Abstract

The adhesion mechanism of deposit/substrate interface prepared by the cold spray method is not fully understood at present. It seems that the adhesion strength is mainly determined by the mechanical (including the plastic deformation of particle and substrate) and thermal interaction between particle and substrate when the particles impact onto the substrate with a high velocity. In order to understand the adhesion mechanism, a novel adhesive strength test was developed to measure the higher bonding strength of cold sprayed coatings in this study. The method breaks through the limits imposed by glue strength in the conventional adhesive strength test, and it can be used to measure the coatings with a higher adhesive strength. The particle velocity was obtained with DPV-2000 measurement and CFD simulation. The relationships between the adhesion strength of deposits/substrate interface and particle velocity were discussed. The results show that stronger adhesion strength can be obtained with the increase of particle velocity. There are two available ways to improve the adhesion strength. One is to increase the temperature of working gas, and another is to employ helium gas as the working gas instead of nitrogen gas.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Cold spray is an emerging spray coating technology that was first developed in the mid 1980s at the Institute of Theoretical and Applied Mechanics in the former Soviet Union (Ref 1). In the cold spraying process, spray particles are injected into a supersonic jet of compressed gas and accelerated to a high velocity (300-1200 m/s). The deposition of particles takes place through intensive plastic deformation upon impact in solid state at a temperature well below the melting point of the spray materials (Ref 2). As a result, spray particles experience little oxidation or decomposition in cold spray (Ref 3) and (Ref 4). So far, cold spray has been used to spray not only ductile materials such as copper (Ref 5, 6), aluminum (Ref 7), nickel (Ref 8), nickel based alloys (Ref 9), zinc (Ref 10) but also metal matrix composites (Ref 11), cermets (Ref 12) and ceramic materials (Ref 13).

Previous studies suggested that particle deposition depends on the impact velocity and only the particles with a velocity higher than a critical velocity can be deposited. Below the critical velocity, impacting particles would only cause erosion of the substrate (Ref 14, 15). Experimental and theoretical results showed that the critical velocity is dependent on the properties of powder and substrate materials (Ref 16, 17), particle size and geometry (Ref 1), particle temperature (Ref 18), particle oxygen content (Ref 19) and substrate preparation (Ref 20). This may partially explain why even for the same powder materials the reported critical velocity was somewhat different (Ref 19, 21).

Adhesive strength of coatings prepared by cold spray determines its applications in the industrial field. Therefore, many researchers have been focused on the bonding mechanism in the last few years. Mäkinen et al. presented the influences of powder, substrate and heat treatment on the adhesive strength (Ref 22). Moreover, recently numerical simulation also has helped to explore the bonding mechanism (Ref 23–26). These studies on the bonding mechanism of cold spray suggested that the adhesive strength is mainly affected by the mechanical interlock (Ref 23, 24) and diffusion bonding or metallurgical bonding caused by molten impact (Ref 10, 26) based on the shear instability (Ref 25). But so far, the underlying mechanism of bonding of cold spray has not been well clarified (Ref 18).

In the present study, a novel method was employed to measure the higher adhesive strength of copper coatings instead of the conventional method using the epoxy resin adhesive. In order to control the particle impact velocity, coatings for the adhesive strength experiment were prepared on three types of substrate, A5052, A6063 and copper, and changes of the working gas pressure and temperature were employed. The velocity and temperature of working gas and in-flight particle were calculated by Fluent, commercial CFD software. The particle velocity was also measured by an on-line diagnostic system of DPV-2000. In addition, the relationships between the impact velocity and the adhesive strength of copper coatings were discussed.

Experimental Procedure

Feedstock Powder and Cold Spray Process

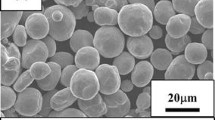

Commercially available copper particles of particle diameters ranging from 5 to 45 μm were used. The morphology of the powder is presented in Fig. 1(a). The powder size distribution was characterized by the laser diffraction particle size analyzer (Seishin Trading Co., Ltd. Kobe, Japan). The volume and number distributions of diameters are shown in Fig. 1(b). The volume average diameter is about 30 μm, and the number average diameter is about 18 μm.

In this study, a commercial cold spray system, model number PCS-305 designed by Plasma Giken Co. Ltd., was used to prepare the coatings for adhesive strength measurement. A converging-diverging (De-Laval) nozzle with the throat diameter of 3 mm and outlet diameter of 6.5 mm was configured in the cold spray system. The nozzle is cooled by chilled water in order to alleviate nozzle clogging and improve the reliability of this system. As a gas pressure controlled system, the gas flow rate is adjusted by the gas pressure. In order to control the mixed gas temperature of the powder feeding gas (cold gas) and the working gas (hot gas), the ratio of the mass flow rate for the two gases was set to about 1/4 by adjusting the pressure of powder feeding gas in the experiments. The detailed spray conditions for cold spraying are shown in Table 1.

The Measurement of In-Flight Particle Velocity

The in-flight particle velocity was measured at the center line of the flow, using the DPV-2000 system (Tecnar Automation Ltd., St-Bruno, Québec, Canada) under the conditions of preparing coatings as shown in Table 1. The substrate was removed during the particle velocity measurement process. For the cold spray process, the radiation intensity emitted from the in-flight particles is too weak to be detected by the optical sensor because of the low temperature of the particles. Therefore, a high-power diode laser system, the CPS-2000, was equipped in the DPV-2000 system to beam the in-flight particles. By detecting the monochromatic light scattered by particles, the velocity of particles can be measured by the DPV-2000 system. In this study, the velocity measurements were made at the position on the centerline of the gas flow 30 mm away from the spraying gun exit.

A Novel Method to Measure Adhesive Strength

In the conventional adhesive strength test for thermal spray coatings, an epoxy resin adhesive is employed to glue the sample to another identical, but uncoated sample. The schematic illustration of the method is shown in Fig. 2. The testing results are tremendously restricted by the strength of the glue. The strength of epoxy resin adhesive is generally not higher than 70 MPa, and consequently the testing method cannot be employed to measure coating adhesions with a higher adhesive strength than that of the adhesive.

With cold spray, a suitable spray condition can prepare coatings with high adhesive strength. Therefore, the conventional testing method became invalid for the high adhesive strength coatings prepared by the cold spray process. Fortunately, quite thick coatings can be obtained by the process of cold spray, without difficulty. The adhesive strength of thick coatings can be measured using a novel testing method as shown in Fig. 3. First, thick coatings of more than 5 mm were deposited on a conventional tensile specimen with a diameter of 25 mm, as shown in Fig. 3(a). And then the test piece was machined into a shape as shown in Fig. 3(b). The part near the coating/substrate interface was cut thinner to ensure the rupture happened in that area during the tensile test. The inner edges of the machined part were cut to an arc transition with a radius of 1 mm in order to prevent a stress concentration effect. Finally, the sample can be pulled directly with a special jig as shown in the Fig. 3(c).

The Numerical Simulation Method

The CFD code of Fluent was used to simulate the cold spray process. Due to the axisymmerical characteristic of flow in the gun, a two-dimensional symmetrical steady-state mode was used in the current study. According to the previous study, the presence of a substrate had little influence on particle acceleration (Ref 27). Therefore, the substrate was not involved in this simulation. Considering the water-cooled gun used in this study, the outer boundary of the gun was set to a constant temperaure wall with the temperature of 40 °C for the water-cooled part, and an adiabatic wall for the other part.

The working gas was taken as an ideal and compressible one. A coupled implicit method was used to solve the flow field. The realizable K-ε turbulence model was utilized in the simulation because of the high pressure gradients. Considering the actual particle diameter ultized in this study, a spherical particle with the diameter of 18 μm was fed into the gun at the axisymmetric center for the calculation of particle velocity and temperature. The accelerating and heating of particles were computed using Discrete Phase Modeling (DPM) of Fluent (Ref 28).

Results and Discussions

Simulation Results Compared with Measured Results by DPV-2000

The distributions of temperature and gas velocity calculated by Fluent are shown in Fig. 4(a) under the conditions of N2, 3 MPa, 1000 °C. In this study, the boundary conditions of adiabatic wall were not used but a constant temperature was taken into consideration for the nozzle’s outer wall because a water-cooled gun was used. Therefore, it can be seen that the temperature of the nozzle is low and similar to the temperature of cooling water. A copper particle with a diameter of 18 μm was fed into the gas field at the axisymmetric center, and the calculated temperature and velocity of the particle are shown in Fig. 4(b) and (c). The particle is preheated before passing through the nozzle throat and the temperature drops with the fast descent of the gas temperature while passing through the nozzle throat due to the expansion of gas. However, the particle is accelerated only while passing the nozzle throat until a location beyond about 100 mm from the nozzle exit.

Taking the particle velocity calculated at the location beyond 30 mm of nozzle exit, the extracted particle velocities are shown in Fig. 5 under different spray conditions. It reveals that the particle velocity rises with the increase of working gas temperature from 200 to 1000 °C. However, only a minor increase of particle velocity was observed with the increase of working gas pressure from 3 to 4 MPa. When helium gas was utilized as the working gas, higher particle velocities were obtained even under a lower gas temperature compared with the use of N2 gas. It seems that the valid ways to obtain a high particle velocity are to develop a high temperature cold spray system or use helium instead of nitrogen as the working gas.

Depending on the detection of scattering light in the experiment, the DPV-2000 system cannot measure particle diameter correctly. Therefore, the number distributions and average of particle velocities can be calculated instead of volume ones. The number distributions of particle velocity measured by DPV-2000 are shown in Fig. 6. Similar to the results of simulations, the gas temperature and gas type have great influences on the particle velocity, and the gas pressure has little influence on the particle velocity. The profiles of the velocity distributions present that the particle velocity ranged from 300 to 1000 m/s if nitrogen gas was used, and from 600 to 1400 m/s if helium gas was used.

From the distributions of particle velocity above, the number average velocities can be obtained. Assuming that the particle velocity measured at the specific position is only influenced by the particle diameter, the number average particle velocity measured can be considered as the velocity of the particle with the diameter of 18 μm, the number average diameter of the copper powder used in the experiments. The comparison between the number average velocities measured by DPV-2000 and the ones calculated by Fluent is shown in Fig. 7. It reveals that the particle velocities calculated are very close to the ones measured, and moreover the same tendency of particle velocity to change relative to the gas temperature can be observed regardless of which way is used. Even though the shape of the actual particle used in the experiments was not a perfect sphere and the drag force of actual particle is a little larger than that of the spherical particle, the deviation of the experimental results from the ideal numerical calculated results somewhat compensates for the error caused by the little difference in the drag coefficient. Therefore, the numerical calculation is a valid way to predict the in-flight particle velocity.

Adhesive Strength of Coatings

The adhesive strength of copper coatings deposited on the three substrates is shown in Fig. 8. It can be seen that the tensile strength of coatings increased with the increase of gas temperature. The tensile strength experienced a small increase when adjusting the gas pressure from 3 to 4 MPa. When helium gas was employed as the working gas, the tensile strength was much higher than those prepared with nitrogen gas. The tensile strength of coatings on the A5052 and A6063 substrates are very similar, but some difference from that can be observed on the Cu substrates. The coatings deposited on Cu substrates have lower adhesive strength than those on the Al alloy substrates at the lower working gas temperature. It seems that a higher particle velocity is necessary to make much larger plastic deformation for the Cu substrates compared with the Al alloy substrates in order to form an effective bonding.

If the gas temperature exceeded 800 °C, almost all the specimens ruptured in the coating instead of the interface of coating/substrate as shown in Fig. 9. It seems that the particle velocity caused a good bonding even for the Cu substrate owing to the sufficient plastic deformation that happened in the particles and substrates. One of the reasons causing failure within the coatings is stress concentration. In spite of the arc transition used at the inner corner near the interface of coating/substrate, the stress concentration may have caused the failure of some specimens near the inner corner. Another reason is the inherent defects in the cold sprayed coatings. Although the coatings prepared by the cold spray process have a lower ratio of defects than the ones prepared by conventional thermal spray, defects do still exist in the coatings as shown in the Fig. 10. These defects are so sensitive to the tensile stress that the cohesive strength of coatings decreases intensively. Consequently, the adhesive strength was stronger than the cohesive strength of coatings, which results in the ruptures inside the coatings.

Discussion

From the results mentioned above, it seems that the spray conditions of working gas pressure and temperature have similar influences on the adhesive strength of coatings and particle velocity. Figure 11 shows the relationship between the tensile strength and the calculated particle velocity. It reveals that the adhesive strength is low at a lower particle velocity, and sharply increases with the particle velocity exceeding about 700 m/s. The adhesive strength is stronger than the cohesive tensile strength of coatings sprayed at high particle velocity, and consequently the adhesive strength cannot be tested, but rather the cohesive tensile strength of coatings due to the rupture position inside of the coatings. Taking consideration of the rupture position and the stress concentration, Fig. 11 only shows the lower limit of adhesive strength of coating/substrate at the higher particle velocity region, and the real adhesive strength is stronger than the measured one. Even so, a conclusion can be drawn that the adhesive strength benefits from an increase in particle velocity.

Splats of copper particles impacting on A5052 substrates are shown in Fig. 12. With increases of particle velocity, the copper particles deeply embedded into the A5052 substrate, and more intensive plastic deformation occurred in both particles and substrates. “Jetting” was almost unobservable under the conditions of N2, 3 MPa, 200 °C, and small jetting was obtained when the gas temperature was increased to 600 °C. If the particle velocity increased further such as under conditions employing helium as the working gas, the particle deeply embedded in the substrate and consequently extensive jetting was generated. Unlike the splat, which is only one particle impacting on the substrate, in the actual cold spray process, the subsequent particle will impact on the jetting and mechanical interlock will occur between the coating and substrate as shown in Fig. 12(d). The severe mechanical interlock resulting from intensive plastic deformation results in high adhesive strength, more than 250 MPa under the conditions of He gas, 2 MPa, 600 °C.

Conclusions

In this study, copper particle velocity was measured by the DVP-2000 system and calculated by the CFD software of Fluent. The copper coatings were prepared using the cold spray process under different spray conditions and the adhesive strength on three substrates was also tested. Thanks to the novel adhesive strength test, higher tensile strength was obtained. Even though the geometry of a specimen has not been optimized, the lower limit of adhesive strength can be obtained. By this method, up to 250 MPa of adhesive strength was observed for copper coatings on A5052 substrates in the current study. Results showed that simulation is a valid way to predict in-flight particle velocity because the calculated particle velocity was nearly identical to the one measured. The in-flight particle velocity increased with the increase of gas pressure and temperature or using helium instead of nitrogen gas. Similarly to the particle velocity, the adhesive strength of coatings to the substrates increased too with the increase of gas pressure and temperature or using helium instead of nitrogen gas. It seems that particle velocity plays an important role in improving adhesive strength based on plastic deformation. A higher particle velocity benefits the mechanical interlock effect resulting in excellent bonding between the coating and substrate.

References

P. Richer, B. Jodoin, K. Taylor, E. Sansoucy, M. Johnson, and L. Ajdelsztajn, Effect of particle geometry and substrate preparation in cold spray, Thermal Spray 2005: Explore Its Surfacing Potential, E. Lugscheider, Ed., May 2-4, 2005 (Basel, Switzerland), DVS-Verlag, Düsseldorf, Germany, 2005, p 193-198

W.-Y. Li, C.-j. Li, and H. Liao, Effect of Annealing Treatment on the Microstructure and Properties of Cold-Sprayed Cu Coating, J. Therm. Spray Technol., 2006, 15(2), p 206-211

T. Stoltenhoff, H. Kreye, and H.J. Richter, An Analysis of the Cold Spray Process and Its Coatings, J. Therm. Spray Technol., 2002, 11(4), p 542-550

R.C. McCune, W.T. Donlon, O.O. Popoola, and E.L. Cartwright, Characterization of Copper Layers Produced by Cold Gas-Dynamic Spraying, J. Therm. Spray Technol., 2000, 9(1), p 73-82

E. Calla, D.G. McCartney, and P.H. Shipway, Deposition of copper by cold gas dynamic spraying: an investigation of dependence of microstructure and properties of the deposits on the spraying conditions, Thermal Spray 2004: Advances in Technology and Applications, D. von Hofe, Ed., May 10-12, 2004 (Osaka, Japan), ASM International, 2004, p 382-387

T. Xiong, Z. Bao, T. Li, and Z. Li, Study on Cold-Sprayed Copper Coating’s Properties and Optimizing Parameters for the Spraying Process, Thermal Spray 2005: Explore Its Surfacing Potential, E. Lugscheider, Ed., May 2-4, 2005 (Basel, Switzerland), DVS-Verlag, Düsseldorf, Germany, 2005, p 178-184

R. Morgan, P. Fox, J. Pattison, C. Sutcliffe, and W. O’Neill, Analysis of Cold Gas Dynamically Sprayed Aluminum Deposits, Mater. Lett., 2004, 58(7-8), p 1317-1320

M.K. Decker, R.A. Neiser, D. Gilmore, and H.D. Tran, Microstructure and Properties of Cold Spray Nickel, Thermal Spray 2001: New Surfaces for a New Millennium, C.C. Berndt, K.A. Khor, and E.F. Lugscheider, Ed., May 28-30, 2001 (Singapore), ASM International, 2001, p 433-439

F. Raletz, G. Ezo’o, M. Vardelle, and M. Ducos, Characterization of Cold-Sprayed Nickel-Base Coatings, Thermal Spray 2004: Advances in Technology and Applications, D. von Hofe, Ed., May 10-12, 2004 (Osaka, Japan), ASM International, 2004, p 344-349

W.-Y. Li, C.-J. Li, and G.-J. Yang, Effect of Impact-Induced Melting on Interface Microstructure and Bonding of Cold-Sprayed Zinc Coating, Appl. Surf. Sci., 2010, 257(5), p 1516-1523

D. Morelli, A. Elmoursi, T. Vansteenksite, D. Gorkiewicz, and B. Gillispie, Kinetic Spray of Aluminum Metal Matrix Composites for Thermal Management Applications, Thermal Spray 2003: Advancing the Science and Applying the Technology, B.R. Marple and C. Moreau, Ed., May 5-8, 2003 (Orlando, FL), ASM International, 2003, p 85-90

J. Karthikeyan, C.M. Kay, and J. Lindemann, Cold Sprayed Nanostructured, WC-Co, Thermal Spray 2001: New Surfaces for a New Millennium, C.C. Berndt, K.A. Khor, and E.F. Lugscheider, Ed., May 28-30, 2001 (Singapore), ASM International, 2001, p 383-387

G.-J. Yang, C.-J. Li, F. Han, W.-Y. Li, and A. Ohmori, Low Temperature Deposition and Characterization of TIO2 Photocatalytic Film Through Cold Spray, Appl. Surf. Sci., 2008, 54(13), p 3979-3982

C.-J. Li, W.-Y. Li, Y.-Y. Wang, G.-J. Yang, and H. Fukanuma, A Theoretical Model for Prediction of Deposition Efficiency in Cold Spraying, Thin Solid Films, 2005, 489, p 79-85

N. Papyrin, S. V. Klinkov, and V. F. Kosarev, Modeling of Particle-Substrate Adhesive Interaction Under the Cold Spray Process, Thermal Spray 2003: Advancing the Science and Applying the Technology, B.R. Marple and C. Moreau, Ed., May 5-8, 2003 (Orlando, FL), ASM International, Vol. 1, 2003, p 27-35

D.L. Gilmore, R.C. Dykhuizen, R.A. Neiser, T.J. Roemer, and M.F. Smith, Particle Velocity and Deposition Efficiency in the Cold Spray Process, J. Therm. Spray Technol., 1999, 8(4), p 576-582

D. Zhang, P.H. Shipway, and D.G. McCartney, Cold Gas Dynamic Spraying of Aluminum: The Role of Substrate Characteristics in Deposit Formation, J. Therm. Spray Technol., 2005, 14(1), p 109-116

F. Gärtner, C. Borchers, T. Stoltenhoff, H. Kreye, and H. Assadi, Numerical and Microstructural Investigations of the in Cold Spraying, Thermal Spray 2003: Advancing the Science and Applying the Technology, B.R. Marple and C. Moreau, Ed., May 5-8, 2003 (Orlando, FL), ASM International, Vol. 1, p 1-8

Li. Chang-Jiu, Li. Wen-Ya, and Hanlin. Liao, Examination of the Critical Velocity for Deposition of Particles in Cold Spraying, J. Therm. Spray Technol., 2006, 15(2), p 212-222

N. Papyrin, Albuquerque, S. V. Klinkov, and V. F. Kosarev, Effect of the Substrate Surface Activation on the Process of Cold Spray Coating Formation, Thermal Spray 2005: Explore Its Surfacing Potential, E. Lugscheider, Ed., May 2-4, 2005 (Basel, Switzerland), DVS-Verlag, Düsseldorf, Germany, p 145-150

T. Stoltenhoff, J. Voyer, and H. Kreye, Cold spray-state of the art and applicability, Thermal Spray 2002: International Thermal Spray Conference, E. Lugscheider and C.C. Berndt, Ed., March 4-6, 2002 (Essen, Germany), DVS Deutscher Verband für Schweißen, p 366-374

H. Mäkinen, J. Lagerbom, and P. Vuoristo, Adhesion of Cold Sprayed Coatings: Effect of Powder, Substrate, and Heat Treatment, Thermal Spray 2007: Global Coating Solutions, B.R. Marple, M.M. Hyland, Y.-C. Lau, C.-J. Li, R.S. Lima, and G. Montavon, Ed., May 14-16, 2007 (Beijing, China), ASM International, 2007, p 31-36

M. Grujicica, J.R. Saylor, D.E. Beasley, W.S. DeRosset, and D. Helfritch, Computational Analysis of the Interfacial Bonding Between Feed-Powder Particles and the Substrate in the Cold-Gas Dynamic-Spray Process, Appl. Surf. Sci., 2003, 219(3-4), p 211-227

S. Kumar, G. Bae, and C. Lee, Deposition Characteristics of Copper Particles on Roughened Substrates Through Kinetic Spraying, Appl. Surf. Sci., 2009, 255(6), p 3472-3479

M. Grujicic, C.L. Zhao, W.S. Derosset, and D. Helfritch, Adiabatic Shear Instability Based Mechanism for Particles/Substrate Bonding in the Cold-Gas Dynamic-Spray Process, Mater. Des., 2004, 25, p 681-688

S. Guetta, M.H. Berger, F. Borit, V. Guipont, M. Jeandin, M. Boustie, Y. Ichikawa, K. Sakaguchi, and K. Ogawa, Influence of Particle Velocity on Adhesion of Cold-Sprayed Splats, J. Therm. Spray Technol., 2009, 18(3), p 331-342

W.-Y. Li and C.-J. Li, Optimization of Spray Conditions in Cold Spraying Based on the Numerical Analysis of Particle Velocity, Trans. Nonferrous Met. Soc. China, 2004, 14(S2), p 43-48

Ansys Inc., Fluent 6.3 User’s Guider, NH, 2006

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2011 International Thermal Spray Conference and has been expanded from the original presentation. It is simultaneously published in Thermal Spray 2011: Proceedings of the International Thermal Spray Conference, Hamburg, Germany, September 27-29, 2011, Basil R. Marple, Arvind Agarwal, Margaret M. Hyland, Yuk-Chiu Lau, Chang-Jiu Li, Rogerio S. Lima, and André McDonald, Ed., ASM International, Materials Park, OH, 2011.

Rights and permissions

About this article

Cite this article

Huang, R., Fukanuma, H. Study of the Influence of Particle Velocity on Adhesive Strength of Cold Spray Deposits. J Therm Spray Tech 21, 541–549 (2012). https://doi.org/10.1007/s11666-011-9707-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-011-9707-0