Abstract

Submerged friction stir welding of magnesium alloys has not been well investigated to date. ME20M is an important lightweight magnesium (Mg) alloy with enhanced yield strength and heat resistance that merits further research. In this paper, submerged friction stir welding of the ME20M Mg alloy was carried out using different parameters for the underwater cooling. Defect-free weld joints were produced, and the macrostructure, microstructure, tensile properties, and hardness were investigated. The results show that by increasing the rotational speed, the grain size of the weld nugget increased, the tensile strength of the joint decreased, and the microhardness of the different weld zones decreased. The finest obtained grain size was about 3.5 µm in the weld nugget at a rotational speed of 1100 rpm. The highest tensile strength achieved was 183.2 MPa, which was ~ 76.32% of the base metal. The highest and lowest hardness values of the weld joint were obtained at rotational speeds of 1100 and 1600 rpm, respectively, in the weld nugget and heat-affected zones.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Friction stir welding (FSW) was invented in 1991 as an advanced joining method and has been investigated by many researchers. During FSW, a rotational tool travels along the length of the plates to be welded and the associated stirring action produces a highly plastic joint with refined grains (Ref 1, 2).

Magnesium (Mg) alloys are increasingly important lightweight structural materials for application in the aerospace, automotive, and shipbuilding industries because of their low density and high specific strength (Ref 3). Mg alloys have a hexagonal close-packed structure with a limited number of room temperature deformation mechanisms, such as basal slips and tensile twinning (Ref 4).

Recently, improvements in the formability of Mg alloys at room temperature have been demonstrated by the addition of rare earth (RE) elements, such as cerium (Ce) and lanthanum (La) (Ref 4,5,6,7,8). The ME20M Mg alloy (also previously known as MB8), which contains manganese (Mn) and cerium (Ce) (nominal composition Mn-1.3-3.2 wt.% and Ce-0.15-0.35 wt.%), is known to have enhanced yield strength and heat resistance compared with the other Mg alloys; however, it has been minimally studied to date. Improving the ductility of magnesium alloys through grain refinement has drawn considerable interest, since the practical application of Mg alloys has generally been limited because of their poor formability (Ref 9).

Wang and Zhang (Ref 10) carried out FSW of MB8 and observed that the grain size was refined from about 16.5-6 µm; additionally, its elongation was improved by 57% at 1200 rpm, which was ~ 160% that of the base metal. Xu (Ref 11) studied the forming characteristics, microstructural features, and mechanical properties of the weld. They found that the tensile strength of the weld joints obtained with a traverse speed of 300 mm/min was 73% of the base metal. Xing et al. (Ref 12) obtained a plastic MB8 joint and studied the strength, fracture, structure, and mechanical properties of the joint. They demonstrated defect-free joints with a tensile strength of 76% of the base metal.

Since fine-grained microstructures generally possess improved mechanical properties, there have been considerable efforts to achieve even finer-grained sizes. Mishra and Ma (Ref 13) showed that the metal grain growth could be suppressed if a certain cooling method (such as water cooling) was adopted during the welding. Therefore, submerged friction stir welding (SFSW) was employed, which resulted in increased strength and plasticity for the material.

A limited number of studies have investigated submerged friction stirring of Mg alloys. Fang et al. (Ref 14) studied the friction stir processing of a 6-mm-thick AZ91 Mg alloy in air and underwater, and then investigated the microstructure and mechanical properties of the weld. Friction stir processing transformed the original as-cast microstructure into fine equiaxed grains. The second phase β-Mg17Al12 at the grain boundaries changed from a continuous network to granular structure. Compared with the friction stir processing in air, the grain size obtained by underwater processing was finer; the average grain size was 8.4 ± 1.3 µm in air and 2.8 ± 0.8 µm underwater. Their XRD results showed that the intensity of the diffraction peak for the second phase β-Mg17Al12 processed in air was lower than that for the sample with underwater friction stir processing. Because of the fine-grain strengthening effects, friction stir processing resulted in joint tensile strengths and elongations of 262 MPa and 18.9% (in air), and 282 MPa and 25.4% (underwater), respectively. These results indicated that underwater friction stir processing was an effective method to refine the grains and improve the mechanical properties of AZ91 cast magnesium alloys.

Darras and Kishta (Ref 15) studied the submerged friction stir processing (SFSP) of the AZ31 Mg alloy. They concluded that SFSP was highly effective at grain refinement and porosity reduction, and a significant increase in the elongation % could be achieved. Luo et al. (Ref 16) investigated the ductility improvement of the AZ61 Mg alloy via two pass SFSP. The refined microstructure and texture evolution were also considered to be responsible for the improvement in the ductility.

ME20M is extensively applied in aircraft panels because of its excellent weldability and higher corrosion resistance compared with the AZ31 Mg alloy (Ref 9). Hence, the realization of underwater FSW for ME20M will open new pathways for its welding. In this paper, underwater FSW of ME20M has been carried out and the effects of the processing parameters on the weld microstructure and mechanical properties are discussed in detail.

Material and Experiments

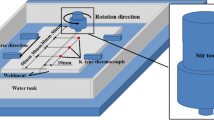

ME20M Mg alloy specimens with a thickness of 5 mm, length of 160 mm, and width of 65 mm were used in this experiment. The chemical composition and partial physical properties of the specimens are shown in Table 1. The welding was done on modified milling machines. The rotating tool was made of SKD11 steel and had a cylindrical pin. Figure 1 shows the dimensions of the tool: The shoulder diameter was 20 mm; the pin diameter was 5 mm; and the length of the pin was 4.7 mm. The tool was quenched and tempered to improve the friction heat and mixing ability. The joints were produced in a butt configuration and placed in the setup shown in Fig. 2.

The samples were friction stir welded in a container we designed (fabricated by CNC milling) that held the samples submerged during the welding process. To study the effects of the SFSW rotational speed on the sample properties, different speeds were considered at room temperature. The parameters of the experiments are shown in Table 2. Here, w/v is the ratio of rotational speed to the traverse speed, and it usually expresses the heat input of the FSW.

For the metallographic specimen preparation, the samples were cut perpendicular to the welding direction by wire electrode cutting, and etched with an acetic–picric acid solution composed of: 10 mL acetic acid, 4.2 g picric acid, 10 mL water, and 70 mL ethanol (95%). The samples were then characterized using a QMW550 digital optical microscope and a QVANTA 650 scanning electron microscope (SEM). Additionally, the grain sizes were measured and calculated via the linear intercept method using the SEM images. Phase analysis was carried out using an X’Pert PRO MPD x-ray diffraction (XRD) setup to identify the intermetallic compounds at the joints on the fracture surface.

The hardness of the welds was measured on a HXS-1000A microhardness testing machine by applying a load of 100 g and a dwell time of 15 s. The hardness was measured along the center line of the thickness direction, beginning at the weld center and moving toward the base material with a 0.5-mm spacing between each point.

Tensile tests of the weld joint were carried out using a CMT 5105 SANS microcomputer-controlled electronic universal tensile testing machine (Shenzhen SANS Metering Technology) in accordance with the ASTM E8/E8M standard. The experimental results were recorded, and the average value from two specimens was used to determine the strength.

Results and Discussion

Macrostructure of the Joint

Macrostructure of the Surface of the Joint

Several types of defects can occur at the FSW joint, such as porosity defects, tunnel defects, flashes, cracks, and root flaws. These defects may be due to improper FSW parameters, the assembly state, the welding equipment, or other factors (Ref 17,18,19). The typical weld surface is presented in Fig. 3. The strong agitation by the stirring pin causes the material in the weld nugget area to undergo severe plastic deformation. A regular, compact ringlike texture can be observed, which is considered to be a typical feature of FSW. With a constant traverse speed, the welded ripples are uniform. During FSW, the rotation of the tool pin results in severe plastic deformation and material flow. The material on the advancing side (AS) flows forward and then flows back from the retreating side (RS) (Ref 20). Because of the axial force, the material may be pushed out and form flash defects in the specimen. With a constant traverse speed, the flashes increase as the rotational speed increases. This can be mainly attributed to the increased frictional heat that results in the ejection of more softened material.

Macrostructure of the Cross Section of the Joint

Among the different SFSW parameters investigated, defect-free weld joints were obtained for rotational speeds between 1300 and 1600 rpm. Tunnel defects were found at rotational speeds of 1100 and 1200 rpm, and the weld nuggets in the defective joints were clearly smaller than that of the defect-free joints. The typical cross sections of the defect-free and defective samples are shown in Fig. 4. Tunnel defects were primarily caused by insufficient heat input during welding (Ref 19). Since the ME20M Mg alloy has a low thermal conductivity coefficient of ~ 0.32 J/(cm s °C), it radiates heat quickly. In this experiment, because of the water cooling, the heat input was lower than in air. When the w/v values were 27.5 and 30, the heat input was insufficient for the metal to form a thermoplastic fluid; therefore, the flow, filling, extrusion, and diffusion processes could not be fully completed, resulting in the formation of tunnel defects. As the input heat increased, the metals flowed smoothly and defect-free weld joints were obtained.

Microstructure of the Cross Section of the Joint

Microstructure Characterization

FSW joints are typically divided into four zones: base metal (BM), heat-affected zone (HAZ), thermo-mechanically affected zone (TMAZ), and the weld nugget (WN). The microstructures of the welds are shown in Table 3.

The BM was annealed after rolling and revealed a recrystallized α + β (Mn) microstructure, with fine and coarse grains randomly distributed. The precipitated phase was found at the boundary of the grains. The average grain size of the BM was ~ 11.34 µm.

The WN was located at the center of the weld joint. This region experienced strong stirring and a high-temperature thermal cycle; hence, dynamic recrystallization occurred in the region, transforming the original structure of the base material into a fine equiaxed recrystallized structure. Twinning first occurred under cold conditions, and then, dynamic recrystallization takes place in the twins. As the thermo-mechanical effect increased, particle-simulated nucleation, discontinuous dynamic recrystallization, and continuous dynamic recrystallization occurred. Greater dynamic recrystallization and more particles contribute to finer and more uniform grains during FSP of the Mg alloy (Ref 21). With underwater cooling, the heat input was sufficient to plasticize the WN. Dynamic recrystallization subsequently occurred, and the dynamically recrystallized grains were broken up by the strong stirring. However, because the cooling rate was improved, the growth of grains was restricted and fine equiaxed grains formed. With increasing rotational speed, the heat input increased, the cooling rate decreased and the grains grew larger. As reported by Commin et al., the nugget temperature decreased with decreasing rotational speed during FSW (Ref 22). This promotes grain refinement in the WN after FSW. A significant body of work has indicated that increased grain size results in reduced slip and twin propagation resistance, where the twin modes exhibit more pronounced grain size dependences (Ref 23, 24). With increasing rotational speed, the average grain size increased from 3.75 to 14.12 µm (Fig. 5), while the intermetallic particles coarsened at a high welding speed of 1600 mm/min. Compared with the results (Ref 11) mentioned before, the grain size of the FSW joint with a rotational speed of 800 rpm and a traverse speed of 60 mm/min was 6 µm. This was much larger than the grain size of the SFSW joint at a higher heat input with a rotational speed of 1100 rpm and traverse speed of 40 mm/min.

The heat and stirring affect the metal in the TMAZ, which results in the occurrence of bending deformation, and generates a reverse reaction. The TMAZ of the welds can be easily found, and the size of the grains is obviously increased with increasing rotational speed. As the rotational speed increases, the temperature near the weld region and the normal and transverse stresses increase (Ref 25). Without adequate heat input, the grains grow slowly and the effect of stirring on the grains is clear.

Generally, the HAZ is the weakest part of the joint. It experiences grain growth and transformation of the meta-stable precipitates but does not reprecipitate because of insufficient heat (Ref 26,27,28,29). Investigations have revealed that the HAZ was a narrow precipitate-free zone along the grain boundary. This can be attributed to a lower level of precipitate coarsening underwater cooling and adversely effects on the mechanical properties of the materials (Ref 30, 31). Due to the effects of water cooling, the coarse-grained zone was inconspicuous in the weld compared with the base metal, which indicated that the thermal effect was not obvious in the water cooled environment.

XRD and EDS Analysis

Lentz et al. (Ref 32) found that Mg12Ce precipitated during Mg-Mn-Ce alloy annealing. Finer Mn-containing precipitates with a diameter of 100-300 nm were observed. The grain boundaries were rich in Ce, while the grain center was mainly composed of Mg (Ref 33). The XRD results (Fig. 6) show that the phases of the BM were α-Mg and β-Mn. At a low Ce content, Mg12Ce and Mg17Ce2 may exist in the BM. After SFSW, the intensity of the second peak (Fig. 6a) reduced, grain refinement of the α-Mg grains in the matrix phase occurred, and the grains were uniformly distributed. When the intensity of the peak associated with Mn reduced, MnAl and MnZn formed an intermetallic compound, which precipitated at the grain boundary and promoted grain refinement. As w/v increased, the grain size of the α-Mg matrix became coarser. This may be attributed to the common influence of heat input and applied stress during SFSW.

The energy-dispersive spectroscopy (EDS) results of the different regions are shown in Fig. 7, and the test positions correspond to the 4 points in Fig. 4(a). All the trace elements precipitated at the weld joint after SFSW. The content of Ce and Zn was significantly improved in the WN and TMAZ, and decreased minimally in the HAZ. The contents of Mn and Al were slightly improved, which was in agreement with the XRD results. Mn promotes grain refinement and improves the corrosion resistance of the Mg alloys. Ce promotes grain refinement and inhibits twin growth in the Mg alloys. The precipitation of Mn, Ce, Al, and Zn from the microstructure was proved by the grain refinement of the WN and TMAZ, and the quality improved compared with the HAZ. Because of lower solution, the effects of solution strengthening in the HAZ were limited.

Mechanical Properties

Hardness Distribution

The microhardness was tested along the midline of the thickness direction, and the hardness curves are shown in Fig. 8. All of the curves display a slight “w”-type shape. The hardness of the base metal was in the range of 46.5-48.5 HV0.1. The lowest hardness values appeared at the transition area of the AS, and then, hardness rapidly rose to a stable level. On the RS side, the hardness of the TMAZ declined slowly. The sample with the largest w/v had the lowest hardness of 39.4 HV0.1. The largest hardness was 57.9 HV0.1 and was located at the WN of the weld joint at a rotational speed of 1100 rpm and a traverse speed 40 mm/min.

As previously mentioned, the grain size of the weld nugget affected the mechanical properties of the weld joint (Ref 20). The transformation and flow of materials were different between the AS and the RS, and the temperature on the AS was higher than that of the RS (Ref 34). A higher heating temperature resulted in larger grains and caused a decrease in the hardness. This meant that the lowest hardness was not located on the RS but on the AS. The WN was subject to the stirring process and had a grain size that was much finer than that of the base metal at a rotational speed of 1100 rpm. The fine grains resulted in a high observed hardness value. The largest grains were found at the HAZ of the weld joint at a rotational speed of 1600 rpm. Figure 8 shows that apart from the lowest hardness value, there was a general decline in the hardness. It is well known that the HAZ is the weakest part of the joint and has the lowest hardness. The rapid decline in hardness meant that the HAZ was small.

Tensile Properties

Samples for the tensile tests were cut by a wire cutting machine according to the ASTM E8/E8M standard. The dimensions of the samples are shown in Fig. 9. Two samples were tested for each parameter and the average value was used to calculate the strength. Defects in the tensile samples were ground off to ensure the weld joint would not fracture at the defects. The results of the tensile tests are shown in Table 4 and contain the fracture position and the determined strength values.

The strength values present a decreasing trend as the rotational speed increases. The highest strength value of 183.2 MPa was obtained at a rotational speed of 1100 rpm, which was ~ 76.32% of the BM. The lowest value of 121.9 MPa was ~ 50.80% of the BM at a rotational speed of 1600 rpm.

The tensile properties of the joints after SFSW were inferior compared with the BM. The strength was generally proportional to the hardness in metallic materials including magnesium alloys. Furthermore, the residual stress and dislocations in the TMAZ may also affect the mechanical properties of the joints. As previously mentioned, the HAZ had the largest grain size. According to the Hall–Petch relationship, coarser grains result in a lower strength as well as hardness. It was also previously reported that in defect-free FSW joints, the part with the lowest hardness was also the weakest (Ref 35, 36). Commin et al. (Ref 37) confirmed that the dislocation content and high residual stress in the TMAZ were the factors influencing the mechanical properties of the joints. As the rotational speed increased, the heat input correspondingly increased and the grains grew larger, in particular, in the HAZ, where the strength of the joint decreased. FSW resulted in high grain refinement, dissolution and dispersion of the eutectic networks, and a strong basal texture, which also affected the tensile strength. The dynamically recrystallized grains decreased in size, and the size volume fraction of the dispersed particles increased as the heat input decreased (Ref 37). With increasing rotational speed, the grain size became larger and the fraction of dispersed particles decreased, which resulted in a reduction in the fine-grain strengthening and dispersion strengthening effects. However, increasing the rotational speed increased the dissolution of the second phase and resulted in a lower degree of solution strengthening. Figure 5 shows that there were minimal Mn- and Ce-containing precipitates in the HAZ. Because of the reduced precipitation, the effects of precipitate strengthening on the HAZ were limited.

Fracture Surface

Fractures were always located in regions with lower strength or hardness (Ref 38). It can be found that the fracture location is on the advancing side (Table 4), where the hardness is the lowest. The fracture of Mg alloys under transverse tension is sometimes attributed to double {1011}-{1012} twinning. The strain distribution in the stir zone is also inhomogeneous in the weld nugget (Ref 39,40,41).

Figure 10 shows the SEM test results of the fracture section. All the fractures present a mixture of cleavage and ductile fracture. From the image, it can be seen that the fracture in the tensile specimens has a large number of uniformly distributed dimples. As the rotational speed increases, the cleavage surfaces increased and the number of dimples decreased. Cleavage fractures were due to stress concentration and rupture at the grain boundary. There were many cleavage planes with a low crystal surface index. The material in the stir zone also experienced plastic strain. A radial pattern and herringbone ridge-shaped pattern appeared at the fracture.

The Mg alloy has a close-packed hexagonal structure and cleavage fractures can easily occur. The main factors effecting cleavage fractures were the stress state and the grain size. Increasing the rotational speed led to a larger tensile stress and larger grains, which resulted in increased cleavage fractures (Ref 42). Increased tensile stress and grain size commonly resulted in a decrease in the hardness and tensile strength. Therefore, cleavage fractures increased as the rotational speed increased, while the hardness and tensile strength decreased.

Conclusion

In this work, the ME20M Mg alloy was friction stir welded underwater with rotational speeds ranging from 1100 to 1600 rpm and a constant traverse speed of 40 mm/min. The effects of SFSW on the macrostructure, microstructure, hardness, and tensile properties of the ME20M Mg alloy were investigated.

The main conclusions were as follows.

-

(1)

After the SFSW of ME20M, flash defects were observed on the surface of the samples and they increased with increasing rotational speed. When the rotational speed was below 1300 rpm, tunnel defects were found on the sample cross section.

-

(2)

ME20M Mg alloys were jointed at different rotational speeds by friction stir welding underwater cooling. The weld nugget produced at 1100 rpm had a refined grain size of ~ 3.75 µm, while the grain size of the base metal was 11.34 µm. As the rotational speed increased, the grain size of the weld nugget also increased, with a grain size of 14.12 µm as the rotational speed increased to 1600 rpm.

-

(3)

After SFSW, the microelements Mn, Ce, Al, and Zn precipitated at the grain boundary and promoted grain refinement of the TMAZ and WN regions. The matrix phase α-Mg grains were refined by thermal and mechanical action.

-

(4)

The microhardness of the welded joint presented a subtle “w”-type shape along the middle line of the thickness. The highest hardness value of 57.9 HV was obtained at a rotational speed of 1100 rpm, while the lowest hardness of 39.4 HV occurred in the HAZ of the advancing side at the highest rotational speed 1600 rpm.

-

(5)

The tensile strength of the welded joint was 183.2 MPa at a rotational speed of 1100 rpm, which was ~ 76.32% of the base metal. With increased rotational speed, the strength of the welded joint decreased. The fractures presented a mixture of cleavage and ductile fractures.

References

R. Nandan, T. DebRoy, and H.K.D.H. Bhadeshia, Recent Advances in Friction-Stir Welding—Process, Weldment Structure and Properties, Prog. Mater. Sci., 2008, 53(6), p 980–1023

Z. Ma, Friction Stir Processing Technology: A Review, Metall. Mater. Trans. A, 2008, 39(3), p 642–658

Z.H. Chen, H.G. Yan, J.H. Chen, Y.J. Quan, H.M. Wang, and D. Chen, Magnesium Alloy, Chemical Industry Press, Beijing (in Chinese), 2004

K. Hantzsche, J. Wendt, K.U. Kainer, J. Bohlen, and D. Letzig, Mg Sheet: The Effect of Process Parameters and Alloy Composition on Texture and Mechanical Properties, JOM, 2009, 61(8), p 38–42

T. Al-Samman and X. Li, Sheet Texture Modification in Magnesium-Based Alloys by Selective Rare Earth Alloying, Mater. Sci. Eng. A, 2011, 528(10), p 3809–3822

Y. Chino, X. Huang, K. Suzuki, K. Sassa, and M. Mabuchi, Influence of Zn Concentration on Stretch Formability at Room Temperature of Mg-Zn-Ce Alloy, Mater. Sci. Eng. A, 2010, 528(2), p 566–572

J. Min and J. Lin, An elastic Behavior and Phenomenological Modeling of mg ZEK100-O Alloy Sheet Under Cyclic Tensile Loading–Unloading, Mater. Sci. Eng. A, 2013, 561(3), p 174–182

J. Bohlen, M.R. Nürnberg, J.W. Senn, D. Letzig, and S.R. Agnew, The Texture and Anisotropy of Magnesium-Zinc-Rare Earth Alloy Sheets, Acta Mater., 2007, 55(6), p 2101–2112

H. Xu, J. Liu, and S. Xie, Magnesium Alloy Fabrication and Processing Technology, Metallurgical Industry Press, Beijing (in Chinese), 2007

S. Wang and D. Zhang, Microstructure and Mechanical Properties of Frictional Stirring Processed (FSP) MB8 Magnesium Alloy, SCNA, 2011, 31(1), p 83–86

W. Xu, Friction Stir Welding of Magnesium Alloy MB8, J. Mater. Eng., 2002, 8, p 35–36

L. Xing, L. Ke, D. Sun, and X. Zhou, Friction Stir Welding of MB8 Magnesium Alloy Sheet, Trans. China Weld. Inst., 2001, 22(6), p 18–20

R.S. Mishra and Z.Y. Ma, Friction Stir Welding and Processing, Mater. Sci. Eng. R, 2005, 50(1), p 1–78

C. Fang, D. Zhang, and Y. Li, Microstructures and Tensile Properties of Submerged Friction Stir Processed AZ91 Magnesium Alloy, J. Magn. Alloy, 2015, 3, p 203–209

B. Darras and E. Kishta, Submerged Friction Stir Processing of AZ31 Magnesium Alloy, Mater. Des., 2013, 47(9), p 133–137

X. Luo, G. Cao, W. Zhang, C. Qiu, and D. Zhang, Ductility Improvement of an AZ61 Magnesium Alloy through Two-Pass Submerged Friction Stir Processing, Materials, 2017, 10(3), p p253

J.P. Ramulu, R.G. Narayanan, S.V. Kailas et al., Internal Defect and Process Parameter Analysis during Friction Stir Welding of Al 6061 Sheets, Int. J. Adv. Manuf. Technol., 2013, 65(9–12), p 1515–1528

P. Vilaça and W. Thomas, Friction Stir Welding Technology, Sci. Technol. Rev., 2012, 8, p 85–124

J. Rasti, Study of the Welding Parameters Effect on the Tunnel Void Area during Friction Stir Welding of 1060 Aluminum Alloy, Int. J. Adv. Manuf. Technol., 2018, 97, p 2221–2230

T.G. Santos, R.M. Miranda, and P. Vilaça, Friction Stir Welding Assisted by Electrical Joule Effect, J. Mater. Process. Technol., 2014, 10, p 2127–2133

Y. Huang, Y. Wang, X. Meng et al., Dynamic Recrystallization and Mechanical Properties of Friction Stir Processed Mg-Zn-Y-Zr Alloys, J. Mater. Process. Technol., 2017, 249, p 331–338

L. Commin, M. Dumont, J.E. Masse, and L. Barrallier, Friction Stir Welding of AZ31 Magnesium Alloy Rolled Sheets: Influence of Processing Parameters, Acta Mater., 2009, 57(2), p 326–334

V.V. Patel, V.J. Badheka, and A. Kumar, Effect of Velocity Index on Grain Size of Friction Stir Processed Al-Zn-Mg-Cu Alloy, Procedia Technol., 2016, 23, p 537–542

M.R. Barnett, A Rationale for the Strong Dependence of Mechanical Twinning on Grain Size, Scr. Mater., 2008, 59(7), p 696–698

H.T. Serindag, B.G. Kiral, H.T. Serindag, and B.G. Kiral, Friction Stir Welding of AZ31 Magnesium Alloys—A Numerical and Experimental Study, Lat. Am. J. Solids Struct., 2016, 14(1), p 113–130

S.S. Kumar, N. Murugan, K.K. Ramachandran, Effect of Friction Stir Welding on Mechanical and Microstructural Properties of AISI 316L Stainless Steel Butt Joints. Weld. World, 2019, 63, p 137–150

P. Schempp, C.E. Cross, A. Pittner, and M. Rethmeier, Influence of Solute Content and Solidification Parameters on Grain Ref inement of Aluminum Weld Metal, Metall. Mater. Trans. A, 2013, 44(7), p 3198–3210

G. Sharma and D.K. Dwivedi, Study on Microstructure and Mechanical Properties of Dissimilar Steel Joint Developed Using Friction Stir Welding, Int. J. Adv. Manuf. Technol., 2016, 88(5–8), p 1–9

Z.L. Hu, M.L. Dai, and Q. Pang, Influence of Welding Combined Plastic Forming on Microstructure Stability and Mechanical Properties of Friction Stir-Welded Al-Cu Alloy, J. Mater. Eng. Perform., 2018, 27, p 4036–4042

H. Zhang, H. Liu, and L. Yu, Effect of Water Cooling on the Performances of Friction Stir Welding Heat-Affected Zone, J. Mater. Eng. Perform., 2012, 21(7), p 1182–1187

G. Ran, J.E. Zhou, and Q.G. Wang, Precipitates and Tensile Fracture Mechanism in a Sand Cast A356 Aluminum Alloy, J. Mater. Process. Technol., 2008, 207(1), p 46–52

M. Lentz, J. Nissen, C. Fahrenson, S.C. Vogel, and W. Reimers, Macro- and Microtexture Evolution of an Extruded Mg-Mn-Ce Alloy during Annealing, Mater. Sci. Eng. A, 2016, 655, p 17–26

P. Carlone, A. Astarita, F. Rubino, and N. Pasquino, Microstructural Aspects in FSW and TIG Welding of Cast ZE41A Magnesium Alloy, Metall. Mater. Trans. B, 2016, 47(2), p 1–7

F. Liu, L. Fu, and H. Chen, Microstructure Evolution and Mechanical Properties of High-Speed Friction Stir Welded Aluminum Alloy Thin Plate Joints, J. Mater. Eng. Perform., 2018, 27(7), p 3590–3599

L. Zhou, H.J. Liu, and Q.W. Liu, Effect of Rotation Speed on Microstructure and Mechanical Properties of Ti-6Al-4 V Friction Stir Welded Joints, Mater. Des. (1980-2015), 2010, 31(5), p 2631–2636

S. Li, Y. Chen, X. Zhou, J. Kang, Y. Huang, and H. Deng, High-Strength Titanium Alloy/Steel Butt Joint Produced Via Friction Stir Welding, Mater. Lett., 2019, 234, p 155–158

L. Commin, M. Dumont, R. Rotinat, F. Pierron, J.E. Masse, and L. Barrallier, Influence of the Microstructural Changes and Induced Residual Stresses on Tensile Properties of Wrought Magnesium Alloy Friction Stir Welds, Mater. Sci. Eng. A, 2012, 551(31), p 288–292

Y. Wang, Y. Huang, X. Meng, L. Wan, and J. Feng, Microstructural Evolution and Mechanical Properties of Mg-Zn-Y-Zr Alloy during Friction Stir Processing, J. Alloys Compd., 2017, 696, p 875–883

R.D. Fu, Z.Q. Sun, R.C. Sun, Y. Li, H.J. Liu, and L. Liu, Improvement of Weld Temperature Distribution and Mechanical Properties of 7050 Aluminum Alloy Butt Joints by Submerged Friction Stir Welding, Mater. Des., 2011, 32(10), p 4825–4831

S. Mironov, T. Onuma, Y.S. Sato, S. Yoneyama, and H. Kokawa, Tensile Behavior of Friction-Stir Welded AZ31 Magnesium Alloy, Mater. Sci. Eng. A, 2017, 679, p 272–281

W.H. Hartt and R.E. Reed-Hill, Internal Deformation and Fracture Of Second-Order 1011-1012 Twins in Magnesium, Trans. Metall. Soc. AIME, 1968, 242, p 1127–1132

D. Ando, J. Koike, and Y. Sutou, Relationship Between Deformation Twinning and Surface Step Formation in AZ31 Magnesium Alloys, Acta Mater., 2010, 58(13), p 4316–4324

Acknowledgments

The study work of this paper is supported by the National Natural Science Foundation of China (Grant No. 51475232). This is a project funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, W., Shen, Y., Guo, C. et al. Effect of Rotational Speed on Microstructure and Mechanical Properties in Submerged Friction Stir Welding of ME20M Magnesium Alloy. J. of Materi Eng and Perform 28, 4610–4619 (2019). https://doi.org/10.1007/s11665-019-04205-w

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04205-w