O–CH2CH2–O–CH2CH2OH (D5)

Synthesized from diethylene glycol to the general procedure-A and general procedure-B. Purified by general workup procedure. FTIR (γ cm−1) 3200 (–OH stretch), 1704 (O=C–O stretch), 2915–2847 (asymmetric and symmetric stretch of CH2 groups), 1536–1242 (O–C(O)–C stretching), 1148 (O–C(O)–C bending), 1096 (C–O–C bending); 1H NMR (DMSO-d6, 400 MHz) δ 3.39 (2H), 3.48 (2H), 3.54 (2H), 4.62 (2H); 13C{1H} NMR (DMSO-d6, 100 MHz) δ 56.40, 57.25, 72.94, 72.94, 167.06; TGA (TG %) MWCNT–COCl: 70.64 (595 °C) and D5: 73.90 (577 °C).

Synthesis of MWCNT–CO–O–CH2CH2–O–CH2CH2–O–CH2CH2–OH (D6)

Synthesized from triethylene glycol to the general procedure-A and general procedure-B. Purified by general workup procedure. FTIR (γ cm−1) 3200 (–OH stretch), 1702 (O=C–O stretch), 2916–2844 (asymmetric and symmetric stretch of CH2 groups), 1535–1243 (O–C(O)–C stretching), 1147 (O–C(O)–C bending), 1025 (C–O–C bending); 1H NMR (CDCl3, 400 MHz) δ 1.47 (1), 1.73 (2H), 1.87 (2H), 2.10 (2H), 2.58 (2H) 3.44 (2H), 3.57 (2H); 13C{1H} NMR (CDCl3, 100 MHz) δ 45.42, 55.22, 60.84, 72.54, 165.15; TGA (TG %) MWCNT–COCl: 70.64 (595 °C) and D6: 81.33 (595 °C).

Synthesis of MWCNT–CO–O–CH2CH2–O–CH2CH2–O–CH2CH2–O–CH2CH2OH (D7)

Synthesized from tetraethylene glycol to the general procedure-A and general procedure-B. Purified by general workup procedure. FTIR (γ cm−1) 3200 (–OH stretch), 1702 (O=C–O stretch), 2918–2847 (asymmetric and symmetric stretch of CH2 groups), 1539–1243 (O–C(O)–C stretching), 1162 (O–C(O)–C bending), 1083 (C–O–C bending); 1H NMR (DMSO-d6, 400 MHz) δ 3.40 (2H), 3.50 (8H), 3.89 (2H), 4.56 (2H), 4.00 (H); 13C{1H} NMR (DMSO-d6, 100 MHz) δ 60.66, 63.25, 67.19, 70.23, 70.28, 72.79, 165.00; TGA (TG %) MWCNT–COCl: 70.64 (595 °C) and D7: 67.90 (576 °C).

Results and discussion

MWCNTs were reacted with acid mixture for synthesis of the precursor compound carboxylated MWCNTs. The compound MWCNTs–COOH was checked with FTIR; 3297 cm−1, and carboxylic acid stretch was observed. Carboxylated MWCNTs were treated with thionyl chloride to handle acyl-substituted MWCNTs. After disposing the excess of thionyl chloride, in order to verify the product, a few pieces of silver nitrate were added into some MWCNTs–COCl. At the end of the experiment, white cloudiness in acyl chloride was observed while no turbidity was observed in the carboxylic acid. And also the precursor compound was evaluated with FTIR spectra; 3297 cm−1 carboxylic acid stretch was disappeared.

Mono/di/triethylene glycol dithiol- and mono/di/tri/tetraethylene glycol-substituted MWCNTs were synthesized with esterification reaction. The reaction scheme is given in Scheme 1 and the best reaction conditions are given in Table 1. MWCNTs–COCl reacted with excess of dithiol and glycol derivatives in an esterification reaction. Classic method and microwave-assisted synthesis method were compared for reaction conditions (reaction times, solvents, heating system) between methods. In the classic method, the reaction performed in an oil bath to reflux reaction system (conventional heating). Microwave-assisted method needs shorter time, less solvent usage, etc. In spite of the fact that pyridine was used as a catalysis to synthesis of dithiol-functionalized MWCNTs, no catalyst was used to synthesize glycol-substituted MWCNTs. While absolute ethanol was used as a solvent in classical method, there was no solvent used in microwave-assisted synthesis method to synthesize dithiol derivatives.

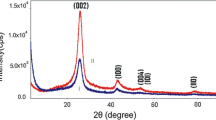

FTIR, 1H-NMR, 13C-NMR, TGA spectra and TEM images were collected for the target compounds. Figure 1 shows FTIR spectra for the mono/di/tri-ethylene glycol dithiol-substituted MWCNTs and MWCNT–COCl. In the FTIR spectra of MWCNT–COCl, carbonyl stretch at 1683 cm−1, Cl–C(O)–C stretch at 1241 cm−1 were observed. In the FTIR spectra of the D1 compound is examined, while carbonyl (C=O) stretch observed at 1683 cm−1 in the MWCNT–COCl compound; the carbonyl (C=O) stretch shifted to 1721 cm−1 after the thio-esterification reaction. In addition, asymmetric and symmetrical CH2 stretching at 2920–2850 cm−1, –SH stretching at 2614 cm−1, S–C(O)–C stretching at 1534–1243 cm−1, CH2CH2–O bending was observed at 1058 cm−1. A similar situation exists for the compound D2; the carbonyl (C=O) stretch shifted to 1716 cm−1 after the thio-esterification reaction. Also asymmetric and symmetrical stretches of CH2 groups at 2915–2848 cm−1, –SH stretching at 2616 cm−1, S–C(O)–C stretching at 1535–1241 cm−1, CH2CH2–O bending at 1052 cm−1 were observed in the FTIR spectra. The FTIR spectra of the D3 compound is examined, the carbonyl (C=O) stretch shifted to 1719 cm−1 after the thio-esterification reaction. The asymmetric and symmetrical CH2 stretching at 2920–2845 cm−1, –SH stretching at 2616 cm−1, S–C(O)–C stretching at 1535–1263 cm−1, C–O–C bending at 1070–1052 cm−1 were observed.

Figure 2 shows FTIR spectra for the mono/di/tri/tetraethylene glycol-substituted MWCNTs. In the FTIR spectra of the D4 compound is examined, while carbonyl (C=O) stretch observed at 1683 cm−1 in the MWCNT–COCl compound; the shift of carbonyl (Cl–C=O) stretch at 1683 cm−1 to carbonyl (O=C–O) stretch at 1705 cm−1 after the esterification reaction. Also –OH stretch at 3200 cm−1, asymmetric and symmetrical stretch of CH2 group at 2918–2845 cm−1, O=C–O–CH2 bending at 1536–1242 cm−1, O–C(O)–C bending at 1142 cm−1 were observed. In the FT-IR spectra of the compound D5, –OH stretching at 3200 cm−1, carbonyl (O=C–O) stretch at 1704 cm−1, asymmetric and symmetrical CH2 stretching at 2915–2847 cm−1, O–C(O)–C stretching at 1536–1242 cm−1, O–C(O)–C bending at 1148 cm−1, CH2CH2–O bending in 1096 cm−1 were observed. In the spectra of D6 compound, –OH stretching at 3200 cm−1, carbonyl (O=C–O) stretch at 1702 cm−1, asymmetric and symmetrical CH2 stretching at 2916–2844 cm−1, O–C(O)–C stretching at 1535–1243 cm−1, O–C(O)–C bending at 1147 cm−1, C–O–C bending in 1025 cm−1 were observed. Similarly, D7 compound characterized with FTIR. In the FTIR spectra of D7 compound, –OH stretching at 3200 cm−1, carbonyl (O=C–O) stretching at 1702 cm−1, asymmetric and symmetrical CH2 stretching at 2918–2847 cm−1, O–C(O)–C stretching at 1539–1243 cm−1, O–C(O)–C bending at 1162 cm−1, C–O–C bending at 1083 cm−1 were observed. According to these results, it was observed that carbonyl vibration shifted to low frequency values with the effect of high volume groups in line with the literature (Kaya et al. 2012). Also proton NMR and carbon NMR spectra show that the success on synthesis of esterification and thioesterification products.

The compounds were characterized with 1H-NMR and 13C-NMR in DMSO-d6 and CDCl3 solvents. For this purpose, all synthesized compounds were dispersed in some of solvents (Fig. 5) to find the NMR solvent. As a result of stability and solubility test CDCl3 and DMSO-d6 were chosen for NMR solvents. While proton NMR spectra showed that no peak was observed on the proton NMR spectrum of acylated MWCNTs and some peaks were observed on the products’ spectra. These new peaks comes from bridges of ethylene glycol and ethylene glycol dithiol which bound by strong chemical bonds. In the 1H-NMR spectra of D1, HS–CH2–CH2–O chemical shift at 1.53 ppm, HS–CH2–CH2–O chemical shift at 3.35 ppm, 4.64 ppm HS–CH2–CH2–O chemical shifts were observed. In 13C-NMR spectrum, HS–CH2–CH2–O chemical shift at 36.00 ppm, CH2–S–C=O chemical shift at 44.00 ppm, O=C–S chemical shift at 170.88 ppm were observed. For D2 compound, HS–CH2–CH2–O chemical shift at 1.51 ppm, HS–CH2–CH2–O chemical shift at 3.36 ppm, 3.66 ppm O=C–S–CH2–CH2–O chemical shift, HS–CH2–CH2–O chemical shift at 4.00 ppm, O=C–S–CH2–CH2–O– chemical shift at 4.67 ppm were observed. When 13C-NMR spectrum is examined, HS–CH2–CH2–O chemical shift at 30.6 ppm, CH2–S–C=O chemical shift at 36.14 ppm, O=C–S–CH2–CH2–O chemical shift at 69.99 ppm, HS–CH2–CH2–O chemical shift at 74.55 ppm, O=C–S chemical shift at 168.8 ppm were observed. The last thiol-substituted compound D3 showed that HS–CH2–CH2–O chemical shift at 1.27 ppm, O=C–S–CH2–CH2–O chemical shift at 1.58 ppm, at 2.65 ppm O=C–S–CH2–CH2–O chemical shift, S–CH2–CH2–O chemical shift at 3.64 ppm in NMR spectra. When 13C-NMR spectrum is examined, HS–CH2- chemical shift at 22.00 ppm, O=C–S–CH2–CH2–O chemical shift at 27.14 ppm, O=C–S–CH2–CH2–O chemical shift at 29.99 ppm, HS–CH2–CH2- chemical shift at 31.25 ppm, O–CH2–CH2–O chemical shift at 69.25 ppm, O=C–O chemical shift at 168.75 ppm were observed. In the 1H-NMR spectrum of D4, O–CH2–CH2–OH chemical shift at 2.56 ppm, O–CH2–CH2–OH chemical shift at 3.44 ppm were observed. In 13C-NMR spectrum, O–CH2–CH2–OH chemical shift at 61.72 ppm, O–CH2–CH2–OH chemical shift at 65.23 ppm, O–C=O chemical shift at 167.17 ppm were observed. In the 1H-NMR spectra of the D5 compound, –O–CH2–CH2–OH chemical shift at 3.39 ppm, –O–CH2–CH2–OH chemical shift at 3.48 ppm, –O–CH2–CH2–O–C=O chemical shift at 3,54 ppm, –O–CH2–CH2–O–C=O chemical shift at 4.62 ppm were observed. In the 13C-NMR spectrum, –O–CH2–CH2–OH chemical shift at 56.40 ppm, –O–CH2–CH2–O–C=O chemical shift at 57.25 ppm, –O–CH2–CH2–O–C=O chemical shift and –O–CH2–CH2–OH chemical shift at 72.94 ppm, O=C–O chemical shift at 167.06 ppm were observed. When 1H-NMR spectra of D6 compound were examined, –O–CH2–CH2–O– chemical shift at 1.73 ppm, –O–CH2–CH2–O– chemical shift at 2.87 ppm, –O–CH2–CH2–OH chemical shift at 2.10 ppm, –O–CH2–CH2–O–C=O chemical shift at 2.58 ppm, –O–CH2–CH2–O–C=O chemical shift at 3.44 ppm, HO–CH2–CH2–O– chemical shift at 3.57 ppm, chemical shift of HO–CH2–CH2–O– at 4.26 ppm were observed. In 13C-NMR spectrum, O–CH2–CH2–O– chemical shift at 45.42 ppm, O–CH2–CH2–O–C=O chemical shift at 55.22 ppm, O–CH2–CH2–O–C=O chemical shift at 60.84 ppm, –CH2–OH chemical shift at 72.54 ppm, O=C–O chemical shift at 165.15 ppm were observed. In the 1H-NMR spectra of D7 compound, –CH2–OH chemical shift at 3.40 ppm, –O–CH2–CH2–O– chemical shift at 3.50 ppm,–O–CH2–CH2–O–C=O chemical shift at 3.89 ppm, –O–CH2–CH2–O–C=O chemical shift at 4.56 ppm,–OH chemical shift at 4.00 ppm were observed. In the 13C-NMR spectrum, –CH2–OH chemical shift at 60.66 ppm, –O–CH2–CH2–O–C=O chemical shift at 63.25 ppm, –O–CH2–CH2–O–C=O chemical shift at 67.19 ppm, HO–CH2–CH2- chemical shift at 70.23 ppm,–O–CH2–CH2–O–CH2–CH2- chemical shift at 70.28 ppm, of –O–CH2–CH2–O–CH2–CH2-, chemical shift at 72.79 ppm, O=C–O chemical shift at 165.00 ppm were observed. That can be seen clearly in proton NMR spectra between 1.47 and 4.64 ppm (–SH, –OH, and –CH2) and in the carbon NMR spectra 165–168 ppm (C=O) indicates synthesis of target compounds (see in Supp. Supp. Matt.).

Additionally, TGA curves of MWCNT, MWCNT–COCl, and triethylene glycol dithiol-substituted MWCNT (D3) are given in Fig. 3 (the TGA curves of all synthesized compounds are given in Supp. Matt.). That can be clearly understood from MWCNTs, MWCNTs–COOH, MWCNTs–COCl and compounds curves. Although a mass loss of 29.36% at 595 °C was observed for MWCNT–COCl in the TGA (TG %) spectrum, it was observed that 14.8% was degraded at 575 °C because the D1 product obtained was more stable than the acyl chloride compound. ~ 2% deterioration in temperatures below 171 °C is caused by impurities that are attached to the structure or trapped. There was a mass loss of about 2% at 203 °C. This is the separation of the ethylene bridge. A maximum mass loss of 0.61% dTG/min and 0.51% dTG/min was observed at 272 and 290 °C. In the 5% mass loss up to 350 °C, both of the thiol groups were removed from the structure. With a 0.58% dTG/min degradation at 380 °C and a 0.36% dTG/min degradation at 450 °C, there was a mass loss of 2.5% structure. This corresponds to the separation of the carbonyl group. For the second compound, D2, despite a 29.36% mass loss at 595 °C for MWCNT–COCl in the TGA (TG %) spectrum, 16.1% was degraded at 577 °C, due to the D2 product obtained was more stable than the acyl chloride compound. In the spectrum, there is a mass loss of approximately 2%, resulting from impurities trapped in the structure and up to 155 °C. A total loss of 9% mass with a maximum distortion of 0.70% dTG/min in the 220–380 °C range corresponds to the separation of the diethylene glycol dithiol group. The 3% mass loss in the 400–580 °C range belongs to the separation of the carbonyl group. Despite a 29.36% mass loss at 595 °C for MWCNT–COCl in the TGA (TG %) spectrum, it was observed that 17.39% at 595 °C deteriorated because the D3 product obtained was more stable than the acyl chloride compound. In the TGA spectrum, a mass loss of 1.15% was observed as a result of the removal of impurities below 100 °C. The mass loss of approximately 16.28% in the range of 217–355 °C corresponds to the degradation of the triethylene glycol dithiol group. Although a mass loss of 29.36% at 595 °C was observed for MWCNT–COCl in the TGA (TG %) spectrum, it was observed that 18.27% of the D4 product was degraded at 574 °C as it was more stable than the acyl chloride compound. The first mass loss of the D4 compound in the TGA spectrum has been observed up to 108 °C and indicates the separation of impurities trapped in the structure. The mass loss of approximately 4% in the 190–413 °C range belongs to the group C=O. Although a mass loss of 29.36% at 595 °C was observed for MWCNT–COCl in the TGA (% TG) spectrum, it was observed that 26.10% of the D5 product was degraded at 577 °C as it was relatively more stable than the acyl chloride compound. At 140 °C, approximately 3% mass loss belongs to the separation of some impurities. A mass loss of approximately 11% with a distortion of 1.08% per minute in the range of 140–250 °C corresponds to the separation of the first ethylene glycol bridge. 8% mass loss (maximum 0.84% dTG/min) in the range of 271–380 °C indicates the separation of the second ethylene glycol bridge. Finally, 4% mass loss in the 400–580 °C range belongs to the C=O group. Despite a 29.36% mass loss at 595 °C for MWCNT–COCl in the TGA (TG %) spectrum, it was observed that 18.67% of the D6 product was degraded at 595 °C because it was more stable than the acyl chloride compound. 1.48% mass loss up to 140 °C was observed in TGA spectrum because of some nanostructures. 17% mass loss in the range of 266–375 °C occurs by separating the triethylene glycol group. Despite a 29.36% mass loss at 595 °C for MWCNT–COCl in the TGA (TG %) spectrum, the D7 product obtained was 32.10% at 576 °C due to its bulky structure and less stability than the acyl chloride compound due to its long glycol chains. In the TGA spectrum, a mass loss of 2% by mass was observed up to 140 °C. A 20% mass loss (2% dTG/min) in the 200–413 °C range results from the separation of the tetraethylene glycol group. The 5% mass loss observed in the 410–576 °C range is due to the separation of the C=O group.

The surface morphology of the substituted MWCNTs were characterized by TEM. TEM images of compound MWCNTs, MWCNTs–COOH and D1–D7 are given in Table 2 (detailed TEM images are given in Supp. Matt.). When the TEM image of MWCNTs is examined, it is seen that it is composed of very complex long and pure nanotubes (Table 2a). It is clear that nanotubes overlap because the modifications on the surface change the interactions between the nanotubes. In addition, the nanotubes are shortened with modifications on the nanotubes, which is also seen in Table 2. The thickness and fluctuations on the nanotubes indicate modifications on the surface. When Table 2b is examined, the breaks in the structure and the narrowing and shortening of the carbon nanotube cavity show that the structure is oxidized, that is, carboxylated. Table 2b–f shows that the thickening points indicated by arrow signs show that the surface morphology changes in the desired direction. The thickening of the D1 compound in Table 2c also shows that it is functionalized with ethylene glycol dithiol. Likewise, when TEM images of D5, D6, D7 molecules are characterized, modification of CNTs with diethylene glycol, triethylene glycol, and tetraethylene glycol, respectively, led to thickening.

Furthermore, solubility experiments of the synthesized compounds play an important role in the characterization of the compounds. For this reason, MWCNTs, MWCNTs–COOH, and D1–D7-substituted MWCNTs were assayed. Figure 4 shows that multi-walled carbon nanotube is not soluble in water (A). However, it is readily dispersible in water after substitution.

In Fig. 5, water, ethanol, dichloromethane, chloroform and DMSO are the best solvents. However, the best solubility in tertiary solvents used in NMR studies was observed in DMSO. In addition, trichloroacetic acid (TCA) was added to DMSO in some studies to increase the solubility.

Conclusions

In this study, three dithiol-substituted MWCNTs and four glycol-substituted MWCNTs were successfully synthesized. For this purpose, commercially available MWCNTs were transformed into MWCNTs–COOH and MWCNTs–COCl, which are the precursor of target-substituted MWCNTs. These precursor compounds were reacted with ethylene glycol, diethylene glycol, triethylene glycol, tetraethylene glycol and ethylene glycol dithiol, diethylene glycol dithiol, triethylene glycol dithiol compounds which were linked to the acyl groups on MWCNTs by esterification–thioesterification reaction. These reactions were synthesized by applying conventional synthesis techniques and eco-friendly syntheses technic called green chemistry in the history of science. Solvent, temperature, use of the microwave synthesizer, and catalyst were examined to determine the optimum reaction conditions. The resulting substituted MWCNTs were characterized in terms of structure and morphology by FTIR, 1H-NMR, 13C-NMR, TGA and TEM techniques. The synthesis of these compounds is essential. In metal enrichment studies, it is aimed to apply metal to environment and water technologies by selectively removing metal ions from metal mixtures. It is also aimed to investigate their use in cytotoxicology studies.

References

Afrin R, Shah NA, Abbas M et al (2013) Sensors and actuators a: physical design and analysis of functional multiwalled carbon nanotubes for infrared sensors. Sens Actuators A 203(203):142–148

Avilés-Barreto SL, Suleiman D (2015) Effect of single-walled carbon nanotubes on the transport properties of sulfonated poly(styrene-isobutylene-styrene) membranes. J Memb Sci 474:92–102. https://doi.org/10.1016/j.memsci.2014.09.049

Banerjee S, Bhattacharya S, Basu S (2005) Absorption spectroscopic study of synergistic extraction of praseodymium with benzoyl acetone in presence of crown ether. Spectrochim Acta A 61:1039–1044. https://doi.org/10.1016/j.saa.2004.06.015

Caddick S, Fitzmaurice R (2009) Microwave enhanced synthesis. Tetrahedron 65:3325–3355. https://doi.org/10.1016/j.tet.2009.01.105

Calisir U, Çiçek B (2017) Comparison of classic and microwave-assisted synthesis of benzo-thio crown ethers, and investigation of their ion pair extractions. J Mol Struct 1148:505–511. https://doi.org/10.1016/j.molstruc.2017.07.081

Chen J, Hamon MA, Hu H et al (1998) Solution properties of single-walled carbon nanotubes. Science 282(80):95–98. https://doi.org/10.1126/science.282.5386.95

Cutress IJ, Marken F, Compton RG (2009) Microwave-assisted electroanalysis: a review. Electroanalysis 21:113–123. https://doi.org/10.1002/elan.200804409

Dai B, Cao M, Fang G et al (2012) Schiff base-chitosan grafted multiwal led carbon nanotubes as a novel solid-phase extraction adsorbent for determination of heavy metal by ICP-MS. J Hazard Mater 219–220:103–110. https://doi.org/10.1016/j.jhazmat.2012.03.065

Dillon AC, Gennett T, Jones KM et al (1999) A simple and complete purification of single-walled carbon nanotube (SWNT) materials. Adv Mater 11:1354–1358. https://doi.org/10.1002/chin.200001250

Dujardin E, Ebbesen TW, Krishnan A, Treacy MMJ (1998) Purification of single-shell nanotubes. Adv Mater 10:611–613. https://doi.org/10.1002/(SICI)1521-4095(199805)10:8%3c611:AID-ADMA611%3e3.0.CO;2-8

Gabriel G, Sauthier G, Fraxedas J et al (2006) Preparation and characterisation of single-walled carbon nanotubes functionalised with amines. Carbon N Y 44:1891–1897. https://doi.org/10.1016/j.carbon.2006.02.010

Hadavifar M, Bahramifar N, Younesi H, Li Q (2014) Adsorption of mercury ions from synthetic and real wastewater aqueous solution by functionalized multi-walled carbon nanotube with both amino and thiolated groups. Chem Eng J 237:217–228. https://doi.org/10.1016/j.cej.2013.10.014

Hamon MA, Chen J, Hu H et al (1999) Dissolution of single-walled carbon nanotubes. Adv Mater 11:834–840

Hong CY, You YZ, Pan CY (2005) Synthesis of water-soluble multiwalled carbon nanotubes with grafted temperature-responsive shells by surface RAFT polymerization. Chem Mater 17:2247–2254. https://doi.org/10.1021/cm048054l

Jeong JS, Jeon SY, Lee TY et al (2006) Fabrication of MWNTs/nylon conductive composite nanofibers by electrospinning. Diam Relat Mater 15:1839–1843. https://doi.org/10.1016/j.diamond.2006.08.026

Jiang G, Wang L, Chen C et al (2005) Study on attachment of highly branched molecules onto multiwalled carbon nanotubes. Mater Lett 59:2085–2089. https://doi.org/10.1016/j.matlet.2005.01.085

Kaya N, Kartal Z, Bahçeli S (2012) FT-IR Spectroscopic Investigation of Some M(Benzoyl Chloride)2Ni(CN)4 Complexes (M = Co, Ni and Cd). J Sci Rep-A 27:23–34

Kim SW, Kim T, Kim YS et al (2012) Surface modifications for the effective dispersion of carbon nanotubes in solvents and polymers. Carbon N Y 50:3–33. https://doi.org/10.1016/j.carbon.2011.08.011

Li R, Chang X, Li Z et al (2011) Multiwalled carbon nanotubes modified with 2-aminobenzothiazole modified for uniquely selective solid-phase extraction and determination of Pb(II) ion in water samples. Microchim Acta 172:269–276. https://doi.org/10.1007/s00604-010-0488-9

Lim JK, Yun WS, Han YM et al (2003) Selective thiolation of single-walled carbon nanotubes. Synth Met 139:521–527. https://doi.org/10.1016/S0379-6779(03)00337-0

Lin Y, Zhou B, Fernando KAS et al (2003) Polymeric carbon nanocomposites from carbon nanotubes functionalized with matrix polymer. Macromolecules 36:7199–7204. https://doi.org/10.1021/ma0348876

Mormann W, Lu Y, Zou X, Berger R (2008) Modification and grafting of multi-walled carbon nanotubes with bisphenol-a- polycarbonate. Macromol Chem Phys 209:2113–2121. https://doi.org/10.1002/macp.200800263

Nagasawa S, Yudasaka M, Hirahara K et al (2000) Effect of oxidation on single-wall carbon nanotubes. Chem Phys Lett 328:374–380. https://doi.org/10.1016/S0009-2614(00)00960-X

Ng SC, Xu G-Q, Yu R et al (2002) Platinum deposition on carbon nanotubes via chemical modification. Chem Mater 10:718–722. https://doi.org/10.1021/cm970364z

Pan B, Cui D, He R et al (2006) Covalent attachment of quantum dot on carbon nanotubes. Chem Phys Lett 417:419–424. https://doi.org/10.1016/j.cplett.2005.10.044

Pandurangappa M, Raghu GK (2008) Chemically modified carbon nanotubes: derivatization and their applications. In: Marulanda JM (ed) Carbon nanotubes applications on electron devices. InTech, Shanghai, pp 499–526

Profumo A, Fagnoni M, Merli D et al (2006) Multiwalled carbon nanotube chemically modified gold electrode for inorganic as speciation and Bi(III) determination. Anal Chem 78:4194–4199. https://doi.org/10.1021/ac060455s

Qiu L, Chen Y, Yang Y et al (2013) A study of surface modifications of carbon nanotubes on the properties of polyamide 66/multiwalled carbon nanotube composites. J Nanomater 2013:1–8

Santhosh P, Manesh KM, Gopalan A, Lee KP (2007) Novel amperometric carbon monoxide sensor based on multi-wall carbon nanotubes grafted with polydiphenylamine-Fabrication and performance. Sens Actuators B Chem 125:92–99. https://doi.org/10.1016/j.snb.2007.01.044

Te Hsieh C, Teng H, Chen WY, Cheng YS (2010) Synthesis, characterization, and electrochemical capacitance of amino-functionalized carbon nanotube/carbon paper electrodes. Carbon N Y 48:4219–4229. https://doi.org/10.1016/j.carbon.2010.07.021

Tsai YC, Chen JM, Marken F (2005) Simple cast-deposited multi-walled carbon nanotube/Nafion™ thin film electrodes for electrochemical stripping analysis. Microchim Acta 150:269–276. https://doi.org/10.1007/s00604-005-0364-1

Wang Y, Iqbal Z, Malhotra SV (2005) Functionalization of carbon nanotubes with amines and enzymes. Chem Phys Lett 402:96–101. https://doi.org/10.1016/j.cplett.2004.11.099

Xiao L, Wildgoose GG, Compton RG (2008) Sensitive electrochemical detection of arsenic (III) using gold nanoparticle modified carbon nanotubes via anodic stripping voltammetry. Anal Chim Acta 620:44–49. https://doi.org/10.1016/j.aca.2008.05.015

Xing L, Imae T (2007) Size-controlled in situ synthesis of metal nanoparticles on dendrimer-modified carbon nanotubes. J Phys Chem C 111:2416–2420. https://doi.org/10.1021/jp065613y

Xu J, Yao P, Li X, He F (2008) Synthesis and characterization of water-soluble and conducting sulfonated polyaniline/para-phenylenediamine-functionalized multi-walled carbon nanotubes nano-composite. Mater Sci Eng B 151:210–219. https://doi.org/10.1016/j.mseb.2008.07.003

Zang Z, Hu Z, Li Z et al (2009) Synthesis, characterization and application of ethylenediamine-modified multiwalled carbon nanotubes for selective solid-phase extraction and preconcentration of metal ions. J Hazard Mater 172:958–963. https://doi.org/10.1016/j.jhazmat.2009.07.078

Acknowledgements

In this study, both Baki Çiçek and Ümit Çalışır designed the study, performed all experiments/analysis, and evaluated the results and prepared the manuscript. Baki Çiçek was the supervisor of Ümit Çalışır during this work, which is presented as a Ph.D. thesis. This work has been supported by Balikesir University Scientific Research Projects Unit with Project Number BAP:2017/080 and BAP:2019/066.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Çalışır, Ü., Çiçek, B. Synthesis of thiol-glycol-functionalized carbon nanotubes and characterization with FTIR, TEM, TGA, and NMR technics. Chem. Pap. 74, 3293–3302 (2020). https://doi.org/10.1007/s11696-020-01158-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-020-01158-6