Silver-copper-titanium (Ag-Cu-Ti) ternary alloys are often used as active braze alloys for joining ceramics to metals at temperatures ranging from 780 °C (the melting point of the Ag-Cu eutectic) up to 900 °C. When Ti/Ag-Cu joints are brazed at low temperature (near 800 °C), the intermetallic compound Ti2Cu3 (tetragonal, P4/nmm, a = 0.313 nm, c = 1.395 nm) is systematically missing from the interface reaction layer sequence. An experimental investigation based on isothermal diffusion experiments in the Ag-Cu-Ti ternary system has then been undertaken to clarify the issues of thermal stability and formation kinetics of this compound. Evidence has been found for the stability of Ti2Cu3 at temperatures ranging from 790 to at least 860 °C. By heat treating Ag-Cu-Ti powder mixtures at 790 °C for increasing times, it has moreover been shown that Ti2Cu3 forms at a much slower rate than the two adjacent Ti-Cu compounds: TiCu4, the first phase to form, and Ti3Cu4. This explains why although thermodynamically stable, Ti2Cu3 is not obtained when temperature is too low or reaction time too short.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Alloys of the Ag-Cu-Ti ternary system are often used for brazing ceramics to metals in the temperature range 800 to 900 °C.[1] Some alloy compositions containing 40 at.% Cu (28 wt.% Cu, binary eutectic alloy with a melting point at 780 °C) and a few percent of titanium are commercially available in the form of prealloyed powders, ribbons, or plates. To develop high-performance metal/ceramic brazed joints, especially when the metal is a titanium-base alloy,[2,3] a thorough knowledge of the phase diagram of the Ag-Cu-Ti system is needed.

Thermodynamic data on the binary Cu-Ti system and the ternary Ag-Cu-Ti system are available from different sources,[4-14] and assessments have recently been made.[15,16] The 800 °C section reported in Fig. 1 and the partial projection drawn in Fig. 2 show the most probable phase equilibria in the Ag-Cu-Ti system at temperatures ranging from 780 to 860 °C. It is to be noted that the reaction scheme given in Ref 16 is drawn in dotted line for that temperature range because of uncertainty on the stability of Ti2Cu3 in the binary Cu-Ti and the ternary Ag-Cu-Ti systems. For Eremenko et al., who conducted extensive experimental investigations on both systems, Ti2Cu3 is stable only at temperatures ranging from 805 to 890 ± 4 °C in the Cu-Ti binary system and from 803 to 890 °C in the ternary Ag-Cu-Ti system.[6,7] For other authors who achieved thermodynamic modeling, Ti2Cu3 is stable at any temperature lower than 875 ± 10 °C[13] or 885 °C.[14] Enthalpies of formation and crystallization of the Ti-Cu compounds were experimentally determined,[17] but the values thus obtained do not remove the uncertainty on the stability of Ti2Cu3.

In the course of a recent investigation on the chemical reactivity near 800 °C of liquid Ag-Cu eutectic alloy with solid titanium,[4] the question arose why the intermetallic compound Ti2Cu3 was systematically missing from the reaction layer sequence that was observed to develop at the liquid/solid interface.[4] To provide a response to that simple but practical issue, more detailed information had to be acquired on the thermal stability and formation kinetics of the intermetallic compound Ti2Cu3. It is with this aim in view that isothermal diffusion experiments were undertaken in the Ag-Cu-Ti system between 700 and 860 °C.

Experimental

For isothermal diffusion experiments, mixtures of commercial powders of silver (99.99 wt.%, grain size d ≈ 100 μm, Goodfellow), copper (99 wt.%, grain size d ≈ 50 μm, Goodfellow), and titanium (98.5 wt.%, grain size 3 < d < 300 μm, Fluka) were ball homogenized and cold pressed under 200 MPa into small rods (3 × 6 × 30 mm). The titanium powder was previously sifted twice so that the diameter of the biggest particles was lower than 100 μm. Each rod was then placed in an alumina boat lined with yttria (STOPYT 62A, Morgan Wesgo) and heated in a silica reaction tube for up to 500 h under pure argon (3 to 5 × 104 Pa) in the presence of titanium powder as gas getter. It is to be noted that at 850 °C and above, heat treatments were realized under dynamic primary vacuum and the annealing time was reduced down to 50 min to avoid spreading of the Ag-Cu-Ti liquid on the alumina boat through the yttria liner. The horizontal furnace was regulated to better than ±1 °C. The exact treatment temperature was controlled by putting the hot junction of a K-type thermoelectric couple inside the alumina boat in place of the rods. At the end of the isothermal treatment, the reaction tube was pulled out of the furnace and allowed to cool in ambient air. Starting from a heating temperature in the range 790 to 860 °C, the cooling rate measured during the first 100 °C drop was faster than 10 °C/s.

Two samples were analyzed by differential thermal analysis (TGA/SDTA 851, Mettler-Toledo, Viroflay, France) in Al2O3 crucibles (sample weight: 1 to 100 mg) under 105 Pa argon. The other samples were characterized after heat treatment by x-ray diffraction (XRD), optical metallography (OM), scanning electron microscopy (SEM), and electron probe microanalysis (EPMA). The XRD spectra were recorded on grossly polished sections, using standard diffraction equipment (MPD-Pro diffractometer equipped with a back monochromator and a X’celerator detector, Cu Kα radiation, Panalytical, Limeil, France). Optical metallography and SEM observations were made on diamond polished sections. Scanning electron microscopy observations and EPMA analyses were carried out using a Camebax apparatus (Cameca, Gennevilliers, France) equipped with an energy dispersive analyzer. The accelerating voltage was of 10 kV and the beam current of 9 nA. After background subtraction, the counting rates obtained for Ag, Cu, and Ti in at least eight different points were averaged and referred to the counting rates recorded under the same conditions on pure and freshly polished element standards. After corrections for atomic number, absorption, and fluorescence, the atomic contents of Ag, Cu, and Ti in the different phases deriving from the Cu-Ti binary system were obtained with accuracy better than ± 0.5 at.%.

Results and Discussion

Synthesis and Annealing at 815 °C and above

All authors who have reported on the Ag-Cu-Ti system agree that in the temperature range 810 to 830 °C, Ti2Cu3 is in equilibrium with an Ag-Cu-Ti liquid.[6-12] Therefore, first attempts to synthesize the compound Ti2Cu3 from the elements in the ternary Ag-Cu-Ti system were carried out in this temperature range. More precisely, three different powder mixtures with compositions F, F′, and G (Fig. 1) were prepared and heated at 815 or 825 °C (Table 1). In full agreement with the literature data, all the treated samples contained as a major constituent Ti2Cu3 (tetragonal, P4/nmm, a = 0.313 nm, c = 1.395 nm[5]). Ti3Cu4 (tetragonal, I4/mmm, a = 0.313 nm, c = 1.994 nm) was still present in small amounts in sample F1 heated at 815 °C for 205 h, but was not detected in samples F2, F′1, and G1 heated at higher temperature (825 °C) and for longer durations (350 h or more). Ti2Cu3 grown from the liquid during isothermal heating always appeared in the form of globular crystals (Fig. 3). These were surrounded by a very thin layer of TiCu4 crystals (orthorhombic, Pnma, a = 0.453 nm, b = 0.4342 nm, c = 1.293 nm) that were formed on cooling near 808 °C, as a product of the incomplete ternary transition reaction (U9 in Fig. 2):

Once treated at 815 or 825 °C, the samples containing Ti2Cu3 were annealed at higher temperatures. Results obtained by XRD for sample F are shown in Fig. 4. On the one hand, no significant modification occurred in the phase composition after annealing at 825 °C (for 353 h), 835 °C (for 237 or 277 h), or 850 °C (for 50 min). Ti3Cu4 initially present at 815 °C just disappeared upon subsequent annealing. On the other hand, an important change occurred upon reheating for 50 min at 854 or 860 °C. Effectively, the intensity of the diffraction peak characteristic of Ti2Cu3 at 2θ ≈ 43° considerably decreased between 850 and 854 °C, whereas a new peak characteristic for Ti3Cu4 appeared (it is noteworthy that in the 37 to 47° angular range represented in Fig. 4, the XRD lines characteristic of Ti2Cu3 and Ti3Cu4 are distinguishable only at 2θ ≈ 43°). At the same time, the morphology of the crystals changed from globular to platelike (Fig. 5). Given that at 850 °C, samples with composition F (or F′) are lying inside a tie triangle Ti2Cu3-Ags-L; such changes mean that upon reheating at 854 or 860 °C, Ti2Cu3 and solid silver have reacted according to the transformation (U8 in Fig. 2):

According to the foregoing XRD and metallographic observations, the temperature of that invariant transformation is 852 ± 2 °C.

Conversion of Ti2Cu3 into Ti3Cu4 was also observed in samples with composition G after 50 min annealing at 860 °C, but Ti2Cu3 remained abundant. This can be explained by the fact that mixtures F and G have different compositions. Consequently, only the compound Ti3Cu4 is in equilibrium with the liquid L at 854 and 860 °C in samples with composition F or F′, whereas in samples with composition G, the three-phase equilibrium Ti2Cu3-Ti3Cu4-L tends to be reached when approaching 860 °C, as shown in Fig. 2.

In the experimental approach by Eremenko et al.,[7] the invariant transformation shown in Eq 2 is reported to occur at 843 °C, whereas we find it at 852 ± 2 °C. The slight shift between these two values may have different origins, one of these being the purity of the samples. Indeed, isothermal diffusion needs use of fine powders that cannot be as pure as the massive ingots used by Eremenko’s coworkers. An illustration of this purity problem is given in Fig. 3 and 5 with the presence in the solidified liquid of small well-faceted crystals that analyze as TiCu with extra aluminum and silicon for a total amount of 2 to 3 at.% (Table 1, phase designated as TiCu(Al,Si)). Because their quantity was too low, these crystals could not be characterized by XRD. They might be either of the tetragonal TiCu type (P4/nmm, a = 0.3107 nm, c = 0.5919 nm[13]) stabilized by impurities or of another crystal type such as B2 cubic Cu2AlTi, as evoked for crystals with a similar composition in a paper by He et al.[18] It is noteworthy that the weak reflection at 2θ = 39° in Fig. 4 might be a strong x-ray diffraction line coming from the small crystals of TiCu(Al,Si) and that Al and Si were not detected in the other phases constituting the samples.

Synthesis and Annealing below 815 °C

A part of sample F1 that was first heated for 205 h at 815 °C was placed in an alumina boat along with an untreated cold-pressed mixture of Ag, Cu, and Ti powders having the same composition. Both samples were heated at 790 °C for 330 h and characterized (Table 2, samples F3 and F4). In sample F3 first heated at 815 °C and annealed at 790 °C, Ti2Cu3 was still the major constituent. The only change concerned the compound Ti3Cu4 that disappeared upon annealing at 790 °C. The cold-pressed mixture directly heated at 790 °C (sample F4) also contained Ti2Cu3 as major constituent, but some Ti3Cu4 was present, such as in sample F1 before annealing at 790 °C.

The same type of experiment was reproduced at 700 °C on samples with composition G. After 512 h annealing at 700 °C, only small changes occurred in the sample previously treated at 825 °C (Table 2, samples G2): Ti2Cu3, TiCu4, and Ag were still the major constituents. As to the cold-pressed mixture directly reacted in the solid state at 700 °C (Table 2, sample G3), it only contained Ti3Cu4 and TiCu4; no trace of Ti2Cu3 at all was found.

If there is no ambiguity from the foregoing results about the existence of Ti2Cu3 at 790 °C, things are not so simple at 700 °C. Effectively, starting from the same initial composition, a mixture heat treated for a long time at 700 °C contains either Ti2Cu3, TiCu4, and Ag or Ti3Cu4, TiCu4, and Ag according to whether it has previously been heated at a higher temperature (790 to 850 °C) or not. Equilibrium has not been reached in one of the two mixtures treated at 700 °C. Complementary experiments have then been carried out at 790 °C to acquire more detailed information on that question.

Isothermal Diffusion at 790 °C

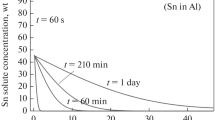

Cold-pressed powders of Ag, Cu, and Ti with the atomic composition F (Ag:Cu:Ti = 20:50:30 at.%) were placed in the furnace at 790 °C for durations varying from 10 min to 330 h. It will be recalled that according to the phase diagram shown in Fig. 1, the chosen composition lies either inside the tie triangle Ti2Cu3-TiCu4-Agsol or inside the wider triangle Ti3Cu4-TiCu4-Agsol.

Results in terms of phase composition of the treated samples are illustrated by the series of XRD patterns presented in Fig. 6. After 10 min in the furnace, the three starting elements Ag, Cu, and Ti are still present. The only noticeable change is an increase in the full width at half maximum and a shift in the angular position of the XRD peaks of these elements (Fig. 6, 10 min). After heating for 1.5 min more, the diffraction lines characteristic for the compound TiCu4 begin to appear (Fig. 6, 11.5 min). After 15 min in the furnace, these lines have attained their maximum height while Cu has disappeared and Ti3Cu4 has become detectable (Fig. 6, 15 min). Then, the diffraction lines characteristic for Ti3Cu4 slightly increase, while those characteristic for TiCu4 decrease, and in the meantime elemental titanium tends to disappear (Fig. 6, 30 min, 12 h, and 64 h). Finally, Ti2Cu3 develops to the detriment of Ti3Cu4 as the heat treatment time increases from 64 to 330 h (Fig. 6, 330 h). It is noteworthy that for nonambiguous characterization, the unit-cell parameters of Ti2Cu3 had to be refined. Indeed as indicated by EPMA results (Table 2), 1.4 at.% of silver enter (very likely by Ag/Cu substitution) in the framework of Ti2Cu3. The refined tetragonal unit-cell parameters found for such a phase with Ag/Cu substitution were a = 0.3138(5) nm and c = 1.4064(3) nm, which corresponds to a slight increase compared with the pure Ti2Cu3 binary compound (a = 0.313 nm, c = 1.395 nm).

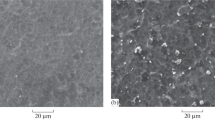

Combining these XRD results with metallographic examination and EPMA characterization, a reaction scenario can be proposed for the formation of Ti2Cu3 from the elements at 790 °C. The series of micrographs presented in Fig. 7 illustrates the four main stages of this reaction scenario.

Morphological changes in mixture F after heating for increasing times at 790 °C. (a) untreated cold-pressed mixture: Ag, Cu, and Ti grains. (b) After 15 min in the furnace: small TiCu4 crystals around Ti and in the Cu-free solid Ag matrix. (c) After 12 h reaction: formation of Ti3Cu4 and recrystallization of TiCu4. (d) After 330 h reaction: the stable Ti2Cu3-TiCu4-Ags three-phase equilibrium tends to be reached

Stage I

The first process that develops during the rise in temperature of the cold-pressed powder mixture (Fig. 7a) is the solid-state volume interdiffusion of atoms, mostly by Ag/Cu substitution. Such a solid-state interdiffusion is known to modify the unit-cell parameters of the two elements, and a shift with enlargement of their XRD reflections is effectively observed in Fig. 6 after 10 and 11.5 min heating.

Stage II

When the temperature attains 780 °C, which occurs between 10 and 11.5 min heating, a eutectic reaction proceeds between the grains of Ag and Cu, giving a Ag-Cu liquid alloy. As soon as it is formed, the Ag-Cu eutectic alloy spreads at the surface of the titanium grains by reactive wetting. Comparison between Fig. 7(a) and (b) clearly shows consumption of copper and spreading of a silver-rich phase over the titanium grains. As previously shown by XRD (Fig. 6, 11.5 min and 15 min) and confirmed by EPMA, it is essentially TiCu4 that is produced in that fast-rate process. Two simultaneous reactions can then be written:

At the end of this second stage, most of the solid elemental copper initially introduced has been first dissolved in the Ag-Cu liquid, L, and then converted into TiCu4 at the Ti grains surface. It is this process that has left the large pores visible in Fig. 7(b). As to the nearly eutectic liquid phase, L, it has disappeared. Indeed, formation of TiCu4 by reaction between the (Ag-Cu) liquid, L, and solid Ti according to the reaction in Eq 4 implies the precipitation of solid Ag from the liquid. Arrived at this point, the Ti grains are surrounded with a TiCu4 reaction layer and embedded in a white Ag-base matrix with many small crystals of TiCu4 dispersed in it (Fig. 7b).

Stage III

In the third stage, Ti3Cu4 slightly increases, TiCu4 slightly decreases, and elemental titanium tends to disappear (Fig. 6, 30 min, 12 h, and 64 h). This means that TiCu4 reacts in the presence of solid Ag with remaining Ti to form Ti3Cu4 according to the reaction:

During the course of this reaction that proceeds until titanium is completely consumed, the remaining TiCu4 recrystallizes in blocky crystals, as shown in Fig. 7(c).

Stage IV

In the last stage, Ti3Cu4 and TiCu4 react by solid-state diffusion through solid Ag to form round-shaped crystals of Ti2Cu3 (Fig. 7d). The reaction can be written:

Ti2Cu3 with 1.4 at.% of silver substituted for Cu is thus formed as the equilibrium phase for mixture F reacted at 790 °C.

From a kinetics standpoint, it can be said that Stage II proceeds at a very fast rate. Indeed, between the formation of the first liquid droplets after a little more than 10 min of temperature rise and complete isothermal solidification at 790 °C of the liquid by Cu depletion and Ag precipitation, only 5 min have passed. Fast-rate formation of TiCu4 as first reaction product is confirmed by the SDTA results reported in Fig. 8. It can effectively be seen that when titanium is added to a eutectic Ag-Cu powder mixture, the endothermic peak corresponding to the formation at 780 °C of a liquid with the eutectic composition completely disappears. In place of it appears an exothermic peak that corresponds to the formation of the compound TiCu4 by reaction of solid titanium with the Ag-Cu eutectic liquid as it is produced. Then, formation of Ti3Cu4 during stage III proceeds at a medium rate (within a few tens of hours), whereas conversion of Ti3Cu4 into the equilibrium phase Ti2Cu3 during stage IV proceeds at a very slow rate. Indeed, it has only begun after 60 h heating and reaction has not yet gone to completion after 330 h.

Of course, the real scenario might be more subtle. First, reactions may progress at different rates depending on the size of Ti grains and on the distance between them. Secondly, because of the detection limit inherent to the characterization techniques used, several minor reactions have not been considered such as, for instance, the possible formation of TiCu or Ti2Cu in the solid state at the interface between Ti and Ti3Cu4. It remains that, although a bit simplistic, the proposed scenario describes the four main processes that successively develop in a Ag-Cu-Ti mixture isothermally heated at 790 °C before attainment of equilibrium. The most striking features are that (i) TiCu4 is the first phase to form by interface reaction at 780 °C between solid Ti and a liquid Ag-Cu eutectic alloy and (ii) when Ti2Cu3 and Ti3Cu4 are likely to form from the elements, the former develops at a much slower rate than the latter. This explains why TiCu4 and Ti3Cu4 can be the major reaction products in a heated mixture, whereas Ti2Cu3 is actually the equilibrium phase for that mixture. The same explanation remains valid to justify that Ti2Cu3 is “missing” from the reaction layer sequence at the interface of Ti/Ag-Cu couples brazed at 800 °C.[4]

Conclusion

Ti2Cu3 has been synthesized by solid-liquid reaction from Ag, Cu, and Ti powder mixtures after long-time annealing at 790, 815, or 825 °C. No indication for decomposition of Ti2Cu3 at 700 °C for 500 h was observed being in line with data described in Ref 11 to 16. At high temperature, Ti2Cu3 is stable in the Ag-Cu-Ti system up to at least 860 °C, the temperature at which existence of the three-phase equilibrium Ti2Cu3-Ti3Cu4-L is confirmed. Occurrence of the invariant transformation:

is also confirmed at a temperature that might be slightly higher than 843 °C.

From a kinetics standpoint, it has been shown by SDTA in the range 750 to 800 °C and by isothermal diffusion at 790 °C that TiCu4 is the first phase to form when a transient Ag-Cu eutectic liquid spreads onto solid titanium between 780 and 790 °C. Then, Ti3Cu4 is formed by reaction between TiCu4 and unconverted titanium. Finally, Ti2Cu3 slowly appears as a product of the reaction between TiCu4 and Ti3Cu4. These features explain why Ti2Cu3 is not characterized after reaction at 790 °C for too short a time (less than 60 h) or after reaction for a long time (more than 500 h) at too low a temperature (700 °C). They also explain why Ti2Cu3 can be missing from the reaction layer sequence at Ti/Ag-Cu interfaces after brazing near 800 °C.

References

N. Eustathopoulos, M.G. Nicholas, and B. Drevet, Wettability at High Temperature, Pergamon, 1999, p 348-384

M.F. Wu, Z.S. Yu, C.Y. Jiang and C. Liang, Growth Mechanism of Compound at Interface of Ti-6Al-4V Joint Brazed with 72Ag-28Cu Filler Alloy, Mater. Sci. Technol., 2002, 18, p 1314-1316

H.Y. Chan, D.W. Liaw and R.K. Shiue, Microstructural Evolution of Brazing Ti-6Al-4V and TZM Using Silver-Based Braze Alloy, Mater. Lett., 2004, 58, p 1141-1146

J. Andrieux, O. Dezellus, F. Bosselet, M. Sacerdote-Peronnet, and J.C. Viala, “Reactivity of the Ag-Cu28 Braze Alloy with Titanium,” XXXII JEEP, Rouen, France, April 2006

K. Schubert, On the Constitution of the Ti-Cu and Ti-Ag Systems, Z. Metallkd., 1965, 56, p 197-198

V.N. Eremenko, Y.I. Buyanov and N.M. Panchenko, The System Ti-Ag-Cu at 700 °C, Izv. Akad. Nauk SSSR, Metalli, 1969, 3, p 188-192 (in Russian)

V.N. Eremenko, Y.I. Buyanov, and N.M. Panchenko, Polythermal, and Isothermal Sections of the System Ti-Cu-Ag. Part II, Sov. Powder Metall. Met. Ceram., 1970, 10, p 410-414, translated from Porosh. Metall., 1970, 89, p 73-78

V.N. Eremenko, Y.L. Buyanov, and N.M. Panchenko, The Liquidus Surface of the System Ti-Cu-Ag, Sov. Powder Metall. Met. Ceram., 1970, 9, p 301-304, translated from Porosh. Metall., 1970, 88, p 44-48

O. Kubaschewski, Ag-Cu-Ti, Ternary Alloys, Vol. 2, G. Petzow and G. Effenberg, Ed., VCH, Weinheim, 1988, p 55-59

A. Prince, Ag-Cu-Ti, Handbook of Ternary Alloy Phase Diagrams, P. Villars, A. Prince, and H. Okamoto, Ed., ASM International, 1995, p 2353-2360

R. Arroyave, “Thermodynamics and Kinetics of Ceramic/Metal Interfacial Interactions,” Ph.D. thesis, Massachusetts Institute of Technology, 2004

R. Arroyave and T.W. Eagar, Thermodynamic Assessment of the Ag-Cu-Ti System, TMS Lett., 2003, 1, p 887-888

J.L. Murray, The Cu-Ti System, Phase Diagrams of Binary Titanium Alloys, J.L. Murray, Ed., ASM International, 1987, p 80-95

K.C. Hari Kumar, I Ansara, P. Wollants and L. Delaey, Thermodynamic Optimisation of the Cu-Ti System, Z. Metallkd., 1996, 87, p 666-672

I. Ansara and V. Ivanchenko, Cu-Ti (Copper-Titanium), MSIT Binary Evaluation Program, in MSIT Workplace, G. Effenberg, Ed., Materials Science International Services GmbH, Stuttgart; Document ID: 20.11457.1.20, 2002

Ag-Cu-Ti (Silver-Copper-Titanium), Non-Ferrous Metal Ternary Systems. Selected Soldering and Brazing Systems: Phase Diagrams, Crystallographic and Thermodynamic Data, Landolt-Börnstein—Group IV Physical Chemistry, Vol 11C3, Non-Ferrous Metal Systems, Part 3, Springer Berlin Heidelberg, 2007, p 63-74

C. Colinet, A. Pasturel and K.H.J. Buschow, Enthalpies of Formation of Ti-Cu Intermetallic and Amorphous Phases, J. Alloys Compd., 1997, 247, p 15-19

P. He, J.C. Feng and W. Xu, Microstructure and Kinetics of Induction Brazing TiAl-based Intermetallics to Steel 35CrMo Using AgCuTi Filler Metal, Mater. Sci. Eng. A, 2006, A418, p 53-60

Acknowledgment

The authors gratefully acknowledge the staff of CTμ (Université Lyon 1, France) where SEM observations and EPMA analyses were performed.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Andrieux, J., Dezellus, O., Bosselet, F. et al. Details on the Formation of Ti2Cu3 in the Ag-Cu-Ti System in the Temperature Range 790 to 860 °C. J Phs Eqil and Diff 29, 156–162 (2008). https://doi.org/10.1007/s11669-008-9247-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-008-9247-6