Abstract

Weld simulation methods have often employed mathematical functions to describe the size and shape of the molten pool of material transiently present in a weld. However, while these functions can sometimes accurately capture the fusion boundary for certain welding parameters in certain materials, they do not necessarily offer a robust methodology for the more intricate weld pool shapes that can be produced in materials with a very low thermal conductivity, such as the titanium alloy Ti-6Al-4V. Cross-sections of steady-state welds can be observed which contain a dramatic narrowing of the pool width at roughly half way in to the depth of the plate of material, and a significant widening again at the base. These effects on the weld pool are likely to do with beam focusing height. However, the resultant intricacy of the pool means that standard formulaic methods to capture the shape may prove relatively unsuccessful. Given how critical the accuracy of pool shape is in determining the mechanical response to the heating, an alternative method is presented. By entering weld pool width measurements for a series of depths in a Cartesian co-ordinate system using FE weld simulation software Sysweld, a more representative weld pool size and shape can be predicted, compared to the standard double ellipsoid method. Results have demonstrated that significant variations in the mid-depth thermal profile are observed between the two, even though the same values for top and bottom pool-widths are entered. Finally, once the benefits of the Cartesian co-ordinate method are demonstrated, the robustness of this approach to predict a variety of weld pool shapes has been demonstrated upon a series of nine weld simulations, where the two key process parameters (welding laser power and travel speed) are explored over a design space ranging from 1.5 to 3 kW and 50 to 200 mm/s. Results suggest that for the faster travel speeds, the more detailed Cartesian co-ordinate method is better, whereas for slower welds, the traditional double ellipsoid function captures the fusion boundary as successfully as the Cartesian method, and in faster computation times.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fusion welding techniques have been utilised in the structural joining of safety-critical components across aerospace,[1] automotive,[2] and power generation[3,4] industries for many years, thanks to high productivity rates, the considerable joint-integrity that they can offer, and their relatively inexpensive experimental and production costs.[1] While older welding methods such as tungsten inert gas (TIG) welding produce large weld pools and heat-affected zones[5] due to the size of the arc formed, newer “high power-density” beam type processes, such as laser welding, offer a much narrower fusion zone and heat-affected zone,[6] as the energy from the power source is much more focused.

Computer simulation of fusion welding processes has been studied for many years,[6–9] particularly as it offers a method of analysing a joint without the need for costly experimental procedures, allows for the study of parameter-effects, and permits the investigation of through-process results, which may prove difficult or even impossible experimentally with current measurement techniques to be considered. However, a critical requirement for any fusion welding computer model is to accurately understand the size, shape, and location[6] of the molten pool boundary at any given time through the process. The specialist welding FE code Sysweld (owned and developed by ESI) requires some rudimentary weld pool dimensions to be taken (often from cross-sectioning and metallurgical analysis of a representative experimental weld),[10] as well as welding process parameter information, to allow a heat source to be fitted to predict the correct molten pool size and shape.

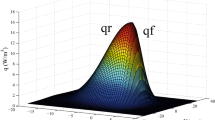

It is reasonably well understood that the size of the molten pool reaches a steady-state during the process[11] (when a constant weld parameter set of heat source power, travel speed, and joint thickness are used), hence the weld can be simulated as a steady boundary traversing along the fixed weld path, at the relevant travel speed. In order to accurately capture the boundary of this molten pool, many researchers have used mathematical functions such as the conical function,[12] or the double ellipsoid (so-called Goldak) function.[13] Usually for wide weld pool formations, or for reasonably regular-shaped weld pool formations, these functions can be used to accurately describe the fusion zone boundary. However, if the travel speed of the heat source is very fast (so the energy being deposited in to the material per unit length is very low) and if the material is one with very poor thermal conductivity (such as a titanium alloy), so the heat, and therefore the molten pool, does not have time to disperse in to the regular type of weld pool shape associated with a Goldak or a conical function. Instead, a very narrow weld pool, often with a tapering waist, and flared top and bottom, which can prove difficult to capture with a mathematical function, is observed (see Figure 1), and needs to be simulated with a different method. Hence, an alternative method is proposed to program this weld pool shape by directly entering the precise weld pool width for a number of depths in to the material, for a 2D transverse cross-section of the weld (taken at its widest point). The development of integrated computational materials engineering (ICME) tools for the optimisation of weld integrity require location specific property approaches that accurately represent the material state during processing and final microstructures. Hence the industrial need for improved predictions of the weld pool geometry requires a modeling framework that accounts for the multi-physics associated with the welding process.

Methodology

Sysweld has been developed as an FE weld simulation tool for several years.[10] As a software package, it has been demonstrated to offer excellent predictive capabilities regarding thermal predictions, distortions, and residual stresses.[14–16] However, the current Sysweld modeling framework does have a number of limitations. When required to enter the weld pool formed as result of the material interacting with the heat source, Sysweld typically asks for the molten pool to be described as either a Goldak double ellipsoid function or a conical function. However, due to the limitations of these functions when representing narrow, tapering welds, It is also possible to directly enter a set of Cartesian x,z co-ordinates to describe the ½ width of the weld pool (assuming a symmetrical weld shape) at any given depth, about the widest region of the molten weld pool in its y axis (length). The operator is asked to enter a table of data directly in to the input deck (not possible through the software GUI), giving approximate Cartesian co-ordinates for the fusion zone boundary. The software will then apply the power across the volume of material within the fusion boundary, making a best-attempt to maintain the fusion boundary at these specified Cartesian co-ordinates, and heating the enclosed material above the liquidus temperature. Typically for FE weld modeling, the measurements of the fusion boundary would come from experimental weld analysis. Sysweld is run in a weakly coupled mode,[10] so the thermal analysis is completed and every time step saved, before the thermal results are fed in to the mechanical analysis.

Using the specialist FE welding code Sysweld, by ESI Group, a series of models has been built, using the baseline set-up shown in Figure 2, exploring the effects upon weld pool formation for a variety of welding process parameters, using a material file—with data gathered from various sources of experiment, literature, and the materials modeling software code JMatPro[17]—representing the titanium alloy Ti-6Al-4V. These three models were computed using both a standard double ellipsoid function to shape the heat source, and the alternative method of entering Cartesian co-ordinates. The weld parameters are given in Table I, see welds W1 to W3. Additionally, using this baseline model (as shown in Figure 2), a further six weld models were set-up in an identical fashion identical to the three weld models using the Cartesian method from before, except varying the travel speed of the welding source, the laser energy per unit length travelled, an efficiency term, and lastly the description of the shape of the weld pool (see Table I, welds W4 to W9).

The model considered a 30 mm wide by 20 mm long by 1 mm thick plate, with the welding performed as a bead-on-plate type weld, along the center of the plate up the full length. A graded mesh was used, with brick elements of a constant depth (0.125 mm) and length (0.5 mm) and varying width, ranging from 0.05 mm close to the weld line, coarsening out to 2.5 mm away from the weld. The simulated plate was assigned a material file containing the flow stress, thermal conductivity, heat capacity, yield strength, liquidus temperature, and thermal strain properties of Ti-6Al-4V, a material with low thermal conductivity, commonly used in welding applications within the aerospace industry. The mesh was sufficient such that the molten zone contained well in excess of the minimum four elements across it in each direction,[6] and was fine enough in the perpendicular direction to be able to determine variations in bead width of down to the nearest 0.05 mm. Models were computed on a simple i5 desktop computer, parallelised over four cores, with a typical run-time of roughly 1 hour per thermal-mechanical simulation. Typically, the models considering the double ellipsoid equation were simulated in just under 1 hour, while models using the Cartesian boundary description were simulated in slightly longer, just over 1 hour.

For validation purposes a set of three welds at the 100 mm/s travel speed, using the three welding powers considered in the models, were performed and the resultant welding bead was metallographically analysed for its steady-state fusion zone size and shape. The testing procedure was carried out as a bead-on-plate type weld test, on Ti-6Al-4V plates of 1 mm thickness, to make the experiment match the modeled conditions exactly. The welds were performed using a Trumpf 4 kW laser cell at the University of Birmingham.

Results

The first series of models—comparing the newly proposed Cartesian co-ordinate method, with the widely used double ellipsoid (Goldak) heat source—has highlighted a number of interesting trends. Cross-sections of the molten pool from the two methods of FE modeling are illustrated in Figure 3(a), and the more tapered shaping of the weld pool boundary by the Cartesian co-ordinate method is well demonstrated. Additionally, Figure 3(a) gives the weld pool metallographic cross-section from experiment. An improved matching of the weld pool boundary using the Cartesian co-ordinate method is observed for the lower powered weld pools—see Figure 3(b). For the 3 kW weld performed at 100 mm/s, the Cartesian model is over-estimating the tapering of the pool at the waist than is observed experimentally. However, this could possibly be corrected by further refining the boundary co-ordinates of the heat source in the definition, or by including a more accurate definition of the process efficiency for laser welding, which remains largely an unknown quantity, given that some energy will possibly pass straight through the weld pool without heating the component at all. Similarly, the side-on view of the weld pools illustrates a much more detailed fusion zone boundary in the Cartesian method, while the double ellipsoid function cannot predict the narrowing in the centre and re-flaring out at the base (see Figure 4).

(a) Varying cross-sections through the weld pool when the model is prepared using the Cartesian co-ordinate method (top) and the double ellipsoid method (middle). All models performed using a source travel speed of 100 mm/s. Compared to (bottom) experimentally observed weld pool shapes. (b) Comparison of weld bead half widths for the experiment, and for the two heat source modeling approaches

While the classical Goldak function can maintain the programmed values for the widths of the weld pool on the top and bottom surfaces, this method predicts almost a linear decay of the width through the depth to achieve this. Whereas, the method of entering the Cartesian co-ordinates of the fusion boundary position has manually included the additional data, for pool width at various depths through the plate, allowing the software to describe a much more detailed weld pool boundary. It has been experimentally observed that certain weld pools contain this tapering and flaring of the fusion boundary, whereby the narrowest region of the weld pool occurs somewhere in the depth of the plate, and then substantially flares outward again on the bottom surface. These pool shapes are often observed with fast-travelling beam welds where the focus of the beam dictates such behavior. In these welds, the limitations of a double ellipsoid function to describe the heat source are evident. However, as is often the case with FE models containing tabular data rather than equation-based functions, the run-time has suffered. The models considering the standard double ellipsoid function heat source took approximately 45 to 50 minutes to compute in parallel calculation, on a 4-core desktop, while the models considering the Cartesian-based tabular input heat source took approximately 1 hour.

A comparison of the thermal profiles perpendicular to the direction of travel illustrate the reasonable agreement between weld pool size at the top surface of the weld for the two methods of programming the heat source (see Figure 5), although Figure 6 then demonstrates some noticeable differences between thermal profiles for the two methods at a depth of ½ mm in to the 1 mm thick plate. It is apparent that for all three weld parameter sets considered, at a depth of ½ mm, the double ellipsoid function has predicted a hotter peak, wider thermal profile than the Cartesian method. This is due to the lack of capturing the tapering waist of the weld bead within the double ellipsoid, compared to the Cartesian method. Figure 7 demonstrates the biggest difference in the thermal profiles of the two methods, as the peak temperature for the 2 and 3 kW welds at the weld line is considerably lower, and the width of the molten zone narrower, compared to the Cartesian method. This difference is due to the lack of flaring out of the weld pool boundary toward the base of the plate in the double ellipsoid method. Given that the key FE modeling outputs such as distortions and residual stresses and other mechanical responses to the heat source are dependent upon the formation, size, and shape of the molten pool of material, it is apparent that inaccurately predicting the tapering of the bead would lead to errors in mechanical response. However, it is important to appreciate that regardless of the method used to describe the heat source (for the same weld parameter set) each method is depositing the same total amount of energy. While peak temperatures, fusion zone widths, and shapes will vary according to the modeling set-up, they both deliver the same total energy, and it is the dissipation of this energy in to the weld zone and the surrounding material that dictate the resultant thermal field.

Thermal profile across the weld pool (perpendicular to direction of travel), at a depth of 0.5 mm in to the plate for both the Cartesian and the double ellipsoid heat sources, for (a)1.5 kW, 100 mm/s, (b) 2 kW, 100 mm/s, (c) 3 kW, 100 mm/s welds. Due to weld symmetry, only half the weld is considered

Once the improvements possible by the Cartesian method had been demonstrated, a further series of models was aimed at demonstrating the capabilities that the Cartesian method offered, in terms of predicting different pool shapes for varying welding parameters. The results are provided in Table II. Clearly, the two process parameters (laser power and speed) both have opposing influences upon weld pool shape. Increasing laser power will clearly produce a wider, deeper, and longer weld pool, as the energy being absorbed by the material will increase. Whereas, increasing the travel speed has the opposite effect, the heat deposited has less time to dissipate in to the material thus the pool will necessarily become smaller and cooler.

Comparing the weld pool cross-sections for these nine welds (see Figure 8), the marked variation in weld pools can be noted. There is still a considerable amount of fitting associated with how the FE software generates the results. If we consider the weld pool for the lowest power and highest travel speed (W7), this has not predicted a fully penetrating weld, simply because there was not enough energy used to produce this. If we further consider the other high-speed welds, the trend for a “nail-head” type weld pool, or a narrowed-waist-and-flared-base weld pool is evident. Thus, the faster travel speed weld pools appear very much to be of the more intricate-type, difficult to be predicted without using this Cartesian co-ordinate method. When compared to the weld pools predicted for the slow welds, there is a clear trend observed that the slower welds form the less intricate, bulky, simplistic weld pool shapes, the type that could also be well predicted by the mathematical double ellipsoid function. The classical tear-drop weld pool shape, when looking top-down on to the material and weld pool, is observed in all of the nine weld simulations performed using the Cartesian method (see Figure 8). However, it must be recognised that this tear-drop shape is a function of the travel speed of the weld pool. Clearly, if the heat source was stationary, then the resultant weld pool would form in a perfect circle (when looking down on to the plate), forming its steady-state shape once the power inputted is balanced by the heat losses. The formation of the weld pool “tail” to form the tear-drop shape arises as the heat source is moved linearly. It is therefore apparent that the width of the weld pool (perpendicular to the direction of travel) is an indication of the power of the heat source, while the ratio of weld pool length to width is an indication of the travel speed.

Figure 9 illustrates a scatter-plot showing the ratio of weld pool length to width against a combined input parameter as a function of both the travel speed and the laser power. Physically, the energy deposited in to the weld path per unit length can be expressed as the laser power divided by the travel speed, hence this combined input parameter is used to demonstrate how the weld ratio varies. The results suggest that the ratio of weld pool length to width increases reasonably linearly with increasing energy per unit length, although there is a lot of scatter in the results at the lower energy per unit length values (20 J/mm and below). This would suggest that for these low values of energy per unit length, there is insignificant energy being deposited in to the material to form a satisfactory weld pool (either due to too low laser power, or too fast travel speed). It can also be noted that for the higher, more stable energy per unit length welds, the ratio of weld length to width is higher for the results at the bottom surface of the plate, and lower for results at the top surface. This would suggest that the weld pool narrows in width faster than it shortens in length through the increasing depth of the material (Figure 10).

The method of incorporating the heat source may initially seem a trivial one, and given the very slightly slower run-times of the Cartesian tabular method, this may initially appear a backward step. However, there is a concerted effort toward developing integrated computational materials engineering (ICME)-type modeling approaches currently. Given that different software packages are often required to perform the various different length-scale modeling work, in order to integrate the models together a method of translating the output from one model to the input for the next is needed. Further, due to the fact that software packages often produce output file formats that may not be compatible with other software packages’ input requirements, this Cartesian approach offers a method of incorporating the weld pool shape which could be calculated from an earlier modeling approach, such as a CFD model, as opposed to the traditional but time-consuming and experimentally reliant method of weld pool cross-section metallographic analysis.

Conclusions

A series of weld simulation FE models have been computed, to demonstrate the capability of a Cartesian co-ordinate method of describing the weld pool shape compared to a traditional double ellipsoid weld pool function. Further, a small parametric study on the two key process variables (laser power and travel speed) using this Cartesian approach was undertaken to demonstrate the robustness of the method, and the wide range of varying weld pool shapes capable of being formed for different parameters. The following conclusions are drawn from this work:

-

1.

Simulations suggest that for welds using a medium or a fast travel speed (100, 200 mm/s), the cross-section of the weld pool boundary becomes considerably more tapered, with a narrowed “waist” but a flared base. Using the Cartesian approach to describe the fusion boundary, as illustrated here, allows for an improved representation of the weld pool, with a matching narrowed “waist”.

-

2.

Whereas, simulations suggest that the slower weld pools (50 mm/s) display a far less tapered weld pool boundary, and would likely be capable of being accurately predicted with the double ellipsoid function. Given the superior calculation speed of the double ellipsoid over the Cartesian tabular method, it clearly makes sense to utilise the equation-based function in these cases.

-

3.

An approximate weld pool length to width ratio has been calculated for all the simulated welds, and results strongly suggest that a linear increase of this ratio is present with increasing energy per unit length. However, significant scatter in results at lower energy per unit lengths suggest this relationship is less well-defined in this regime.

References

J.C. Williams and E.A. Starke: Acta Mater, 2003, 51 pp. 5775–99.

J.A. Hamill, Jr. and P. Wirth: SAE Technical paper 940355, SAE International Congress, Detroit, 1994.

Y. Shimokusu, S. Fukumoto, M. Nayama, T. Ishide, and S. Tsubota: Mitsubishi Heavy Industries, Ltd. Technical Review, 2001, vol. 38, p. 1.

D. Iordachescu, M. Blasco, R. Lopez, A. Cuesta, M. Iordachescu, and J.L. Ocaña: Proceedings of International Conference on Optimization of the Robots and Manipulators (OPTIROB), 2011.

Q. Wang, D.L. Sun, Y. Na, Y. Zhou, X.L. Han, and J. Wang, Procedia Engineering, 10, (2011) pp37-41.

R. Turner, J. Gebelin, R.M. Ward, J. Huang, and R.C. Reed: Proceedings of 8th International Trends in Welding research Conference, Chicago, 2012.

H.J. Stone, S.M. Roberts and R.C. Reed, Met Trans A, Vol. 31A (2000), pp2261-73.

L.E. Lindgren, Comput. Methods Appl. Mech. Engrg, Vol. 195, 48-49 (2006) pp6710-6736.

V.D. Fachinotti, A. Anca and A. Cardona, Commun. Numer. Meth. Engng, Vol. 27 (2011) pp595-607.

D. Pont and T. Guichard: Computational Mechanics ’95, Springer, Berlin, 1995, pp. 248–53.

O. Grong: Metallurgical Modelling of Welding, The Institute of Materials, Cambridge, 1997.

A. Lundback: Licentiate Thesis, Lulea University of Technology, 2003.

J. Goldak, A. Chakravarti and M. Bibby, Met Trans B, Vol. 15B (1984), pp. 299-305.

R. Prakash and R. Gangradey, Fusion engineering and Design, 88, 9-10, (2013) pp2581-2584.

J.J. Xu, P. Gilles, Y.G. Duan, and C. Yu: Int. J. Press. Vessels Pip., 2012, 99, pp. 51-60.

S.K. Bate, R. Charles and A. Warren, Int. J. Pressure Vessels and Piping, 86, (2009) pp73-78.

JMatPro Materials properties software: Sente Software Ltd, Surrey Technology Centre, Guildford, UK, 2015.

Acknowledgements

This work has been conducted as a part of the CASiM2 collaborative project, between the University of Birmingham, the MTC and Rolls-Royce plc. The authors wish to acknowledge the financial support provided by the ERDF toward this project. Additionally, the authors wish to thank technical staff at software company ESI Group, manufacturers of Sysweld, for the technical support they have provided. Additional thanks to Sente software, manufacturers of JMatPro, for advice and materials data.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 28, 2015.

Rights and permissions

About this article

Cite this article

Turner, R.P., Villa, M., Sovani, Y. et al. An Improved Method of Capturing the Surface Boundary of a Ti-6Al-4V Fusion Weld Bead for Finite Element Modeling. Metall Mater Trans B 47, 485–494 (2016). https://doi.org/10.1007/s11663-015-0489-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-015-0489-5