Abstract

A green multi-component inhibitor was developed in this study to obtain suitable scale and corrosion inhibitor for the cooling water treatment of central air conditioners. The inhibitor formulation consisted of hydrolyzed polymaleic anhydride/Tween-80/sodium N-lauroyl sarcosinate/tolyltriazole (named 4-HTSA). Weight loss test and electrochemical method were used to investigate the corrosion inhibition performance of 4-HTSA on A3 carbon steel and T2 red copper in synthetic cooling water, and the scale inhibition performance of 4-HTSA was studied by the calcium carbonate precipitation method. The influence of parameters, such as pH, temperature, scaling and corrosive ion, on 4-HTSA was researched. Scanning electron microscopy (SEM) and x-ray diffraction were used for examination of the scale, and corrosion coupons were analyzed by SEM/energy-dispersive x-ray spectroscopy. Results showed that 4-HTSA had excellent scale and corrosion inhibition performance and wide tolerance to pH, temperature and the concentration of scaling and corrosive ion. Polarization curves indicated that 4-HTSA was anodic inhibitor.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The cooling water of central air conditioner is roughly similar to the industrial circulating cooling water, and the existing water treatment method almost refers to the treatment of industrial circulating cooling water, which are mainly by adding chemicals (scaling inhibitor, corrosion inhibitor, bactericide) into circulating cooling water to inhibit scale formation and corrosion (Ref 1).

The ratio of the amount of feed water to the amount of circulating water in central air conditioner cooling water system is very small, compared with that in industrial cooling water system, which as a result the running water will deteriorate in a short time. Therefore, inhibitor added in the cooling water is required to have good adaptability to running water.

The equipment of cooling water system of central air conditioners is mostly made from carbon steel, red copper and a small amount of stainless steel. Among them, copper equipment accounts for a larger proportion than that in industrial cooling water system; thus, it is particularly important to inhibit copper-iron corrosion of the cooling water system. In conclusion, inhibitor added in the cooling water of central air conditioners must be able to inhibit scale formation and copper-iron corrosion at the same time.

There are many types of scale and corrosion inhibitors, most of them are phosphates and inorganic salts of heavy metals (Ref 2). Owing to the concern over their toxic effect on aquatic animals and humans, the addition of them is diminishing. As a result, it is becoming the trend to choose the environmentally friendly, that is, ‘green’ chemical (Ref 3). Hydrolyzed polymaleic anhydride (HPMA) is recognized as green water treatment agent with properties of non-toxic, phosphate-free and good biodegradability. HPMA has excellent anti-scaling performance, which can prevent CaCO3 precipitation with carboxylic ion. Carboxylic ion has good chelating ability to be absorbed on the crystal nuclei of calcium carbonate scale. However, high cost limits the application of HPMA in circulating cooling water. To reduce the dosage of HPMA, the way of compounding HPMA and Tween-80 in this paper had been adopted. Tween-80 as a surfactant has a suitable dispersing effect on HPMA and improves the stability of HPMA. HPMA and a small amount of Tween-80 had a synergistic effect on inhibiting scale formation, and the scale inhibition efficiency could improve upon mixing. Meanwhile, research shows that sodium N-lauroyl sarcosinate (SLS) is a kind of green corrosion inhibitor, which is free of heavy metals and phosphorus, and has excellent corrosion inhibition performance for A3 carbon steel, but not an ideal corrosion inhibitor for T2 red copper. Tolyltriazole (TTA) is an excellent corrosion inhibitor for T2 red copper (Ref 4). So in this paper, the compounded formula of SLS and TTA was developed.

In order to inhibit scale formation and copper-iron corrosion at the same time, a preliminary series of experiment was conducted in synthetic cooling water to research the quaternary compound inhibitor (HPMA/Tween-80/SLS/TTA) under different composition. The most promising mixture was selected for subsequent test.

Experimental Procedure

Formulation of Inhibitor

In the previous work, it has been found that the proper multi-component inhibitor has a great scale-corrosion inhibition performance, which was composed of HPMA/Tween-80/SLS/TTA. Screening test of various concentrations of the component and their blend indicated that the formula ratio of each component was 8:1:37:1 and that the best dosage was 100 mg/L. Thus, we took 4-HTSA as the main research object in this experiment.

Experimental Water

Local tap water is usually used for the cooling water of central air conditioners. Cooling water can be concentrated during operation, leading to the increase in concentration of impurity ion (Ref 5). The experimental water was synthetic cooling water that was prepared according to the actual operation of the cooling water of central air conditioners. Table 1 shows the chemical composition of the synthetic cooling water.

Scale Inhibition Test

The scale inhibition efficiency of the inhibitor was evaluated according to the national standard GB 16632-2008 (in Chinese) in flasks, to which Ca2+ and HCO3 − were added. The test condition was as follows: With and without 100 mg·L−1 of inhibitor, experimental water was heated in water bath for 10 h at 80 °C. When time was on, water was removed from the water bath heater and was filtered totally. The filtrate was titrated for Ca2+ (the calcium concentration was determined by a chemical dosage with ethylenediaminetetraacetic acid) (Ref 6).

Weight Loss Test

The corrosion inhibition efficiency of the inhibitor was evaluated according to the national standard GB/T 18175-2000 (in Chinese) by rotary coupon corrosion test. The test was conducted in 2-L glass beaker containing aerated synthetic cooling water with and without the inhibitor. The temperature and rotation rate were adjusted to 45 °C and 75 r/min, respectively (Ref 7). Test coupons were made from A3 carbon steel and T2 red copper with dimensions of 50 mm × 25 mm × 2 mm. These coupons were polished with a silicon carbide paper to a 600-grit surface finish, cleaned in detergent, rinsed with acetone and weighed before immersion in experimental water. Each group of test used four parallel coupons. The initial weight of A3 carbon steel is 20 g, and the main initial weight of T2 red copper is 25 g. After 72 h of immersion test, the coupons were soaked in acid pickling solution to remove the corrosion sediment on the surface of coupons, cleaned by water, acetone and ethanol successively, put in desiccators for hours and reweighed at last.

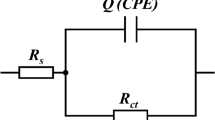

Electrochemical Experiment

The electrochemical tests were started in a standard three electrode electrolytic cell, and the reference electrode was saturated calomel electrode. The counter electrode was a platinum electrode with a surface area of 2 cm2. The working electrode was in the form of a cylinder with 1.0 cm2 cross-sectional area, which was made from A3 carbon steel and T2 red copper. Before immersed in experimental water, the working electrode was polished with emery paper until 1200 grade, cleaned with distilled water and dried. In the Tafel test, the experimental water was the same as the synthetic cooling water shown in Table 1, and the test was taken at the pH of 8.23 and the temperature of 25 °C. The electrode was immersed in experimental water for 1 h until steady-state open-circuit potential (EOCP) was obtained, and all test was conducted at a scan rate of 1 mV/s (Ref 8). The cathodic polarization curve was recorded by polarization from a more negative direction toward Ecorr with a sweep rate of 1 mV/s. After this scan, the anodic polarization curve was recorded from Ecorr to positive direction with the same sweep rate. These measurements were undertaken using a CHI660C electrochemical workstation by a personal computer. For each concentration three independent experiments were performed. The mean values and standard deviations are presented as well.

Effects on the Inhibition Performance of Inhibitor

pH Value

With the concentration changes in alkali ions (such as Ca2+), or being affected by pipeline leakage, the pH value of central air conditioner cooling water will be changed, as a result the scaling and corrosion trend of the water changed as well. Therefore, inhibition performance of 4-HTSA in the pH interval from 4 to 10 was studied by scale inhibition test and weight loss test. Hydrochloric acid and sodium hydroxide were used to adjust the pH of experimental water, and pH was measured by the digital pH meter.

Temperature

It is known that temperature can affect the scaling and corrosion tendency, thereby affecting the scale and corrosion inhibition performance of water treatment agent. Thus, inhibition performance of 4-HTSA in the experimental water with different temperature was investigated by scale inhibition test and weight loss test in thermostatic water heater. The temperature of 30, 40, 50, 60, 70 and 80 °C was selected here to study the inhibition performance of 4-HTSA.

Concentration of Scaling and Corrosive Ion

Ca2+ and HCO3 − (scaling ion) are always considered to be an important factor for scaling, whereas Cl− (corrosive ion) is the main corrosive ion in cooling water. The scale inhibition efficiency of 4-HTSA in the experimental water with different concentration of Ca2+ and HCO3 −, and the corrosion inhibition efficiency in the experimental water with different Cl− concentration were studied by scale inhibition test and weight loss test, respectively. EDTA titration and hydrochloric titration were adopted to measure concentration of Ca2+ and HCO3 −, while concentration of Cl− was measured by nitrate radical titration.

Surface Analysis

After scale inhibition and weight loss test, scanning electron microscopy (SEM) was used to observe the morphology of the scale sample and corrosion coupon. X-ray diffraction (XRD) and energy-dispersive x-ray spectroscopy (EDX) were used to analyze the crystal form of calcium carbonate scale sample and elements content on metal coupon surface, respectively.

Results and Discussion

Scale Inhibition Test

Calcium carbonate precipitation method was used to investigate the scale inhibition performance of 4-HTSA in experimental water. As shown in Table 2, the concentration of Ca2+ after the test in the presence of 4-HTSA greatly increased compared with the concentration in the absence of inhibitor. The scale inhibition rate can reach above 95%, so it indicated that 4-HTSA had an excellent scale inhibition performance. Scale inhibition rate (IE) was determined by the following equation (Ref 9):

where ρ 2 is the concentration of Ca2+ after the test in the presence of inhibitor (mg/L), ρ 0 is the concentration of Ca2+ in the absence of inhibitor after test (mg/L) and ρ 1 is the concentration of Ca2+ before the test (mg/L).

SEM Morphology and XRD Analysis on Scale Sample

The scale sample from the test above was observed by SEM. The micrographs are shown in Fig. 1.

As shown in Fig. 1(a), the calcium carbonate crystal formed in the solution without 4-HTSA presented a regular hexahedron calcite structure. The crystal structure was compact and had a smooth surface. It indicated that the calcium carbonate crystal grew regularly. The calcium carbonate crystal formed in the solution with 4-HTSA presented irregular flakiness, as shown in Fig. 1(b). The crystal type was completely distorted, showing good dispersion state. The calcium scale crystal was significantly larger in size than that in the absence of inhibitor. This result can be explained by the function of HPMA long chain, which is composed of multiple carboxyl (-COOH). Polycarboxylic ions, produced by the hydrolysis of HPMA, could react with the active site on the crystal surface. So HPMA molecule could inhibit the CaCO3 crystal growth by binding the crystal nucleus (Ref 10).

XRD measurement was conducted to identify the crystal composition of scale sample formed in test solution with and without 4-HTSA. The spectrograms are shown in Fig. 2.

The results showed that the XRD pattern of scale sample formed in the solution with and without 4-HTSA was almost the same and that calcite was the only crystal form. In the presence of 4-HTSA, the crystal structures were not altered and only the crystal habit or morphology was changed, as evidenced by SEM micrograph (Ref 11). CaCO3 scale has three kinds of polymorphic form, namely calcite, aragonite and vaterite, among which thermal stability of calcite is the best, while vaterite has the least stable form (Ref 12). Vaterite is the initial phase during the growth of calcium carbonate scale in CaCO3 supersaturated solution, whereas calcite can be transformed from aragonite or vaterite in the absence of inhibitor (Ref 13). Thermodynamically unstable vaterite and aragonite cannot be stabilized kinetically in the presence of 4-HTSA.

Weight Loss Tests

The corrosion rate of coupons in the experimental water with and without 4-HTSA is presented in Table 3. Corrosion rate (ν) and corrosion inhibition efficiency (X) were determined by Eq 2 and 3, respectively (Ref 14):

From Eq 2 and 3, m 1 and m 2 are the weight of coupons before and after test (g), \( \overline{\Delta m} \) is the average mass loss of coupons before and after test (g), s is the surface area of coupons (28 cm2), ρ is the density of coupons (A3 is 7.85 g/cm2, while T2 is 8.95 g/cm2), t is the testing time (72 h), 8760 is hours in a year (h/a), 10 is corresponding millimeters (mm/cm), \( v_{1} \) and \( v_{0} \) are the corrosion rate of metals with and without inhibitor (mm/a), respectively.

The results showed that the corrosion rate of A3 and T2 decreased obviously in experimental water in the presence of 4-HTSA. The national standard GB50050-2007 (in Chinese) stipulated that the corrosion rate of A3 carbon steel must be slower than 0.075 mm/a, whereas that of T2 red copper must be slower than 0.005 mm/a (Ref 15). The corrosion rate of A3 and T2 in experimental water in the presence of 4-HTSA was slower than the rated value, which showed that 4-HTSA had excellent corrosion inhibition performance.

SEM Morphology and EDX Analysis on Corrosion Coupons

The corrosion coupons of A3 and T2 after weight loss test were observed by SEM. The micrographs are shown in Fig. 3: (b) and (a) are the micrographs of A3 coupons in the experimental water with and without 4-HTSA, respectively; (d) and (c) are the micrographs of T2 coupons in the experimental water with and without 4-HTSA, respectively. In the absence of inhibitor, the metal surface had obvious corrosion product, particularly A3 carbon steel. In the presence of inhibitor, the metal surface was smooth, with only a trace of grinding. Obviously, 4-HTSA had inhibited corrosion of A3 and T2 efficiently. The inhibition mechanism was that SLS and TTA can adsorb on metal surface and form a monolayer adsorption film on it (Ref 16, 17).

EDX measurement was conducted to further analyze the surface element of corrosion coupons. The spectrogram is shown in Fig. 4, where (b) and (a) are the EDX spectra of A3 coupons in the experimental water with and without 4-HTSA, respectively; (d) and (c) are the EDX spectra of T2 coupons in the experimental water with and without inhibitor, respectively. Table 4 shows the element content of metal surface. The results showed that the iron content of the corrosion product of A3 coupons was only 18.46% in the experimental water in the absence of inhibitor, whereas the calcium content reached up to 37.65%. Thus, the calcium scale mainly deposited on A3 coupon’s surface in the experimental water in the absence of 4-HTSA, leading to corrosion under the scale eventually. In the experimental water in the presence of 4-HTSA, decreased calcium and increased iron were detected on A3 coupons’ surface, which indicated that the scale formation and corrosion on A3 were inhibited by 4-HTSA. The oxygen content on T2 coupons’ surface in the experimental water in the presence of 4-HTSA decreased compared with it in the absence of 4-HTSA; so, the corrosion on T2 was inhibited by the 4-HTSA. These figures showed that 4-HTSA had excellent corrosion and scale inhibition efficiency on A3 carbon steel and T2 red copper.

Electrochemical Tests

Figure 5 shows the polarization curves of A3 carbon steel and T2 red copper in the experimental water in the absence and in the presence of 4-HTSA. The polarization curves of the electrode immersed in the experimental water in the presence of 4-HTSA indicated a shift in the corrosion potential toward more positive values of potential compared with the electrode in the experimental water without 4-HTSA. This shift was a result of the anodic inhibition effect of SLS and TTA (Ref 18), which indicated that 4-HTSA was anodic inhibitor. The corrosion current density (i corr) of A3 and T2, which was determined by the Tafel extrapolation method, significantly decreased. Accordingly, 4-HTSA had good corrosion inhibition efficiency on A3 and T2. Table 5 shows the electrochemical parameters of the A3 and T2 electrode system obtained in the experimental water with and without 4-HTSA. The inhibition efficiency (η) of 4-HTSA was calculated according to i corr as follows (Ref 19, 20):

where i corr and i 0corr is the corrosion current density value with and without the inhibitor, respectively.

The result of electrochemical test corroborated the result of the weight loss test.

The Effect of Parameters’ Change on Scale and Corrosion Inhibition Performance of 4-HTSA

Scale inhibition test and weight loss test in the experimental water with different pH, temperature, concentration of scaling and corrosive ions (Ca2+, HCO3 − and Cl−) were conducted to study the adaptability of 4-HTSA in the cooling water of central air conditioners.

Effect of pH on 4-HTSA Performance

As is shown in Fig. 6, with pH increasing from 4 to 10, the scale inhibition efficiency decreased from 98 to 87%. The reason may be that when HPMA was in acid status with low pH level, hydrogen bond on the carboxyl of HPMA could be easily adsorbed on microcrystalline of CaCO3 (Ref 21), leading to better anti-scaling performance. To the contrary, when HPMA was in ionic state with high pH level, it was difficult for carboxyl of HPMA to adsorb on microcrystalline, followed with the reduction in scale inhibition rate. Meanwhile, the higher pH was, the lower the solubility of CaCO3 could be, so more scale precipitation appeared. Overall, the scale inhibition efficiency decreased in strong alkaline condition, but it reached above 87% when the pH of cooling water ranged from 4.0 to 10.0.

As shown in Fig. 6, the corrosion inhibition efficiency on A3 carbon steel and T2 red copper increased with pH increase from 4.0 to 10.0. Especially when the pH was below 6.0, the corrosion inhibition rate of A3 and T2 significantly decreased. The reason may be that metal easier to be oxidized in low pH (Ref 22). With the increase in pH, the amount of hydrogen ion in solution reduced, and protective layer in metal surface was more easily formed, leading to the increase in anti-corrosion rate. Nonetheless, the corrosion inhibition rate of A3 and T2 was still above 80% even in strong acidic condition (pH as 4.0).

Overall, 4-HTSA had good scale and corrosion inhibition performance even in strong alkaline or acidic condition. The wide pH range of 4-HTSA application was appropriate for the cooling water system of central air conditioners.

Effect of Temperature on 4-HTSA Performance

Figure 7 shows that higher temperature made the decrease in scale inhibition rate. This can be explained by the fact that the adsorption capability of 4-HTSA on the surface of calcium carbonate crystal nucleus declined with increase in temperature (Ref 23), while it resulted in scale layer forming faster and thicker. The scale inhibition efficiency decreased from 99 to 95% with temperature rising from 30 to 80 °C, i.e., the effect of temperature on the scale inhibition performance of 4-HTSA was not that obvious.

With increasing temperature, the corrosion inhibition efficiency on A3 and T2 gradually decreased. The corrosion inhibition rate of A3 decreased from 96 to 83% and that of T2 decreased from 93 to 80% with temperature rising from 30 to 80 °C. This can be explained that high temperature could accelerate the reduction process of dissolved oxygen at the cathode and metal dissolution process at the anode, which would result in decreased anti-corrosion efficiency (Ref 24). However, the corrosion inhibition rate of A3 and T2 remained above 80% even in the condition of 80 °C. From the above, 4-HTSA had excellent temperature adaptability.

Effect of Changing Concentration of Scaling and Corrosive Ion on 4-HTSA Performance

As shown in Fig. 8, Ca2+ and HCO3 − concentration had an obvious effect on scale inhibition efficiency of 4-HTSA. With increasing Ca2+ and HCO3 − concentration, especially when Ca2+ and HCO3 − concentration was above 500 mg/L, the scale inhibition efficiency decreased. It can be explained by the face that high concentration of Ca2+ and HCO -3 had broken the balance of the carbonate in experimental water, accelerating the synthesis of calcium carbonate scale and making the maximum inhibition capacity of 4-HTSA exceeded (Ref 25). However, the scale inhibition efficiency of 4-HTSA still reached 80% even when Ca2+ and HCO3 − concentration approached 720 mg/L. This result indicated that 4-HTSA had good tolerance to high concentration of scaling ion.

The obvious decline trend of the corrosion inhibition efficiency with increase in Cl- concentration is observed in Fig. 8. The corrosion inhibition rate of A3 decreased from 96 to 81%, whereas that of T2 decreased from 94 to 80% with Cl- concentration rising from 100 to 1000 mg/L. The reason may be that Cl- could penetrate to the protective layer on metal surface (Ref 26). The increase in Cl- concentration led to negative shift of pitting potential and decreased the stability of protective layer on metal surface, thereby reducing the anti-corrosion performance of 4-HTSA. The corrosion inhibition efficiency on A3 and T2 was above 80% even when Cl- concentration increased to 1000 mg/L, which indicated that 4-HTSA had good adaptability on high concentration of Cl-.

Conclusions

The scale and corrosion inhibition performance of the green, multi-component inhibitor 4-HTSA for the cooling water treatment of central air conditioners was investigated in this study. The main conclusions are as follows:

-

1.

4-HTSA presents good inhibition efficiency for calcium carbonate scale by binding the crystal nucleus. 4-HTSA can change the crystal habit or morphology, but cannot alter the crystal structure.

-

2.

4-HTSA also shows excellent anti-corrosion performance on A3 carbon steel and T2 red copper by forming monolayer adsorption film on metal surface. Polarization curves show that 4-HTSA is anodic corrosion inhibitor for A3 and T2, mainly by inhibiting the anode reaction of corrosion cell.

-

3.

4-HTSA has wide tolerance to pH and temperature and excellent adaptability to high concentration of scaling and corrosive ion.

-

4.

As described in the end, the kind of environmentally-friendly and efficient water treatment agent, 4-HTSA, is promising to inhibit scale and copper-iron corrosion in circulating cooling water of central air conditioners.

References

H.B. Wang, C. Hu, X.X. Hu, M. Yang, and J.H. Qu, Effects of Disinfectant and Biofilm on the Corrosion of Cast Iron Pipes in a Reclaimed Water Distribution System, Water Res., 2012, 46(4), p 1070–1078

Z. Zhou, W.M. Qiao, Y.B. Lin, X.L. Shen, D.L. Hu, J.Q. Zhang, L.M. Jiang, and L.C. Wang, Phosphonate Removal from Discharged Circulating Cooling Water Using Iron-Carbon Micro-Electrolysis, Water Sci. Technol., 2014, 70(3), p 524–532

N. Srisuwan, N. Ochoa, N. Pébère, and B. Tribollet, Variation of Carbon Steel Corrosion Rate with Flow Conditions in the Presence of an Inhibitive Formulation, Corros. Sci., 2008, 50(5), p 1245–1250

A. Aruchamy, A. Fujishima, A. Ibrahim, and B.H. Loo, A Surface-Enhanced Raman Spectroscopic Study of Benzotriazole and 6-Tolyltriazole Corrosion Inhibitors on Copper Electrodes in Alkaline Solutions, J. Electroanal. Chem., 1990, 281(1–2), p 299–304

I. Nishida, Y. Okaue, and T. Yokoyama, The Inhibition Abilities of Multifunctional Polyelectrolytes for Silica Scale Formation in Cooling Water Systems: Role of the Nonionic Functional Group, J. Colloid Interface Sci., 2011, 360(1), p 110–116

National Standardization Technical Committee of Chemistry, GB/T16632-2008, Determination of Scale Inhibition Performance of Water Treatment Agents—Calcium Carbonate Precipitation Method, 2008

National Standardization Technical Committee of Chemistry, GB/T 18175-2000, Determination of Corrosion Inhibition Performance of Water Treatment Agents—Rotary Coupon Method, 2000

R.A. Belakhmima, N. Dkhireche, R. Touir, and M. Ebn Touhami, Development of a Multi-component SG with CTAB as Corrosion, Scale, and Microorganism Inhibitor for Cooling Water Systems, Mater. Chem. Phys., 2015, 152, p 85–94

H.M. Luo, D.J. Chen, X.P. Yang, X. Zhao, H.X. Feng, M.Y. Li, and J.Q. Wang, Synthesis and Performance of a Polymeric Scale Inhibitor for Oilfield Application, J. Petrol. Explor. Prod. Technol., 2015, 5, p 177–187

Z.H. Shen, J.S. Li, K. Xu, L.L. Ding, and H.Q. Ren, The Effect of Synthesized Hydrolyzed Polymaleic Anhydride (HPMA) on the Crystal of Calcium Carbonate, Desalination, 2012, 284, p 238–244

A.L. Kavitha, T. Vasudevan, and H.G. Prabu, Evaluation of Synthesized Antiscalants for Cooling Water System Application, Desalination, 2011, 268(1–3), p 38–45

C. Wang, S.P. Li, and T.D. Li, Calcium Carbonate Inhibition By a Phosphonate-Terminated poly(Maleic-co-Sulfonate) Polymeric Inhibitor, Desalination, 2009, 249(1), p 1–4

Y.M. Tang, W.Z. Yang, X.S. Yin, Y. Liu, P.W. Yin, and J.T. Wang, Investigation of CaCO3 Scale Inhibition by PAA, ATMP and PAPEMP, Desalination, 2008, 228(1–3), p 55–60

F. Liu, L. Zhang, X. Yan, X.H. Lu, Y. Gao, and C.C. Zhao, Effect of Diesel on Corrosion Inhibitors and Application of Bio-enzyme Corrosion Inhibitors in Laboratory Cooling Water System, Corros. Sci., 2015, 93, p 293–300

Ministry of Construction of the People’s Republic of China, GB50050-2007, Design Specification for Industrial Circulating Cooling Water Treatment, 2007

N. Dkhireche, A. Dahami, A. Rochdi, J. Hmimoub, R. Touir, M. Ebn Touhami, M. El Bakri, A. El Hallaoui, A. Anouar, and H. Takenouti, Corrosion and Scale Inhibition of Low Carbon Steel in Cooling Water System By 2-Propargyl-5-o-Hydroxyphenyltetrazole, J. Ind. Eng. Chem., 2013, 19(6), p 1996–2003

Mahbuboor R. Choudhury, Radisav D. Vidic, and David A. Dzombak, Inhibition of Copper Corrosion by Tolyltriazole in Cooling Systems Using Treated Municipal Wastewater as Makeup Water, Arab. J. Sci. Eng., 2014, 39, p 7741–7749

D.J. Choi, S.J. You, and J.G. Kim, Development of an Environmentally Safe Corrosion, Scale, and Microorganism Inhibitor for Open Recirculating Cooling Systems, Mat. Sci. Eng. A: Struct., 2002, 335(1–2), p 228–236

H. Ashassi-Sorkhabi, E. Asghari, and M. Mohammadi, Effects of Solution Hydrodynamics on Corrosion Inhibition of Steel By Citric Acid in Cooling Water, J. Mater. Eng. Perform., 2014, 23(8), p 2992–3000

Zahra Sharifi, Mahmoud Pakshir, and Somayeh Mohamadi, Investigation of Synthesize Sulfonated Melamine Formaldehyde as a Novel Corrosion Inhibitor for Mild Steel in Saline Environment, J. Mater. Eng. Perform., 2015, 24(2), p 664–669

M.Z. Xia, F.Y. Wang, W. Lei, and S.G. Zhang, Scale Inhibiting Effect and Mechanism of Carboxylic Polymer on Apatite, Acta. Chim. Sin., 2008, 66(4), p 476–480 ((in Chinese))

R. Touir, N. Dkhireche, M. Ebn Touhami, M. Sfaira, O. Senhaji, J.J. Robin, B. Boutevin, and M. Cherkaoui, Study of Phosphonate Addition and Hydrodynamic Conditions on Ordinary Steel Corrosion Inhibition in Simulated Cooling Water, Mater. Chem. Phys., 2010, 122, p 1–9

F. Liu, X.H. Lu, W. Yang, J.J. Lu, H.Y. Zhong, X. Chang, and C.C. Zhao, Optimizations of Inhibitors Compounding and Applied Conditions in Simulated Circulating Cooling Water System, Desalination, 2013, 313, p 18–27

A.N. Senthilkumar, K. Tharini, and M.G. Sethuraman, Studies on a Few Substituted Piperidin-4-One Oximes as Corrosion Inhibitor for Mild Steel in HCl, J. Mater. Eng. Perform., 2011, 20, p 969–977

Y. Xu, B. Zhang, L.J. Zhao, and Y.C. Cui, Synthesis of Polyaspartic Acid/5-Aminoorotic Acid Graft Copolymer and Evaluation of Its Scale Inhibition and Corrosion Inhibition Performance, Desalination, 2013, 311, p 156–161

W. Chen, S. Hong, H.Q. Luo, and N.B. Li, Inhibition Effect of 2,4,6-Trimercapto-1,3,5-Triazine Self-Assembled Monolayers on Copper Corrosion in NaCl Solution, J. Mater. Eng. Perform., 2014, 23, p 527–537

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, M., Dai, C., Yang, B. et al. New and Green Multi-component Scaling and Corrosion Inhibitor for the Cooling Water of Central Air Conditioners. J. of Materi Eng and Perform 26, 764–772 (2017). https://doi.org/10.1007/s11665-016-2474-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2474-9