Abstract

The article proposes new possibilities for the estimation of the maximum phosphate retention capacities (PRC) in blast furnace slags using their modeling. The amorphous blast furnace slag model (BFS–SG) and slag samples along the joining of the CaO:SiO2 = 1 and (CaO + MgO):SiO2 = 1 of the CaO–MgO–Al2O3–SiO2 phase diagram were prepared by the sol–gel method. The surface analysis of BFS–SG was performed and the results were compared with real BFS. Batch adsorption experiments were performed to evaluate the phosphate removal of slags. SEM analysis and Raman spectroscopy were used to identify phosphate adsorbed forms. Phosphate retention is realized by the surface reactions of hydration products resulting in a nanostructured Ca-hydroxyapatite. The acid–base properties of the model samples in the selected cross-sections were characterized by the values of the optical basicity. An excellent linear relation between the phosphorus retention capacity (PRC) and the optical basicity of the model samples was found, which allows an estimation of slag retention capacities and the forms of adsorbed phosphorus.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The worldwide massive usage of phosphates for fertilizers and household cleaning agents causes the gradual depletion of natural resources. At the same time, there is an increase of environmental burden, the accumulation of phosphates in waste waters, and the eutrophication of surface waters occurs. Among the variety of removal techniques, adsorption is very effective. Various materials have been widely tested for the removal of phosphate from waste water, e.g., half-burned dolomite (Mangwandi et al. 2014) and layered double hydroxides (Kostura et al. 2012). Existing agricultural and industrial wastes (e.g. metallurgical slags) are ideal to be used as sorbents. Blast furnace slag (BFS), representing the chemically and thermally converted tailings, components of limestone and iron ores, is one of the suitable sorbent materials. The chemical and mineralogical composition of the slag results from the phase diagram of the four-component system CaO–MgO–Al2O3–SiO2. The chemical composition of blast furnace slags depends on the composition of raw materials in charge and is within the range: SiO2 from 36 to 40%, Al2O3 from 5 to 7%, CaO from 34 to 42% or more, and MgO from 7 to 16% (Agyei et al. 2000; Sakadevan and Bavor 1998). The main mineralogical component in air-cooled blast furnace slag is melilite (a solid solution of gehlenite and akermanite) 2CaO·Al2O3·SiO2–2CaO·MgO·2SiO2. Furthermore, monticellite CaO·MgO·SiO2, merwinite 3CaO·MgO·2SiO2, rankinite 3CaO·2SiO2, dicalcium silicate 2CaO·SiO2, pseudo-wollastonite CaO·SiO2, and silicate glass may be present. Rapidly cooled slags, called granulated slags, are mainly used as an effective hydraulic additive to produce cement. Granulated blast furnace slag contains 99–100% of the glass.

Batch experiments (Oguz 2004), column experiments (Johansson 1999), and field studies (Johansson and Gustafsson 2000) have shown that BFS is capable of removing phosphate from aqueous solutions. Nevertheless, a number of mechanisms are involved in this process. Dominant retention mechanism is usually caused by various factors, such as the composition of a slag, the adsorption time (Yang et al. 2009), and the pH of the solution (Lee et al. 1997). In the study by Bhatnagar and Sillanpää (2010), it was observed that the dominant removal mechanism of phosphorus is physical sorption at pH <8, while at pH >10 it is the precipitation of Ca-phosphates. A vast majority of the articles deal with samples of real industrial slags, which partly differ in composition. This may be one reason, among many others, why tested BFS varies in its retention capacities, which are in the range from 2.1 mg(P) g−1 (Oguz 2004) to 44.2 mg(P) g−1 (Sakadevan and Bavor 1998). Currently, there is no methodology that would allow for an estimation of retention capacities with a defined slag composition. A linear relationship between the retention capacities of slags and the ANC3.8 values was found, (Kostura et al. 2005). This shows that the acid–base properties of slags play a key role in these retention processes.

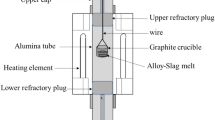

The preparation of exactly defined model samples is important for further research on slag retention capacities. The slag models are prepared by melting mixtures of appropriate oxides or carbonates at temperatures 1500–1600 °C (Hwa-Jun et al. 2015). Considerable energy demands and higher requirements on the equipment are common disadvantages of these methods. The melt is highly viscous, making it difficult to degas and produce perfectly homogeneous samples. On the contrary, the sol–gel method represents an alternative approach. This method is used especially for the preparation of glasses with various oxide contents. The following glass ceramics: CaO–B2O3–SiO2 (Wang et al. 2011), CaO–P2O5–SiO2 (Catauro et al. 2015), SiO2–CaO–MgO–P2O5 (Ma et al. 2010) or SiO2–Al2O3–CaO–CaF2 (Zolotar and Zavaglia 1999) is included. There are only few articles that deal only with CaO–Al2O3–SiO2 and CaO–MgO–Al2O3–SiO2 systems (Sales and Alarcon 1995; Fu and Lin 2003). The cross-sections of the phase diagram of the CaO–MgO–SiO2–Al2O3 system in the blast furnace slag region were not prepared by the latter mentioned method.

Our preliminary results for the preparation of model slags of the CaO–Al2O3–SiO2 system were published in Huczala et al. (2017). In this ternary system, a possible dependence between the optical basicity and the phosphate retention capacity of the prepared samples was shown. Therefore, there was a need to extend this system to quaternary, taking into account that the optical basicity of MgO is not clearly defined.

The objective of this work is to prepare BFS models of a defined composition by the sol–gel method as the cross-sections of the phase diagram of the CaO–MgO–Al2O3–SiO2 system. Furthermore, the study is designed to assess the effect of the slag compositions of acid–base properties on phosphate retention from aqueous solutions.

Experimental

Samples

A real blast furnace slag model (BFS–SG) and further several slag samples (SG-01–SG-05), along the joining of the CaO:SiO2 = 1 and (CaO + MgO):SiO2 = 1 of CaO–MgO–Al2O3–SiO2 phase diagram, were prepared by the sol–gel method, according to previously published work by Fu and Lin (2003). The formal oxide content of all slag model samples is shown in Table 1.

Corresponding hydrated nitrates were used as sources of CaO, MgO and Al2O3, as a source of SiO2 tetraethyl orthosilicate (TEOS). All chemicals used were of p.a. purity. The metal salts were dissolved in demineralized water and TEOS in absolute alcohol. The TEOS solution was added while stirring in an aqueous solution of salt, the ratio of TEOS:ethanol:water 1:2.5:5. The solution was then stirred for 2 h at 250 rev min−1 at room temperature and subsequently evaporated in an oven at 80 °C for 24 h. The resulting gel was calcined for 4 h at a temperature of 700 °C. Grain sizes of the prepared samples were adjusted by grinding and sieving under 0.1 mm.

Static batch experiments

A series of suspensions containing 0.5 g of sorbent and 100 cm3 of phosphate solution (c = 100, 300, 500, 750, and 1000 mg(PO4) dm−3) were prepared for the evaluation of the theoretical retention capacity of the slag samples and construction of their adsorption isotherms. The suspensions were left unused for 72 h and were vigorously shaken once every 24 h. Then, the suspensions were filtered and the residual phosphorus contained in the filtrate was determined by means of spectrophotometry. The acquired data were analyzed using the Langmuir adsorption isotherm model. The theoretical retention capacities were calculated for all slag samples. The Langmuir isotherm was used in the following mathematical form:

where Q e (mg g−1) is the equilibrium retention capacity of phosphorus, c e (mg dm−3) is the equilibrium concentration of the adsorbed matter, a L (dm3 mg−1) is the Langmuir constant, and Q m (mg g−1) is the Langmuir retention maximum.

The essential characteristics of the Langmuir isotherm can be expressed in terms of dimensionless constant separation factor R L that is given by the following equation:

where c 0 is the highest initial concentration of adsorbate (mg dm−3). The R L values between 0 and 1 indicate favorable adsorption, while R L > 1 indicate an unfavorable adsorption process (Mangwandi et al. 2014).

Measuring techniques and apparatus

The specific surface area of BFS–SG and BFS was measured using the instrument Sorptomatic 1990 (ThermoFinnigan, Italy). Phosphate (as phosphorus) was determined spectrophotometrically as phosphomolybdenum blue on a UV spectrophotometer (UV-1800 Shimadzu, Japan). A Quanta FEG 450 (FEI) scanning electron microscope with EDS analysis APOLLO X (EDAX) was used as the microscopic method for morphology and the elemental characterization of the studied samples. The samples for SEM were coated with Au film to ensure their conductivity. A 180° sampling was used as the measurement technique of Raman spectroscopy. The Raman spectra were measured on a dispersive Raman spectrometer DXR SmartRaman (ThermoScientific, USA) with a CCD detector. The measurement parameters were as follows: excitation laser 780 nm, grating 400 lines mm−1, aperture 50 μm, exposure time 1 s, number of exposures 250, and spectral region 1400–400 cm−1. An empty sample compartment was used for background measurement. Treatment of spectra: fluorescence correction (6th order).

Results and discussion

Amorphous BFS–SG was prepared by the sol–gel method. Industrial amorphous blast furnace slag (BFS) tested in the study by Kostura et al. (2017) served as the pattern. The amorphous structure of the sample was confirmed by X-ray diffraction (Huczala et al. 2017). BFS–SG and BFS surface analysis were carried out and the results are summarized in Table 2.

The table presents that the slag model has a relatively large specific surface area, which contains a large amount of mesopores and micropores. The industrial BFS is not porous and has a considerably smaller free surface area. The BFS–SG surface structure arises from the differences in the method of preparation and, above all else, the temperature regime was subjected.

BFS–SG was tested as a sorbent of phosphates from the aqueous solution. Table 3 provides a comparison of the achieved results with those BFS.

The table shows that the retention of BFS–SG phosphates follows the same mechanism as in the case of BFS. The R L values between 0 and 1 indicate favorable adsorption. The value of Q m for BFS–SG, determined by the Langmuir adsorption isotherm, can be considered as the maximum PRC achieved by the slag of the same composition. The significant disparity between the size of the active surfaces and the retention capacity values of BFS and BFS–SG indicates that the phosphate retention is not realized by a physical, but a chemical pathway. The larger specific surface of BFS–SG improves the hydration availability of certain components, mainly CaO. A study by Tsuyuki and Koizumi (1999) found that the surface content of the glass-forming components is decreasing in the order CaO–SiO2 > Al2O3–SiO2 > SiO2. The ionic CaO–SiO2-type glass is more reactive than the covalent Al2O3–SiO2-type glass. This phenomenon is reflected in a greater retention capacity of the slag.

Identification of phosphate forms captured on the BFS–SG surface was based on SEM analysis and Raman spectroscopy. The SEM analysis of the BFS–SG surface before and after phosphate retention demonstrated phosphate precipitation. The particle size of the precipitate was around 0.2 m (Fig. 1a, b).

For the selected BFS–SG particle after phosphate retention (Fig. 2a), distribution maps of the basic elements (Ca, Mg, Al, and Si) were assembled and compared to the distribution of the captured phosphorus. A coincidence was found between the distribution of Ca and P, as shown in Fig. 2b, c.

Phosphorus is therefore bound in the form of a nanostructured Ca-phosphate. Raman’s spectroscopy was used to identify it (Fig. 3). The symmetric stretching mode of the tetrahedral phosphate ion in Ca-HAp appears as the band at 955 cm−1 in the Raman spectrum of the BFS–SG–P sample. The band at 433 cm−1 corresponds to the symmetric bending mode of the phosphate ion (Yamini et al. 2014). The presence of calcium silicates is discerned by two bands at 912 and 881 cm−1, corresponding to the symmetric stretching vibration modes (Potgieter-Vermaak et al. 2006). The band at 1086 cm−1 and a few distinct bands at 848, 820, and 708 cm−1 refer to carbonates according to Guerra-López et al. (2015).

The formation of Ca-HAp on the BFS–SG surface can be simplified by two Eqs. (3, 4):

Phosphate retention and subsequent Ca-HAp precipitation are thus closely related to the hydration processes on the slag surface. Phosphorus on the slag surface is thus probably bound in the form of the nanostructured Ca-HAp.

The amorphous slag models SG1 to SG5, selected along the junction CaO:SiO2 = 1 and samples SG6 to SG9 with respect to (CaO + MgO):SiO2 = 1, both belonging to the phase diagram of the CaO–MgO–Al2O3–SiO2 system, were prepared to assess the influence of their acid–base properties on the phosphate retention from aqueous solutions. The composition of all samples is shown in Table 1. Theoretical phosphorus retention capacities (PRC) were determined for all samples using the Langmuir adsorption isotherm (1).

It is well known that the basicity (B) is commonly used for the general characterization of the acid–base properties of metallurgical slags. For example, it can be calculated from the weight composition of slag (Tsuyuki and Koizumi 1999), according to the relation:

where w CaO, w MgO, \( w_{{{\text{Al}}_{2} {\text{O}}_{3} }} \) and \( w_{{{\text{SiO}}_{ 2} }} \) are mass fractions of the individual components in percentages. Basicity values for the model samples SG1–SG9 are given in Table 1. The relation between the B and the PRC values of the model slags was investigated (Fig. 4). It is apparent from the figure that no closer relationship exists between the two variables (R 2 = 0.391). Thus, the defined basicity of the slag does not allow for the estimation of its retention capabilities.

The quantitative scale of Lewis basicity, i.e., optical basicity Λ, is used for a more precise characterization of the acid–base properties of oxide melts and glass. The optical basicity concept is based on the direct spectroscopic measurements of the shift of frequency in the UV region of a selected absorption band of doping agents (Bi3+, Pb2+, and Tl+) caused by the electron donor environment of a glass made from the oxide system. This parameter is used in metallurgy to determine the phosphate capacity of slag for the phosphorus distribution between the molten oxide system and the metal (Young et al. 1992). This is a rather complicated expression because it is necessary to include also the oxidative capacity of the slag and temperature dependence, which Λ does not directly possess. Parameter Λ is defined by the relationship (6) for any glass without the necessity to include its oxidation capabilities and temperature dependence:

where n i is the number of oxygen atoms in the molecule, x i is the mole percentage, and Λ i is optical basicity of appropriate oxide (Guo-Hua and Kuo-Chih 2010), specifically Λ CaO = 1.00, Λ MgO = 0.78, Λ Al2O3 = 0.60, and Λ SiO2 = 0.48. This is the reason why we were looking for a relationship describing the distribution of phosphates between the glass surface (amorphous slag) and the ion solution. Table 1 summarizes the Λ values for the prepared samples SG1–SG9 and BFS–SG. By comparing Λ with the PRC values of model slags, an excellent linear dependence (R 2 = 0.9866) was obtained, as shown in Fig. 5.

As shown in Fig. 5, the linear relationship is valid for the points of both cross-sections and for BFS–SG (R 2 = 0.9663). This dependence can be expressed by the following equation:

Equation (7) allows the calculation of the theoretical retention capacity, which the slag of the composition and thus the particular optical basicity possess. It also follows from the above equation that if the slag optical basicity decreases below 0.584, phosphate precipitation will no longer occur on the slag surface. From Fig. 5, the actual retention capacity values of real BFS of a given optical basicity may differ from the theoretical PRC values considerably. This explains the substantial variance of the retention capacities published by various authors in slags of a similar composition. This begs the question, how to modify the industrial slag to maximize its retention capacity. A paper presented by Kostura et al. (2017) provides one possible solution. It is the disintegration of amorphous slag by an ultra-high-pressure water jet mill and subsequent controlled freeze drying of the obtained suspension. As shown in Fig. 5, the retention capacity (PRC = 30.49 mg(P) g−1) of the obtained disintegrated product BFS–D of the same composition as BFS has already been close to the theoretical value.

A measurement of Raman spectra was performed to verify the forms of adsorbed phosphate on the selected SG2, SG6, and SG9 samples after phosphate sorption. From their comparison (Fig. 6), it is clear that crystalline Ca-HAp (955–960 cm−1) precipitation does not occur in all model samples but is dependent on the Λ value, which is related to the amount of activated CaO in the slag. Amorphous Ca-phosphates are formed on sample SG9, which has the lowest Λ value. Nanostructured Ca-HAp arises only at samples with a higher Λ value, which occurs also at BFS–SG. It is also apparent from the spectra that the Ca-carbonate formation (a band at 1084 cm−1) increases with increasing optical basicity. This finding could also be important for BFS applications as a crude material for cement production.

Conclusions

The modeling of blast furnace slags by the sol–gel method has introduced new possibilities for estimating phosphate retention capacities. It was found that phosphate adsorption on the slag model (BFS–SG) is controlled by the same mechanisms as in the case of the real blast furnace slag (BFS) of the same composition. Phosphate retention is closely associated with the hydration of the slag. During this process, Ca2+ ions are released from the slag surface and react with phosphate ions to form a nanostructured Ca-HAp. Optical basicity Λ was used to characterize the acid–base properties of the slag models along the junctions CaO:SiO2 = 1 and (CaO + MgO):SiO2 = 1 of the CaO–MgO–Al2O3–SiO2 phase diagram. The dependence between the phosphate distribution in the surface of the amorphous slag and the ion solution was investigated. The result was the linear dependence between the retention capacities (PRC) of the slags and Λ, allowing the calculation of the theoretical retention capacity that the slag of the given optical basicity should possess. The Raman spectra of the selected slag model samples, after phosphate sorption, showed that the formation of Ca-HAp only occurs in slags with a higher Λ value. Thus, there is a higher content of activated CaO and simultaneously precipitation of competitive Ca-carbonate occurs.

Implications relating to the use of BFSs in practice

-

1.

Optical basicity of BFS in a glassy state can be calculated using the majority of CaO, MgO, Al2O3, and SiO2 components and their molar ratio. These slags are prepared by rapid cooling in the form of a so-called granulate.

-

2.

The maximum phosphate retention capacity (PRC) of BFS can be calculated from the Λ values.

-

3.

The usefulness of other mechanical or the chemical treatment of slag can be assessed from the laboratory results of phosphate retention and from a maximum PRC.

-

4.

The level of precipitation of Ca-HAp, as well as competitive Ca-carbonate, can be estimated using Raman spectroscopy.

Abbreviations

- Q e :

-

Equilibrium amounts of P (mg g−1)

- c e :

-

Equilibrium concentration (mg dm−3)

- Q m :

-

Langmuir retention maximum (mg g−1)

- a L :

-

Langmuir constant (dm3 mg−1)

- R L :

-

Separation factor

- c 0 :

-

Initial concentration of adsorbate (mg dm−3)

- V meso :

-

Mesopore volume (cm3 g−1)

- V micro :

-

Volume of micropores (cm3 g−1)

- w i :

-

Mass fraction (%)

- PRC:

-

Phosphorus retention capacity (mg g−1)

- Λ :

-

Optical basicity

- BFS:

-

Blast furnace slag

- SG:

-

Amorphous slag model prepared by the sol–gel method

- B:

-

Basicity

References

Agyei MN, Strydom CA, Potgieter JH (2000) An investigation of phosphate ion adsorption from aqueous solution by fly ash and slag. Cem Concr Res 30:823–826. doi:10.1016/S0008-8846(00)00225-8

Bhatnagar A, Sillanpää M (2010) Utilization of agro-industrial and municipal waste materials as potential adsorbents for water treatment-A review. Chem Eng J 157:277–296. doi:10.1016/j.cej.2010.01.007

Catauro M, Bollino F, Renella RA, Papale F (2015) Sol–gel synthesis of SiO2–CaO–P2O5 glasses: influence of the heat treatment on their bioactivity and biocompatibility. Ceram Int 41:12578–12588. doi:10.1016/j.ceramint.2015.06.075

Fu YP, Lin CH (2003) Synthesis and microwave characterization of 2(MgO, CaO)-2 Al2O3-5 SiO2 glass ceramic from the sol–gel proces. J Mater Sci 38:3081–3084

Guerra-López JR, Echeverría GA, Güida JA, Viña R, Punte G (2015) Synthetic hydroxyapatites doped with Zn(II) studied by X-ray diffraction, infrared, Raman and thermal analysis. J Phys Chem Solids 81:57–65. doi:10.1016/j.jpcs.2015.01.017

Guo-Hua Zhang, Kuo-Chih Chou (2010) Model for evaluating density of molten slag with optical basicity. J Iron Steel Res Int 17(4):1–4. doi:10.1016/S1006-706X(10)60077-5

Huczala R, Kostura B, Matýsek D (2017) Study of phosphate retention on model of amorphous blast furnace slags. Hut listy (Metallurgical J) 2:28–32

Hwa-Jun L, Sang-Woo K, Sung-Soo R (2015) Sintering behavior of aluminum nitride ceramics with MgO–CaO–Al2O3–SiO2 glass additive. Int J Refract Met Hard 53:46–50. doi:10.1016/j.jrmhm.2015.04.013

Johansson L (1999) Blast furnace slag as phosphorus sorbents—column studies. Sci Total Environ 229:89–97

Johansson L, Gustafsson JP (2000) Phosphate removal using blast furnace slags and opoka—mechanisms. Water Res 34:259–265. doi:10.1016/S0043-1354(99)00135-9

Kostura B, Kulveitová H, Leško J (2005) Blast furnace slags as sorbents of phosphate from water solutions. Water Res 39:1795–1802. doi:10.1016/j.watres.2005.03.010

Kostura B, Matýsek D, Kukutschová J, Leško J (2012) Phosphate interaction with calcined form of Mg–Al–CO3 hydrotalcite in aqueous solutions. Ann Chim Sci Mat 37(1):11–20. doi:10.3166/acsm.37.11-20

Kostura B, Dvorský R, Kukutschová J, Študentová S, Bednář J, Mančík P (2017) Preparation of the sorbent with a high active sorption surface based on blast furnace slag for phosphate removal from wastewater. Environ Prot Eng 43:161–168. doi:10.5277/epe170113

Lee SH, Vigneswaran S, Chung Y (1997) A detailed investigation of phosphorus removal in soil and slag media. Environ Technol 18(7):699–709. doi:10.1080/09593331808616588

Ma J, Chen CZ, Wang DG, Jiao Y, Shi JZ (2010) Effect of magnesia on the degradability and bioactivity of sol–gel derived SiO2–CaO–MgO–P2O5 system glasses. Colloid Surf B 81:87–95. doi:10.1016/j.colsurfb.2010.06.022

Mangwandi C, Albadarin AB, Gloucheux Y, Walker GM (2014) Removal of ortho-phosphate from aqueous solution by adsorption onto dolomite. J Environ Chem Eng 2:1123–1130. doi:10.1016/j.jece.2014.04.010

Oguz E (2004) Removal of phosphate from aqueous solution with blast furnace slag. J Hazard Mater B114:131–137. doi:10.1016/j.jhazmat.2004.07.010

Potgieter-Vermaak SS, Potgieter JH, Belleil M, DeWeerdt F, Van Grieken R (2006) The application of Raman spectrometry to the investigation of cement part II: a micro-Raman study of OPC, slag and fly ash. Cem Concr Res 36:663–670. doi:10.1016/j.cemconres.2005.09.010

Sakadevan K, Bavor HJ (1998) Phosphate adsorption characteristics of soils, slags and zeolite to be used as substrates in constructed wetland systems. Water Res 32:393–399. doi:10.1016/S0043-1354(97)00271-6

Sales M, Alarcon J (1995) Crystallization of sol–gel derived glass ceramic powders in the CaO–MgO–Al2O3–SiO2 systém, part II. J Mater Sci 30:2341–2347

Tsuyuki N, Koizumi K (1999) Granularity and surface structure of ground granulated blast-furnace slags. J Am Ceram Soc 82(8):2188–2192

Wang M, Zuo R, Jin J, Su S, Zhai J (2011) Investigation of the structure evolution process in sol–gel derived CaO–B2O3–SiO2 glass ceramics. J Non-Cryst Solids 357:1160–1163. doi:10.1016/j.jnoncrysol.2010.11.028

Yamini D, Devanand Venkatasubbu G, Kumar J, Ramakrishnan V (2014) Raman scattering studies on PEG functionalized hydroxyapatite nanoparticles. Spectrochim Acta A 117:299–303. doi:10.1016/j.saa.2013.07.064

Yang J, Wang S, Lu Z, Lou S (2009) Converter slag-coal cinder columns for the removal of phosphorous and other pollutants. J Hazard Mater 168:331–337. doi:10.1016/j.jhazmat.2009.02.024

Young RW, Duffy JA, Hassall GJ, Xu Z (1992) Use of optical basicity concept for determining phosphorus and sulphur slag-metal partitions. Ironmak Steelmak 19:201–219

Zolotar MS, Zavaglia CA (1999) Study of the sol–gel processing of glass-ceramic powders in the SiO2–Al2O3–CaO–CaF2 systém. I. Effect of powder composition on gel time and temperature. J Non-Cryst Solids 247:50–57. doi:10.1016/s0022-3093(99)00032-0

Acknowledgements

The research is supported by the projects SP2016/77 and SP2017/50. The authors would like to thank Dr. K. Dědková from Centrum for Nanotechnology, VSB-TU Ostrava, for measuring SEM-analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kostura, B., Huczala, R., Ritz, M. et al. Retention of phosphates from aqueous solutions with in sol–gel-derived amorphous CaO–MgO–Al2O3–SiO2 system as a model of blast furnace slag. Chem. Pap. 72, 401–408 (2018). https://doi.org/10.1007/s11696-017-0289-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-017-0289-2