Abstract

The high temperature hot corrosion behavior of bare and detonation-gun-sprayed Ni-5Al coatings on Ni-based superalloy Inconel-718 is comparatively discussed in the present study. Hot corrosion studies were carried out at 900 °C for 100 cycles in Na2SO4-60% V2O5 molten salt environment under cyclic heating and cooling conditions. The thermo-gravimetric technique was used to establish the kinetics of hot corrosion. X-ray diffraction, SEM/EDAX, and X-ray mapping techniques were used to analyze the hot corrosion products of bare and coated superalloys. The results indicate that Ni-5Al-coated superalloy showed very good hot corrosion resistance. The overall weight gain and parabolic rate constant of Ni-5Al-coated superalloy were less in comparison with the bare superalloy. The D-gun-sprayed Ni-5Al coating was found to be uniform, adherent, and dense in hot corrosion environment. The formation of nickel- and aluminum-rich oxide scale might have contributed for the better hot corrosion resistance of the coated superalloy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Detonation-gun (D-gun) spraying is one of the most promising techniques among the thermal spray processes and has been used in the manufacture of hot corrosion, oxidation, and wear-resistant coatings. Due to higher particle velocity (800-1200 m/s) during D-gun spray deposition, there is minimum decomposition of feed powder and the coatings obtained exhibit excellent morphological features such as low porosity, high density with fine gain structure along with superior mechanical properties such as high hardness and bond strength (Ref 1-4). Senderowski et al. (Ref 5-10) have reported extensively on Fe-Al coatings deposited on NiAl and NiCr intermediate layers using D-gun process on carbon steel substrate material. They found that D-gun technology has advantageous effects for spraying self-decomposing Fe-Al powders, and the deposited coatings were characterized by low porosity, high temperature corrosion and oxidation resistance, reduced negative gradients of stress and temperature influencing the substrate and increased adhesion strength. Further, it has been reported in the literature that the porosity values of D-gun-sprayed coatings are very much lower than that of the coatings deposited by other thermal spray techniques (Ref 1, 4). Due to low porosity and good adhesion of the D-gun-sprayed coatings, the inward diffusion of oxygen and corrosive species is prevented, thereby providing very good hot corrosion and oxidation resistance. Hence, the D-gun spray technique has been widely used in elevated temperature applications and capital intensive industries (Ref 11, 12).

Hot corrosion is a serious problem and one of the main modes of failure in high temperature applications such as gas turbines, boilers, industrial waste incinerators, heat exchangers, and aero-engines (Ref 13, 14). It occurs as a result of attack by compounds like sodium, vanadium, sulfur and chlorine that are present in the fuels used for combustion in the above-mentioned applications. In the combustion system, sodium and sulphur present in fuel react to form Na2SO4, while vanadium reacts with oxygen to form V2O5. These compounds deposit on the surface of the materials and induce accelerated oxidation, due to which a porous, non protective oxide scale is formed at the surface and sulfides in the substrate. This form of corrosion, unlike oxidation, consumes the material at an unpredictably rapid rate. Consequently the load-carrying ability of the components is reduced, leading eventually to its catastrophic failure. It has been reported that Na2SO4 is prerequisite for hot corrosion, and in the presence of V2O5 the attack becomes even more catastrophic (Ref 12, 15, 16). A number of nickel-based superalloys are used for elevated temperature applications, as they exhibit superior mechanical strength, surface stability, creep, and fatigue resistance at high temperatures (Ref 17-19). However, the presence of combustion gases constitutes an extreme environment, and hot corrosion is inevitable when alloys are used at high temperatures for long periods of time (Ref 15). Sidhu et al. have reported that a mixture of Na2SO4 and V2O5 in the ratio of 40:60 wt.% is reported to be a very aggressive environment for hot corrosion to occur in superalloys (Ref 14). One of the effective solutions to counter the problem of hot corrosion is to coat the alloy with a protective layer using various surface-treatment techniques (Ref 17, 20).

Nickel aluminide (NiAl) coatings have attracted considerable attention because of their potential for high temperature structural applications due to their high melting points, excellent resistance to environmental degradation, and good mechanical and chemical stability at high temperatures (Ref 21, 22). NiAl coatings are one of the most widely used inter-metallic coatings on hot section components of gas turbines (Ref 23). NiAl coatings have the ability to form a continuous, compact, and fully adherent Al2O3 layer at higher temperature, which acts as a protective barrier separating the substrate material from aggressive agents in the environment (Ref 24). Buta Singh et al. (Ref 25). evaluated the oxidation and hot corrosion resistance of plasma-sprayed Ni3Al coatings on boiler steels in Na2SO4-60% V2O5 molten salt environments at 900 °C for 50 cycles. They inferred that the Ni3Al coating was very effective in decreasing the corrosion rate of boiler steels in oxidizing and hot corrosive environments. Mahesh et al. (Ref 26). studied cyclic oxidation behavior of magnetron sputtered Ni-Al thin films on Ni- and Fe-based superalloys in air at 900 °C for 100 cycles and concluded that Ni-Al-coated superalloys provided better oxidation resistance in the given environment. Mahesh et al. (Ref 27, 28). investigated oxidation and hot corrosion resistance of HVOF-sprayed Ni-5Al coatings on Ni- and Fe-based superalloys in air and Na2SO4-60% V2O5 molten salt environments at 900 °C for 100 cycles, respectively, and reported that Ni-5Al coatings provided good protection against oxidation and hot corrosion environment. However, although the effectiveness of the coating composition and processing techniques, the lifetime of components operating in high temperature degrading environments is limited by the lifetime of the protective coatings (Ref 29). As no alloy is immune to hot corrosion for infinitely long period, any improvement in the performance of Ni-5Al coatings will be of great importance to the field of surface engineering. There is very little literature available on the hot corrosion behavior of D-gun-sprayed Ni-5Al coatings on superalloys. Therefore, the present study investigates the cyclic hot corrosion behavior of D-gun-sprayed Ni-5Al coatings on nickel-based superalloy Inconel-718 in Na2SO4-60% V2O5 molten salt environment at 900 °C for 100 h in simulated laboratory conditions. The cyclic hot corrosion studies create the severest conditions for testing, which simulate the conditions prevailing in actual service environment of the superalloy components, where breakdown/shutdown occurs frequently. The hot corrosion test procedure used in this study is similar to the one reported by many researchers (Ref 1, 30-32). The thermo-gravimetric technique was used to establish kinetics of corrosion. X-ray diffraction, SEM/EDAX, and X-ray mapping techniques were used to analyze the corrosion products of bare and coated samples.

Experimental Procedure

Substrate Material and Coating Formulation

Nickel-based superalloy Inconel-718 (In-718) used in the present study was procured from Narendra Steels, Mumbai, (India), in rolled sheet form. The nominal chemical composition (wt.%) of the substrate material is given in Table 1. Each specimen measuring approximately 20 mm × 15 mm × 5 mm was cut from the rolled sheet. The specimen were polished and grit blasted (grit 45) with alumina prior to D-gun coating. Commercially available Ni-Al powder of nominal composition Ni-5Al (wt.%) (MEC 906® Powder), supplied by Metallizing Equipment Company Pvt. Limited (MECPL), Jodhpur, (India), was used in this study. The particle size of the Ni-5Al powder used was in the range of 50-80 μm (Fig. 1). D-gun (Model: Awaaz) process was used to apply coatings on all six sides of the superalloy at SVX Powder M Surface Engineering Pvt. Ltd, New Delhi, (India). The spray parameters used during coating deposition are given in Table 2. All the process parameters, including the spray distance, were kept constant throughout the coating process.

Characterization of Coatings

XRD analysis of the samples was carried out using a Bruker AXS D-8 Advance diffractometer with Cu Kα radiation for the phase identification. The coated samples were wheel polished and the surface morphology of the coatings was analyzed using scanning electron microscope (SEM) [JEOL (JSM-5800)] with EDAX attachment of Oxford (Model-6841). The equipment could directly indicate the phases (oxides) present along with their compositions (wt.%) based on built in EDAX software which is a patented product of Oxford ISIS300. After preliminary characterization, the samples were cut along cross-section, mounted in transoptic powder and subjected to mirror polishing. The polished samples were characterized to obtain their cross-sectional morphology, composition, and X-ray mapping of the coatings using field-emission scanning electron microscope (FESEM, FEI, Quanta 200F Company) with EDAX Genesis software attachment: made in Czech Republic. The porosity of the coatings was measured with a Zeiss Axiovert 200MAT inverted optical microscope, fitted with imaging software Zeiss AxioVision release 4.1 which is developed based on ASTM B276. The micro-hardness of the coating was measured using a Leitz miniload 2 (Germany) hardness tester. A load of 15 g (147.1 mN) was provided to the needle for penetration and the hardness value was calculated from the relation Hv = 1854.4 × F/d 2 (where F is load in grams and d is the mean penetrated diameter in micrometer). Surface roughness tester (Mitutoyo SJ-201, Japan) was used to measure the surface roughness of the as-sprayed coatings at five different locations.

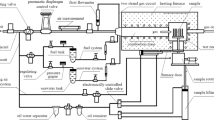

Hot Corrosion Tests in Molten Salt Environment

Cyclic hot corrosion studies were performed on bare and Ni-5Al-coated In-718 superalloy substrate in Na2SO4-60% V2O5 molten salt environments at 900 °C for 100 cycles. Each cycle consists of 1 h heating at 900 °C followed by 20 min cooling at room temperature. A coating of uniform thickness with 3-5 mg/cm2 of Na2SO4-60% V2O5 salt mixed in distilled water was applied with the help of camel hair brush on samples preheated in an oven maintained at 250 °C for 2 h. The preheating of samples was found necessary for the proper adhesion of the salt layer. The salt-coated specimens were then kept in an oven maintained at 150 °C for 2 h for complete drying and proper adhesion of the salt. Subsequently, the specimen were placed in alumina boat and weighed using micro balance (model BSA224S-CW, Sartorius) with a sensitivity of 0.1 mg, before exposing to hot corrosion tests. The spalled scale was also included at the time of weight change measurement to determine total rate of corrosion. The kinetics of corrosion was analyzed from the results of weight change measurements. XRD, SEM/EDAX and X-ray mapping techniques were used to analyze the corrosion products.

Results

Porosity and Coating Thickness

Porosity is one of the important parameters to be measured for the coatings, as it affects the corrosion resistance by providing easy access to corrosive species to penetrate through it and reach the substrate material. The as-sprayed Ni-5Al-coated samples were cut along the cross-section and mirror polished before scanning them under the optical microscope at the appropriate magnification. Optical micrographs obtained at different areas on the specimen cross-section were processed by image analysis software to calculate the porosity values. The cross-sectional porosity values of D-gun-sprayed Ni-5Al coating were found to be around 0.9%. The optical micrograph (200×) of the cross-section of as-sprayed Ni-5Al coatings is shown in Fig. 2(a). Figure 2(b) shows the SEM image of the surface morphology of Ni-5Al coating.

The coating thickness was measured from the back-scattered electron images (BSEI) collected with a scanning electron microscope for Ni-5Al coating, taken along the cross-section of the mounted sample (Fig. 2c). The average thickness of the Ni-5Al coating was found to be 175 μm.

Micro-hardness and Roughness of the Coatings

The minimum and maximum micro-hardness values of Ni-5Al coating measured along the cross-section of the coating were found to be 253 and 306 Hv, respectively. The surface roughness (Ra) of the as-sprayed coatings were found to be in the range of 4.5-5.6 μm. The center line average (CLA) method was used to obtain the Ra values.

Visual Observations

Figure 3 shows the photographs of bare and Ni-5Al-coated superalloys after hot corrosion studies at 900 °C for 100 cycles in Na2SO4-60% V2O5 environment. The scale formed on the surface of bare superalloy was initially dark gray in color and later turned to dark brown during the course of the study. By the end of 100 cycles, a complete layer of oxide scale got exfoliated from the bare superalloy with lot of scale falling in the alumina boat (Fig. 3a). In case of Ni-5Al-coated superalloy, light greenish and dark brown color patches were observed on the scale during initial few cycles and later the entire scale turned to light green in color (Fig. 3b). Minor spalling of the oxide scale, mainly near the edges was observed and the oxide scale formed was found to be intact with the coating.

Cyclic Hot Corrosion in Molten Salt

The weight gain per unit area versus number of cycles plot for the bare and Ni-5Al-coated superalloys subjected to hot corrosion in Na2SO4-60% V2O5 salt mixture at 900 °C for 100 cycles is shown in Fig. 4(a). The bare superalloys showed large weight gain up to 30 cycles with no spalling of oxide scale. But, after the end of 31st cycle spalling of oxide scale started and continued till the end of 57th cycle. Due to spalling, corrosion products started to fall outside the alumina boat and it became difficult to monitor the actual weight gain after 30 cycles. The bare superalloy nearly followed parabolic rate law up to 30 cycles and deviated from it during subsequent cycles (Fig. 4b).

In case of Ni-5Al-coated superalloy, the weight gain was high initially (up to 15 cycles) and becomes nearly constant during subsequent cycles as seen in Fig. 4(a). Minor spalling of oxide scale mainly near the edges was observed after 35th cycle and continued during the course of the study. The coated superalloy nearly followed parabolic rate law during the entire study (Fig. 4b). The parabolic rate constant K p was calculated by a linear least-square algorithm to a function in the form of (∆W/A)2 = K p t, where ∆W/A is the weight gain per unit surface area (mg/cm2) and t is the corrosion time in seconds. The parabolic rate constants (K p in 10−10/g2/cm4/s) for bare (up to 30 cycles) and Ni-5Al-coated (up to 100 cycles) superalloys were found to be 13.1 and 3.7, respectively.

XRD Analysis of Oxide Scales

The X-ray diffraction patterns of surface oxide scale of bare and Ni-5Al-coated superalloys after cyclic hot corrosion studies are shown in Fig. 5. The main phases identified in case of bare superalloy were Fe2O3, Cr2O3, NiO, NiVO3, NiFe2O4, NiCr2O4, and TiO2. In case of Ni-5Al coating the main phases identified were NiO, α-Al2O3, NiAl2O4, Cr2O3, and FeVO4.

SEM/EDAX Analysis

Surface-Scale Analysis

The SEM micrographs with EDAX spectrum at selected points of interest on the surface of the bare and Ni-5Al-coated superalloys subjected to cyclic hot corrosion studies are shown in Fig. 6. The scale formed on the bare superalloy shows numerous micro cracks on the surface and is porous in nature (Fig. 6a). EDAX analysis shows mainly the presence of Cr2O3, Fe2O3, and NiO phases along with small amounts of TiO2, MnO, and Nb2O5 in the scale. The scale formed on the Ni-5Al-coated superalloy was uniform (Fig. 6b). EDAX analysis shows mainly the presence of NiO, Al2O3, and Cr2O3 phases in the oxide scale.

Cross-Sectional EDAX Analysis of the Scale

The bare and Ni-5Al-coated samples subjected to hot corrosion were cut along the cross-section and mounted in epoxy resin, mirror polished, and gold coated to study the cross-sectional details using FESEM/EDAX analysis. The cross-sectional EDAX analysis of bare superalloy is shown in Fig. 7(a). Analysis of top scale of the bare superalloy shows mainly the presence of O, Fe, Ni, and Cr (point 1). The concentration of O and Cr increases, while that of Fe and Ni decreases in the sub scale region (point 2 and 3). The presence of O is negligible at points 4-6. Small amount of sulfur (1.23%) was observed at point 5 (see Fig. 7a).

The cross-sectional EDAX analysis of Ni-5Al coating is shown in Fig. 7(b). The top scale mainly consists of O, Ni, and Al (points 1 and 2). The coating shows Ni-rich light gray (point 1, 3 and 5) and Al-rich dark gray regions (point 2 and 4). The presence of O increases in the subscale region, but becomes negligible further towards the coating-substrate interface (points 4-6). Point 6 is at the coating-substrate interface and indicates the presence of Ni, Cr, Al, and Fe. The Cr has diffused from the substrate into the coating (point 2-6). Point 7 indicates the composition of the substrate material.

X-ray Mapping

The X-ray mapping analysis of Ni-5Al coatings subjected to hot corrosion studies (Fig. 8) shows that the splats mainly consists of Ni. The concentration of Ni and O is high in the top scale indicating the formation of nickel oxide. The Ni-rich splats in the subscale region are mostly un-oxidized. The region surrounding splat boundaries are rich in Al, Ni, and O thereby indicating the formation of their oxides. The Al is mainly concentrated in the inter splat region. Cr and Fe show a relatively higher percentage near the coating-substrate interface and have diffused from the substrate to the coating. Higher percentage of chromium has diffused into the coating compared to the iron. Traceable amount of Na has diffused through splat boundaries into the coatings, while small amount of Nb has diffused from the substrate into the coating as seen in Fig. 8.

Discussion

The D-gun spray process can be successfully used to deposit Ni-5Al coatings. The measured values of cross-sectional porosity, micro-hardness, and surface roughness of the coatings in the present work were found to be 0.9%, 253-306 Hv, and 4.5-5.6 μm, respectively, while the similar properties of HVOF-deposited Ni-5Al coatings as reported by Mahesh et al. (Ref 27). are 2%, 210-272 Hv, and 9.22-9.45 μm, respectively. The better values of porosity, micro-hardness, and surface roughness of Ni-5Al coatings obtained by D-gun spray process in comparison to that of HVOF spray process may be due to higher kinetic energy and low thermal energy of the powder particles during D-gun spraying process (Ref 6).

The surface photographs of bare and Ni-5Al-coated superalloys after hot corrosion studies are shown in Fig. 3. It was observed that the oxide scale developed on bare superalloy has suffered intense spalling and a complete layer of oxide scale got exfoliated from the bare superalloy surface (Fig. 3a). Similar observations were made by Kamal et al. (Ref 1). The spalling after initial few cycles of bare superalloy may be due to mismatch in co-efficient of thermal expansion between the substrate material and the scale formed due to hot corrosion (Ref 27). It has been reported in the literature that at temperatures above 700 °C, V2O5 dissolves the products of oxidation to form low melting eutectics, namely V2O5-Cr2O3-Fe2O3 (m.p 480 °C) and NiO-V2O5-Cr2O3 (m.p 550 °C). Upon cooling to lower temperatures Fe2O3 and Cr2O3 precipitate from the liquid phase and the presence of various phases in a thin layer of scale would impose such severe strain on the film that results in cracking and exfoliation of oxide scale (Ref 15, 31, 33, 34). In case of Ni-5Al coating, the oxide scale was found to be intact with the coating with minor spalling mainly near the edges. The minor spalling of the oxide scale in case of coated superalloy may be due to different values of thermal expansion co-efficient of the coating, substrate, and oxides (Ref 1). Further, the scale formed on the coated superalloy was light green in color, which may be due to the formation of NiO, similar observations were made by Mahesh et al. (Ref 27) and Sidhu (Ref 35). The role of Ni-5Al coating is to act as a sacrificial layer in order to protect the substrate material.

The weight change data of bare and Ni-5Al-coated superalloys after cyclic hot corrosion studies are shown in Fig. 4. The plots clearly indicate that the weight gained by bare superalloy is higher than the coated superalloy. The weight gain of bare superalloy could not be monitored after 30 cycles, due to intense spalling of the oxide scale. The weight gain of the Ni-5Al-coated superalloy was high during the initial stages and then it becomes nearly constant as observed from Fig. 4(a). The higher weight gain during initial few cycles of coated superalloy may be due to the rapid formation of oxides at the surface and splat boundaries of the coating, and within open pores. As all the internal surfaces get oxidized, the coating becomes dense and the diffusion of corrosive species to internal portions of the coatings slows down, while the growth of the oxides becomes limited mainly at the surface of the specimen. Therefore, the weight gain and the corrosion rate becomes steady with time (Ref 12). The cumulative weight gain by D-gun-sprayed Ni-5Al coating at the end of 100 cycles in Na2SO4-60% V2O5 environment at 900 °C was found to be 13.1 mg/cm2. Mahesh et al. (Ref 27) have reported that the cumulative weight gain of HVOF-deposited Ni-5Al coating on Ni-based superalloys in Na2SO4-60% V2O5 environment at 900 °C to be 16.2 mg/cm2. Therefore, the overall weight gain of D-gun-sprayed Ni-5Al coating is 19.1% less in comparison to that of HVOF-sprayed Ni-5Al coatings. The lower weight gain by D-gun-sprayed Ni-5Al coating may be attributed to the lower porosity value of the coating, as the porosity provides easy access to corrosive species to penetrate through it and reach the underlying coating and substrate material. Ni-5Al-coated superalloy followed nearly a parabolic behavior. A small deviation from the parabolic rate law may be due to cyclic scale growth (Fig. 4b). The parabolic rate constant (Kp in 10−10/g2/cm4/s) for bare and D-gun-sprayed Ni-5Al-coated superalloys are found to be 13.1 and 3.7, respectively, while that of HVOF sprayed Ni-5Al-coated superalloys is 5.08 (Ref 27). The Kp value is least for D-gun-sprayed Ni-5Al coating as compared to that of bare and HVOF sprayed Ni-5Al-coated superalloys, thereby indicating better resistance of D-gun-sprayed Ni-5Al coating to hot corrosion in the given environment at 900 °C.

The XRD analysis (Fig. 5) of bare superalloy after cyclic hot corrosion studies indicates the presence of Fe2O3, NiO, NiVO3, Cr2O3, and TiO2 phases in the oxide scale. The Fe2O3 is reported to be porous non protective oxide scale and might have allowed the penetration of corrosive species through the scale (Ref 12). Further, the sodium sulfate (Na2SO4) and vanadium pentoxide (V2O5) react in the temperature range of 900 °C to form sodium meta-vanadate (NaVO3) by following reaction:

The NaVO3 has relatively low melting point (630 °C), it is volatile and rapidly vaporizes from the surface. It acts as a catalyst and also serves as an oxygen carrier to the base alloy through the open pores present on the surface leading to rapid oxidation of the base elements (Ref 27). Further, NaVO3 dissolves protective oxides such as Cr2O3 as given by the Eq 2 leading to depletion of protective oxides on the surface of the material (Ref 36).

This may be the reason for poor resistance of bare superalloy in the hot corrosive environment. In case of Ni-5Al coating the main phases identified were NiO, Al2O3, NiAl2O4, and Cr2O3. Mahesh et al. (Ref 27). have also reported the presence of similar phases in their XRD analysis of HVOF-sprayed Ni-5Al coatings.

Nickel aluminide undergoes following chemical reactions when exposed to high temperature oxidizing environment (Ref 37),

The formation of NiO, Al2O3, and NiAl2O4 phases might have inhibited interaction of corrosive species with underlying coating. These oxides are reported to be very protective in nature in hot corrosion environment (Ref 27). Further, the presence of Cr2O3 and FeVO4 on the oxide scale reveals that Cr and Fe have diffused from the substrate to the coating surface during hot corrosion studies.

The surface EDAX analysis of bare and Ni-5Al-coated superalloys shows mainly the presence of Cr2O3, NiO, Fe2O3, and Al2O3 phases, respectively. The presence of these phases on the surface scale is also supported by XRD analysis. The higher percentage of Fe2O3 (34.4 and 26.97% at points 1 and 2, respectively, Fig. 6a) present on the oxide scale may be the reason for the low resistance of bare superalloy against hot corrosion in the given environment. But in case of Ni-5Al coating, the presence of NiO and Al2O3 phases (points 3 and 4 Fig. 6b) might have blocked the diffusion of corrosive species into the underlying coating. Al2O3 has excellent high temperature corrosion resistance in molten salt environment, as it has a high melting point and stability at high temperature (Ref 38). This may be one of the reasons for better resistance against hot corrosion of Ni-5Al coating in comparison with bare superalloy. The small peaks of surface EDAX spectrum indicate the formation of Cr2O3 and Fe2O3 on the surface of the coating. The above findings are also supported by XRD and X-ray mapping analysis.

The cross-sectional EDAX analysis of bare and Ni-5Al-coated superalloys subjected to hot corrosion tests are shown in Fig. 7. The bare superalloy has suffered extensively due to hot corrosion attack. The top scale of bare superalloy (points 1 and 2) shows relatively higher percentage of Fe, Cr, and Ni along with O, indicating the formation Fe2O3, Cr2O3, and NiO. Oxygen has penetrated (points 1-3) deep into the superalloy (Fig. 7a). Also, point 5 indicates the presence of sulfur (1.23%) underneath the subscale region thereby indicating the porous and non protective nature of the oxide scale formed on the bare superalloy. In case of Ni-5Al coating (Fig. 7b), the tops scale (point 1) consists of mainly NiO phase along with small amount of Al2O3. The subscale region shows Ni-rich light gray (points 3 and 5) and Al-rich dark gray (points 2 and 4) areas. Oxygen has diffused into the subscale region (points 1-4). Further, the presence of oxygen near the coating-substrate interface is negligible there by indicating that it could not penetrate easily through the subscale region. On the other hand, the presence of Fe is also negligible in the subscale region (points 1-4), as it could not penetrate easily from substrate into the coating. This may be due to low porosity and dense, adherent nature of protective oxides formed in the Ni-5Al coatings (Fig. 7b). The dense coatings provide better hot corrosion resistance than the porous coatings and prevent short-circuit transport of the reactants. Point 7 in Fig. 7b indicates that the substrate material was unaffected by the external environment and Ni-5Al coating has provided necessary protection to it against hot corrosion.

It is noticed from X-ray mapping analysis of Ni-5Al coating that the top scale is partially oxidized, where Ni, Al, and O coexist indicating the formation of NiO, NiAl2O4, and Al2O3 on the top scale (Fig. 8). Lee et al. (Ref 37) have reported that the NiAl2O4 spinel phase has better hot corrosion resistance than NiO phase, since the solubility of NiAl2O4 spinel is smaller than NiO in the molten salt. Also, from Fig. 8 it is clear that Al and O coexist near Ni-rich splat boundaries suggesting the formation of Al2O3. This is also confirmed by XRD, surface, and cross-sectional EDAX analysis. Cr and O coexist as a thin layer near the coating-substrate interface indicating the formation of Cr2O3. The Ni-rich splats are mostly un-oxidized in the subscale region indicating the as-sprayed nature of the coating. Further, the penetration of oxygen is negligible below the subscale region, thereby indicating that the formation of NiO, NiAl2O4, and Al2O3 in the top and subscale region might have acted as solid diffusion barrier that decreases the availability of oxygen with underlying substrate material. This in turn favors the formation of Cr2O3 near the coating and substrate interface. The Cr2O3 is thermodynamically stable up to high temperatures due to its high melting point. It forms a dense, continuous, and adherent layer that grows relatively slowly and acts as a solid diffusion barrier that inhibits interaction of corrosive species with the underlying substrate material. The diffusion of Fe from the substrate material into D-gun-sprayed Ni-5Al coating is very little as seen in Fig. 8, whereas the X-ray mapping analysis of HVOF-sprayed Ni-5Al coatings (Ref 27) shows higher diffusion of Fe into the coating. So, Fe is like a diffusion tracer, showing that the Ni-5Al coating deposited by D-gun process has slower diffusion, leading to slower scale growth in comparison to Ni-5Al coating deposited by HVOF process.

It can be inferred based on the present investigation that Ni-5Al coating has provided very good hot corrosion resistance in the given environment when compared with bare superalloy.

Conclusion

The high temperature cyclic hot corrosion behavior of D-gun-sprayed Ni-5Al coating on Ni-based superalloy In-718 has been studied and the following conclusions were made.

-

1.

D-gun spraying process has been successfully used to deposit Ni-5Al coating on In-718 substrate material. The average coating thickness was 175 μm and the coating deposited was uniform and adherent to the substrate material.

-

2.

The Ni-5Al coating exhibited dense and uniform lamellar structure with cross-sectional porosity values of around 0.9%, micro-hardness values in the range of 253-306 Hv, and surface roughness values in the range of 4.5-5.6 μm.

-

3.

The bare superalloy suffered intense spallation with oxide scaled getting exfoliated from the surface. The oxide scale on Ni-5Al coating showed minor spalling and was intact with the coating.

-

4.

The Ni-5Al-coated superalloy nearly followed parabolic rate law after exposure at 900 °C for 100 cycles. The parabolic rate constant of coated superalloy was much lower than that of bare superalloy.

-

5.

The hot corrosion resistance of Ni-5Al coating was better in comparison with bare superalloy. The formation of NiO, NiAl2O4, and Al2O3 oxides on the scale of Ni-5Al coating have provided better hot corrosion resistance in the given environment. The presence of these oxides is confirmed by XRD, EDAX, and X-ray mapping.

-

6.

Small amount of chromium and iron were present on the top scale of the Ni-5Al-coated sample indicating the diffusion of these elements from the substrate to the top scale.

References

S. Kamal, R. Jayaganthan, S. Prakash, and S. Kumar, Hot Corrosion Behaviour of Detonation Gun Sprayed Cr3C2–NiCr Coatings on Ni and Fe-Based Superalloys in Na2SO4–60% V2O5 Environment at 900°C, J. Alloys Compd., 2008, 463, p 358-372

S. Kamal, R. Jayaganthan, and S. Prakash, Hot Corrosion Studies of Detonation-Gun-Sprayed NiCrAlY + 0.4wt.%CeO2 Coated Superalloys in Molten Salt Environment, J. Mater. Eng. Perform., 2011, 20(6), p 1068-1077

G. Kaushal, H. Singh, and S. Prakash, Performance of Detonation Gun-Sprayed Ni-20Cr Coating on ASTM A213 TP347H Steel in a Boiler Environment, J. Therm. Spray Technol., 2012, 21(5), p 975-986

G. Sundararajan, K.U.M. Prasad, D.S. Rao, and S.V. Joshi, A Comparative Study of Tribological Behaviour of Plasma and D-gun Sprayed Coatings under Different Wear Modes, J. Mater. Eng. Perform., 1998, 7(3), p 343-351

C. Senderowski and Z. Bojar, Gas Detonation Spray Forming of Fe–Al Coatings in the Presence of Interlayer, Surf. Coat. Technol., 2008, 202(15), p 3538-3548

C. Senderowski and Z. Bojar, Influence of Detonation Gun Spraying Conditions on the Quality of Fe-Al Intermetallic Protective Coatings in the Presence of NiAl and NiCr Interlayers, J. Therm. Spray Technol., 2009, 18(3), p 435-447

C. Senderowski, Z. Bojar, W. Wołczyński, and A. Pawłowski, Microstructure Characterization of D-gun Sprayed Fe–Al Intermetallic Coatings, Intermetallics, 2010, 18(7), p 1405-1409

C. Senderowski, Nanocomposite Fe-Al Intermetallic Coating Obtained by Gas Detonation Spraying of Milled Self-Decomposing Powder, J. Therm. Spray Technol., 2014, 23(7), p 1124-1134

C. Senderowski, D. Zasada, T. Durejko, and Z. Bojar, Characterization of As-synthesized and Mechanically Milled Fe–Al Powders Produced by the Self-Disintegration Method, Powder Technol., 2014, 263, p 96-103

C. Senderowski, A. Pawłowski, Z. Bojar, W. Wołczyński, M. Faryna, J. Morgiel, and Ł. Major, TEM Microstructure of Fe-Al Coatings Detonation Sprayed onto Steel Substrate, Arch. Metall. Mater., 2010, 55(2), p 373-381

S. Kamal, R. Jayaganthan, and S. Prakash, High Temperature Oxidation Studies of Detonation-Gun-Sprayed Cr3C2–NiCr Coating on Fe- and Ni-Based Superalloys in Air Under Cyclic Condition at 900°C, J. Alloys Compd., 2009, 472, p 378-389

S. Saladi, J. Menghani, and S. Prakash, Hot Corrosion Behaviour of Detonation-Gun Sprayed Cr3C2–NiCr Coating on Inconel-718 in Molten Salt Environment at 900°C, Trans. Indian Inst. Met., 2014, 67(5), p 623-627

T.S. Sidhu, R.D. Agrawal, and S. Prakash, Hot Corrosion of Some Superalloys and Role of High-Velocity Oxy-Fuel Spray Coatings—A Review, Surf. Coat. Technol., 2005, 198, p 441-446

T.S. Sidhu, S. Prakash, and R.D. Agrawal, Characterizations and Hot Corrosion Resistance of Cr3C2-NiCr Coating on Ni-Base Superalloys in an Aggressive Environment, J. Therm. Spray Technol., 2006, 15(4), p 811-816

H. Singh, D. Puri, and S. Prakash, An Overview of Na2SO4 And/Or V2O5 Induced Hot Corrosion of Fe- and Ni-Based Superalloys, Rev. Adv. Mater. Sci., 2007, 16, p 27-50

N. Eliaz, G. Shemesh, and R.M. Latannision, Hot Corrosion in Gas Turbine Components, Eng. Fail. Anal., 2002, 9, p 31-43

H. Singh, S. Prakash, D. Puri, and D.M. Phase, Cyclic Oxidation Behavior of Some Plasma-Sprayed Coatings in Na2SO4-60%V2O5 Environment, J. Mater. Eng. Perform., 2006, 15(6), p 729-741

T.S. Sidhu, S. Prakash, and R.D. Agrawal, Hot Corrosion Behaviour of HVOF-Sprayed NiCrBSi Coatings on Ni- and Fe-Based Superalloys in Na2SO4–60%V2O5 Environment at 900°C, Acta Mater., 2006, 54(3), p 773-784

A. Thomas, M. El-Wahabi, J.M. Cabrera, and J.M. Prado, High Temperature Deformation of Inconel 718, J. Mater. Process. Technol., 2006, 177, p 469-472

T.S. Sidhu, S. Prakash, and R.D. Agrawal, Hot Corrosion Resistance of High-Velocity Oxyfuel Sprayed Coatings on a Nickel-Base Superalloy in Molten Salt Environment, J. Therm. Spray Technol., 2006, 15(3), p 387-399

J.T. Chang, A. Davison, J.L. He, and A. Matthews, Deposition of Ni–Al–Y Alloy Films Using a Hybrid Arc Ion Plating and Magnetron Sputtering System, Surf. Coat. Technol., 2006, 200(20-21), p 5877-5883

Buta Singh Sidhu and S. Prakash, Degradation Behavior of Ni3Al Plasma-Sprayed Boiler Tube Steels in an Energy Generation System, J. Mater. Eng. Perform., 2005, 14(3), p 356-362

M.J. Donachie and S.J. Donachie, Superalloys: A Technical Guide, 2nd ed., ASM International, Materials Park, 2002

J.A. Hearley, J.A. Little, and A.J. Sturgeon, The Erosion Behaviour of NiAl Intermetallic Coatings Produced by High Velocity Oxy-Fuel Thermal Spraying, Wear, 1999, 233-235, p 328-333

B.S. Sidhu and S. Prakash, Evaluation of the Corrosion Behaviour of Plasma-Sprayed Ni3Al Coatings on Steel in Oxidation and Molten Salt Environments at 900°C, Surf. Coat. Technol., 2003, 166(1), p 89-100

R.A. Mahesh, R. Jayaganthan, S. Prakash, V. Chawla, and R. Chandra, High Temperature Cyclic Oxidation Behavior of Magnetron Sputtered Ni–Al Thin Films on Ni- and Fe-Based Superalloys, Mater. Chem. Phys., 2009, 114(2-3), p 629-635

R.A. Mahesh, R. Jayaganthan, and S. Prakash, A Study on Hot Corrosion Behaviour of Ni–5Al Coatings on Ni- and Fe-Based Superalloys in an Aggressive Environment at 900°C, J. Alloys Compd., 2008, 460(1-2), p 220-231

R.A. Mahesh, R. Jayaganthan, and S. Prakash, Oxidation Behavior of HVOF Sprayed Ni–5Al Coatings Deposited on Ni- and Fe-Based Superalloys Under Cyclic Condition, Mater. Sci. Eng. A, 2008, 475(1-2), p 327-335

R.A. Rapp, J.H. Devan, D.L. Douglass, P.C. Nordine, F.S. Pettit, and D.P. Whittle, High Temperature Corrosion in Energy Systems, Mater. Sci. Eng., 1981, 50, p 1-17

Z. Xu, L. He, R. Mu, S. He, G. Huang, and X. Cao, Hot Corrosion Behavior of Rare Earth Zirconates and Yttria Partially Stabilized Zirconia Thermal Barrier Coatings, Surf. Coat. Technol., 2010, 204, p 3652-3661

G. Goyal, H. Singh, and S. Prakash, Effect of Superficially Applied ZrO2 Inhibitor on the High Temperature Corrosion Performance of Some Fe-, Co- and Ni-Base Superalloys, Appl. Surf. Sci., 2008, 254(20), p 6653-6661

M. Kaur, H. Singh, and S. Prakash, High-Temperature Corrosion Studies of HVOF-Sprayed Cr3C2-NiCr Coating on SAE-347H Boiler Steel, J. Therm. Spray Technol., 2009, 18(4), p 619-632

K. Sachs (1958) Accelerated High Temperature Oxidation Due to Vanadium Pentoxide. Metallurgia p. 167-173

S.R. Iyer, K.J.L. Iyer, and V.M. Radhakrishan, High Temperature Corrosion of a Ni-Base Superalloy by Vanadium, Proc. of 10th ICMC, IV, 1987, p. 3665

B. Sidhu, Ph.D. Thesis, Department of Metallurgical and Materials Engineering, Indian Institute of Technology, Roorkee, India, 2003

J. Swaminathan, S. Raghavan, and S.R. Iyer, Studies on the Hot Corrosion of Some Nickel-Base Superalloys by Vanadium Pentoxide, Trans. Indian Inst. Met., 1993, 46(3), p 175-181

W.H. Lee and R.Y. Lin, Hot Corrosion Mechanism of Intermetallic Compound Ni3Al, Mater. Chem. Phys., 2002, 77, p 86-96

Z. Chen, N.Q. Wu, J. Singh, and S.X. Mao, Effect of Al2O3 Overlay on Hot-Corrosion Behavior of Yttria-Stabilized Zirconia Coating in Molten Sulfate-Vanadate Salt, Thin Solid Films, 2003, 443(1-2), p 46-52

Acknowledgment

The authors would like to thank Dr. Mukul Gupta of UGC-DAE Consortium for Scientific Research, Indore for performing XRD analysis. The authors also wish to thank Mr. Hiren Upadhyay and Mr. Sagar Jagtap of SIC, NIT Surat for performing SEM/EDAX analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saladi, S., Menghani, J.V. & Prakash, S. Characterization and Evaluation of Cyclic Hot Corrosion Resistance of Detonation-Gun Sprayed Ni-5Al Coatings on Inconel-718. J Therm Spray Tech 24, 778–788 (2015). https://doi.org/10.1007/s11666-015-0235-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-015-0235-1