Abstract

Homocoupling of aryl halides (Ullmann-type reaction) promoted by a Pd-poly(N-vinyl-2-pyrrolidone)/MCM-48 (Pd–PVP/MCM-48) nanocomposite catalyst is described. In situ polymerization method was employed to prepare composite poly(N-vinyl-2-pyrrolidone)/MCM-48 (PVP/MCM-48) which was used as a support for palladium nanoparticles obtained by reducing Pd(OAc)2 with hydrazine hydrate. FT-IR, XPS, XRD, UV–Vis, SEM, and BET techniques were used to study the chemical and physical properties of the catalyst. The catalytic performance of this heterogeneous catalyst was specified for Ullmann-type reaction between aryl halies in DMF. The catalyst was good with regard to its stability and it can be reused up to six times without significant loss of its activity.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Palladium catalyzed cross-coupling reactions are famous for generating carbon–carbon bonds (Phan et al. 2006; Seganish et al. 2005). Heck, Sonogashira, Suzuki–Miyaura, and Ullmann reactions have proved to be excellent methods for synthesizing organic compounds (Molnar 2011; Anbarasan et al. 2011), and homogeneous palladium (II) complexes (Kantchev et al. 2007; Fu 2008) are the most commonly used catalysts for such reactions. However, there are disadvantages such as non-reusability of catalyst, high cost, and environmental pollution due to the presence of organic solvents and heavy metallic ions (Mark 2006; Zheng et al. 2008; Ostapenko et al. 2008; Morales et al. 2010) in homogeneous catalysis. In general, because of their easy separation from the products, heterogeneous catalysts are preferable to homogeneous ones. Thus, heterogeneous catalysts could be used repeatedly, and this reduces the cost. Since there seems to be a problem regarding their low activity and/or selectivity (Yin and Liebscher 2007), the development of heterogeneous palladium nanocatalysts, with high stability, activity, and recyclability is an important task in nanomaterial researches.

Recently, much attention has been attracted to periodic mesoporous materials for various applications including drug delivery, catalysis, etc. Due to their large surface area and pore volume and tunable pore size, these materials have attracted much attention as catalysts (Taguchi and Schuth 2005). The cubic MCM-48 (Mobil Composition of Matter) has two interwoven independent three-dimensional pore systems that are suited in a mirror-plane position to each other. Compared to MCM-41 in a one-dimensional hexagonal bisectional pore system (Wei et al. 2010), MCM-48 provides more favorable mass transfer kinetics in catalytic and separation applications, but this material has not been vastly explored as a support for catalytic reactions, and literature reports in this area are limited (Wang et al. 2012a, b). Catalytic components are often supported on high-specific surface area carriers like mesoporous silica in an attempt to increase the catalyst durability or activity.

Hybrid organic–inorganic polymers have attracted increasing attention due to their unique properties (Zheng et al. 2008; Mark 2006); however, there are few reports on their application as a heterogeneous catalyst (Ma et al. 2009; Alves et al. 2010). In our previous studies (Kalbasi and Mosaddegh 2011), different kinds of such polymers were used as catalysts. In this study, we concentrated on preparing poly(N-vinyl-2-pyrrolidone)/MCM-48 as a good support for Pd nanoparticles, and generated a suitable heterogeneous catalyst with a large surface area. The catalytic activity of this novel hybrid material was studied in Ullmann cross-coupling reaction.

Experimental

General identification methods

The samples were all analyzed using FT-IR spectroscopy (using a Perkin Elmer 65 in KBr matrix in the range of 4000–400 cm−1). Using a Series BEL SORP 18, their BET specific surface areas and BJH pore size distribution were determined by adsorption–desorption of nitrogen at liquid nitrogen temperature. The X-ray powder diffraction (XRD) of the catalyst was done on a Bruker D8 Advance X-ray diffractometer by employing Ni-filtered Cu Kα radiation at 40 kV and 20 mA. In addition, X-ray photo-electron spectra (XPS) were recorded on ESCA SSX-100 (Shimadzu) by employing a non-mono-chromatized Mg Ka X-ray as the source of excitation. Scanning electron microscopic (SEM) studies were carried out on Philips, XL30, SE detector. The DRS UV–Vis spectra were recorded with JASCO spectrometer, V-670 from 190 to 2700 nm.

Chemicals

All chemicals were obtained from Merck and were used without further purification.

Preparation of poly(N-vinyl-2-pyrrolidone)/MCM-48 (PVP/MCM-48)

MCM-48 was prepared according to the previous work (Kalbasi and Mosaddegh 2011). N-Vinyl-2-pyrrolidone (NVP) (0.5 mL, 4.6 mmol) and MCM-48 (0.5 g) in 7 mL of THF were poured in a round bottom flask, and the mixture was stirred for 5 h. Then, benzoyl peroxide (3% mol, 0.034 g) was added to the mixture and it was refluxed again for 5 h while being stirred under N2 atmosphere. The resulting colorless fine powder composite (PVP/MCM-48) was collected by filtration, washed with THF, and dried at 60 °C under reduced pressure. The yield of polymerization was 75%.

Preparation of Pd nanoparticle–poly(N-vinyl-2-pyrrolidone)/MCM-48 (Pd–PVP/MCM-48)

Poly(N-vinyl-2-pyrrolidone)/MCM-48 (PVP/MCM-48) (0.1 g) and 10 mL of an aqueous hydrochloric acid (CHCl = 0.09 M) solution of Pd(OAc)2 (0.053 g, 0.236 mmol) were placed in a round bottom flask. The mixture was heated to 80 °C for 5 h while being stirred under N2 atmosphere. After that, 0.6 mL (9.89 mmol) aqueous solution of hydrazine hydrate (N2H4·H2O) (80 vol%) was added to this mixture dropwise in 15–20 min, and the solution was stirred at 60 °C for 1 h prior to being filtered and washed sequentially with CHCl3 and MeOH to remove excess N2H4·H2O. Then, it was dried at room temperature to yield palladium nanoparticle–poly(N-vinyl-2-pyrrolidone)/MCM-48 composite (Pd–PVP/MCM-48) (Scheme 1). The Pd content of the catalyst, which was estimated by inductively coupled plasma atomic emission spectrometry (ICP-AES), was 1.14 mmol g−1 (the yield of Pd loading is about 49%).

General procedure for Ullmann coupling reaction

A mixture of iodobenzene (3 mmol), K2CO3 (4.5 mmol), and catalyst (0.12 g, Pd–PVP/MCM-48) in DMF (5 mL) was stirred at 100 °C for appropriate time (Scheme 2). The reaction progress was checked by TLC using hexane or hexane/AcOEt (4:1) as eluent. The reaction mixture was cooled to room temperature. After extraction with water and diethyl ether, the combined organic layer was dried over MgSO4 and solvent was removed under reduced pressure. The crude product was purified by flash column chromatography (hexane or hexane/EtOAc) to afford the desired coupling product. The final product was identified with 1H NMR, 13C NMR, and FT-IR spectroscopic techniques.

Results and discussion

Figure 1 shows the powder X-ray diffraction patterns of silica MCM-48 (a), PVP/MCM-48 (b), and Pd–PVP/MCM-48 (c). All samples exhibit a strong (211) diffraction peak at ~ 2.35° (Pedernera et al. 2009; Bandyopadhyay and Gies 2005).

The characteristic reflections of a well-ordered cubic structure are present in all cases, and this indicates that polymerization and Pd immobilization have no adverse effects on the ordered structure of MCM-48. However, the intensity of the characteristic reflection peaks of the PVP/MCM-48 and Pd–PVP/MCM-48 (2θ = 0.7–10) samples is reduced (Fig. 1) to some extent. In fact, composites have much less MCM-48 because of the dilution of the silicious material by PVP and Pd. This dilution can be the reason for the decrease in the peak intensity. Figure 1 illustrates the wide-angle XRD pattern of the Pd–PVP/MCM-48 nanocomposite (2θ = 10–85), too. Four diffraction peaks in the XRD pattern at 39.92°, 46.54°, 67.90°, and 81.84° are (111), (200), (220), and (311) diffractions of the Pd fcc lattice, respectively (Wang et al. 2008).

Figure 2 presents the FT-IR spectra of MCM-48 (a), PVP/MCM-48 (b), and Pd–PVP/MCM-48 (c). Just like mesoporous silica MCM-48 (Fig. 2a), PVP/MCM-48 and Pd–PVP/MCM-48 samples show the typical vibrations of symmetric and asymmetric stretching in addition to the rocking of Si–O–Si at around 1075, 800, and 460 cm−1 (Fig. 2).

The band at around 950 cm−1 is attributed to Si–OH vibrations of the surface silanols (Fig. 2), which is characteristic of mesoporous silica. The typical PVP vibration in the FT-IR spectrum (Fig. 2b) shows the presence of PVP in the PVP/MCM-48 composite. In the FT-IR spectrum of PVP/MCM-48 (Fig. 2b), the new band at 1661 cm−1 is related to the carbonyl group of PVP [23]. Furthermore, the bands at 2800–3000 cm−1 are related to the aliphatic C–H stretching in PVP/MCM-48 (Fig. 2b).

The band around 1654 cm−1 corresponding to carbonyl bond of PVP is shifted to lower wave number (1654 cm−1, red shift) as shown in Pd–PVP/MCM-48 spectrum (Fig. 2c). This may be resulted from the interaction between the Pd nanoparticles and C=O groups, meaning that the C=O stretching vibration becomes weaker by being coordinated to Pd nanoparticles (Iwamoto et al. 2009; Metin and Zkar 2008).

The BET specific surface areas and the pore size, the host MCM-48, PVP/MCM-48, and Pd–PVP/MCM-48 had already been calculated by employing the Brunauer–Emmett–Teller (BET) and Barrett–Joyner–Halenda (BJH) methods, respectively (Table 1). After hybridization of MCM-48 with PVP through in situ polymerization, PVP/MCM-48 shows a smaller specific area, pore size, and pore volume in comparison with those of pure MCM-48, and this might be resulted from the presence of polymer on the surface of the MCM-48 (Table 1 and Fig. 3).

The UV–Vis spectra of Pd(OAc)2 reveal a peak at 400 nm, indicating the existence of Pd(II) (Ahmadian-Namini et al. 2007), but UV–Vis spectra of Pd–PVP/MCM-48 showed no characteristic peak in this region, indicating complete reduction of Pd(II)–Pd nanoparticles.

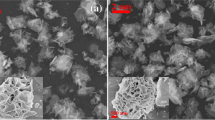

The SEM images of the MCM-48 (a), PVP/MCM-48 (b), and Pd–PVP/MCM-48 (c) are shown in Fig. 4. Obviously, no change is observed on the morphology of MCM-48 after hybridization with poly(N-vinyl-2-pyrrolidone) and palladium nanoparticles (Fig. 4b, c). This can be attributed to the polymerization and incorporation of PVP and Pd nanoparticles inside the pores of MCM-48.

The XPS study was carried out on the Pd–PVP/MCM-48 catalyst (Fig. 5a). In comparison with the standard binding energy [Pd0 with Pd 3d5/2 of about 335 eV and Pd 3d3/2 of about 340 eV (Teranishi and Miyake 1998)], we can conclude that the Pd peaks in Pd–PVP/MCM-48 shifted to lower binding energy than Pd0 standard binding energy.

The position of Pd 3d peak is usually influenced by the local chemical/physical environment around Pd species in addition to the formal oxidation state, and shifts to lower binding energy with an increase in the charge density around it (Teranishi and Miyake 1998).

Therefore, the peaks at 333.8 and 339.1 eV should be resulted from Pd0 species bounded directly to oxygen atom of the carbonyl group of PVP. The full XPS spectrum of Pd–PVP/MCM-48 showed peaks of carbon, oxygen, Si, and palladium. Carbon peaks were related to PVP structure (Fig. 5b).

Catalytic activity

In the beginning, we conducted the coupling reaction of iodobenzene (3 mmol) in the presence of Pd–PVP/MCM-48 as catalyst and K2CO3 (4.5 mmol) as base in DMF. The mixture was stirred under nitrogen atmosphere at 100 °C for 12 h, and the desired product (biphenyl) was obtained in 90% yield. Because the proper combination of base and solvent is very important, several different solvents and bases were examined for the Ullmann cross-coupling reaction.

The effects of base on homocoupling reactions were studied. Indeed, the base is necessary for terminal reduction, and the catalytic cycle is not completed without it. According to the results, K2CO3 was selected as an inorganic and cheaper base (Table 2). This feature may be interpreted by the fact that in the presence of an inorganic base, DMF decomposes into carbon monoxide and dimethylamine. The latter could reduce aryl halides in the presence of Pd(0) catalysts (Zawisza and Muzart 2007). Moreover, in the presence of K2CO3, higher selectivity toward biphenyl was achieved (5% benzene was produced). In the presence of Na3PO4 and Et3N, 17 and 12% benzene was obtained, respectively. It means that the selectivity toward biphenyl is lower in the presence of these bases.

In the next stage, the effect of the solvent was investigated. As shown in Table 3, the reaction rate is greatly affected by the kind of solvent used. Among the commonly used organic solvents, the best results were obtained with DMF (Table 3). The choice of DMF is favored also by the fact that DMF is soluble in water, which facilitates product isolation. In case of ethanol and water, the selectivity toward biphenyl was lower which 23 and 31% benzene as byproduct was obtained, respectively. The yield of benzene as byproduct in the presence of other solvents was about 5% which means that the selectivity is higher in these cases.

The effect of temperature was finally examined, and it was found that the reaction temperature has a significant effect. The results showed that the yield and the rate of the reaction are relatively low below 100 °C. It should be mentioned that the selectivity toward biphenyl abruptly decreased when the reaction temperature increased from 100 to 120 °C (the same results were reported by Li , Chai et al.). Actually, at higher temperatures, Pd leaching is increased to some extent and hydrodehalogenation may be catalyzed by leached Pd atoms. Therefore, 100 °C was chosen as an optimal condition.

Other important issues concerning the application of a heterogeneous catalyst are its reusability and stability under reaction conditions. Catalyst recycling experiments were carried out using an Ullmann reaction of iodobenzene, and the results are shown in Table 4. After each cycle, the catalyst was filtered off, washed with water (10 mL), diethyl ether and acetone (3 × 5 mL). Then, it was dried in an oven at 60 °C and was reused in the Ullmann reaction. The results show that there was very low Pd leaching during the reaction (only about 3.5%) and the catalyst exhibited high stability even after six recycles (Table 4). However, the selectivity toward biphenyl was constant even after 6 cycles of the reaction.

It should be mentioned that the catalyst consists of mesoporous silica and polymer parts, which both parts contribute stabilizing the palladium nanoparticles and preventing aggregate formation. The mesoporous structure of MCM-48 prevents uncontrolled growth of palladium nanoparticles and make the size of nanoparticles be small which cause enhancing in catalytic activity. In addition, simultaneous presence of polymer and mesoporous silica decreases palladium leaching. Thus, the stability and reusability of the catalyst get increase and this is an important advantage in compared to catalysts which palladium nanoparticles are fixed on polymeric substrate or supported in mesoporous cavities.

The general applicability of Pd–PVP/MCM-48 as catalyst was explored with different arylhalids containing electron-withdrawing or electron-donating substituents in the Ullmann homocoupling reaction (Table 5) using the optimized reaction conditions.

The reactions were carried out in DMF at 100 °C, and coupling reactions with aryl bromides (Entries 5 and 6) proceeded with good yields. Activation of C–Cl bond is more difficult than C–Br and C–I bonds, and generally requires harsher reaction conditions in heterogeneous catalysis systems. As shown in Table 5, chlorobenzene was converted to biphenyl in 55% yield. However, the yield of the reaction at 130 °C was 95%. Thus, the catalyst afforded reasonable yields of biaryl products. In addition, the selectivity toward biaryl products was high and the yield of benzene as byproduct was lower than 10%.

A comparative study was conducted for the use of Pd–PVP/MCM-48 with some of the reported catalysts for Ullmann reaction with respect to the catalyst, aryl halide, solvent, base, reaction time, yield and selectivity of the products (Table 6). The results clearly show that Pd–PVP/MCM-48 promotes the reaction reasonably in a good yield and high selectivity. Moreover, Pd–PVP/MCM-48 can be effectively used for the Ullmann reaction of chloro and bromo benzene.

Conclusions

In summary, a novel polymer–inorganic hybrid material, Pd nanoparticle–PVP/MCM-48, was prepared by a simple method. The catalytic activity of this novel organic–inorganic hybrid was good for Ullmann cross-coupling reaction of aryl bromide, chloride, and iodides at 100 °C. This new heterogeneous catalyst can practically replace soluble catalysts in view of the following advantages: (a) high catalytic activity under relatively mild reaction conditions; (b) easy separation of the catalyst after the reaction; and (c) reusability of the catalyst for several times without significant loss in the yield of the reaction. Moreover, with regard to environmental concerns, the synthetic method reported here may be considered as an environment-friendly process.

References

Ahmadian-Namini P, Babaluo AA, Bayati B (2007) Palladium nanoparticles synthesis using polymeric matrix: poly(ethyleneglycol) molecular weight and palladium concentration effects. Int J Nanosci Nanotechnol 3:37–44

Alves MH, Riondel A, Paul JM, Birot M, Deleuze H (2010) Polymer-supported titanate as catalyst for the transesterification of acrylic monomers. C R Chim 13:1301–1307. https://doi.org/10.1016/j.crci.2009.12.001

Anbarasan P, Schareina T, Beller M (2011) Recent developments and perspectives in palladium-catalyzed cyanation of aryl halides: synthesis of benzonitriles. Chem Soc Rev 40:5049–5067. https://doi.org/10.1039/C1CS15004A

Bandyopadhyay M, Gies H (2005) Synthesis of MCM-48 by microwave-hydrothermal process. C R Chim 8:621–626. https://doi.org/10.1016/j.crci.2005.01.009

Dhital RN, Kamonsatikul C, Somsook E, Bobuatong K, Ehara M, Karanjit S, Sakurai H (2012) Low-temperature carbon–chlorine bond activation by bi-metallic gold/palladium alloy nanoclusters: an application to Ullmann coupling. J Am Chem Soc 134:20250. https://doi.org/10.1021/ja309606k

Fu GC (2008) The development of versatile methods for palladium-catalyzed coupling reactions of aryl electrophiles through the use of P(t-Bu)3 and PCy3 as ligands. Acc Chem Res 41:1555–1564. https://doi.org/10.1021/ar800148f

Iwamoto T, Matsumoto K, Matsushita T, Inokuchi M, Toshima N (2009) Direct synthesis and characterizations of fct-structured FePt nanoparticles using poly(N-vinyl-2-pyrrolidone) as a protecting agent. J Colloid Interface Sci 336:879–888. https://doi.org/10.1016/j.jcis.2009.03.083

Kalbasi RJ, Mosaddegh N (2011) Synthesis and characterization of poly(4-vinylpyridine)/MCM-48 catalyst for one-pot synthesis of substituted 4H-chromenes. Catal Commun 12:1231–1237. https://doi.org/10.1016/j.catcom.2011.04.004

Kantchev EAB, O’Brien CJ, Organ MG (2007) Palladium complexes of N-heterocyclic carbenes as catalysts for cross-coupling reactions—a synthetic chemist’s perspective. Angew. Chem. Int Ed 46:2768–2813. https://doi.org/10.1002/anie.200601663

Li H, Chai W, Zhang F, Chen J (2007) Water-medium Ullmann reaction over a highly active and selective Pd/Ph-SBA-15 catalyst. Green Chem 9:1223–1228. https://doi.org/10.1039/b706360a

Li H, Zhu Z, Li H, Li P, Zhou X (2010) Recyclable hollow Pd–Fe nanospheric catalyst for Sonogashira-, Heck-, and Ullmann-type coupling reactions of aryl halide in aqueous media. J Colloid Interface Sci 349:613–619. https://doi.org/10.1016/j.jcis.2010.06.009

Ma ZH, Han HB, Zhoua ZB, Nie J (2009) SBA-15-supported poly(4-styrenesulfonyl(perfluorobutylsulfonyl)imide) as heterogeneous Brønsted acid catalyst for synthesis of diindolylmethane derivatives. J Mol Catal A Chem 311:46–53. https://doi.org/10.1016/j.molcata.2009.06.021

Mark JE (2006) Some novel polymeric nanocomposites. Acc Chem Res 39:881–888. https://doi.org/10.1021/ar040062k

Metin O, Zkar SO (2008) Synthesis and characterization of poly(N-vinyl-2-pyrrolidone)-stabilized water-soluble nickel (0) nanoclusters as catalyst for hydrogen generation from the hydrolysis of sodium borohydride. J Mol Catal A Chem 295:39–46. https://doi.org/10.1016/j.molcata.2008.08.014

Molnar A (2011) Efficient, selective, and recyclable palladium catalysts in carbon–carbon coupling reactions. Chem Rev 111:2251–2320. https://doi.org/10.1021/cr100355b

Morales G, van Grieken R, Martin A, Martinez F (2010) Sulfonated polystyrene-modified mesoporous organosilicas for acid-catalyzed processes. Chem Eng J 161:388–396. https://doi.org/10.1016/j.cej.2010.01.035

Ostapenko N, Dovbeshko G, Kozlova N, Suto S, Watanabe A (2008) Conformation change of nanosized silicon-organic polymer oriented into ordered nanoporous silicas. Thin Solid Films 516:8944–8948. https://doi.org/10.1016/j.tsf.2007.11.069

Pedernera M, Iglesia OD, Mallada R, Lin Z, Rocha J, Coronas J, Santamaría J (2009) Preparation of stable MCM-48 tubular membranes. J Membr Sci 326:137–144. https://doi.org/10.1016/j.memsci.2008.09.050

Phan NT, Sluys SMVD, Jones CW (2006) On the nature of the active species in palladium catalyzed Mizoroki–Heck and Suzuki–Miyaura couplings—homogeneous or heterogeneous catalysis. Adv Synth Catal 348:609–679. https://doi.org/10.1002/adsc.200690005

Seganish WM, Mowery ME, Riggleman S, DeShong P (2005) Palladium-catalyzed homocoupling of aryl halides in the presence of fluoride. Tetrahedron 61:2117–2121. https://doi.org/10.1016/j.tet.2004.12.040

Taguchi A, Schuth F (2005) Ordered mesoporous materials in catalysis. Microporous Mesoporous Mater 77:1–45. https://doi.org/10.1016/j.micromeso.2004.06.030

Teranishi T, Miyake M (1998) Size control of palladium nanoparticles and their crystal structures. Chem Mater 10:594–600. https://doi.org/10.1021/cm9705808

Wan Y, Chen J, Zhang D, Li H (2006) Ullmann coupling reaction in aqueous conditions over the Ph-MCM-41 supported Pd catalyst. J Mol Catal A Chem 258:89–94. https://doi.org/10.1016/j.molcata.2006.05.018

Wang P, Wang Z, Li J, Bai Y (2008) Preparation, characterizations, and catalytic characteristics of Pd nanoparticles encapsulated in mesoporous silica. Microporous Mesoporous Mater 116:400–405. https://doi.org/10.1016/j.micromeso.2008.04.029

Wang LZ, Jiang L, Xu CC, Zhang JL (2012a) Influence of Cr-MCM-48 and Cr-KIT-6 matrixes synthesized in alkaline and acidic conditions to the visible-light driven photocatalytic performance of loaded TiO2. J Phys Chem C 116:16454–16460. https://doi.org/10.1021/jp302289e

Wang Z, Ci X, Dai H, Yin L, Shi H (2012b) One-step synthesis of highly active Ti-containing Cr-modified MCM-48 mesoporous material and the photocatalytic performance for decomposition of H2S under visible light. Appl Surf Sci 258:8258–8263. https://doi.org/10.1016/j.apsusc.2012.05.033

Wei F, Yang J, Gu FN, Gao L, Zhu JH (2010) Direct synthesis of high quality cubic Ia3d mesoporous material under organosilane assisted. Microporous Mesoporous Mater 130:266–273. https://doi.org/10.1016/j.micromeso.2009.11.019

Yin L, Liebscher J (2007) Carbon–carbon coupling reactions catalyzed by heterogeneous palladium catalysts. Chem Rev 107:133–173. https://doi.org/10.1021/cr0505674

Zawisza AM, Muzart J (2007) Pd-catalyzed reduction of aryl halides using dimethylformamide as the hydride source. Tetrahedron Lett 48:6738–6742. https://doi.org/10.1002/chin.200752067

Zheng J, Li G, Ma X, Wang Y, Wu G, Cheng Y (2008) Polyaniline–TiO2 nano-composite-based trimethylamine QCM sensor and its thermal behavior studies. Sens Actuators B 133:374–380. https://doi.org/10.1016/j.snb.2008.02.037

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mosaddegh, N., Yavari, I. Pd-poly(N-vinyl-2-pyrrolidone)/MCM-48 nanocomposite: a novel catalyst for the Ullmann reaction. Chem. Pap. 72, 2013–2021 (2018). https://doi.org/10.1007/s11696-018-0421-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-018-0421-y