Abstract

Ball bearings failure analysis using vibrations is widely researched. Bearings are main part of rotary machines that work for years if they work in a proper situation. Fluting occurs in a drive motor bearing and driven machine’s bearings because of current discharge from variable frequency drive motors to the bearings by transferring from the shaft and coupling to the bearings. In this research, spherical roller bearing is analyzed. Envelope and spectrum analysis is used to show what occurs when stray current flows to the gearbox bearings by passing through shaft and coupling. Fluting response in vibrations by using envelope and spectrum is shown. This paper shows how ball pass frequency inner race, ball pass frequency outer race with fundamental train frequencies side bands are excited in the natural frequencies area or high frequencies by stray current at the first time of running before bearing failed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

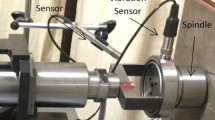

Bearings are main part of rotary machines that guide shaft to rotate in geometry centerline. Ball bearing failure diagnosis is the best method to have a good rotating shaft in centerline without any side effects and unanticipated shutdowns. Failure analysis researches were done by applying of stereographic, optical microscopy, scanning electron microscopy, and energy-dispersive X-ray spectroscopy analysis and hardness test. This research shown that the bearing part loosing and inappropriate clearance can produce relative displacements under cyclic gradient loading [1]. Fretting failure in rolling elements bearing causes stress, and dynamic loads are investigated. Rolling element bearing is going to be failed because of brinelling early [2]. Periodic dynamic loads on ball bearings cause bearing fatigue and failure so uncertainly and experimental analysis for detective failure of rolling elements bearing is done and researched for silicon nitride bearings [3]. Environments, excessive load, bad start-up and many other things are vital to how much time bearing can turn without failure so a methodology for identifying the cause failure for antifriction bearings used in electric motors using antifriction bearings is presented [4]. The experimental data-based model (EDBM) is a method to show how bearing is going to be failed so presentation of the application of the EDBM technique to data collecting on a test-rig to test damaged fibrizer roller bearings in different working conditions is shown [5]. Various parameters such as spall size, radial load, rotor unbalance, axial load, inner race speed, grease grade, radial clearance, number of rollers etc. on the vibration acceleration amplitude of the bearings is researched and analyzed [6]. An analytical model of bearing is investigated to study the rolling element bearing systems behavior to detect failure of the rolling bearing by using nonlinear dynamic modeling [7]. Lubricant viscosity is an important factor to prevent the rotary machine bearings wear so it can cause vibrations if it will be used in unsuitable grade. Experiment for NU205 roller bearings analysis is presented, and its lubrication with mineral oil of three different viscosity grades (ISO 10, 32 and 68) is investigated to show roller bearing vibrations behavior [8]. In this study, bearing failure because of stray current from variable frequency drive (VFD) motor is investigated. Bearing failure frequencies by vibrations analysis methods using envelope and spectrum are researched. Spherical roller bearing with 23160 NTN code failure analysis for prevent catastrophic failure is analyzed, and after detecting this failure, bearing was replaced. The bearing that is analyzed is shown (Fig. 1).

Bearing Failure Frequencies

Spherical roller bearings for tolerating loads in two directions including radial and axial are used in gear boxes to neutralizing axial and radial loads. Spherical roller bearings have many failure frequencies that are identified when the bearing is failed. Equation 1 shows the ball pass frequency inner race that it is identified in spectrum when bearing inner race is failed. Equation 2 shows the ball pass frequency outer race that it is identified in spectrum when bearing outer race is failed. Equation 3 shows fundamental train frequency that it is identified in spectrum when bearing cage is failed. Equation 4 shows the ball spin frequency two times that of it is identified in spectrum when bearing ball is failed.

Table 1 shows the bearing properties and bearing failure frequencies. Data and bearing failure frequencies are calculated for 924 rpm.

Output Results

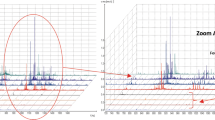

Currents in shaft of induction motors fail bearings as a fluting failure. While there are multiple causes of these currents, the level of shaft voltage and current increases with the use of VFD motor. At the first time of running and start-up of the drive motor and gearbox, bearings failure frequencies in natural frequencies area are exited. Figure 2 left and right shows envelope spectrum acceleration of NSK 23160 bearing with BPFI and BPFO with FTF side bounds, respectively. Figure 3 left and right shows spectrum acceleration of NSK 23160 bearing with natural frequencies area excited with BPFO harmonic and BPFO frequencies with FTF side bounds, respectively.

Spectrum acceleration response shows how natural frequencies area with BPFO harmonics is exited for failed bearings. When bearing is failed, BPFO frequencies harmonics are excited with FTF side bounds.

Fluting Failure and Replaced Bearing

VFD driver motor and driven gear box are shown left side in Fig. 4. This gear box was analyzed and monitored for detecting of failure in bearings and gears. Figure 4 right side shows the replaced gear for changing bearings.

After replacing bearings, failure in inner race and outer race cause of stray current bearing was clear that its failure was fluting failure symptoms in inner and outer race of bearing. Figure 5 left and right side shows fluting on inner and outer race of bearing. In a zoom area for clearing of failure in races of bearing, Fig. 6 presents failure so clearly.

Bearing is failed, and gear must be checked because of currents that occurred in the bearings. After checking the gear on the shaft, stray currents symptoms are clear in parallel line patterns. Parallel line patterns cause of currents discharge are called fluting (Fig. 7).

Recommendations

It is necessary to discharge currents from shaft because of stray currents in VFD motors. Fluting in bearings is controlled by using coated and silicon nitride bearings but not for gearboxes as a driven component because fluting occurs in gears by transferring from shaft to the gearbox. It is recommended that stray currents are discharged by using earth brushes or the systems before it is transferred by shaft and coupling to the driven or gear box. Coated coupling and isolated coupling can be used for protected bearings and gears. If it is used the original bearings, bearings failure frequencies shouldn’t be excited at the first time of running. If bearings failure frequencies are excited at the first time of running, VFD motor must be checked for stray currents discharge.

Conclusion

Bearing failure with failure frequencies symptoms cause of stray currents from VFD motor is occurred. If motor’s earth brushes do not discharge whole stray currents, they will be discharged through bearings outer and inner raceway. Most of the failure frequencies presented cause of fluting. When drive motor is coupled to driven component same gear box, stray currents will be transferred by shaft and coupling to driven component. As a result of transfer of stray currents by coupling, stray currents discharged on bearings and gear surface. BPFO, BPFI, FTF bearing failure frequencies are presented as a result of fluting. In gear boxes for prevent fluting, it cannot use coated and hybrid bearings. If it uses a coated and hybrid bearing, bearings will be protected, but stray currents discharge on gearbox. As a result of this research, stray currents must be protected before transferring by coupling and shaft. The importance of this research is obtained of fluting symptoms at the first time of running. In fact, when BPFI and BPFO with FTF side bounds are exited at the first time of running or at the start-up, VFD motor must be checked for electrical discharged and currents before bearings catastrophically going to be failed.

References

M. Mehdizadeh, F. Khodabakhshi, Investigation into failure analysis of interfering part of a steam turbine journal bearing. Case Stud. Eng. Fail. Anal. 2, 61–68 (2014)

R.K. Upadhyay, L.A. Kumaraswamidhas, M.S. Azam, Rolling element bearing failure analysis: a case study. Case Stud. Eng. Fail. Anal. 1, 15–17 (2013)

S. Pattabhiraman, G. Levesque, N.H. Kim, N.K. Arakere, Uncertainty analysis for rolling contact fatigue failure probability of silicon nitride ball bearings. Int. J. Solids Struct. 47, 2543–2553 (2010)

A.H. Bonnett, Cause and analysis of anti-friction bearing failures in AC induction motors, in Conference, 21–25 June 1993

R.G. Desavale, R. Venkatachalam, S.P. Chavan, Antifriction bearings damage analysis using experimental data based models. J. Tribol. 135(4), 041105 (2013)

I.M. Jamadar, D.P. Vakharia, An in situ synthesized model for detection of defective roller in rolling bearings. Eng. Sci. Technol. Int. J. 19, 1488–1496 (2016)

A. Rafsanjani, S. Abbasion, A. Farshidianfar, H. Moeenfard, Nonlinear dynamic modeling of surface defects in rolling element bearing systems. J. Sound Vib. 23, 1150–1174 (2009)

R. Serrato, M.M. Maru, L.R. Padovese, Effect of lubricant viscosity grade on mechanical vibration of roller bearings. Tribol. Int. 40, 1270–1275 (2007)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hemati, A. A Case Study: Fluting Failure Analysis by Using Vibrations Analysis. J Fail. Anal. and Preven. 19, 917–921 (2019). https://doi.org/10.1007/s11668-019-00715-w

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-019-00715-w