Abstract

The liquid Mg–Zn–Y alloy was conditioned by an application of high-intensive shearing with a pair of intermesh twin screws prior to high-pressure die casting (HPDC). Melt conditioning produces a uniform microstructure with fine grain size and high integrity. The microstructure was analyzed thoroughly, and the solidification characteristics of the melt-conditioned HPDC (MC-HPDC) structure were discussed. The enhancement in I-phase precipitation and the improvement in mechanical properties of MC-HPDC Mg–Zn–Y alloy can be achieved through cyclic annealing.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Because they are the lightest structural material, magnesium alloys have been used increasingly for structural components for several decades, particularly in the automobile industry. However, magnesium alloys exhibit moderate strength with limited ductility at room temperature because of their hexagonal close-packed (HCP) structure. Thus, magnesium alloys mostly are fabricated through casting, especially, die casting.[1] Although high-pressure die casting (HPDC) is a well-established process with high efficiency and low cost, the application of this procedure is limited to only certain Mg alloys, such as AZ91D and AM60, because most Mg alloys have poor castability. HPDC components also contain a substantial amount of porosity because of gas entrapment during filling of the die cavity and hot tearing during solidification.[2] Such porosity not only adversely affects mechanical properties but also prevents property enhancement with a subsequent heat treatment.

One of the promising technologies capable of producing high-integrity components is the melt-conditioned HPDC (MC-HPDC) process,[3] which offers advantages such as extremely low porosity, fine and uniform microstructure, as well as enhanced mechanical properties.[4] In this process, the liquid melt undergoes high-intensive shearing and turbulence, which are generated by specially designed twin profile screws in a heated barrel with precise temperature control. The application of intensive shearing to the liquid melt has shown an increase in the effective nucleation rate by maintaining a homogeneous chemical composition and temperature distribution in the liquid melt, which gives survival opportunity to numerous nuclei in the subsequent solidification process.[5] More importantly, the final MC-HPDC products have close-to-zero porosity owing to bulk solidification and, therefore, can be heat treated in downstream processes. It also has been shown that a wider composition range of Mg alloys with limited castability can be processed by MC-HPDC, which opens up new opportunities for die-cast Mg alloys in high-performance applications.

In various Mg alloys, Mg–Zn alloys have shown improved mechanical properties compared with other Mg alloys through the addition of rare earth elements like yttrium (Y), which form quasicrytalline precipitates named the I-phase.[6–9] Most quasicrystal phases in Mg–Zn–Y alloys is a stable three-dimensional phase that looks like an icosahedron platonic solid in normal casting conditions.[8,9] However, only limited public literature is available for HPDC Mg–Zn–Y alloys. In this article, we investigate the microstructural development and mechanical properties of a dilute Mg–Zn–Y alloy produced by the MC-HPDC process and apply the annealing technique to improve the mechanical properties of the diluted Mg–Zn–Y alloy.

Experimental Procedure

A ternary Mg95.99–Zn3.45–Y0.56 alloy with a liquidus temperature of 613 °C was prepared in an electric resistance furnace from pure Mg, Zn, and Mg–Y master alloy with 78 wt pct Y, in an protective atmosphere with a mixture of (N2 + 0.5 vol pct SF6). The alloy was melted at 720 °C and then held at 680 °C for 30 minutes to homogenize the chemical composition. The melt was processed with HPDC and MC-HPDC under identical conditions for comparison study. For the MC-HPDC process, the liquid metal was fed into the melt conditioner and sheared at 611 °C (semisolid), 614 °C (around liquidus), and 623 °C (above liquidus) for 45 seconds at a shearing speed of 800 rpm to find the microstructural differences among the shearing temperatures. The barrel was heated and held the temperature with multiple sets of heaters equipped with separated precise temperature controllers. The temperature deviation of each controller was under ±1 °C. Typical MC-HPDC setup is shown in Figure 1. For conventional HPDC, the liquid metal was poured directly into the shoot sleeve at 660 °C without melt conditioning. A 280-ton cold chamber HPDC machine was used to produce standard tensile test samples. The dimensions of the tensile test samples were 6.4 mm and 25 mm in gauge diameter and length, respectively. Die temperature was kept constant at 220 °C.

Several heating and cooling cycles were carried out for the cyclic annealing between 360 °C and 420 °C for different times, whereas for the conventional annealing process, the samples were held at a specific temperature between 360 °C and 420 °C for 3 hours and air cooled after the heat treatment. The heating and cooling rates used in annealing were 20 °C/min. The schematic illustration of the difference between conventional and cyclic annealing is shown in Figure 2.

The specimens for optical microscopy (OM) were prepared through the standard technique of grinding them with SiC abrasive papers, polishing them with an Al2O3 suspension, and then etching them in a solution of 75 vol pct ethylene glycol, 24 vol pct acetic acid, and 1 vol pct concentrated HNO3. A Zeiss optical microscope, Zeiss Axioskop2 (Zeiss Gmbh, Gottingen, Germany), equipped with quantitative analysis software Axiovision 4.3 was used for the OM observations and grain size measurement under the ASTM E112-96 standard. The experimental error in this experiment was ±5 μm. Transmission Electron Microscopy (TEM) foil was prepared using Ion-miller from a 3 mm diameter discs with a thinness of 80–90 μm. High resolution TEM (HRTEM) analysis was carried out using JEOL JEM2100 microscope (JEOL Ltd., Tokyo, Japan) equipped with EDS, operated at an accelerating voltage of 200 kV. Phase identification also was performed with a Philips PW1710 (Philip, Eindhoven, The Netherlands) X-ray diffractometer using monochromatic Cu K-radiation. Tensile testing was performed at a strain rate of 1 × 10−3 s−1 at room temperature using an Instron 5500 Universal Electromechanical Testing Systems (Norwood, MA) equipped with a Bluehill software and a ±50 kN load cell, and the hardness was measured by a Vickers microhardness tester, Buehler Micromet II (Buehler Ltd., Lake Bluff, IL).

Results and Discussion

As-Cast Microstructure of MC-HPDC Mg95.99–Zn3.45–Y0.56 Alloy

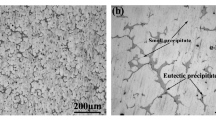

Figure 3 illustrates the microstructures of the conventional HPDC and MC-HPDC Mg95.99–Zn3.45–Y0.56 alloy. The typical microstructure of HPDC shows highly developed dendrites with an extremely nonuniform microstructure. Some dendrites have much coarser arms than others. Porosity was observed in the grain boundaries of the HPDC sample in Figure 3(a). In contrast, MC-HPDC shows a more uniform microstructure than conventional HPDC as shown in Figure 3(b) through (d). The presence of porosity and shrinkage cavity hardly was observed in the MC-HPDC samples even under high magnification (Figure 4). The microstructure of the MC-HPDC samples mostly consists of equiaxed primary α phase instead of dendrites in conventional HPDC. The average grain size of the primary phase was 28 ± 2 μm for the sample sheared at 611 °C (Figure 2(a)), 21 ± 5 μm at 614 °C, and 30 ± 3 μm at 623 °C. Obvious primary α-Mg rosettes were observed in the samples with shearing temperature of 614 °C and 623 °C. X-Ray Diffraction (XRD) patterns of MC-HPDC samples suggest the presence of α-Mg, I-phase and weak Mg7Zn3 peaks that are illustrated by the spectrum in Figure 5. The presence of I-phase in the as-cast alloys with similar composition has been reported in Reference 10.

It is well known that a liquid Mg alloy has potential nucleation sites for subsequent solidification. The application of high-intensive shearing and turbulence to the liquid metal will disperse nucleation sites uniformly and maintain a uniform composition and temperature distribution throughout the liquid metal.[5] If the shearing temperature is lower than the liquidus temperature, then primary α-Mg will nucleate homogeneously and form semisolid slurry inside the twin screw barrel. After the semisolid slurry is delivered into shoot sleeves, more solidification occurs on the presolidified α-Mg. Only a few of the survived nuclei can develop independently to the rosette α-Mg phase as shown in Figure 3(b). If the shearing temperatures were varied, then solidification microstructures would be different as shown in Figures 3(b) through (d). Samples sheared at a higher temperature show more primary α-Mg rosettes than those samples sheared at a lower temperature. It is interesting to see that finally solidified secondary α phases continues to reveal equiaxed grains in the MC-HPDC samples, as shown in Figure 4.

Annealed Microstructure of MC-HPDC Mg95.99–Zn3.45–Y0.56 Alloy

The microstructure of cyclic annealed MC-HPDC is shown in Figure 6 comparing with the conventional annealed sample. Discontinuous precipitates along the grain boundaries and across the original α phase were observed in conventional annealed samples. However, in the cyclic annealed samples, the primary α phase retained the similar grain size as the as-cast sample, and the precipitates only formed within the grain boundaries (Figure 6(b)). No obvious coarsening could be found in either primary or secondary α phase. The XRD results presented in Figure 7 suggest that those precipitates comprise mostly α phase, I-phase, minor w-phase, and Mg7Zn3. Detailed characteristics of the particles precipitated in the grain boundaries were studied using TEM techniques for the cyclic annealed MC-HPDC sample. The results are shown in Figure 8. A selected area diffraction pattern shows 3-fold symmetry in the black needlelike precipitates. It also suggests that the precipitates in the cyclic heat-treated sample contain I-phase.

Mechanical Properties of MC-HPDC Mg95.99–Zn3.45–Y0.56 Alloy

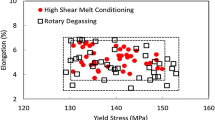

Variations of hardness values for the samples subjected to conventional and cyclic annealing are tabulated in Tables I and II, respectively. A fluctuation in hardness was observed in the conventional annealed samples, which can be linked to the formation and dissolution of precipitates in annealed Mg–Zn–Y alloys. Table I shows that the hardness of the alloy decreased from 68.5 Hv at room temperature to 59.2 Hv at 380 °C annealing for 3 hours. This result reveals that solid solution occurred in this temperature range, which lowered the hardness value of the sample. From 380 °C to 400 °C, however, the value increased to 60.3 Hv through precipitation hardening. The precipitates may dissolve after 400 °C. The hardness of the sample decreased again from 60.3 to 55.5 at an annealing temperature of 420 °C. From these results, we conclude that annealing affected the mechanical properties of the MC-HPDC Mg–Zn–Y samples. Because of the results for the conventional annealing, the cyclic annealing was executed between 360 °C and 400 °C, as shown in Table II. The cyclic annealing processes between 360 °C and 380 °C as well as between 360 °C and 420 °C were compared here as well. Sample cyclic annealed between 360 °C and 400 °C had the highest hardness among the cyclic annealed samples. The yield stress (0.2 pct proof, YS), ultimate tensile strength (UTS), and elongation to the point of failure for the samples all were measured by the Instron testing machine, and the results are listed in Table III. An increase in the elongation to the point of failure along with an improvement in tensile strength were observed after cyclic annealing between 360 °C and 400 °C across 1.5 hours for the MC-HPDC sample with YS, UTS, and elongation to failure measurements of 148 MPa, 217 MPa, and 4.5 pct, respectively.

Because of the high-intensive shearing effect, the MC-HPDC Mg–Zn–Y products achieved a fine uniform microstructure with dispersed tiny I-phase after cyclic annealing. The yield strength of the Mg alloy depended greatly on grain size,[11] whereas UTS was determined by the amount of the defects. For the MC-HPDC process, the samples had fine equiaxed grains, less porosity/hot cracks, and microstructural nonuniformity under optimized conditions, thus showing the improvement in mechanical property compared with the HPDC process. However, because of the Y enrichment after the heat treatment, many precipitated particles, including I-phase, occurred in the grain boundaries (as shown in Figure 6). Moreover, because of the close-to-zero porosity, cyclic annealing can be applied to the MC-HPDC samples so that I-phase can precipitate more dispersively in an ultra-fine size to help increase the strength of the samples.

Conclusions

Application of high-intensive shearing to the liquid Mg–Zn–Y melt produces a uniformly fine microstructure with no noticeable porosity or cavities and shows improvement in tensile properties. Application of cyclic annealing is identified as a unique technique to improve the tensile properties of the MC-HPDC Mg–Zn–Y alloy because it allows I-phase to be precipitated without coarsening the primary α-Mg with cyclic annealing.

References

I.J. Polmear: Mater. Trans. JIM 1996, vol. 37, pp. 12.

A. Balasundaram, and A.M. Gokhale: in Magnesium Technology, J. Hryn, ed., TMS, Warrendale, PA, 2001, p. 155.

Z. Fan, S.J. Bevis, and S. Ji: PCT Patent, WO 01/21343 A1, 1999.

Z. Fan, G. Liu, and Y. Yun: J. Mater. Sci. 2006, vol. 41, pp. 3631.

Z. Fan, Y. Wang, M. Xia, and S. Arumuganathar: Acta Mater., 2009, vol. 57, p. 4891.

Z.P. Luo, S.Q. Zhang, Y.L. Tang, and D.S. Zhao: Scripta Metall. 1993, vol. 28, pp. 1513.

Z.P. Luo, S.Q. Zhang, Y.L. Tang, and D.S. Zhao: Scripta Metall. 1995, vol. 32, pp. 1411.

A.P. Tsai, A. Niikura, A. Inoue, T. Masumoto, Y. Nishita, K. Tsuda, and M. Tanaka: Philos. Mag. Lett. 1994, vol. 70, pp. 169.

A.P. Tsai, Y. Murakami, and A. Niikura: Philos. Mag. Lett. 2000, vol. 80 pp. 1043.

J.Y. Lee, H.K. Lim, D. Hyung Kim, W.T. Kim, and D. Hyang Kim: Mater. Sci. Eng. A, 2007 vol. 449-451, pp. 987.

P. Andersson, C.H. Cáseres, and J. Koike: Mater. Sci. Forum 2003, vol. 419–422, pp. 123.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 2, 2009.

Rights and permissions

About this article

Cite this article

Xia, M., Mitra, S., Dhindaw, B. et al. Melt-Conditioned, High-Pressure Die Casting of Mg–Zn–Y Alloy. Metall Mater Trans B 41, 209–213 (2010). https://doi.org/10.1007/s11663-009-9312-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-009-9312-5