Abstract

In this communication, the cerium (Ce) modified (Bi0.4Fe0.4)(Pb0.6Ti0.3Ce0.3)O3 (BF-PT) ceramics is prepared by conventional solid-state reaction technique. The compound is found to crystallize in the rhombohedral crystal system with space group R-3c (#167). The refined lattice parameters are a = b = 4.989 Å, c = 17.062 Å, \(\alpha = \beta = 90^{^\circ } , \gamma = 120^{^\circ }\), V = 367.78 Å3 and \( \rho = 2.71\) g/cm3 (JCPDS No.-00-005-0586). The average crystallite size and lattice micro-strain in the ceramics are estimated at 47.6 nm and 0.117% respectively. Scanning electron microscopy analysis indicates low porosity and well-defined grain boundaries, with an average grain size of 13.7 μm. Raman spectroscopy confirms the presence of all constituent elements and ferroelectric character. Ultraviolet–visible (UV–Vis) spectroscopy analysis suggests a bandgap of 1.72 eV for the modified BF-BT ceramics, which is suitable for photovoltaic applications. The study of complex impedance suggests a Cole–Cole-type relaxation with a decrease in bulk resistance from 6.283 × 1013 Ω cm2 at 25°C to 1.783 × 104 Ω cm2 at 500°C, confirming the negative temperature coefficient of resistance. The calculated activation energies are 849.8 meV, 706.5 meV, 575.1 meV, and 499.4 meV at 1 kHz, 10 kHz, 100 kHz, and 1000 kHz, indicating ionization of oxygen vacancy and the involvement of the released electrons in the hopping conduction process, and support a thermally activated conduction mechanism. The increase in the peak frequency difference between the \( Z^{{{\prime \prime }}}\) and \(M^{{{\prime \prime }}}\) spectrum with temperature suggesting a non-Debye-type relaxation in the material. The material is characterized to a high dielectric constant and low tangent loss suitable for optoelectronic devices.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Multiferroics, where ferroelectricity, ferroelasticity, and ferromagnetism coexist in a single phase, constitute an important branch in materials science. The magnetoelectric coupling in multiferroic material yields an additional advantage in device design applications.1,2,3 Recent material research interests are getting pivoted towards the new materials known as ferroelectromagnetic owing to their potential applications in memory devices, sensors, and spintronics.4 BiFeO3 is a special multiferroic material showing both ferroelectric and ferromagnetic properties.5 With an aim to achieve improved multiferroic properties in the materials, it is prudent to combine different perovskite materials possesses with different ferroic properties. The multiferroic properties on combined perovskite systems such as BiFeO3 (BF)-PrFeO3 (PF)-PbTiO3 (PT) and BiFeO3 (BF)-PbTiO3 (PT) have been studied.6,7,7 BiFeO3 is a well-studied material having ferroelectric properties with a Curie temperature of Tc = 1103 K and antiferromagnetic (TN = 643 K), because of which it has a wide range of applications. The detailed study on BiFeO3 suggests that while the 6s lone pair electrons in Bi promotes ferroelectricity in the material, the partially filled d orbital in Fe accounts for the existence of magnetic ordering. Despite many advantages of the BiFeO3 compound, the study on this material is limited because of weak polarization and ferromagnetic order parameters. The highly volatile nature of bismuth and also the existence of multiple oxidation states of Fe (Fe+2/Fe+3) promote a large number of oxygen vacancies resulting in a high leakage current and a reduction in the ferroelectric properties.8,9,10 Therefore, to enhance the multiferroic properties of BiFeO3 ceramics, many attempts have been made to replace the A and B sites by proper dopants including Ba2+, Sr2+, Ca2+, La3+, Gd3+, Ti4+, Mn4+, and Nb5+.11 The preparation of BiFeO3 traces of impurities is very difficult. To overcome this problem and to achieve enhanced physical properties, one has to consider the synthesis of its mixed compound with compounds like BaTiO3, PbTiO3, and SrTiO3. Further, dopants like gallium, tantalum, neodymium, cerium, or other rare-earth materials can be added to improve the magnetic properties.12,13,14,15,16 Therefore, BiFeO3-ABO3 solid solution systems have attracted much attention as a means to increase the structural, electrical, and magnetic properties. Lead-based perovskite materials have been widely studied for applications particularly in high-performance optoelectronic and efficient photovoltaics due to their ability to tune optical bandgaps from the ultraviolet to near-infrared and the high absorption coefficient.17,18,19

Keeping the above-mentioned points in mind and considering the potentiality of the BF compounds, we were motivated to study the properties of rare-earth Ce-doped BF-PT ceramics. To the best of our knowledge, the effects of Ce (x = 0.3) doping on the optoelectronic applications of BF-PT ceramics have not been reported. Therefore, the present work investigates the optical and electrical properties of the rare-earth (RE) ion-doped BF-PT. We have synthesized rare-earth substituted BF-PT with chemical formula Bi0.4Fe0.4Pb0.6Ti0.3Ce0.3O3 in the ceramics form via solid-state reaction method and reported the consistency of evolution of the crystal structural, dielectric, and optical properties.

Experimental Detail

PbO (99.9%), TiO2 (99.0%), BiO2 (99.0%), Fe2O3 (99.9%), and CeO2 (99.9%) are the metal oxides taken as starting materials for high-temperature solid-state reaction technique for the powder sample of Bi0.4Fe0.4Pb0.6Ti0.3Ce0.3O3 ceramics. In the first step, all the oxides are taken in the stoichiometric ratio as per relation 1.\(2\)\({\text{PbO}} + 0.6{\text{TiO}}_{2} + 0.6{\text{CeO}}_{2} + 0.4{\text{Bi}}_{2} {\text{O}}_{3} + 0.4{\text{Fe}}_{2} {\text{O}}_{3} \to 2{\text{Bi}}_{0.4} {\text{Fe}}_{0.4} {\text{Pb}}_{0.6} {\text{Ti}}_{0.3} {\text{Ce}}_{0.3} {\text{O}}_{3}\)\({\text{PbO}} + 0.6{\text{TiO}}_{2} + 0.6{\text{CeO}}_{2} + 0.4{\text{Bi}}_{2} {\text{O}}_{3} + 0.4{\text{Fe}}_{2} {\text{O}}_{3} \to 2{\text{Bi}}_{0.4} {\text{Fe}}_{0.4} {\text{Pb}}_{0.6} {\text{Ti}}_{0.3} {\text{Ce}}_{0.3} {\text{O}}_{3}\) were mixed in an agate pestle. The powder mixture was calcinated at 1100°C (10 h). After pelletization under a uniaxial pressure of 3–4 MPa, the pellets were sintered at 1200°C (6 h). The x-ray diffraction technique was carried out with a CuKα radiation source (λ = 1.5406 Å) to evaluate unit cell, crystal structure, and phase identification of the material. X'Pert HighScore Plus software analysis was employed for x-ray diffraction (XRD) analysis. SEM micrograph was used to identify the distribution of grains and the effect of the grain boundaries. For electrical measurement, the prepared pellet was silver painted and then cured. Different electrical properties including dielectric, impedance, ac conductivity, and modulus were recorded by using an LCR meter (N4L PSM, 1735) with varying temperature and frequency. In our case, the temperature was varied from 25°C to 500°C, and the frequency range from 1 kHz to 1 MHz.

Results and Discussion

Sample Preparation

As is well known, for the stability of perovskite compounds, the tolerance factor of the structure is calculated using the relation \( t = \frac{{r_{A} + r_{o} }}{{\sqrt 2 \left( {r_{B} + r_{0} } \right)}}\), where \(r_{A} , r_{B}\) and \(r_{0} \) are the ionic radii of A-, B- and oxygen atom respectively lie within the range from 0.75 to 1.0 with additional conditions: \(r_{A} > 0.9\) Å and \(r_{B} > 0.51\) Å nm.20 Hines suggested possible values of t for different crystal structures: hexagonal crystal structure, 1.00 < t < 1.13; cubic structure, 0.9 < t < 1.0; orthorhombic structure, 0.75 < t < 0.9; and for t < 0.75, the structure favours the hexagonal ilmenite structure (FeTiO3).21 The ionic radii of the relevant atoms in their respective valence state are taken as Bi3+ = 0.103 nm, Fe+3 = 0.0645 nm, Pb+2 =0.119 nm, Ti+3 = 0.069 nm, and Ce+4 = 0.097 nm respectively.22 For calculation, \(r_{A} = {\text{Bi}}_{0.4} {\text{Pb}}_{0.6} =\) 0.4(0.103) + 0.6(0.119) = 0.1126 nm. Similarly, for calculation \(r_{B} =\) \({\text{Fe}}_{0.4} {\text{Ti}}_{0.3} {\text{Ce}}_{0.3} =\) 0.4(0.0645) + 0.3(0.069) + 0.3(0.097) = 0.0756 nm and \(r_{0} =\) 0.14 nm. The tolerance factor can be calculated; \(t = \frac{{r_{A} + r_{o} }}{{\sqrt 2 \left( {r_{B} + r_{0} } \right)}} = \frac{0.067 + 0.14}{{1.414\left( {0.1212 + 0.14} \right)}} = 0.84 \).Therefore, tolerance factor of Ce-doped BF-PT perovskite is 0.84, which confirm that prepared sample has rhombohedral crystal.

XRD Analysis

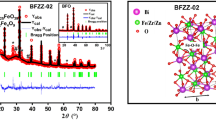

XRD is an important tool to determine the structure, space group, unit cell volume, and density. Figure 1a shows the XRD pattern of the Bi0.4Fe0.4Pb0.6Ti0.3Ce0.3O3 ceramics

X'Pert High-Score Plus software was used to analyse the structure of the prepared material.23 The XRD results confirm that the sample has a rhombohedral structure with space group R-3c (#167) matched with JCPDS file No. 00-005-0586. The calculated cell parameters are as follows: a = b = 4.989 Å, c = 17.062 Å, \( \alpha = \beta = 90^{^\circ } \;{\text{ and}}\; \gamma = 120^{^\circ }\). The volume and density of the unit cell of the sample are 367.78 Å3 and 2.71 g/cm3 respectively. Small impurity phases were observed in the XRD pattern as matched with JCPDS file No. 01-075-0134. For estimation of the average crystallite size, Scherrer’s equation \(D_{hkl} = \frac{k\lambda }{{\beta_{1/2 } \cos \theta }}, \) \(D_{hkl} = {\text{average}}\;{\text{crystalline}}\;{\text{size}}, k\sim0.89, \lambda = 0.154 \;{\text{nm}}, \beta_{1/2 } = \) full-width at half maximum (FWHM), and θ = peak position are employed.24

Figure 1b presents the SEM micrograph of the Bi0.4Fe0.4Pb0.6Ti0.3Ce0.3O3 ceramics. SEM analysis confirms that the sintered sample has high density with closely packed grains and quite low porosity. It is also observed that the grains are uniformly distributed through well-defined grain boundaries. The average grain size of the sample calculated by the intercept method is 13.7 μm. The small grains in the sample shield the dopant growth and lead to larger surface area, which is necessary to upgrade the efficiency of the sample. From the SEM micrograph, it is observed that each grain contains several crystallites, for which the grain size becomes larger than the average crystallite size. The observed agglomeration rate (DSEM/DSC = 288) suggests good compatibility of grains, which may be an important reason for the enhanced ferroelectric properties of the material under study.25 Figure 1c is plotted by taking 1/β along the x-axis and cosθ along the y-axis. A slope to the linear fit of the experimental data gives the average crystalline size, which is about 47.6 nm. The strong interaction and mechanical bond stretching among different atoms in the sample produces the lattice strain after doping the Ce in the host matrix. The micro lattice strain produced in the Bi0.4Fe0.4Pb0.6Ti0.3Ce0.3O3 ceramics can be evaluated by the Williamson–Hall (W-H) method. The relation between micro lattice strain (\(\varepsilon\)) and FWHM (\(\beta\)) was derived by the W-H method, which can be written as; \(\beta \cos \theta = 4\varepsilon \sin \theta + \frac{k\lambda }{D}\) , all the symbols have their usual meaning. Figure 1d is plotted by taking \(4\sin \theta\) along the x-axis and \(\beta \cos \theta\) along the y-axis, respectively. The value of the lattice strain can be calculated from the slope of the linear fit for Bi0.4Fe0.4Pb0.6Ti0.3Ce0.3O3 ceramics is about 0.117%.

Raman Spectroscopy

Raman spectroscopy is a powerful and highly sensitive technique for providing the complete information of the dopant incorporation. Raman characterization is used to identify the signature of vibrational frequency in cerium-doped BF-PT ceramics. In the Raman technique, a laser source was pointed onto the material of diameter 1–2 μm by using a 10 mW power supply, and the scattered signal was received using a thermoelectrically cooled CCD camera as the detector.

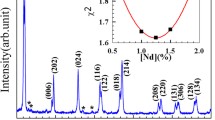

Different modes of vibrations observed at 260 cm−1, 468 cm−1, 739 cm−1, 869 cm−1, 1396 cm−1, 1686 cm−1, 1762 cm−1, 2423 cm−1, 2458 cm−1, and 2646 cm−1 as shown in Fig. 2. The rhombohedral crystal structure, space group R3c, and ten atoms in a unit cell is expected to provide 18 optical phonon modes that can be calculated using a relation: Γopt = 4A1+ 5A2 + 9E; according to group theory, 13 observed modes (ΓRaman,3c = 4A1 +9E) are Raman active, whereas 5A2 are Raman inactive modes.26,27,27 In the present study, for Ce-doped BF-PT ceramic; A1 and E-symmetry normal modes for R3c symmetry including A1-1, A1-2, A1-3, A1-4, E-1, E-4, E-6, E-7, E-8, and E-9 at around 260 cm−1, 468 cm−1, 739 cm−1, 869 cm−1, 1396 cm−1, 1686 cm−1, 1762 cm−1, 2423 cm−1, 2458 cm−1, and 2646 cm−1 are observed. These results match well with the Raman active vibration modes identified for BFO (R3c).28,29,29 The ferroelectricity of BFO generally originates from the stereochemical activity of the Bi3+-6s2 lone pair electron that is mainly responsible for the change in both Bi-O covalent bonds. The low-frequency characteristic modes below 300 cm−1 may be responsible for the ferroelectric nature of the modified BF-PT ceramics.

UV-Visible Investigation

UV technique is generally used to determine the band structure of the semiconductor. It counts the response of UV and visible range of incident electromagnetic radiation. The diffuse transmittance of the material can be calculated by taking the ratio of the number of photons transmitted to the number of photons incident. A relation between absorbance (A) and transmittance (T) can be written as; \(A = - \log_{10} \left( T \right)\).

Figure 3a represents the absorbance as the function of wavelength from 200 nm to 800 nm. The absorbance power of the cerium is decided by the size of the anions in its neighbour.30 The energy band gap is calculated by measuring the absorbance coefficients of the molecules. The bandgap of the prepared material can be calculated using the relation given by Mott and Davis: \(\alpha h\nu = A \left( {h\nu - E_{g} } \right) ^{n}\), where α is the absorbance coefficient, hν is incident photon energy, A is a constant, Eg is the optical energy and n is a different electronic transitions index.31,32,33 For electronic transition, index n takes values of 1/2, 3/2, 2 and 3 for direct allowed transition, direct forbidden transition, indirect allowed transition, and indirect forbidden transition, respectively.34 The linear fitting to the graph between (αhν)2 versus hν gives the bandgap energy of the prepared material, which is equal to 3.32 eV represented in Fig. 3b.35,36,37 According to Sallis et al.,38 6s orbitals of Bi+3 ion which create bonding and anti-bonding states with 2p orbital of O-2 ion are chemically active. The anti-bonding states causes an interaction between 6s and 2p orbital through structural distortion, which is responsible for a decrease in the energy bandgap of the studied compound to previously reported compounds of similar type.39,40,40 The observed bandgap energy for the compound is suitable for photovoltaic applications.

Modulus Study

The study of electric modulus is an important technique to understand electrode polarization, grain and grain boundaries effect, bulk properties of the material, electrical conductivity mechanism, and electric relaxation processes in the compound. Figure 4a represents the frequency dependence of the real part of impendence from 25°C to 500°C. Here, the value of Mʹ approaches zero at low frequencies, indicating either absence or small effect of electrode polarization. The monotonic dispersion of curves with the rise of frequency may be related to the conduction mechanism and also confirms the presence of short-range mobility of charge carriers. This is because restoring force that requires to flow the charges under the action of external electric field becomes insufficient. But, at a higher frequency, the value of Mʹ approaching to same for all temperatures may be related to the space charge polarization.41 Figure 4b shows the frequency dependence of the imaginary part of modulus from 25°C to 500°C. It is observed that M″ increases with the rise of frequency and then reaches its maximum (M″ʹmax) which indicates the presence of an electrical relaxation process in the material. The value of M″ʹmax peak shifts to higher frequency side with increasing temperature indicating the presence of temperature-dependent relaxation mechanism. The presence of asymmetric broadening of the M″ʹ peaks confirms a non-Debye-type of conduction process.42

Impedance Study

To understand basic electrical parameters like charge carriers, bulk and grain boundary effects, relaxation process, and polarization, impedance spectroscopy is most suitable. Figure 5a represents the frequency dependence of Z′ from 25°C to 500°C. The observed pattern represents a sigmoid variation in the low frequency and becomes saturated in the high-frequency region, which confirms the presence of electronic, dipolar, and orientation polarization. Therefore, the prepared material is ferroelectric. The decreasing value of Z′ with the increase of temperature confirms the negative temperature coefficient of resistance (NTCR) character.43 However, at high frequency, the entire curve tends to merge into one for all temperatures, suggesting the possibility of an increase in ac conductivity with the rise in temperature due to the release of space charge and also barrier lowering. Figure 5b shows the frequency dependence of the Z″ from 25°C to 500°C. The value of Z″ decreases with the increase of frequency and is related to electric polarization.44

To calculate Rb and Rgb we have adopted commercially available software ZSimpWin version 2.0 to fit the experimental data. The curves were well fitted when the circuit model was selected by the parallel combination of (CQR) and (CR). Here, Q is known as the constant phase element whose dimension is the same as capacitance. Figure 6 represents the (CQR) (CR) model fitted Z′ versus Z″ graph at 25°C, 50°C, 100°C, 150°C, 200°C, and 250°C while inset figure represents fitted Nyquist plots at 350°C, 400°C, 450°C, and 500°C, respectively. Here, evaluated parameters like the bulk capacitance (Cb), constant phase factor (Q), bulk resistance (Rb), boundary resistance-capacitance (Cgb), grain boundary resistance (Rgb), and frequency power (n) are enlisted in Table I. It is observed that bulk resistance decreases from 6.283 × 1013 Ω cm2 at 25°C to 1.783 × 104 Ω cm2 at 500°C as given in Table I confirming the NTCR character. With the rise of temperature, the diameter of the semi-circular arcs decreases supporting the thermally activated conduction process.45

Figure 7a represents the variation of \( Z^{{{\prime \prime }}}\) versus \(M^{{{\prime \prime }}}\) at 100 °C and Fig. 7b represents the variation of \( Z^{{{\prime \prime }}}\) versus \(M^{{{\prime \prime }}}\) at 350 °C of the Bi0.4Fe0.4Pb0.6Ti0.3Ce0.3O3 ceramics. At fixed T = 100°C, it is observed that two curves show a single peak at the same frequency, suggesting the dominant role of long-range movement of charge carriers.46 At fixed T = 350°C, it is seen that the gap between the peak of \( Z^{{{\prime \prime }}}\) and \(M^{{{\prime \prime }}}\) is becoming wider with temperature suggesting a non-Debye-type relaxation in the material47,48,48

Figure 8 shows the Cole–Cole plots of Bi0.4Fe0.4Pb0.6Ti0.3Ce0.3O3 ceramics at temperature of 200°C, 250°C, 300°C, 350°C, 400°C, 450°C, and 500°C, while the inset figure shows Cole–Cole plots at 25°C, 50°C, 100°C, and 150°C, respectively. Normally, the Cole–Cole plot is simulated with an equilibrium circuit element containing resistance (R), capacitance (C), and sometimes inductance (L), in which the electrode interphase is inherently incorporated. Therefore, the real and imaginary parts of the impedance plot may provide the state of the electrode surface and also the kinetics of the metal electrode. The presence of perfect semicircular arcs of the Cole–Cole plot indicates the semiconductor nature of the sample.49 The above calculated electrical parameters are suitable for application in energy storage devices.

AC Conductivity

To understand the dopant incorporation effect, and type of charge carriers participating in the conduction process, the study of ac conductivity as a function of frequency and temperature is reported. The evaluation of the ac conductivity (σac) of the prepared material can be calculated using the relation σac = ε0εrωtanδ, where the symbols have their usual meaning. Figure 9 represents the variation of ac conductivity with frequency from 25°C to 500°C. It is observed from the given plots that in the higher frequency range, the ac conductivity curves approach closely to each other suggesting a low-frequency dispersion phenomena. The Jonscher’s power law can be used to analyze the dispersed ac conductivity curves as50 σac = σdc + Aωn, where A is temperature-dependent constant, and n is a temperature-dependent exponent in the range of 0 ≤ n ≤ 1. The electrode polarization effect and dielectric interface are two main reasons for the observation of ac conductivity at a lower frequency. The decrease in accumulation of charge carriers may lead to the increase of ac conductivity with the frequency. A translational motion of hopping of charge carriers is proposed for n < 1, whereas an action that involves localized hopping of charge carriers without leaving the species in the neighborhood is required for n > 1.51

Figure 9b represents temperature-dependent ac conductivity in the Bi0.4Fe0.4Pb0.6Ti0.3Ce0.3O3 ceramics. The ac conductivity increases with the rise in temperature, suggesting thermally assisted carrier activation with an activation energy (Ea) expressed through the relation \(\sigma_{ac} = \sigma_{0} e^{{\frac{{ - E_{a} }}{{K_{B} T}}}}\), where all terms have their usual meaning. The calculated activation energies are found to be 849.8 meV, 706.5 meV, 575.1 meV, and 499.4 meV at 1 kHz, 10 kHz, 100 kHz, and 1000 kHz, respectively. It is observed that the calculated activation energy decreases with the increase of the frequency. The calculated activation energy points to the activation of both singly and doubly charged oxygen vacancy in the sample and support a thermally activated conduction process.

Dielectric Study

Figure 10a shows the variation of dielectric constant with frequency from 25°C to 500°C and 10b shows the variation dielectric constant with temperature from 1 kHz to 1000 kHz in the studied material. The dispersed dielectric curves can be explained by Maxwell–Wagner and Koop’s model,52 according to which a dielectric medium comprises of highly conducting grains and poorly conducting grain boundaries. It is observed that grains are becoming more active at higher frequencies whereas the grain boundaries are becoming more active at lower frequencies range. The decreasing trend of the dielectric constant value with frequency may be related to the electron hopping at octahedral sites that cannot match the alteration frequency of the applied ac electric field. The charge carriers generated through the oxygen vacancy now can hop easily through the comparatively well-defined conducting grains but gets piled up at the more resistive grain boundary forming a barrier capacitor. Therefore, the prepared material has a large dielectric constant in the low-frequency range. Due to inertial reluctance at higher frequency the accumulation of charges at the grain boundaries decreases and hence decreases the dielectric constant.53 Further, at higher frequencies beyond a few kilohertz, the effect of the space charge polarization decreases and the variation is due to orientational polarisation which has larger inertia and thus the polarisation decreases with the frequency. This describes the dielectric dispersion or dipolar relaxation behavior of the prepared material.54,55,55 The cations are responsible to respond to the high-frequency oscillating field, which results in decreased dipole relaxation time.56 Further, as temperature increases, the movement of the cations within the oxygen octahedra position is well expedited because of the decreased electrostatic interaction force between the cations and the anions.

Figure 11a and b show the variation of tangent loss with frequency and temperature in the Bi0.4Fe0.4Pb0.6Ti0.3Ce0.3O3 ceramics. In lower frequency, the natural increment of tangent loss with temperature corresponds to dominating character of DC conductivity which leads to the hopping electrons between Ce3+ and Ce4+. A high amount of energy loss at low-frequency occur for the passage of charges. This implies that a high resistance zone is set up at grain boundaries and requires more energy to transport the electric charges at a low-frequency range so that both dielectric constant (εr) and tangent loss (tanδ) attain higher value. But at a higher range of frequency, very small energy is required to electric charge carriers to overcome low resistance of the grain and thus resulting in a small dielectric loss in the sample.

Conclusion

The studied material was synthesized by the standard solid-state reaction technique. The structural analysis of the sample suggests a rhombohedral crystal with space group R-3c (#167). The average crystallite size and lattice micro-strain of the material are found to be 47.6 nm and 0.117%, respectively. Highly dense material with small porosity and well-defined grains surrounded by grain boundaries is observed in the SEM micrograph. Raman's study confirms the presence of all constituent elements and ferroelectric character. UV-Vis spectroscopy analysis suggests the bandgap of modified BF-BT ceramics is about 1.72 eV; suitable for photovoltaic applications. The dielectric study suggests that material has a high dielectric constant and low tangent loss. It is observed that bulk resistance decreases from 6.283 × 1013 Ω cm2 at 25°C to 1.783 × 104 Ω cm2 at 500°C, indicating the semiconductor nature of the material. The temperature dependence conductivity study gives an increasing tendency of activation energy with increase in frequency confirming thermally activated conduction process. The gap between the peak of \( Z^{{{\prime \prime }}}\) and \(M^{{{\prime \prime }}}\) is becoming wider with temperature, which confirms the non-Debye-type relaxation in the material.

Change history

28 January 2022

Editor’s Note: Readers are alerted that the reliability of data presented in this article is currently in question. Appropriate editorial action will be taken once all parties have had the opportunity to respond in full.

25 April 2022

This article has been retracted. Please see the Retraction Notice for more detail: https://doi.org/10.1007/s11664-022-09649-w

Reference

T. Kieliba, S. Bau, R. Schober, D. Oßwald, S. Reber, A. Eyerand, and G. Willeke, Sol. Energy Mater. Sol. Cells. 74, 261 (2002).

M. Fiebig, T. Lottermoser, D. Fröhlich, A.V. Goltsev, and R.V. Pisarev, Nature 419, 818 (2002).

D.V. Efremov, J. van den Brink, and D.I. Khomskii, Nat. Mater. 3, 853 (2004).

T.J. Park, G.C. Papaefthymiou, A.J. Viescas, A.R. Moodenbaugh, and S.S. Wong, Nano Lett. 7, 766 (2007).

B.H. Park, S.J. Hyun, S.D. Bu, T.W. Noh, J. Lee, H.D. Kim, T.H. Kim, and W. Jo, Appl. Phys. Lett. 74, 1907 (1999).

Y. Saito, H. Takao, T. Tani, T. Nonoyama, K. Takatori, T. Homma, T. Nagaya, and M. Nakamura, Nature 432, 84 (2004).

K. Mishra, A. Satya, A. Bharathi, V. Sivasubramanian, V. Murthy, and A. Arora, J. Appl. Phys. 110, 123529 (2011).

Z. Cheng, X. Wang, S. Dou, H. Kimura, and K. Ozawa, Phys. Rev. B 77, 092101 (2008).

A.R. Makhdoom, M.J. Akhtar, M.A. Rafiq, and M.M. Hassan, Ceram. Int. 38, 3829 (2012).

M. Shami, M. Awan, and M. Anis-ur-Rehman, Key Eng. Mater. 510, 348 (2012).

R. Rai, I. Bdikin, M.A. Valente, and A.L. Kholkin, Mater. Chem. Phys. 119, 539 (2010).

G.L. Yuan, S.W. Or, J.M. Liu, and Z.G. Liu, Appl. Phys. Lett. 89, 052905 (2006).

G.L. Yuan, and S.W. Or, Appl. Phys. Lett. 88, 062905 (2006).

V.A. Khomchenko, D.A. Kiselev, I.K. Bdikin, V.V. Shvartsman, P. Borisov, W. Kleemann, J.M. Vieira, and A.L. Kholkin, Appl. Phys. Lett. 93, 262905 (2008).

J.R. Cheng, and N. Li, CrossJ. Appl. Phys. 94, 5153 (2003).

V. Mathe, K. Patankar, R. Patil, and C. Lokhande, J. Magn. Magn. Mater. 270, 380 (2004).

J. Huang, Y. Shao, and Q. Dong, J. Phys. Chem. Lett. 6, 3218 (2015).

J.L. Knutson, J.D. Martin, and D.B. Mitzi, Inorg. Chem. 44, 4699 (2005).

J.M. Frost, K.T. Butler, F. Brivio, C.H. Hendon, M. van Schilfgaarde, and A. Walsh, Nano Lett. 14, 2584 (2014).

R.J.H. Voorhoeve, Advanced Materials in Catalysis. (Acad. Press, 199, 1977).

R.I. Hines, Atomistic Simulation and Ab-initio Studies of Polar Solids. (Ph.D., Bristol, 1997).

R.D. Shannon, Acta Crystallogr. A A32, 751 (1976).

S.K. Parida, J. Mohapatra, and D.K. Mishra, Mater. Lett. 181, 116 (2016).

B.D. Cullity, R.S. Stock, Elements of x-Ray Diffraction. (Prentice-Hall. New Jersey. 3rd edn, 2001)

A. Ben Jazia Kharrat, N. Moutiab, K. Khirouni, and W. Boujelben, Mater. Res. Bull. 105, 75 (2018).

M.K. Singh, H.M. Jang, S. Ryu, and M.H. Jo, Appl. Phys. Lett. 88, 42907 (2006).

R. Haumont, J. Kreisel, P. Bouvier, and F. Hippert, Phys. Rev. B 73, 132101 (2006).

J. Wu, and J. Wang, Acta Mater. 58, 1688 (2010).

D. Kothari, V.R. Reddy, V.G. Sathe, A. Gupta, A. Banerjee, and A.M. Awasthi, J. Magn. Magn. Mater. 320, 548 (2008).

G. Blasse, and A.F. Corsmit, J. Solid State Chem. 6, 513 (1973).

A. Kumar, R. Kumar, N. Verma, A.V. Anupama, H.K. Choudhary, R. Philip, and B. Sahoo, Opt. Mater. 108, 110163 (2020).

L.N. Mahour, H.K. Choudhary, R. Kumar, A.V. Anupama, and B. Sahoo, Ceram. Int. 45, 24625 (2019).

R. Kumar, A. Kumar, N. Verma, R. Philip, and B. Sahoo, Phys. Chem. Chem. Phys. 22, 27224 (2020).

P. Keburis, J. Banys, A. Brilingas, J. Prapuolenis, A. Kholkin, and M.E.V. Costa, Ferroelectrics 353, 149 (2007).

R. Kumar, A. Kumar, N. Verma, V. Khopkar, R. Philip, and B. Sahoo, ACS Applied Nano Materials. 3, 8618 (2020).

R. Kumar, A. Kumar, N. Verma, R. Philip, and B. Sahoo, J. Alloy. Compd. 849, 156665 (2020).

R. Kumar, A. Kumar, N. Verma, A.V. Anupama, R. Philip, and B. Sahoo, Carbon 153, 545 (2019).

S. Sallis, L.F.J. Piper, J. Francis, J. Tate, H. Hiramatsu, T. Kamiya, and H. Hosono, Phys. Rev. B. 85, 085207 (2012).

G. Volonakis, A.A. Haghighirad, R.L. Milot, W.H. Sio, M.R. Filip, B. Wenger, M.B. Johnston, L.M. Herz, H.J. Snaith, and F. Giustino, J. Phys. Chem. Lett. 8, 772 (2017).

S. Zhao, K. Yamamoto, S. Iikubo, S. Hayase, and T. Ma, J. Phys. Chem. Solids. 117, 117 (2018).

Q. Hang, Z. Xing, X. Zhu, M. Yu, Y. Song, J. Zhu, and Z. Liu, Ceram. Int. 38, S411 (2012).

A. Ben Jazi Akharrat, N. Moutiab, K. Khirouni, and W. Boujelben, Mater. Res. Bull. 105, 75 (2018).

S.K. Parida, R.N.P. Choudhary, and P.G.R. Achary, Int. J. Microstruct. Mater. Prop. 15, 107 (2020).

S.K. Sinha, S.N. Choudhary, and R.N.P. Choudhary, J. Mater. Sci. 39, 315 (2004).

P.G.R. Achary, A.A. Nayak, R.K. Bhuyan, R.N.P. Choudhary, and S.K. Parida, J. Mol. Struct. 1226, 129391 (2021).

Q. Ke, X. Lou, Y. Wang, and J. Wang, Phys. Rev. B. 82, 024102 (2010).

S. Thakura, R. Raia, I. Bdikinb, and M. Almeida Valente, Mater. Res. 19, 1 (2016).

A. Khlifi, R. Hanen, A. Mleiki, H. Rahmouni, N. Guermazi, K. Khirouni, and A. Cheikhrouhou, Eur. Phys. J. Plus. 135, 790 (2020).

S. Sen, R.N.P. Choudhary, and P. Pramanik, Phys. B Condens. Matter. 387, 56 (2007).

Z.-L. Hou, M.-S. Cao, J. Yuan, X.-Y. Fang, and X.-L. Shi, J. Appl. Phys. 105, 076103 (2009).

S.K. Barik, P.K. Mahapatra, and R.N.P. Choudhary, Appl. Phys. A. 85, 199 (2006).

A. Hilczer, K. Kowalska, E. Markiewicz, A. Pietraszko, and B. Andrzejewski, Mat. Sci. Eng. B. 207, 47 (2016).

S.K. Parida, and R.N.P. Choudhary, Phase Trans. 93, 981 (2020).

S. Madolappaa, V. Anupamap, W. Jaschink, and B.R. Varmab Sahoo, Bull. Mater. Sci. 39, 593 (2016).

V. Khopkar, and B. Sahoo, Phys. Chem. Chem. Phys. 22, 2986 (2020).

S.T. Dadami, S. Matteppanavar, S. Rayaprol, B. Angadi, and B. Sahoo, J. Mag. Mag. Mater. 418, 122 (2016).

Acknowledgments

The authors would like to extend their gratitude and sincere thanks to our host institute for providing XRD and electrical characterization.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article has been retracted. Please see the retraction notice for more detail: https://doi.org/10.1007/s11664-022-09649-w

About this article

Cite this article

Parida, S.K., Swain, M.K., Bhuyan, R.K. et al. RETRACTED ARTICLE: Effect of Cerium on Structural and Dielectric Properties of Modified BiFeO3-PbTiO3 Ceramics for Photovoltaic Applications. Journal of Elec Materi 50, 4685–4695 (2021). https://doi.org/10.1007/s11664-021-09016-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-021-09016-1