Abstract

In this report, a combination of the diffusion multiple technique and the recently developed pragmatic numerical inverse method was employed for a high-throughput determination of interdiffusivity matrices in Co-Cr-FeMn-Ni high-entropy alloys (HEAs). Firstly, one face-centered cubic (fcc) quinary Co-Cr-Fe-Mn-Ni diffusion multiple at 1373 K was carefully prepared by means of the hot-pressing technique. Based on the composition profiles measured by the field emission electron probe micro analysis (FE-EPMA), the composition-dependent interdiffusivity matrices in quinary Co-Cr-Fe-Mn-Ni system at 1373 K were then efficiently determined using the pragmatic numerical inverse method. The determined interdiffusivities show good agreement with the limited results available in the literature. Moreover, the further comparison with the interdiffusivities in the lower-order systems indicates the sluggish diffusion effect in Co-Cr-Fe-Mn-Ni HEAs, which is however not observed in tracer diffusivities. In order for the convenience in further analysis, a generalized transformation relation among interdiffusivities with different dependent components in multicomponent systems was finally derived.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Due to their unique multiprincipal element compositions and excellent properties, high-entropy alloys (HEAs) have gained more and more attentions in the material science community nowadays.[1,2,3] Co-Cr-Fe-Mn-Ni alloys with a single-phase face-centered cubic (fcc) solid solution are one of the representative HEAs which are widely investigated from the aspects of the lattice structures, thermodynamics, kinetics and mechanics properties.[4,5,6] It should be noted that the diffusion kinetics including diffusion-controlled phase transformation in HEAs are slower than those in conventional alloys, which is named as “sluggish diffusion”. The sluggish diffusion effect in HEAs can affect the microstructure evolution during preparation process, and finally the properties of the materials.[4] In order to utilize the sluggish diffusion effect to design the high-performance HEAs, a comprehensive understanding of such sluggish diffusion effect is the prerequisite, which is however hampered due to lack of adequate diffusivity information currently.[4,7] Thus, there is an urgent need to remedy this situation.

Single-phase diffusion couple technique is the most frequently used method to determine the interdiffusivities in the liquid and solid states.[8,9] In a binary system, the composition-dependent interdiffusivities over the investigated composition range can be obtained from the traditional Boltzmann-Matano method or its variations. While in a ternary or N-order system, the situation becomes dramatically complex because four or (N − 1)2 independent interdiffusivities should be figured out at any composition point. To obtain the multicomponent interdiffusivity matrix at one fixed point with the aid of the Matano-Kirkaldy method, two or (N − 1) diffusion couples with a common point along their diffusion paths should be carefully designed, which is extremely difficult in high-order systems.

Very recently, the present authors proposed a pragmatic numerical inverse method for the reliable composition-dependent interdiffusivities by using a single diffusion couple.[10,11] Up to now, the pragmatic numerical inverse method has been successfully applied in different binary, ternary and multicomponent alloys.[10,11,12,13,14] In addition, Zhao[15,16,17,18] developed the concept of diffusion multiple from the diffusion couple technique. With an efficiency order of magnitude much higher than that of conventional diffusion couple technique, a number of composition profiles can be mapped in one diffusion multiple at one temperature.

The major purpose of the present work is to investigate the composition-dependent interdiffusivities in fcc quinary Co-Cr-Fe-Mn-Ni alloys by using the combination of the pragmatic numerical inverse method and the advanced diffusion multiple technique. Consequently, a solid diffusion multiple of fcc Co-Cr-Fe-Mn-Ni system at 1373 K was experimentally prepared by using the hot-pressing technique, from which a series of composition profiles can be measured. After that, the corresponding multicomponent interdiffusivities can be then efficiently determined by the pragmatic numerical inverse method[10,11] and comprehensively compared with the literature data.[4,19,20,21,22,23,24]

2 Experimental Procedure

Cobalt (purity: 99.95 wt.%) and nickel (purity: 99.5 wt.%) foils, iron (purity: 99.98 wt.%) and manganese (purity: 99.98 wt.%) granules and chromium (purity: 99.997 wt.%) pieces purchased from Alfa Aesar (China) Chemicals Co., Ltd. were used as starting materials. The alloys in quinary Co-Cr-Fe-Mn-Ni system were prepared by arc melting under an Ar atmosphere using a non-reactive Welectrode (WKDHL-1, Opto-electronics Co., Ltd., Beijing, China). The buttons were re-melted for at least five times to improve their homogeneities. No chemical analysis for the alloys was conducted since the weight loss of each alloy was less than 0.5 wt.% during arc-melting. The buttons were linearly cut into blocks with the size of 5 × 5 × 5 mm3. These blocks ground by SiC papers were sealed into an evacuated quartz tube, and then homogenized at 1373 ± 2 K for 14 days. After being polished, a diffusion multiple of fcc Co-Cr-Fe-Mn-Ni system was carefully prepared by hot-pressing at 1373 ± 2 K for 4 h in a self-assembly vacuum hot-pressing apparatus. The well-prepared Co-Cr-Fe-Mn-Ni diffusion multiple was then sealed into an evacuated quartz tubes, and annealed at 1373 ± 2 K for 116 h. The effective diffusion time for diffusion multiple should be the sum of the time during the period of hot-pressing and vacuum annealing, and thus the diffusion time of Co-Cr-Fe-Mn-Ni diffusion multiple should be 120 h. After standard metallographic treatment, the composition profiles of each diffusion multiple were determined by using field emission electron probe micro analysis (FE-EPMA, JXA-8530, JEOL, Japan) with an accelerating voltage of 15 kV. Here, variations in alloy compositions were determined to be within ±0.5 at.% for each component.

3 Calculation Method for Multicomponent Interdiffusivity Matrix

A pragmatic numerical inverse method for determining the composition-dependent interdiffusivities in binary and multicomponent systems from a single diffusion couple was proposed by the present authors[10,11] based on Fick’s second law. The composition evolution of component i in N-component systems can be governed by Fick’s second law,

where c i is composition of component i, x is diffusion distance, t is diffusion time, \(\tilde{D}_{ij}^{N}\) is either main or cross interdiffusivity with component N chosen as the solvent. The multicomponent interdiffusivities \(\tilde{D}\) and the atomic mobility M i are related by,[25,26]

where R is the gas constant, and T is absolute temperature. The second term on the right-hand side denotes the vacancy-wind effect, and its contribution is determined by the parameter s (i.e., equals either 0 or 1). The parameter A 0 is a factor depending only on crystal structure.[25] The thermodynamic factor \(\varPhi\) is expressed by,

where the chemical potential μ i can be obtained from the corresponding thermodynamic descriptions. It should bear in mind that whether the thermodynamic description is accurate or not has negligible effect on the quality of the finally obtained interdiffusivities.[11] Here, the ideal solution model was adopted to describe fcc phase in Co-Cr-Fe-Mn-Ni system. In order to assign more physical meanings, the mobility for element i is given by,

where ΔG j i , ΔG j,k i and ΔG j,k,l i are the end-members and interaction parameters for diffusion of element i in element j and in the binary and ternary systems, respectively. As stated above, the parameter ΔG j i can be fixed first according to the experimental data and theoretical values. In this work, the end-members can be directly fixed by using the assessed values.[27] The adjustable parameter, ΔG j,k i and ΔG j,k,l i , need to be evaluated on the basis of one or several sets of composition profiles. By combining Eq 1-4, the composition profiles of component i can be simulated. An optimal set of adjustable parameters such as ΔG j,k i and ΔG j,k,l i were carefully chosen by iterative fitting until the minimization of the error between the measured and the calculated composition and interdiffusion flux profiles is achieved,

where \(c_{ij}^{\text{cal}}\), \(\tilde{J}_{ij}^{\text{cal}}\), \(c_{ij}^{ \exp }\) and \(\tilde{J}_{ij}^{ \exp }\) are the calculated and the experimental composition and interdiffusion flux of component i at the jth point, respectively, and Num is the number of the experimental data. As demonstrated in Ref 11, the more sensitive interdiffusion flux needs to be included as the minimization criteria. In addition, the weights of composition and interdiffusion flux in the minimization are determined by the divergence of the experimental data. With the optimal set of fitting parameters, the composition profiles can be nicely reproduced, and the composition-dependent interdiffusivites in the target system can be computed via Eq 1-4. Moreover, the interdiffusion flux \(\tilde{J}\) at any location x′ for diffusion couples based on a laboratory frame of reference can be calculated directly from the normalized composition profile,[28]

where c L and c R are the composition normalized variables at the far left end (x L) and far right end (x R) of the diffusion couple, respectively. A composition ratio Y at the distance coordinate x′ is defined by,

The standard deviation (SD) for the pragmatic numerical inverse method can be evaluated by using the scientific statistical method.[29,30]

4 Results and Discussion

Figure 1 shows the schematic diagram of the solid diffusion multiple prepared in the present work. The composition profiles can be experimentally measured along the specific direction of the diffusion multiple as shown in Fig. 1. Considering its high efficiency in determination of composition-dependent interdiffusivities in target alloys, the pragmatic numerical inverse method[10,11] was directly utilized here. Table 1 lists the adjustable parameters of Co, Cr, Fe, Mn and Ni in fcc Co-Cr-Fe-Mn-Ni HEAs at 1373 K in the present work.

Figure 2 illustrates the measured composition profiles and the simulated results for the Co-Cr-Fe-Mn-Ni diffusion multiple after annealing at 1373 K for 120 h. The corresponding quinary main interdiffusivities in the Co-Cr-Fe-Mn-Ni HEAs at 1373 K are determined by the pragmatic numerical inverse method and shown in Fig. 2. In addition, the quinary cross interdiffusivities are provided in the Electronic Supplementary Materials in order to make a clear demonstration in Fig. 2. The average relative uncertainty of the present results determined by using the numerical inverse method is 37%, which is determined by the average error between the simulated compositions and the experimental data along all the diffusion paths. The good agreement between the simulated composition profiles and the measured ones indicates that the composition-dependent quinary interdiffusivities in Co-Cr-Fe-Mn-Ni system at 1373 K are reasonable. It can be clearly seen that the main interdiffusivity \(\tilde{D}_{\text{MnMn}}^{\text{Ni}}\) is the largest while the main interdiffusivity \(\tilde{D}_{\text{CrCr}}^{\text{Ni}}\) is larger than \(\tilde{D}_{\text{FeFe}}^{\text{Ni}}\), which is similar to the previous quasi-binary results.[4] In addition, the main interdiffusivities \(\tilde{D}_{\text{CoCo}}^{\text{Ni}}\) are the lowest over the most composition ranges, while the main interdiffusivities \(\tilde{D}_{\text{CoCo}}^{\text{Ni}}\) over the specific composition range are slightly larger than those of \(\tilde{D}_{\text{CrCr}}^{\text{Ni}}\) and \(\tilde{D}_{\text{FeFe}}^{\text{Ni}}\), indicating that the interdiffusivities are composition-dependent data rather than the constant value. Therefore, the fast diffusion phenomenon may exist in specific composition areas of the HEAs, which has also been observed in an Al0.5CrFeCoNiCu HEA.[31] It is noted that the present main interdiffusivities \(\tilde{D}_{\text{FeFe}}^{\text{Ni}}\)(0.98–1.98 × 10−15 m2/s) at 1373 K are close to the corresponding average interdiffusivity with the component Ni dependent (1.06 × 10−15 m2/s) in quaternary Co-Cr-Fe-Ni alloy at 1273 K,[19] indicating the exact existence of the sluggish diffusion kinetics in Co-Cr-Fe-Mn-Ni HEAs.

(color on web) Composition profiles and the corresponding main interdiffusivities for the Co23.95Cr23.3Fe23Mn6.66Ni23.09/Co22.4Cr27Fe17.5Mn7.5Ni25.6/Co10.8Cr22.8Fe33.4Mn10.8Ni22.2/Co33.3Cr22.4Fe16.2Mn6.65Ni21.45/Co23.95Cr23.3Fe23Mn6.66Ni23.09 (at.%) diffusion multiple after annealing at 1373 K for 120 h. Symbols designate the results from the present experimental measurements while solid lines are the model-predicted composition profiles and main interdiffusivities obtained by using the pragmatic numerical inverse method

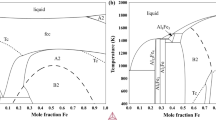

Figure 3 shows the main interdiffusivities \(\tilde{D}_{\text{CoCo}}^{\text{Ni}}\) and \(\tilde{D}_{\text{FeFe}}^{\text{Ni}}\) in quinary Co23.95Cr23.3Fe23Mn6.66Ni23.09 alloy at 1373 K, compared with the corresponding interdiffusivities in binary Co-50 at.% Ni and Fe-50 at.% Ni alloys and ternary Co-33 at.% Fe-33 at.% Ni alloy varied with the increasing temperature (a) and those at 1373 K (b).[20] It can be found that the binary interdiffusivities are larger than the ternary interdiffusivities and much larger than the quinary interdiffusivities, which also indicates that the interdiffusivities at the core composition of the multicomponent system are restrained by the addition of the element number. According to the Einstein relation (D i = RTM i), tracer diffusivity of Ni in quinary Co23.95Cr23.3Fe23Mn6.66Ni23.09 alloy at 1373 K can be extrapolated from the present mobility. Here, the relative uncertainty of the tracer diffusivity is estimated to be 10.52% by disregarding the effect of thermodynamics. Figure 4 illustrates the presently obtained tracer diffusivity of Ni in Co23.95Cr23.3Fe23Mn6.66Ni23.09 alloy, the experimental data[21,22,23,24] in Co-49.3Ni, Fe-45.3Ni, Fe-15Cr-20Ni, CoCrFeNi and CoCrFeMnNi alloys and the extrapolated data[4] in CoCrFeMn0.5Ni alloy. In Fig. 4(b), the tracer diffusivities of Ni in quinary alloys are lower than the data in binary alloys but larger than the values in ternary and quaternary alloys, which seems to indicate that the sluggish diffusion characteristic of Co-Cr-Fe-Mn-Ni HEAs is suitable for the interdiffusivity, rather than the tracer diffusivity. The present tracer diffusivity of Ni in CoCrFeMn0.5Ni alloy at 1373 K is lower than the other value[4] extrapolated from the interdiffusion experiments, which may be caused by the effect of the off-diagonal terms. According to the present result in Co23.95Cr23.3Fe23Mn6.66Ni23.09 alloy and the directly measured data[21] in CoCrFeNi and CoCrFeMnNi alloys, the tracer diffusivities of Ni increases with the addition of the element Mn, which may be caused by the enhancement of the diffusion entropy with the increment of the large atom (Mn). The further verification needs more direct measurements for Ni tracer diffusion in CoCrFeMn(0−1)Ni alloys at 1373 K.

(color on web) Main interdiffusivities \(\tilde{D}_{\text{CoCo}}^{\text{Ni}}\) and \(\tilde{D}_{\text{FeFe}}^{\text{Ni}}\) obtained by using the pragmatic numerical inverse method in quinary Co23.95Cr23.3Fe23Mn6.66Ni23.09 alloy at 1373 K, compared with the binary interdiffusivities in Co-50 at.% Ni, and Fe-50 at.% Ni, as well as the ternary ones in Co-33 at.% Fe-33 at.% Ni alloys (a) varied with the increasing temperature and (b) at 1373 K[20]

(color on web) Tracer diffusivity of Ni in quinary Co23.95Cr23.3Fe23Mn6.66Ni23.09 alloy at 1373 K extrapolated from the present interdiffusion experiments, compared with the tracer diffusivities of Ni in Co-49.3Ni, Fe-45.3Ni, Fe-15Cr-20Ni, CoCrFeNi, CoCrFeMnNi and CoCrFeMn0.5Ni alloys (a) varied with the increasing temperature and (b) at 1373 K[4,21,24]

It should be noted that any element in the equiatomic or near-equiatomic HEAs can be selected as the dependent component (i.e., the solvent). In order for the convenience in further analysis, one set of multicomponent interdiffusivities with a particular dependent component should be easily converted to other set with a different dependent component. Based on a common assumption on constant molar volume, a generalized transformation relation in an N-component system can be derived as,

The detailed derivation is given in the “Appendix”. According to the above transformation relations, the presently obtained quinary interdiffusivities with respect to Ni solvent (\(\tilde{D}_{ij}^{\text{Ni}}\)) can be easily transformed into those with other dependent component Mn, Fe, Cr or Co (\(\tilde{D}_{ij}^{\text{Co}}\), \(\tilde{D}_{ij}^{\text{Cr}}\), \(\tilde{D}_{ij}^{\text{Fe}}\) or \(\tilde{D}_{ij}^{\text{Mn}}\)).

5 Conclusion

In the present work, we illustrated a high-throughput method by combining the diffusion multiple technique and the pragmatic numerical inverse method for the development of interdiffusion databank in HEAs. A Co-Cr-Fe-Mn-Ni diffusion multiple at 1373 K was experimentally prepared and measured here. On the basis of the measured composition profiles, pragmatic numerical inverse method was adopted to determine the accurate interdiffusivity matrices over the composition spaces in Co-Cr-Fe-Mn-Ni HEAs. The sluggish diffusion effect in Co-Cr-Fe-Mn-Ni HEAs was further confirmed on the basis of the comprehensive comparison between the obtained interdiffusivity matrices in quinary Co-Cr-Fe-Mn-Ni alloys and those in lower-order alloys, while was not for the tracer diffusivities. Moreover, it is anticipated that the present combinational method, i.e., diffusion multiple technique in combination with the pragmatic numerical inverse method, is applicable to the high-throughput establishment of the interdiffusion databank in different HEAs. Finally, generalized transformation relations on interdiffusivities with different dependent components in multicomponent systems is derived under the assumption of constant molar volume, which should be helpful for further analysis on the effect of different elements on the interdiffusion behavior in HEAs.

References

M.C. Gao, B. Zhang, S.M. Guo, J.W. Qiao, and J.A. Hawk, High-Entropy Alloys in Hexagonal Close-Packed Structure, Metall. Mater. Trans. A, 2016, 47, p 3322-3332

J. Morral, Skepticism, Science and High Entropy Alloys, J. Phase Equilib. Diff., 2015, 36, p 305

D.B. Miraclea and O.N. Senkov, A Critical Review of High Entropy Alloys and Related Concepts, Acta Mater., 2017, 122, p 448-511

K.Y. Tsai, M.H. Tsai, and J.W. Yeh, Sluggish Diffusion in Co-Cr-Fe-Mn-Ni High-entropy Alloys, Acta Mater., 2013, 61, p 4887-4897

F. Zhang and U. Kattner, CALPHAD and the High Entropy Alloy, J. Phase Equilib. Diff., 2015, 36, p 1-2

B. Schuh, F. Mendez-Martin, B. Völker, E.P. George, H. Clemens, R. Pippan, and A. Hohenwarter, Mechanical Properties, Microstructure and Thermal Stability of a Nanocrystalline CoCrFeMnNi High-Entropy Alloy After Severe Plastic Deformation, Acta Mater., 2015, 96, p 258-268

A. Chyrkin, A. Epishin, R. Pillai, T. Link, G. Noize, and W.J. Quadakkers, Modeling Interdiffusion Processes in CMSX-10/Ni Diffusion Couple, J. Phase Equilib. Diff., 2016, 37, p 201-211

F. Faupel, W. Frank, M.-P. Macht, H. Mehrer, V. Naundorf, K. Rätzke, H.R. Schober, S.K. Sharma, and H. Teichler, Diffusion in Metallic Glasses and Supercooled Melts, Rev. Mod. Phys., 2003, 75, p 237-280

R.F. Sekerka, G.B. McFadden, and W.J. Boettinger, Analytical Derivation of the Sauer-Freise Flux Equation for Multicomponent Multiphase Diffusion Couples with Variable Partial Molar Volumes, J. Phase Equilib. Diffus., 2016, 37, p 640-650

W. Chen, L. Zhang, Y. Du, C. Tang, and B. Huang, A Pragmatic Method to Determine the Composition-Dependent Interdiffusivities in Ternary Systems by Using a Single Diffusion Couple, Scripta Mater., 2014, 90–91, p 53-56

W. Chen, J. Zhong, and L. Zhang, An Augmented Numerical Inverse Method for Determining the Composition-Dependent Interdiffusivities in Alloy Systems by Using a Single Diffusion Couple, MRS Comm., 2016, 6, p 295-300

H. Xu, W. Chen, L. Zhang, Y. Du, and C. Tang, High-throughput Determination of the Composition-Dependent Interdiffusivities in Cu-rich Fcc Cu-Ag-Sn Alloys at 1073 K, J. Alloys Compd., 2015, 644, p 687-693

J. Chen, L. Zhang, J. Zhong, W. Chen, and Y. Du, High-throughput Measurement of the Composition-Dependent Interdiffusivity Matrices in Ni-rich Fcc Ni-Al-Ta Alloys at Elevated Temperatures, J. Alloys Compd., 2016, 688, p 320-328

S. Deng, W. Chen, J. Zhong, L. Zhang, Y. Du, and L. Chen, Diffusion Study in Bcc_A2 Fe-Mn-Si System: Experimental Measurement and CALPHAD Assessment, CALPHAD, 2017, 56, p 230-240

J.-C. Zhao, M.R. Jackson, L.A. Peluso, and L.N. Brewer, A Diffusion-Multiple Approach for Mapping Phase Diagrams, Hardness, and Elastic Modulus, JOM, 2002, 54, p 42-45

J.-C. Zhao, X. Zheng, and D.G. Cahill, High-Throughput Diffusion Multiples, Mater. Today, 2005, 8, p 28-37

J.-C. Zhao, Reliability of the Diffusion-Multiple Approach for Phase Diagram Mapping, J. Mater. Sci., 2004, 39, p 3913-3925

J.-C. Zhao, Combinatorial Approaches as Effective Tools in the Study of Phase Diagrams and Composition-Structure-Property Relationships, Prog. Mater Sci., 2006, 51, p 557-631

K. Kulkarni and G.P.S. Chauhan, Investigations of Quaternary Interdiffusion in a Constituent System of High Entropy Alloys, AIP Adv., 2015, 5, p 097162

Y.W. Cui, M. Jiang, I. Ohnuma, K. Oikawa, R. Kainuma, and K. Ishida, Computational Study of Atomic Mobility in Co-Fe-Ni Ternary Fcc Alloys, J. Phase Equilib. Diffus., 2008, 29, p 312-321

M. Vaidya, S. Trubel, B.S. Murty, G. Wilde, and S.V. Divinski, Ni Tracer Diffusion in CoCrFeNi and CoCrFeMnNi High Entropy Alloys, J. Alloys Compd., 2016, 688, p 994-1001

B. Million, J. Růžičková, J. Velíšek, and J. Vřešťál, Diffusion Processes in the Fe-Ni System, Mater. Sci. Eng., 1981, 50, p 43-52

S.J. Rothman, L.J. Nowicki, and G.E. Murch, Self-Diffusion in Austenitic Fe-Cr-Ni Alloys, J. Phys. F: Met. Phys., 1980, 10, p 383-398

B. Million and J. Kučera, Concentration Dependence of Nickel Diffusion in Nickel-Cobalt Alloys, Czech. J. Phys. B, 1971, 21, p 161-171

J.R. Manning, Diffusion and the Kirkendall Shift in Binary Alloys, Acta Metall., 1967, 15, p 817-826

W. Chen, L. Zhang, Y. Du, and B. Huang, Viscosity and Diffusivity in Melts: From Unary to Multicomponent Systems, Philos. Mag., 2014, 94, p 1552-1577

W. Zhang, Y. Du, W. Chen, Y. Peng, P. Zhou, S. Wang, G. Wen, and W. Xie, CSUDDCC1—A Diffusion Database for Multicomponent Cemented Carbides, Int. J. Refract. Met. Hard Mater., 2014, 43, p 164-180

F. Sauer and V.Z. Freise, Diffusion in Binären Gemischen mit Volumenänderung, Z. Elektrochem., 1962, 66, p 353-362

A. Ben Abdellah, J.G. Gasser, K. Bouziane, B. Grosdidier, and M. Busaidi, Experimental Procedure to Determine the Interdiffusion Coefficient of Miscibility Gap Liquid Alloys: Case of GaPb System, Phys. Rev. B, 2007, 76, p 174203

J. Lechelle, S. Noyau, L. Aufore, A. Arredondo and E. Audubert, Volume Interdiffusion Coefficient and Uncertainty Assessment for Polycrystalline Materials. Diffusion-fundamentals.org, 2012, 17, p 1–39.

N.G. Jones, R. Izzo, P.M. Mignanelli, K.A. Christofidou, and H.J. Stone, Phase Evolution in an Al0.5CrFeCoNiCu High Entropy Alloy, Intermetallics, 2016, 71, p 43-50

Acknowledgments

The financial support from the National Natural Science Foundation of China (Grant No. 51474239), the National Key Research and Development Program of China (Grant No. 2016YFB0301101) and the Hunan Provincial Natural Science Foundation for Youth of China (Grant No. 2015JJ3146) is acknowledged. Weimin Chen acknowledges the financial support from Guangdong Provincial Natural Science Foundation for Doctoral Research Project, the Innovation Foundation of Jinan University (Grant No. 21617340) and the Scientific Research Funds for the Talents of Jinan University, Guangzhou, China. Lijun Zhang acknowledges the project supported by State Key Laboratory of Powder Metallurgy Foundation, Central South University, Changsha, China.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendix

Appendix

In an N-component system, the interdiffusion flux of a component i under constant molar volume can be expressed by Fick’s first law,

Then, one can obtain

In fact, Eq 9-11 are presented when the component N is treated as the dependent component. If the component N − 1 is selected as the dependent component, one can have

Considered the relation (\(\frac{{\partial c_{N} }}{\partial x} = - \sum\limits_{j = 1}^{N - 1} {(\frac{{\partial c_{j} }}{\partial x})}\)), Eq 12 and 13 can be revised as,

A direct comparison between Eq A6 with Eq A4 leads to,

By substituting Eq 14 into Eq 15, one can obtain

A direct comparison between Eq 17 with Eq 11 leads to,

According to the above mathematical derivations, a generalized transformation relation in an N-component system is achieved.

Rights and permissions

About this article

Cite this article

Chen, W., Zhang, L. High-Throughput Determination of Interdiffusion Coefficients for Co-Cr-Fe-Mn-Ni High-Entropy Alloys. J. Phase Equilib. Diffus. 38, 457–465 (2017). https://doi.org/10.1007/s11669-017-0569-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-017-0569-0