Abstract

TiB2 among other borides like ZrB2 and HfB2 represents a unique class of ceramics, which displays good wetting by liquid metals, such as Cu and Au, without chemical interaction that may be detected by conventional characterization techniques. The nature of the wetting in these systems is commonly attributed to the “metallic-like” character of borides. In this study, improved wetting of TiB2 by Cu and Au (50° and 15°, respectively) was confirmed and evidence of a limited chemical interface interaction was observed using TEM analysis. Moreover, it was shown that the addition of B to Au and Cu improves wetting. It was suggested that not only “metallic-like” character of TiB2 but also the chemical interaction stands behind good wetting in these systems.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

TiB2-based ceramics are used as structural materials for high temperature applications due to their high melting temperature, corrosion and thermal shock resistance. Like most ceramics, its brittleness is a major drawback, therefore TiB2-metal ceramic composites (MCCs) have significant technological benefits. Compatibility of metals and TiB2 is also very important for ceramics brazing and soldering. The ability to fabricate MCCs and successfully join metals to ceramics strongly depends on the wetting properties of the system. Due to the high thermodynamic stability of ceramics, they are usually not wetted well by liquid metals. The lack of wetting is typical for the systems, in which metals are considered as “non-reactive” (like Au, Sn, Ag, or Cu). In these cases, an active element (like Ti, Zr, Hf, or in some cases Si, Fe or Ni) is usually added to improve wetting.

Although good wetting is essential for successful metal infiltration and joining this property does not always provide desired mechanical properties, which depend on the structure and composition of the metal/ceramic. In some cases, a brittle phase is formed at the interface and leads to its cracking due significant coefficient of thermal expansion (CTE) differences between the ceramic and the newly formed product (Ref 1, 2).

TiB2 among other borides like ZrB2, HfB2, etc., displays a “metallic-like” character and good wetting by liquid metals with limited chemical interaction, which may not always be detected by conventional characterization techniques (Ref 3, 4). At the same time, in our previous works (Ref 5, 6) and in the studies of Passerone and Muolo et al. (Ref 7, 8) some evidence of a limited dissolution of the boride substrate in the melts was detected. Furthermore, the spreading timescale in these studies were in the range of tens of minutes. It was established that for chemically reactive wetting, the time needed for liquid spreading to reach equilibrium contact angles is in 1 to 20 min range (Ref 9, 10), while if only the metallic character of the borides determines the wetting behavior this time has to be in the range of tens of microseconds (Ref 11). The strong temperature dependence of the contact angle in these systems also suggests that chemical interaction is involved in the spreading mechanism. Alternatively, it is possible that spreading kinetics observed for the (Au,Cu)/ZrB2 (Ref 7, 8) and, probably, for the (Au,Cu)/TiB2 systems (Ref 5, 6) is attributed to the reduction of a native oxide layer on the substrate.

In this study, previous wetting results (Ref 5, 6) for the TiB2-Cu, Au and TiB2/Cu-B systems and new results of TiB2/Au of MCC characterization by high-resolution TEM (HRTEM) are presented and discussed.

The effect of a thin oxide layer on the TiB2 substrate and its possible reduction by boron dissolved in the liquid Cu and Au on the spreading kinetics is also discussed.

Experimental

Sessile drop wetting experiments were performed in high vacuum (~10−3 Pa) at 1423 K. Hot pressed TiB2 substrates (98.7% of the theoretical density, SINTEC Keramik USA®) were used for the experiments as described in Ref 5, 6.

In order to study the TiB2/Au interface, a porous TiB2 preforms (~30% porosity) were prepared using FAST apparatus (type HP D5/1, FCT System, Rauenstein, Germany) equipped with a 50 kN uniaxial press. TiB2 powder (F grade, Fe <0.1 wt.%, N, C, and O <3.4 wt.%) manufactured by H.C.Starck® (Goslar, Germany) was inserted into a graphite die (inner diameter 20 mm, outer diameter 40 mm) and sintered at 2273 K under vacuum of 1 Pa with applied pressure of 32 MPa. The heating rate and holding time were 150 K/min and 10 min, respectively. Infiltration of porous preforms by liquid Au was conducted at 1423 K under 10−2 Pa vacuum for 30 min. The infiltrated composite was sectioned and polished using conventional metallographic procedure. The TiB2/Au interface was studied by HRTEM (Tecnai F20-G2) equipped with HR STEM, EELS (resolution <0.8 eV), and EDS (spectral resolution of 133 eV). TEM samples were prepared by two methods.

-

(1)

Using FEI Strata 400S Dual Beam FIB (Focus Ion Beam); the investigated area was chosen directly from the polished sample.

-

(2)

The samples were cross sectioned, mechanically thinned, and finally polished using a Precision Ion Polishing System (PIPS, Gatan® model 691) apparatus at various grazing angles.

Results

Wetting Results

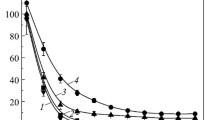

The wetting angles measured after 30 min of contact are presented in Fig. 1. The contact angle for pure Cu is about 50°, while for pure Au its value is about 15°. Addition of 2 at.% B to liquid Au provides the wetting angle close to 10°, while the same contact angle value was achieved if more than 8 at.% B was added to Cu.

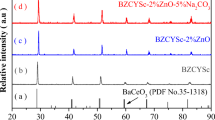

Infiltrated TiB2-Au Composite. Interface Characterization

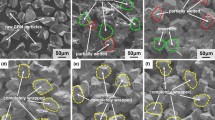

The polished surface of the composite is shown in Fig. 2. The Au metal (bright area) filled completely the porous TiB2 preform (dark gray continuous matrix, Fig. 2). The TEM sample produced by the FIB apparatus was taken from the area marked by the rectangle in the middle of the micrograph. The samples, which were prepared by conventional polishing including ion beam polishing (PIPS), show that Au was almost totally eroded (Fig. 3). Nevertheless, a sharp TiB2/Au interface is observed without evidence of new phases. At the left bottom side of the figure (marked with an arrow) a narrow capillary filled with Au indicates that liquid Au fills even extremely thin capillaries. In the case new phases were formed at the interface, such narrow capillaries would be blocked by these interaction products and could not be fully filled by the melt.

HRTEM images of the TiB2/Au interface are shown in Fig. 4(a) to (c). New phases were not detected but ~10 nm facets were formed at the interface, while TiB2/TiB2 interfaces were always flat (Fig. 4d). Furthermore, no B or Ti enrichment at the TiB2/Au interface was detected by EELS analysis.

Discussion

The interface characterization of the Au infiltrated TiB2 demonstrates that no new phases are formed at the TiB2/Au interface and it may be concluded that a “metallic-like” character of the substrate stand behind the wetting. On the other hand, the presence of facets at the TiB2/Au interface indicates that limited interaction does take place in this system. Similar interfacial features were found by Knechtel et al. (Ref 12) in the Al2O3/Al composites and were attributed to a “dissolution-precipitation” mechanism, which probably operates also in the TiB2/Au system. Furthermore, the effect of B addition cannot be explained by the metallic character of the boride. In order to evaluate the possibility of chemical interaction at the interface a thermodynamic analysis of the TiB2/Me systems was performed.

Wetting Mechanism

In our previous communication (Ref 13), we have estimated Ti concentrations in the melts in equilibrium with TiB2 at 1423 K. The calculations were based on the values of free standard Gibbs energy formation of TiB2 and thermodynamic properties of the dilute Me-Ti (Me = Au, Ag, Cu, and Sn) solutions. Due to high thermodynamic stability of TiB2 (ΔG 0 (1423 K) ≅ −254 kJ/mol, Ref 14) the equilibrium Ti content in liquid Cu and Au are extremely low (~10−9 and 10−6 atomic fraction, respectively). This difference reflects the thermodynamic properties of the binary Cu-Ti and Au-Ti solutions. The Cu-Ti liquid solution exhibits only small negative departure from ideality, while the Au affinity to Ti is much stronger (the activity coefficients for the dilute solutions are \( \upgamma_{\text{Ti}}^{0} ({\text{Cu}}) = 0.36 \; \text{and} \; \upgamma_{\text{Ti}}^{0} ({\text{Au}}) = 1.86 \times 10^{ - 4} \)). Although, the equilibrium Ti concentration is very limited for both systems, the tendency of TiB2 dissolution in liquid Au is significantly higher than in liquid Cu and may be the reason for the different contact angles (15° and 50°, respectively).

It is well known that titanium diboride has a narrow stoichiometric domain (between TiB1.9 and TiB2) and it may be suggested that the effect of boron additions to the melts on the wetting improving, is attributed to altering of a near substrate surface layer composition. According to Misra et al. (Ref 15) for the B-rich composition the Ti activity value at 1273 K (a Ti) is equal to 5.22 × 10−13. For this composition, which corresponds to the equilibrium with pure boron, the activity of B (a B) is equal to 1. At the Ti-rich composition (TiB1.9), the activity of Ti is much higher (1.74 × 10−4) and the activity of B is equal to 5.48 × 10−5. Using an approach suggested in Ref 6 the boron concentration in the melt as a function of the boride composition was calculated (Fig. 5). If TiB1.9 coexists with pure Cu at 1423 K it may dissolve only 0.0013 at.% B. This value for the stoichiometric composition (TiB2) is about 8.6 at.%. Thus, if the initial composition of the substrate has even a small departure from stoichiometry and liquid metal contains dissolved boron, the titanium boride composition changes within its stoichiometric domain.

It is very difficult to determine the composition of the titanium diboride phase, especially; its altering during metal-ceramic interaction and to confirm unambiguously the suggested mechanism of the interface interaction. Therefore, other reasons for the effect of boron on the wetting improvement have to be considered. For a non-reactive system and flat metal-substrate interface, the Young equation is used to determine the equilibrium wetting angle, which depends on the liquid-gas, solid-gas, and liquid-solid interfacial energies. It may be assumed that for the non-reactive system the solid-gas interfacial energy does not change. Moreover, boron is not surface-active element and only slightly affects the liquid/gas surface energy. According to Passerone et al. (Ref 16) addition of 10 at.% of B to Cu leads to decreasing surface energy by about 50 mJ/m2 at 1423 K. This change has a negligible effect on the contact angle (should decrease from 50° to 48°). Thus, altering of the liquid-solid interfacial energy due to boron adsorption at the TiB2 surface may provide improved wetting. A simple estimation shows that if the contact angle decreases from 50° to 20° the liquid/solid interfacial energy has to decrease by ~400 mJ/m2. This value seems to be too large for this system, although for the CaF2/In-Ti with strong Ti affinity to F, this value is estimated as 700 mJ/m2 (Ref 17, 18). The ab-initio calculations based on density function theory have to be performed to estimate this value and clarify the effect of boron adsorption on the liquid/solid interfacial energy.

The effect of boron on the wetting angle may be also attributed to the reduction of a native titanium oxide layer, which always covers the substrate. If this “cleansing” mechanism operates, slow spreading kinetics reflects the rate of the native oxide reduction according to the reaction:

where s, l, and g denote the solid, liquid, and gaseous phases, respectively. The brackets indicate that boron and titanium are in a liquid solution. At 1423 K the standard Gibbs energy (ΔG 0) for the reaction (1) is ~285 kJ/mol (Ref 19) and equilibrium constant \( K(1) = \frac{{a_{\text{Ti}}^{1.5} P_{{{\text{B}}_{ 2} {\text{O}}_{ 3} }} }}{{a_{\text{B}}^{2} }} \) is equal to 3.42 × 10-11. Titanium activity in liquid Cu in equilibrium with TiB2 is equal to 3.6 × 10−10 (Ref 5, 6). The calculated (B2O3) partial pressure changes from 500 MPa for boron concentration of about 8 at.% B (boron activity is equal to 1) to 5 MPa for boron content of about 1 at.%. These two values are significantly higher than the total pressure in the experimental chamber (10−3 Pa), and the “cleansing” mechanism should operate for the all investigated Cu-B alloys. Actually, the significant improved wetting was observed only for relatively high boron contents. Nevertheless, this “cleansing” effect together with the effect of boron adsorption at the interface and altering of the substrate surface composition towards a higher B content have to be further investigated to clarify the wetting mechanism of boron containing melts in contact with TiB2 substrate.

Summary

TiB2 is a unique material, which is wetted well by non-reactive metals like Au and Cu. Since TiB2 possesses “metallic-like” characteristics, the wetting could be attributed to metal-metal bonding across the interface. At the same time, at elevated temperature chemical interactions (for instance, limited substrate dissolution) could not be avoided since the initial state of the system is far from its equilibrium state. The difference between the wetting behavior of pure Cu and Au is explained by the thermodynamic properties of the liquid Cu-Ti and Au-Ti solutions. The reasons of the boron effect on the improved wetting of the TiB2 substrate by Cu-B and Au-B melts were considered. This effect may be attributed to the changes of the liquid-solid interfacial energies, to the altering of the substrate surface composition towards a higher B content as well as to the reduction of the native oxide layer on the substrate. Further investigations are needed to clarify the wetting mechanism of boron containing melts in contact with TiB2 substrate.

References

C. Wan, P. Kritsalis, B. Drevet, and N. Eustathopoulos, Optimization of Wettability and Adhesion in Reactive Nickel-Based Alloys/Alumina Systems by a Thermodynamic Approach, Mater. Sci. Eng. A, 1996, 207(2), p 181–187

C. Valette, M.F. Devismes, R. Voytovych, and N. Eustathopoulos, Interfacial Reactions in Alumina/CuAgTi braze/CuNi System, Scripta Mater., 2005, 52(1), p 1–6

N. Eustathopoulos, M.G. Nicholas, B. Devet, Wettability at High Temperatures, Pergamon Materials Series, Pergamon, New York, 1999, p 300–312

R. Voytovych, A. Koltsov, F. Hodaj, and N. Eustathopoulos, Reactive vs Non-Reactive Wetting of ZrB2 by Azeotropic Au-Ni, Acta Mater., 2007, 55(18), p 6316–6321

M. Aizenshtein, N. Frage, N. Froumin, E. Shapiro-Tsoref, and M.P. Dariel, Interface Interaction in the (B4C + TiB2)/Cu System, J. Mater. Sci., 2006, 41(16), p 5185–5189

M. Aizenshtein, N. Froumin, P. Barth, E. Shapiro-Tsoref, M.P. Dariel, and N. Frage, How Does the Composition of Quasi-Stoichiometric Titanium Diboride Affect its Wetting by Molten Cu and Au?, J. Alloys Compd., 2007, 442(1–2), p 375–378

A. Passerone, M.L. Muolo, R. Novakovic, and D. Passerone, Liquid Metal/Ceramic Interactions in the (Cu, Ag, Au)/ZrB2 Systems, J Eur. Ceram. Soc., 2007, 27(10), p 3277–3285

M.L. Muolo, E. Ferrera, R. Novakovic, and A. Passerone, Wettability of Zirconium Diboride Ceramics by Ag, Cu and Their Alloys with Zr, Scripta Mater., 2003, 48(2), p 191–196

J.A. Warren, W.J. Boettinger, and A.R. Roosen, Modeling Reactive Wetting, Acta Mater., 1998, 46(9), p 3247–3264

C. Rado, S. Kalogeropoulou, and N. Eustathopoulos, Wetting and Bonding of Ni-Si Alloys on Silicon Carbide, Acta Mater., 1999, 47(2), p 461–473

E. Saiz and A.P. Tomsia, Atomic Dynamics and Marangoni Films During Liquid-Metal Spreading, Nat. Mater., 2004, 3(12), p 903–909

M. Knechtel, H. Prielipp, H. Miillejans, N. Claussen, and J. Rodel, Mechanical Properties of Al/Al2O3 and Cu/Al2O3 Composites with Interpenetrating Networks, Scripta Metall. Mater., 1994, 31(8), p 1085–1090

M. Aizenshtein, N. Froumin, N. Frage, and M.P. Dariel, Interface Interaction and Wetting Behaviour in B4C/(Me-Ti) Systems (Me = Cu, Ag, Sn and Au), Mater. Sci. Eng. A, 2005, 395(1–2), p 180–185

Thermodynamic Data-Base SSUB3, version 3.1 (2001). Produced by Scientific Group Thermo-data Europe

K. Misra, Interfaces in Metal-Ceramics Composites, R.Y. Lin, R.J. Arsenault, G.P. Martins, and S.G. Fishman, Ed., The Minerals, Metals & Materials Society, Warrendale, 1989

M. Passerone, M.L. Muolo, F. Valenza, and R. Novakovic, Thermodynamics and Surface Properties of Liquid Cu-B Alloys, Surf. Sci., 2009, 603(17), p 2725–2733

E. Glickman, D. Fuks, N. Frage, S. Barzilai, and N. Froumin, Adsorption Effect in Non-Reaction Wetting: In-Ti on CaF2, Appl. Phys. A. doi:10.1007/s00339-011-6546-2

S. Barzilai, M. Lomberg, M. Aizenshtein, N. Froumin, and N. Frage, The Effect of Thermodynamic Properties of Me-Ti (Me = In, Sn, Ga, Au, and Ge) Melts on the Wetting of the CaF2 Substrate, J. Mater. Sci., 2010, 45(8), p 2085–2089

M.W. Chase, J.L. Curnutt, A.T. Hu, H. Prophet, A.N. Syverud, and L.C. Walker, JANAF Thermochemical Tables, 1974 Supplement, J. Phys. Chem. Ref. Data, 1974, 3(2), p 311–480

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aizenshtein, M., Froumin, N. & Frage, N. The Nature of TiB2 Wetting by Cu and Au. J. of Materi Eng and Perform 21, 655–659 (2012). https://doi.org/10.1007/s11665-012-0171-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-012-0171-x