This article presents, from a historical perspective, some stereological protocols of the first order. Such protocols can be implemented to quantify statistically the architecture of thermal spray coatings and their relevant features (pores, lamellas, etc.). A forthcoming Part II of this article will address some key points to implement, from a practical point of view, such protocols.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Quantification of Thermal Spray Coating Architectures

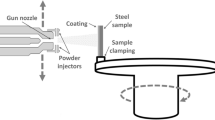

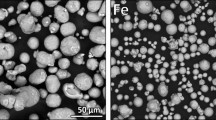

Thermal spray coating structures are built up by stochastic stacking of lamellas resulting from impact, flattening, and rapid solidification of impinging molten or semimolten particles. These structures form a complex three-dimensional (3-D) structure with combination of unique features, such as flattened lamellas, globular pores, intralamellar cracks, interlamellar delaminations, unmolten near-spherical particles, and their related core-shaped pores, among the principal ones.

The coating in-service properties derive to a large extent from the coating architecture that itself depends on the spray parameters (power, feedstock injection, environmental, kinematics, etc.) and the feedstock characteristics (nature, particle size distribution, impurities, etc.).

Quantifying coating structural attributes is hence of prime importance for optimizing spray parameter set to obtain desired in-service properties or, on a more daily basis, for controlling coating quality. Numerous experimental techniques are available to study thermal spray coating structures from the points of view of their composition, phase content, architecture, and so forth. These techniques can yield qualitative or quantitative results, depending on selected protocols.

Metallography is a commonly implemented technique, as it allows one in a relatively “simple” and “quick” way to address the coating architecture or to scan the coating/substrate interface to assess the absence of visible delamination, embedded grit media, and so forth. Several specific and very strict arrangements have to be utilized to prepare samples. This involves implementing optimized and reproducible metallographic protocols—from sample cutting to sample polishing—to limit to the maximum possible extent the introduction of artifacts such as cracks, scratches, pull-outs, and so forth. While the metallography is widely encountered within the thermal spray community, the coating structures are mostly described from a qualitative point of view, sometimes in poetic and colorful styles. A semiquantitative viewpoint by comparing coating structure to a series of reference structures is found less often, and in only limited cases are the results presented from a quantitative viewpoint with adapted size, shape, and spatial descriptors.

The case of the coating porous content is typical and quite revealing. The porous content, “porosity,” is of prime interest and is almost systematically addressed. Nevertheless in this specific case, developers and engineers consider nearly uniformly only global pore content (as void volume fraction) and not the pore network architecture, in terms of pore size, pore shape distribution, their spatial repartition, and so forth—even though the pore content is not the most pertinent descriptor for the coating properties in service. Moreover, the implemented quantification protocols are not always as robust as they should be.

Several quantitative tools allowing the quantification of complex structures exist. They are known as stereological protocols. These are widely used in as various fields as biology, neurology, botany, astronomy, earth observation, metallurgy, and materials science, among various ones. They have proven also to be applicable to the quantification of some specific features of thermal spray coatings (Ref 1, 2).

This review intends to briefly present these protocols from a historical perspective. Part II, to be published in a future issue (“Quantifying Thermal Spray Coating Architecture by Stereological Protocols: Some Key Points to be addressed”), will aim at developing some practical advice in view of their practical implementation. This text does not intend to present exhaustively all of the stereological protocols, but only a few of them that are of interest in quantifying thermal spray coating architecture.

Moreover, authors are not stereologists; that is to say, they did not develop or plan to develop stereological protocols on their own. They implement some of the stereological protocols presented during the last several years, with varying success, to quantify thermal spray architecture. While they may have not succeed systematically, they feel nevertheless that such tools would merit being more widely implemented as they make it possible to address the architecture of thermal spray coatings from a quantitative viewpoint with relatively simple tools (i.e., a metallographic microscope equipped with a CCD camera, image analysis software, and a calculator, or better, a desktop or laptop computer).

Stereology

Definition

A. Vesterby proposed a simple definition (but complete from the point of view of the authors) of stereology as the “the science dealing with the transformation of two-dimensional (2-D) observations to three-dimensional (3-D) information, using mathematical, statistical, and geometrical tools” (Ref 3). This field considers hence the estimation of quantities in matter and materials. The terminology was formalized the first time in 1963 at the First International Congress for Stereology organized in Vienna, Austria (April 18-20) by the Wiener Medizinische Akademie (Ref 4).

Stereology can be conducted at two levels. The first level considers estimations of quantities, in terms of number, length, area, or volume. The second level is related to the spatial organization of bodies of interest, or objects, with the structures to be quantified. Both levels provide complementary information about the structure of matter.

Unlike tomography, stereology does not reconstruct a 3-D object. Indeed, a few cross sections of the object are considered, and their spatial locations are not recorded. Therefore, it is impossible to model the 3-D structure explicitly. Instead, stereology considers nonparametric “geometrical parameters” and the estimation relies only on fundamental geometric facts. As a matter of fact, stereology is almost “assumption-free.”

If the birth certificate of stereology dated 1963 and if this field grew and expanded since.Footnote 1

A Historic Perspective

The Pioneer Period

Italian Bonaventura Francesco Cavalieri (1598-1647) (Fig. 1a), former student of Galileo Galilei, was one of the most influential mathematicians of his time. Of eclectic character, he produced several studies related to mathematics, optics, and astronomy.

In 1635 he published Exercitationes Geometricae Sex (about studies on geometry), in which he developed his principle of indivisibility. Indeed, Cavalieri’s treatise appears to specialists who closely studied the original typescript to be verbose and not clearly written. It is for example difficult to know precisely what he considered to be an “indivisible.” It seems that an indivisible of a planar object is a chord of that object. In the same prospect, an indivisible of a body is a plane section of this body. A planar object is considered as made up of an infinite set of parallel chords and a body as made up of an infinite set of parallel plane sections (Fig. 2). Cavalieri argued that if each member of the set of parallel chords of a planar object is sliced along its own axis, the end point of the chords still describes a continuous boundary. Then, the area of the new planar object is the same of that of the original object, since the two objects are made of the same chords. A similar approach can be applied to any shaped body. This constitutes the assumptions of integral calculus (that was invented by the French Blaise Pascal a few years later, in 1658), and it is known, once generalized, as the Cavalieri’s indivisible principles, which can be expressed as:

-

Principle No. 1 (related to planar objects): “If two planar objects are included between a pair of parallel lines, and if the lengths of the two segments cut by them on any line parallel to the including lines are always in a given ratio, then the areas of the two planar objects are also in this ratio.”

-

Principle No. 2 (related to solid bodies): “If two bodies are included between a pair of parallel planes, and if the areas of the two sections cut by them on any plane parallel to the including planes are always in a given ratio, then the volumes of the two bodies are also in this ratio.”

From a more materials-science-oriented point of view, the Cavalieri’s indivisible principles permit the morphological estimation of total volume of any population of objects of interest from the area on a systematic-random sampling of sections through the objects. These principles still constitute valuable tools in the computation of areas and volumes, and they appear as the first basis of stereological protocols of the first level and constitute indeed the first developed protocol.

Georges Louis Leclerc (1707-1788), Count of Buffon (Fig. 1b), known for posterity as Buffon, is a French natural scientist, mathematician, biologist, cosmologist, and writer, but also a successful industrialist. Nothing less!

His remarkable scientific work was published in an encyclopedia of 36 volumes: 15 volumes dedicated to quadrupeds, 9 volumes on birds, 5 volumes on minerals, and 7 complementary volumes. His encyclopedia influenced the work of two generations of natural scientists. It is in the fourth volume of its complements (Histoire Naturelle Générale et Particulière, Servant de Suite à l’Histoire Naturelle de l’Homme, General and Particular Natural History, Serving as a Suite of the Natural History of Man, Supplements, Forth volume, XXIII, 1777, p 95-100) that he described one of his major contributions to mathematics that can be seen as another very first basis of stereological protocols of the first order based on intercept principles. This contribution is nowadays very well known as the Buffon’s needle problem, one of the oldest problems in geometric probabilities and one of the very first applications of Monte-Carlo techniques.

If a needle of length l is tossed onto a plane ruled by parallel equidistant lines, two possibilities can be observed once the needle has fallen onto the surface: either the needle touches or crosses one of the lines or the needle crosses no line (Fig. 3). The probability for which the needle intersects each line is directly proportional to the length of the needle, with no further assumption. If the needle length is equal to the distance separating the parallel lines, then the probability is a function of π. A brief description of the mathematical solution is displayed in Inset 1. From a stereological point of view, the Buffon’s needle problem provides the theoretical basis permitting the estimation of the total length and the total surface area of any shaped objects.

Inset 1: Buffon’s Needle Problem ... and a Simple Solution | |

Let’s consider a plane ruled by lines spaced apart by a distance d. Let’s consider a needle of length l. | |

Let’s consider the size parameter x defined as the l/d ratio (Fig. 3). | |

For a short needle, that is to say a needle of shorter length that the distance between two lines, the probability P(x) that the needle falls on a line is expressed as follows: | |

\({P(x)=\int\nolimits_0^{2\uppi } {\frac{l\left| {\cos \uptheta} \right|}{d}} \frac{d \uptheta}{2\uppi}=\frac{2l}{\uppi d}\int\nolimits_0^{2\uppi} {\cos \uptheta d \uptheta =} \frac{2l}{ \uppi d}=\frac{2x}{ \uppi}}\) | (Eq 1) |

If the needle length equals the distance between two successive lines, that is to say if x = 1, then the probability becomes: | |

\({P(x=1)=\frac{2}{\uppi} = 0.626619}\) | (Eq 2) |

The Disruption

The French Achille Ernest Oscar Joseph Delesse (1817-1881) (Fig. 1c) entered at age 20 the prestigious Ecole Polytechnique where he was at the top of his class. He subsequently passed through the Ecole des Mines where he obtained his mining engineer degree. Brilliant geologist and mineralogist (his geologic maps are still presented in French schools as examples of remarkable work), professor at the school of mines of Paris, academician at the French Academy of Sciences, he studied the structures of numerous minerals and rocks. This is where he developed, among other studies, the rock structural quantification by metamorphism.

In 1847, he demonstrated that the total area of a diluted phase on random cross sections was proportional to the total content of the considered phase in the entire specimen (Ref 5).

Today, Delesse’s principle provides the basis for estimating the volume of nonclassically shaped objects based on their profile areas on random sections (see Section 3.1 for further details related to the Delesse’s protocol).

Authors were not successful in finding biographical basics related to S.D. Wicksell, apart from the fact that he was a Swedish mathematical statistician in the first half of the 20th Century. In 1922, Wicksell was confronted with the problem of determining the number of thyroid globules in the thyroid gland. From several parallel cross sections through the thyroid, he counted the number of globules in each cross section, N A (number of bodies of interest N per surface area A). After a careful 3-D reconstruction of the thyroid structure, he demonstrated, both from the experimental and mathematical points of view, that the number of globules per unit volume N V (number of bodies of interest N per unit volume V) cannot be estimated from the determination of N A (Fig. 4). This impossibility is known as the corpuscle problem and can be expressed as follows: “an accurate estimation of the number of objects of interest cannot be obtained from profile counts on individual cross sections.” If the first memoir published in 1925 was related to the case of spherical corpuscles (Ref 6), the second one (Ref 7) considered the case of ellipsoidal bodies and Wicksell extended in its introduction (p 152) the potential application of the approach to geology and mineralogy.

Since then, numerous attempts failed in trying to overcome the corpuscle problem using “correction relationships” (Ref 8, 9). Indeed, using correction relationships simply adds further statistical bias through assumptions and models.

The contribution to stereology of these two scientists seems fundamental to authors; Delesse developed a stereological protocol of a very wide application range Footnote 2 and practically implemented it for practical needs, whereas Wicksell clearly established bridges between statistical approaches, topology, and some limitations of stereology, for example that the determination of the number of bodies of interest per unit volume was impossible without introducing bias in the analysis.

The Golden Era

Wars are always periods of destruction and dramas, but also periods of intense technological and scientific developments. World War II did not escape from this law and, among other very noticeable developments, such as the Quantum Electrodynamics (QED) for example, materials science was significantly developed, especially the manufacture of alloys with superior properties. This resulted in critical need to quantify alloy microstructures in order to be able to link the structure to the properties and to control the product quality. Stereology seems to have benefited of this period in further developments. The end of World War II marked the beginning of the golden era for stereology, which lasted for a few decades. Initially applied by materials science to quantify the structures of metals and metallic alloys, the lack of automatic systems and computers rendered the implementation of stereological protocols tedious and labor intensive. Progressively, it seems that the stereology was being marginalized. However, wide availability of computers since the 1970s has been concomitant to the explosion of sciences of the living organisms, where the quantification of tissues is required. The high potential of stereological protocols was fully utilized when applied to biology. This field developed new protocols, and progressively, one observed the transfer of those protocols back into the field of materials science.

If the Delesse’s protocol makes it possible without doubt to collect very quickly and very easily data relative to the volume fraction of features embedded within a structure, it does not permit assessment of the size or shape distributions of those features. However, these define the architecture of the studied structures. If a 3-D structure can be “probed” by an intercept plane (i.e., the polishing plane) and if data corresponding to intercept areas (or length) are recorded, it is then possible to determine the distribution of sizes of the features that produced the recorded data. Nevertheless, following this approach, only a statistical distribution can be determined. Moreover, three major limitations result from such an approach:

-

It is based on an inverse problem for which small variations in the measured data (which can arise if a too limited number of data points is recorded) grow to much larger variations in the inverse solution.

-

It is based on assumptions regarding the shape of the features (e.g., sphere, cylinder, etc.).

-

It considers an isotropic, uniform, and random sampling of the structure. Footnote 3

In this case, collected data are usually presented into a discrete histogram rather than a continuous one (Fig. 5). The bin of the discrete histogram represents the size class. The width of a size class has to be selected in such a way to permit each class to cumulate enough data points for a “reasonable” statistical discrimination. The number of size classes is selected in such a way as to permit a “reasonable” description of the distribution. Most of the time, from 10 to 15 classes linearly spaced in size up to the largest data point is selected.

In 1946, Sarkis A. Saltykov, professor at the Erevan Polytechnical Institute, Erevan, Armenia (formerly USSR), proposed a methodology to unfold the “size distribution of particles in an opaque material from a measurement of the size distribution of their section” (Ref 10-12) based on the aforementioned methodology. He considered in particular the case of features of spherical shape. Indeed, the interception of spheres distributed within an opaque material by a plane will generate a series of circles of varying diameters, depending on the sphere location and the sphere diameter distribution (Fig. 6). Based on probabilistic calculations, Saltykov described the transfer matrix permitting to unfold the number of sphere per unit volume and per size class, \(N_{V_{i}}\) by correlating this distribution to the distribution of number of circles per unit area and per size class, \(N_{A_{i}}\). This contribution to stereology appears to be of major importance as this protocol seems to have been the first permitting one to statically quantify size distributions (see Section 3.2 for further details related to the Saltykov’s protocol).

One of the major limitations of the Saltykov’s protocol lies in its inability to consider feature shapes other than spherical ones. In 1962, the American Robert T. DeHoff adapted Saltykov’s analysis to apply it to systems of diluted particles that consist of spheroids (Ref 13, 14). DeHoff is Professor at the University of Florida in Gainesville, FL and is still active in research at the Materials Sciences and Engineering Department there. Many of the shapes encountered in thermal spray deposits (embedded unmolten particles, splats, globular pores, etc.), can be approximated by spheroids, that is, ellipsoids of revolution. These ellipsoids of revolution result from the rotation of generating ellipses around an axis. Two morphologies can be considered, prolate or oblate, generated by rotation of an ellipse around its major axis or its minor axis, respectively (Fig. 7). The intersection of such features with a test plane generates ellipses, characterized by their major axis, M, and their minor axis, m.

Identically to the Saltykov’s protocol, DeHoff’s makes it possible to unfold the distribution of the number of features per unit volume, N V , as well as the distribution of their volume fraction, that is, the distribution of the volume of those features per unit test volume V V .

Nevertheless, this protocol assumes that the ellipsoids of revolution embedded within the structure are of identical shapes, that is, either oblate or prolate. It is hence required to decide or determine independently whether the features are oblate or prolate, since ellipses of same profiles can result from the interception of these ellipsoids by a test place. Moreover, those ellipsoids need to be assumed to be of same eccentricity, which is to say that the ratio of the minor axis over the major axis of the modeled features remains constant (aspect ratio) whatever the size of the feature. Indeed, such an assumption constitutes a strong limitation in the applicability of the protocol. Nevertheless, from the author’s experience, this protocol can be implemented relatively easily on thermal spray coating architecture to study the pore size distribution for example, as in most cases globular pores exhibit a relatively narrow eccentricity distribution vs. their size. DeHoff is a very active stereologist who, during his entire career, promoted this science and its applications, as for example through reference books (Ref 15, 16), which propose a simple but complete approach of stereology (see Section 3.3 for further details related to the DeHoff’s protocol).

Luis Manuel Cruz-Orive was working at the Department of Probability and Statistics of the University of Sheffield (U.K.) when he solved the “general spheroid problem.” (Today, Luis Manuel Cruz-Orive is professor in statistics and probability at the Department of Mathematics and Computing Sciences at the University of Cantabria, Spain.) Indeed, he developed in a series of two papers the mathematical model (Ref 17) and a stochastic model (as well as a practical guide to implement the methodology) (Ref 18) permitting circumvention of the limitations of the DeHoff’s protocol—that the spheroids are supposed to exhibit the same aspect ratio—and to consider a bivariate distribution, in size and in shape, of diluted spheroid particles embedded within a matrix (see Section 3.4 for further details related to the Cruz-Orive’s protocol).

Some Stereological Protocols of Particular Interest for Quantification of Thermal Spray Coating Architectures

Delesse’s Protocol (1847)

The Delesse’s principle can be expressed as (Ref 5): if a structure containing some objects of a phase p is sectioned randomly, then the area density A A of profiles of objects of phase p on a section is equal to the volume density V V of the phase in the structure:

A brief description of the mathematical solution is displayed hereafter.

Let’s consider a distribution of bodies of interest dispersed in a volume V test, as depicted in Fig. 8.

Let’s consider a slice of thickness δx and surface A test through V. Within this slice of volume l 2 · δx, let’s name (V V )α the relative volume of bodies of interest. The volume of bodies of interest within the slice α, δV α, can be expressed as:

Let’s name A a (x) the relative distribution of the surface of the bodies of interest in the surface A test and \({\overline{A_{\upalpha}} }\) its average value, as depicted in Fig. 9. The volume of bodies of interest δV α can be in such conditions expressed also as:

Equaling Eq 4 and 5 leads to:

Integrating Eq 6 over the domain (i.e., from 0 to 1) leads to:

And finally to:

Dividing both terms of Eq 8 by V test leads to:

Identifying V α/V test and A α/A test to V V and A A , respectively, leads to A A = V V .

In order to avoid statistical biases in the analyses, the features considered in the analysis have to be circumscribed into the reference surface (Fig. 10).

Saltykov’s Protocol (1946)

Let’s consider a dilute phase made of spherical features of a random particle size distribution into an aggregate. Let’s consider a randomly oriented intercept plane. The diameters of the circles resulting from the interception are ranked into different size classes Δ. From a statistical point of view, one can demonstrate that the largest spherical feature embedded within the structure will be intercepted at its center and that the diameter of the resulting intercepted circle, D max, will correspond to the one of the sphere. Under such conditions, let’s consider n size classes of size D max/n.

From Fig. 11, the probability of measuring a circle of radius r ± 2r (corresponding to a data point that would fall into one size class) from a sphere of radius R is equal to the thickness of a slice of the sphere with that diameter:

Following this latter approach, the Saltykov’s protocol aims at solving a set of coupled equations (Ref 12) in which the independent variables are:

-

The number of circles of various radius falling within each size class (and recorded following a discrete histogram), \(N_{A_{i}}\)

-

The number of spheres per size class, \(N_{V_{j}}\)

Independent variables are linked by a transfer matrix \( \upalpha_{ij}^{\prime}\):

Inversing the matrix leads to:

where Δ is the size of a size class. As already quoted, the number of size classes varies usually between 10 and 15 from a practical viewpoint. Decreasing this number no longer permits a pertinent description of the unfolded distribution. Increasing this number requires a very significantly increase in the number of data points.

The alpha matrix first calculated by Saltykov that makes it possible to unfold sphere size distribution from measured circle diameters is displayed in Table 1.

DeHoff’s Protocol (1962)

As already quoted, the DeHoff’s protocol derives directly from the Saltykov’s analysis, but rather than being applied to spherical features, it considers ellipsoidal ones.

Let’s consider an aggregate made of ellipsoidal features of same shape, that is to say either oblate or prolate. Identical to Saltykov’s protocol, the distribution of the number of features per unit test volume and per size class Δ, \(N_{V_{j}}\), can be expressed as a function of the number of interceptions of features per unit test area and per size class, \(N_{A_{i}}\), as follows (Ref 13):

where α ij represents the Saltykov’s alpha matrix and Δ the size increment. For oblate features, Δ corresponds to m max/i, where m max is the minor axis of the largest intercepted ellipse. The coefficient k 0 represents a shape dependent factor for prolate or oblate spheroids (Fig. 12). It is expressed for example for oblate particles as follows:

where ϕ is the angle between the normal to the test plane (i.e., polished plane) and the z-axis, and θ is the angle between the projection of this normal on the xy plane and the x axis, with respect to a standard Cartesian coordinate system.

The unfolded distribution of volume fraction per size class j is simply obtained by multiplying the number of features per unit test volume and per size class \(V_{V_{j}}\) by the volume of the considered ellipsoid (i.e., V oblate = 4/3 · π · m · M 2 or V prolate = 4/3 · π · m 2 · M). Finally, the volume fraction of features results from the summation of the number of features per unit test volume and per size class \(V_{V_{j}}\) over the number of class size.

Cruz-Orive’s Protocol (1976)

Cruz-Orive considered systems of particles consisting of either prolate or oblate ellipsoids of revolution of variable sizes and of variable shapes (Ref 17, 18). In this case, the distribution of the number of features per unit test volume and per size class Δ, \(N_{V_{ij}}\), can be expressed as a function of the number of interceptions of features per unit test area and per size class, \(N_{A_{kl}}\), as follows:

where the subscripts i and j refer to the size and shape in 3-D and the subscripts k and l to the size and shape in 2-D (intercept plane).

If the approach is identical to the DeHoff’s protocol, the determination of the size and shape distributions requires a much larger database due to the consideration of a bivariate distribution (i.e., each size class is made of 10 to 15 shape classes).

Miscellaneous Protocols

The previously presented protocols consider surfaces as probing elements. Other protocols exist based on other types of “probing” elements, such a points and lines. Table 2 displays a few of these protocols.

Concluding Remarks

Stereological protocols of the first order aim at statistically quantifying 3-D structures from 2-D—randomly oriented—plane sections. Several types of analysis can be carried out, depending on the characteristic of the “probing” element: points, lines or areas.

Protocols based on the measurement of areas on plane sections can be implemented to analyze the architecture of thermal spray coatings, from the very simple Delesse’s protocol quantifying the volume fraction of any feature to the more sophisticated Cruz-Orive’s protocol quantifying the bivariate size-shape distribution of features considered as spheroids of revolution. The forthcoming Part II will address some key points to implement from a practical point of view such protocols.

Notes

The International Society of Stereology (ISS, www.stereologysociety.org), incorporated in 1963, includes members from the fields of mathematics, statistics, biology, and materials science. It organizes an International Conference every 4 years (Stereology, Spatial Statistics and Stochastic Geometry, S4G), the last one having being held in Prague in 2006 (Sixth International Conference, Prague, The Czech Republic, June 26-29, 2006). the estimation of quantities and their spatial distribution in a matter have been challenging problems to scientists for several centuries. Thus, authors suggest identifying three major periods during which stereology was progressively developed: “the pioneer period” (16-18th Centuries), “the disruption” (late 19th and early 20th Centuries) and “the golden era” (second-half of the 20th Century).

We are supposed to use the Delesse’s protocol when quantifying the pore fraction of thermal spray coatings implementing image analysis. From author’s experience, the implemented protocols are unfortunately not systematically robust and biases, resulting both from image treatments and image analysis, are quite often introduced.

These techniques can be applied even to materials that are not isotropic (they are very few real structures for which isotropy can be assumed). This requires the introduction of correction coefficients depending on the level of anisotropy.

References

Leigh S.-H., Berndt C.C. (1999) Modelling of Elastic Constants of Plasma Spray Deposits with Ellipsoid-Shaped Voids. Acta Mater. 47(5):1575-1586

Montavon G., Coddet C., Berndt C.C., Leigh S.-H. (1998) Microstructural Index to Quantify Thermal Spray Deposit Microstructures Using Image Analysis. J. Therm. Spray Technol. 7(2):229-241

Vesterby A. (1993) Star Volume in Bone Research. A Histomorphometric Analysis of Trabecular Bone Structure Using Vertical Sections. Anat. Rec. 235:325-334

Minutes of the Sixth General Assembly of the International Union of Crystallography, Acta Crystallogr., 1963, 16, p 76

Delesse A. (1848) Procédé Mécanique Pour Déterminer la Composition des Roches (Mechanical Process to Determine the Composition of Rocks). Ann. Mines 13:379-388 (in French)

Wicksell S.D. (1925) The Corpuscle Problem. A Mathematical Study of a Biometric Problem. Biometrika XVII:84-99

Wicksell S.D. (1926) The Corpuscle Problem. Second Memoir. Case of Ellipsoidal Corpuscles. Biometrika XVIII:151-172

Cruz-Orive L.-M. (1976) Correction of Stereological Parameters from Biases Samples on Nucleated Particle Phases—I. Nuclear Volume Fraction. J. Microsc. 106:1-18

Cruz-Orive L.-M., (1976) Correction of Stereological Parameters from Biases Samples on Nucleated Particle Phases—II. Specific Surface Area. J. Microsc. 106:19-32

Saltykov S.A. (1945) Stereometric Metallography 1st ed. State Publishing House for Metals Sciences, Moscow, Russia (in Russian)

Saltykov S.A. (1946) The Method of Intersections in Metallography. Zavodskaja laboratorija 12:816-825 (in Russian)

S.A. Saltykov, The Determination of the Size Distribution of Particles in an Opaque Material from a Measurement of the Size Distribution of their Sections, of Stereology (proceedings of the Second International Congress for Stereology (Chicago, IL), April 8-13, 1967, H. Elias, Ed., Springer-Verlag, New York, 1967, p 163-173

DeHoff R.T. (1962) The Determination of the Size Distribution of Ellipsoidal Particles from Measurements Made on Random Plane Sections. Trans. Metall. Soc. AIME 224:474-477

DeHoff R.T. (1964) The Determination of the Geometric Properties of Aggregates of Constant Size Particles from Counting Measurements Made on Random Plane Sections. Trans. Metall. Soc. AIME 230:617

DeHoff R.T., Rhines F.N. (1968) Quantitative Microscopy. McGraw Hill, New York

Russ J.C., DeHoff R.T. (1999) Practical Stereology 2nd ed. Plenum Press, New York

Cruz-Orive L.-M. (1976) Particle Size-Shape Distributions: The General Spheroid Problem—I. Mathematical Mode. 107:235-253

Cruz-Orive L.M. (1978) Particle Size-Shape Distributions: The General Spheroid Problem—II. Stochastic Model and Practical Guide. J. Microsc. 112:153-167

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Montavon, G., Antou, G. Quantifying Thermal Spray Coating Architecture by Stereological Protocols: Part I. A Historical Perspective. J Therm Spray Tech 16, 6–14 (2007). https://doi.org/10.1007/s11666-007-9017-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-007-9017-8