Abstract

A new azo-dye reagent was prepared by the reaction between sulfacetamide and rutin compounds. The new synthesized reagent of (E)-N-((4-((5-(5,7-dihydroxy-3-3-[3-α-l-rhamnopyranosyl-(1 → 6)-β-d-glucopyrano-syloxy]-4-oxo-4H-chromen-2-yl)-2,3-dihydroxyphenyl)diazenyl)phenyl)sulfonyl)acetamide [NDRGA] was characterized by FT-IR, 1HNMR, mass spectra and elemental analysis measurements and then used for the spectrophotometric determination of Sm(III). The proposed method was based on the formation of a lemon-colored complex between Sm(III) and NDGRA reagent in an alkaline medium using borate buffer at pH = 8 with absorption maximum at 475 nm. The method was enhanced by the use of cationic surfactant of cetylpyridinium bromide (CPB). Different factors affecting the formation and stability of the complex such as reagent concentration, time, temperature, solvents and order of addition were also studied. The composition of the complex was found to be 1:1 (metal: ligand) by using Job’s and molar ratio methods. The stability constant of the complex was calculated to be 1.1805 × 106. The method showed a good linearity in the concentration range of 2.0–90 µg ml−1 of Sm(III) with molar absorptivity and Sandell’s sensitivity 1.3014 × 104 L mol−1 cm−1 and 1.155 × 10−2 µg cm−2, respectively. The limit of quantification (LOQ) and detection (LOD) were calculated. The interference effect of some foreign ions was also studied. The validity of the calibration curve was found useful for the determination of micro-amounts of Sm(III) in some industrial and blood samples.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Rare earth metal ions were used greatly in nuclear industry, new energy, native defense, aerospace, biological medicine and in agriculture (Li et al. 2016). They were used in lasers, lamps, motion picture projectors, phosphorus, magnets and X-ray condensing screens (Zolfonoun and Yousefi 2016). The natural occurrence of rare earth metal ions was based on their geological conditions. They were found in adequate amount and concentration in only few locations, also they were found in a suitable form and regulation to make their extraction and utilization economically feasible. Geologists use rare earth metal ions as tools to facilitate the scientific research into the chemical attitude of ocean waters and the origin of ores and rocks (Mehmood 2018). In the world of technology, these metal ions were indispensable due to their magnetic, phosphorescence and catalytic characteristics. Many rare earth metal ions are radioactive materials which are hazardous as radioactive soil and water emissions. Their spectroscopic properties of rare earth metal ions for advanced new materials made them have a great attention (Makombe et al. 2018). Samarium has been used in microelectronics, glass, ceramics and nuclear industries. For instance, it has been used as an absorber in the nuclear industry and also as anesthetic with CaF2 crystals for the use in visual lasers or masers (Soylak and Turkoglu 2000). Samarium has been used as a polishing compound and as catalyst in the gasoline cracking process; also, it has been used in the steel and iron industries to remove carbon and sulfur and some other electronegative elements (Ratre and Kumar 2013). Increasing industrial use of samarium has made it essential to have analytical procedures suitable for observation of samarium in environmental and related fields. For this purpose, some suitable analytical methods, such as inductively coupled plasma atomic emission spectroscopy (ICP-AES) (Paama et al. 2001) and inductively coupled plasma mass spectrometry (ICP-MS) (Li et al. 1999), have been utilized for the determination of samarium. Also, many spectrophotometric methods were used for the determination of samarium(III) using various organic reagents such as chrome azurol S, chlorophosphonazo III and 2-[(5-bromo-2-pyridylazo)]-5-diethyl-aminophenol (Soylak and Turkoglu 2000; Uhrovcik and Lesny 2014; Ratre and Kumar 2013). In addition, it has also been determined via the complexation with disodium 2-(2-hydroxy-3-sulfo-5-nitrophenylazo)naphthalene-1,8-dihydroxy-3,6-disulfonate in the presence of cetyltrimethyl-ammonium bromide (Gadzhieva et al. 2005).

In the present study, the synthesis and characterization of a new azo-dye reagent of (E)-N-((4-((5-(5,7-dihydroxy-3-3-[3-α-l-rhamnopyranosyl-(1 → 6)-β-d-glucopyrano-syloxy]-4-oxo-4H-chromen-2-yl)-2,3-dihydroxyphenyl)diazenyl)phenyl)sulfonyl)acetamide [NDRGA] which formed from the reaction between sulfacetamide and rutin was reported. Moreover, it was used for the rapid, simple, sensitive and highly selective spectrophotometric determination of Sm(III) in different analytical applications.

Experimental

Instrumentation

All absorbance measurements were carried out with a UV–Vis spectrophotometer (T80 UV/Vis double beam spectrophotometer, PG instruments Ltd Company, UK), spectral bandwidth 2.0 nm, with 10 mm matched quartz cells. All pH measurements were made using a pH meter (Adwa pH meter, Model AD 1030, Romania). The FT-IR spectra were recorded in KBr pellets on a Shimadzu FT-IR 8101 PC infrared spectrometer in the range from 4000 to 400 cm−1. The 1HNMR spectra were recorded on Bruker (400 MHz) spectrometer using DMSO-d6 as solvent. Mass spectrometry was determined on DI Analysis Shimadzu QP-2010 Plus.

Chemical and materials

All chemicals and solvents used were analytical grade reagents and were used without further purification. Double distilled water was used throughout the experiments.

Alcoholic solution of (1 × 10−3 M) of (E)-N-((4-((5-(5,7-dihydroxy-3-3-[3-α-l-rhamnopyranosyl-(1 6)-β-d-glucopyranosyloxy]-4-oxo-4H-chromen-2-yl)-2,3-dihydroxyphenyl)diazenyl)phenyl)sulfonyl)acetamide [NDRGA] reagent was prepared by dissolving (0.0837 g, M. wt. = 837.71 g mol−1) of the reagent in 100 ml ethanol.

A (1 × 10−3 M) of samarium(III) standard solution was prepared by dissolving 0.03488 g of [Sm2O3, M. wt. 348.718 g mol−1] in the least amount of nitric acid (1:1) in a 100 ml measuring flask and diluting to the mark with distilled water. Working solutions of lower concentrations were prepared from the stock solutions by appropriate dilution.

Series of different surfactants including cetyltrimethyl-ammonium bromide (CTAB), Triton X-100, sodium lauryl sulfate (SLS), cetylpyridinium bromide (CPB), Tween 80 and sodium dioctyl sulfosuccinate (Aerosol GPG-E) were prepared at concentration (1 × 10−2 M) by dissolving the appropriate amount of each surfactant in 100 ml distilled water and used without further purification.

Series of buffer solutions of universal buffer (pH 2.0–11.0), borate buffer (7.0–10.0), citrate buffer (3.0–6.0), acetate buffer (3.0–6.0) and phosphate buffer (7.0–11.0) were prepared by standard methods (Britton 1952; Bower and Bates 1955; Lurie 1978).

Procedures

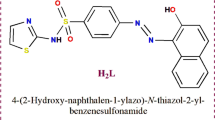

Synthesis of (E)-N-((4-((5-(5,7-dihydroxy-3-3-[3-α-l-rhamnopyranosyl-(1 → 6)-β-d-glucopyranosyloxy]-4-oxo-4H-chromen-2-yl)-2,3-dihydroxyphenyl)diazenyl)phenyl)sulfonyl)acetamide (NDGRA) reagent:

(1.071 g, 0.005 mol) of N-(4-aminophenylsulfonyl) acetamide was dissolved in 10 ml hydrochloric acid (1:1), and diazotized in ice path at 4 °C with sodium nitrite (0.344 g, 0.005 mol) solution in water (5.0 ml). The resulting diazo solution was added dropwise with stirring to an ice-cooled solution of (3.052 g, 0.005 mol) of (3′,4′,5,7-tetrahydroxy-flavone-3-rutinoside [rutin] which was dissolved in (10 ml) of (2 M) sodium hydroxide. The precipitate was filtered and washed with a (1:3) mixture of ethanol and water several times, then left in air to dry. The resulting compound is a solid reddish brown precipitate; yield 85%, m.p. 230–232 °C (Scheme 1).

General spectrophotometric procedures

Suitable aliquots of Sm(III) standard solution (1.0–130 µg ml−1) were transferred into a series of 10 ml calibrated flasks containing 1.0 ml of (1 × 10−3 M) NDGRA reagent, followed by 4.0 ml borate buffer (pH = 8). To each flask, 1.0 ml of (1 × 10−2) cetylpyridinium bromide (CPB) surfactant was added. The volumes were adjusted to the mark with distilled water and mixed well. Spontaneously and at 20 °C, the absorbance was measured at 475 nm against the blank solution. By plotting the absorbance against the concentration of Sm(III) in µg ml−1, the range of Beer’s law can be determined.

Applications

Determination of Sm(III) in monazite sand

0.5 g of monazite sand was dissolved in 10 ml concentrated H2SO4 and was evaporated to almost dryness. The residue was then diluted to 50 ml with distilled water, boiled, filtered and washed with hot water. Samarium ion was precipitated as oxalate by the addition of excess hot solution of oxalic acid till complete precipitation. The oxalate was filtered and ignited to the oxide, which was dissolved in concentrated HCl and HNO3 and evaporated till dryness. The residue was dissolved again in 5.0 ml HCl (1 M) with continued heating to 70 °C for 30 min. The solution was cooled to room temperature, filtered, diluted to fixed volume suitable to the applicable concentration range and then the above procedures were followed. Uranium (VI) was masked using ammonium sulfate (Motojima and Lzawa 1964).

Determination of Sm(III) in crude phosphoric acid

5.0 ml of crude phosphoric acid was taken and diluted to 50 ml with distilled water. The concentration of the metal ion was determined by the procedures described above.

Determination of Sm(III) in phosphate fertilizer

0.5 g of fertilizer sample was dissolved in a (1:3) mixture of concentrated (HCl:HNO3) and evaporated to almost dryness. The residue was dissolved again in 10 ml HCl (1 M) and diluted with 20 ml distilled water with continued heating to 80 °C for 1 h. The solution was cooled to room temperature, filtered, diluted to suitable volume by distilled water and analyzed as described above.

Determination of Sm(III) in permanent magnet

0.144 g of permanent magnet was weighed and dissolved in 5.0 ml of concentrated H2SO4 with heating to 80 °C for 20 min. 10 ml of distilled water was added to the solution with continued heating at 70 °C for 1 h. The solution was cooled to room temperature, diluted and analyzed as in previous procedures. Fe(III) was masked using sodium fluoride (Motojima and Lzawa 1964).

Determination of Sm(III) in blood

A definite volume (10 ml) of blood sample was drawn from adult human body. A 7.5 ml from this sample was centered in a centrifuge using a tube contained sodium citrate as anticoagulant to separate plasma, then center the remained 2.5 ml to separate serum. Fe(III) was masked by using sodium fluoride. The sample was then analyzed as in the above procedures.

Results and discussion

Structural characterization of NDGRA azo-dye reagent

The structure of NDGRA azo-dye reagent was confirmed by the structural data obtained using FT-IR, 1HNMR, mass spectra and elemental analysis measurements.

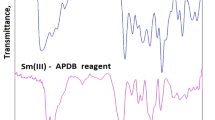

FT-IR spectra

The FT-IR spectrum (Fig. 1) of the synthesized reagent displayed a broad band at 3394 cm−1 for (O–H) hydroxyl groups and a band at 3186 cm−1 for amidic (N–H) group. It also showed bands at 1512 cm−1 for (N = N) azo group, 1659 cm−1 for α, β-unsaturated and amidic carbonyl groups and 1292 cm−1 for asymmetric sulfone (SO2) group.

1HNMR spectra

The 1HNMR (DMSO-d6) spectrum data (Fig. 2) of the reagent showed δ = 1.90 (s, 3H, CH3), 3.04–3.39 (m, 16H, CH2, 7 CHOH and 7 OH of sugar moiety), 6.69 (d, 1H, OCHCH2), 4.37 (s, 1H, OCH), 5.33 (d, 1H, J = 7.9 Hz, anomeric proton of sugar H-1′), 6.18 (s, 1H, Ar–H), 6.38 (s, 1H, Ar–H), 6.82 (d, 2H, J = 8.50 Hz, Ar–H), 7.52 (s, 1H, Ar–H), 7.54 (d, 2H, J = 8.50 Hz, Ar–H), 9.16 (br, 1H, OH, exchange with D2O), 9.65 (br, 1H, OH, exchange with D2O), 10.81 (s, 1H, OH, exchange with D2O), and 12.51 (s, 1H, NH, exchange with D2O).

Mass spectra

The mass spectra (Fig. 3) of the reagent showed a signal at M+ (m/e) = 836.30 (3.50%) attributed to the parent ion and another one at m/e = 302.00 (100%) for the base peak. Mol. formula: C34H35N3O20S (837.71 g mol−1).

Elemental analysis

Anal. calcd. for C34H35N3O20S (837.71 g mol−1): C 48.75; H 4.21; N 5.02.

Found: C 48.76; H 4.22; N 5.01.

Spectrophotometric study of Sm(III)–NDGRA complex

Absorption spectra

The absorption spectra of reagent and its complex were measured in the range of 200–800 nm against the blank solution, (Fig. 4). It was observed that Sm(III) with [NDGRA] reagent formed a lemon-colored complex at 460 nm in alkaline medium (pH = 8). The addition of cetylpyridinium bromide (CPB) surfactant resulted in an increase in absorbance with a redshift to 475 nm.

Optimization of experimental conditions

Different factors were used to select the optimum conditions necessary for the rapid formation and stability of the complex under investigation.

Effect of the pH and buffer solutions

The effect of pH on the complex formation was studied from pH 1–12 by using 0.2 M NaOH and 0.2 M HCl solutions. It was observed that the suitable pH range for complete formation of the complex was from pH = 6 to 9 (Fig. 5). In more acidic or more alkaline solutions, absorbance was decreased gradually due to incomplete formation and partial dissociation of the complex. To fix the pH of the media, the effect of different buffer solutions (acetate, citrate, borate, phosphate and universal) was studied. It was found that the maximum absorbance and color intensity of the complex was obtained using borate buffer (pH = 8). Further, 4.0 ml of borate buffer of pH = 8 gave the maximum absorbance value for the complex formation.

Effect of reagent concentration

The effect of reagent concentration on the complex formation was studied by measuring the absorbance of the solutions containing a fixed concentration 1.0 ml of (1 × 10−3 M) of Sm(III) ion and varied concentrations (0.5–4.0 ml of 1 × 10−3 M) of the reagent. It was observed that the maximum absorbance was obtained by using 1.0 ml of (1 × 10−3 M) of NDGRA reagent.

Effect of time and temperature

To study the effect of time and temperature on the stability of the formed complex, the absorbance readings of the complex were recorded at different times and temperatures in the range from 1.0 to 120 min and 15–75 °C. The complex was formed with maximum absorbance value spontaneously at 20 °C and remained stable up to 24 h, (Figs. 6 and 7). On the other hand, the absorbance values were decreased at higher temperatures.

Effect of surfactants

To improve the sensitivity of the complex formation, the effect of different concentrations ranging from 0.2 to 2.0 ml (1 × 10−2 M) of cationic surfactants [CTAB, CPB], nonionic surfactants [Triton X-100, Tween 80] and anionic surfactants [SLS, Aerosol GPG-E] were studied. It was observed that the maximum absorbance value was obtained when 1.0 ml (1 × 10−2 M) of cetylpyridinium bromide (CPB) was used (Fig. 8a). At higher concentrations of CPB, the absorbance was decreased due to the appearance of turbidity (Fig. 8b).

Effect of organic solvents

The effect of different organic solvents on the absorption spectra of the formed complex was studied in methanol, ethanol, isopropanol, butanol, acetone, DMF and DMSO. It was evident that ethanol was the most suitable solvent for the complex formation and higher absorbance value, while the other solvents decrease the absorbance values.

Effect of order of addition

Different absorbance measurements were performed by changing the order of the addition of the metal ion Sm(III), NDGRA reagent, buffer (borate pH = 8) and CPB surfactant. It was evident that the order (reagent–metal ion–buffer–surfactant) results in maximum absorbance. Otherwise, the other addition orders led to decrease in the absorbance values.

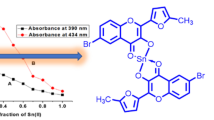

Stoichiometric ratio

To establish the molar ratio between Sm(III) and NDGRA reagent, Job’s method of continuous variation was applied (Job 1928). In this method, an equimolar solution of metal ion and reagent in different proportions from 0.1 to 0.9 ml (1 × 10−3 M) of the same concentration were mixed, while the total molar concentration was kept constant. The absorbance was measured at 475 nm and plotted versus mole fraction (Fig. 9a). The composition of the complex was also confirmed by the molar ratio method (Yoe and Jones 1944). In this method, the concentration of the metal ion was kept constant at 1.0 ml of (1 × 10−3 M), while that of the reagent was different from 0.1 to 1.3 ml of (1 × 10−3 M). The absorbance of these solutions was recorded at 475 nm and then plotted against the molar ratio [ligand]/[metal], (Fig. 9b). Both methods showed that the ratio of Sm(III) and the reagent was 1:1. The stability constant of the complex was calculated by Job’s method (Tirmizi et al. 2012) and found to be 1.1805 × 106, which showed the high stability of the formed complex.

Calibration curve (Beer’s law)

The calibration curve was constructed from the spectrophotometric measurements performed after the optimization of all optimum factors of the formed complex as described above. The calibration curve was obeyed in the concentration range of 2–90 µg ml−1 as shown in (Fig. 10). A Ringbom plot was also carried out to detect the optimum range of concentration for a system that obeyed Beer’s law. It was achieved at intermediate concentration values (8–90 µg ml−1).

Statistical characteristics

The method has good reproducibility for a set of seven measurements of 40 µg/ml of Sm(III) under optimum conditions. Some different statistical parameters such as standard deviation, molar absorptivity, sandell’s sensitivity, Student’s t test, F test, correlation coefficient, limit of detection (LOD) and limit of quantification (LOQ) are summarized in Table 1. The data listed in Table 1 indicate the excellent linearity, high sensitivity, good accuracy and precision of the proposed method.

Effect of diverse ions

The effect of 100-fold molar excess of many interfering ions added relative to (40 µg ml−1) of Sm(III) was tested in the determination of the metal ion with the NDGRA reagent. Then the absorbance was measured as in the procedures mentioned above. It was evident that Sr(III), Cu(II), Cd(II), Mg(II), Zn(II), As(III), Ba(II), Co(II), Ni(II), La(III), Nd(III), Pr(III), Gd(III), Y(III), Th(IV), Ce(III), Ga(III), Bi(III), Sn(IV), Mo(VI), PO43−, NO3−, SO42− and Cl− did not interfere in this determination, while Pb(II), Fe(III), Cr(III), Al(III), V(V), U(VI) and Ba(II), CO32− and NH4+ were interfere seriously.

Analytical applications

The proposed method was applied for the determination of Sm(III) in monazite sand, crude phosphoric acid, phosphate fertilizer, permanent magnet and human blood. The results listed in Table 2 showed good agreement with the recommended method values and indicated the applicability of the proposed method.

Conclusion

A new sulfacetamide azo-dye reagent was prepared and characterized by FT-IR, 1HNMR, mass spectra and elemental analysis and then used for the spectrophotometric determination of Sm(III). The proposed method was simple, highly sensitive and economical, did not involve extraction, heating or other special conditions and was free from most interfering ions. Sm(III) complex was formed directly and remained stable for more than 24 h. The absorbance of the complex was increased by using CPB as a surfactant. The statistical data proved that the method had high sensitivity and good accuracy and precision. The method was successfully applied for the determination of samarium(III) in monazite sand, crude phosphoric acid, phosphate fertilizer, permanent magnet and blood samples with good results.

References

Bower VE, Bates RG (1955) pH values of the Clark and Lubs buffer solutions at 25° C. J Res Natl Bur Stand 55:197–200

Britton HTS (1952) Hydrogen ions, vol 28, 4th edn. Chapman and Hall, London, pp 359–364

Gadzhieva SR, Guseinov FE, Chyragov FM (2005) Spectrophotometric study of the complexation of samarium(III) with disodium 2-(2-hydroxy-3-sulfo-5-nitrophenylazo)naphthalene-1,8-dihydroxy-3,6-disulfonate in the presence of cetyltrimethylammonium bromide. J Anal Chem 60:819–821. https://doi.org/10.1007/s10809-005-0188-5

Job P (1928) Formation and stability of inorganic complexes in solution. Ann Chim 9:113–203

Li B, Sun Y, Yin J (1999) Determination of cerium, neodymium and samarium in biological materials at low levels by isotope dilution inductively coupled plasma mass spectrometry. J Anal At Spectrom 14:1843–1848. https://doi.org/10.1039/A905346H

Li Y, Yu H, Zheng S, Miao Y, Yin S, Li P, Bian Y (2016) Direct quantification of rare earth elements concentrations in urine of workers manufacturing cerium, lanthanum oxide ultrafine and nanoparticles by a developed and validated ICP-MS. Int J Environ Res Public Health 13:1–10. https://doi.org/10.3390/ijerph13030350

Lurie JU (1978) Handbook of analytical chemistry, 2nd edn. Mir Publishers, Moscow

Makombe M, Horst CV, Silwana B, Iwuoha E, Somerset V (2018) Voltammetric and spectroscopic determination of rare earth elements in fresh and surface water samples. Environments 5:1–10. https://doi.org/10.3390/environments5100112

Mehmood M (2018) Rare earth elements-a review. J Ecol Nat Resour 2:1–6. https://doi.org/10.23880/jenr-16000128

Motojima K, Lzawa K (1964) Potentiometric titration of free acid and uranium in uranium (VI) solutions with alkali. Anal Chem 36:733–735. https://doi.org/10.1021/ac60210a011

Paama L, Pamoja E, Must M, Peramaki P (2001) Optimal conditions for europium and samarium determination in cathodoluminophors by inductively coupled plasma atomic emission spectrometry. J Anal At Spectrom 16:1333–1336. https://doi.org/10.1039/B105520H

Ratre P, Kumar D (2013) Spectrophotometric determination of trace amounts of samarium in environmental samples. Am Int J Res Formal Appl Nat Sci 3:110–118

Sangal SP, Agarwala BV, Dey AK (1969) Compleximetric determination of rare earths in aqueous solution. Mikrochim Acta 3:660–663. https://doi.org/10.1007/BF01216471

Soylak M, Turkoglu O (2000) Spectrophotometric determination of samarium(III) with chrome azurol S in the presence of cetylpyridinium chloride. Talanta 53:125–129. https://doi.org/10.1016/S0039-9140(00)00386-6

Tirmizi SA, Wattoo FH, Wattoo MHS, Sarwar S, Memon AN, Ghangro AB (2012) Spectrophotometric study of stability constants of cimetidine–Ni(II) complex at different temperatures. Arab J Chem 5:309–314. https://doi.org/10.1016/j.arabjc.2010.09.009

Uhrovcik J, Lesny J (2014) Extractive spectrophotometric determination of samarium with chlorophosphonazo III. Acta Tech Jaurinensis 7:62–70. https://doi.org/10.1413/actatechjaur.v7.n1.218

Yoe JH, Jones AL (1944) Colorimetric determination of iron with disodium-1,2-dihydroxybenzene-3,5-disulfonate. Ind Eng Chem Anal Ed 16:111–115. https://doi.org/10.1021/i560126a015

Zolfonoun E, Yousefi SR (2016) Simultaneous determination of rare earth elements by ICP OES after on-Line enrichment using multi-walled carbon nanotubes coated cellulose acetate membrane. J Braz Chem Soc 27:2348–2353. https://doi.org/10.5935/0103-5053.20160131

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abd El-wahaab, B., Elgendy, K. & El-didamony, A. Synthesis and characterization of new azo-dye reagent and using to spectrophotometric determination of samarium(III) in some industrial and blood samples. Chem. Pap. 74, 1439–1448 (2020). https://doi.org/10.1007/s11696-019-01000-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-019-01000-8