Abstract

TiO2 freeze-dried precursor powders were synthesized using a coprecipitation route that includes titanium tetrachloride (TiCl4) as initial material prepared at 348 K (75 °C) and pH 7. Differential scanning calorimetry/thermogravimetry (DSC/TG), X-ray diffraction (XRD), transmission electron microscopy (TEM), and selected area electron diffraction (SAED) and high resolution TEM were utilized to characterize the thermal behavior and phase transformation of the TiO2 freeze-dried precursor powders after calcination. The main compound of the TiO2 freeze-dried precursor powders was TiO2·H2O based on a TG analysis conducted at a heating rate of 20 K (20 °C)/min. The anatase TiO2 (a-TiO2) first appeared at 473 K (200 °C), then from a-TiO2 transformed to rutile TiO2 (r-TiO2) at 773 K (500 °C). The activation energy of a-TiO2 formation from TiO2 freeze-dried precursor powders was 242.4 ± 33.9 kJ/mol, whereas, the activation energy of phase transformation from a-TiO2 to r-TiO2 was 267.5 ± 19.1 kJ/mol. The crystallite size of a-TiO2 grew from 3.5 to 23.2 nm when raising the calcination temperature from 473 K to 873 K (200 °C to 600 °C). In addition, the crystallite size of r-TiO2 increased from 17.4 to 48.1 nm when calcination temperature increased from 773 K to 1073 K (500 °C to 800 °C).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

TiO2 is one of the important inorganic material, widely used in sunscreen,[1] photocatalyst,[2,3] and sensors.[4,5] TiO2 possesses three crystal structures: anatase, rutile, and brookite.[6] The anatase and rutile phases are Ti-O octahedral which formed a tetragonal structure, otherwise, the brookite phase formed an orthorhombic.[6] The common phases of TiO2 are anatase and rutile, where the rutile is the most stable one among the three phases. The phase transformation from anatase and brookite to rutile occurred when the anatase and brookite were calcined between 623 K to 1478 K (350 °C to 1175 °C),[7] and 773 K to 873 K (500 °C to 600 °C),[8] respectively.

Recently, numerous techniques have been widely used for synthesizing the TiO2 nanopowders that have greater control properties, such as the coprecipitation,[9,10] hydrothermal,[11,12] and sol–gel method.[13,14] Among these, homogeneous precipitation is one of the most promising techniques because of the advantages of low cost, easy-to-acquire equipments, a simple synthesis process, and nanometric precursor particles. Using the coprecipitation route for synthesis, the amorphous TiO2 precursor powders were obtained for the precipitation through freeze-drying process. After calcinations, the crystalline TiO2 powders were obtained. Hsiang et al.[15,16] have pointed out that the activation energies of a-TiO2 and r-TiO2 crystallization were obtained, namely, 53 to 250 kJ/mol and 205 to 506 kJ/mol, respectively, and the values were dependent on aging process. The value of activation energy for TiO2 crystallization with aging treatment was higher than that without aging. In addition, Kumar et al.[17,18] also proposed that the activation energy of phase transformation from a-TiO2 transformed to r-TiO2 was 147 kJ/mol for the titania membranes prepared by sol–gel process. However, thermal behavior and phase transformation of TiO2 freeze-dried precursor powders prepared by a coprecipitation route have not been discussed in detail.

In the present study, the TiO2 freeze-dried precursor powders synthesized using titanium tetrachloride as initial material prepared by a coprecipitation route were investigated. The thermal behavior and phase transformation of TiO2 freeze-dried precursor powders after calcination were investigated using differential scanning calorimetry/thermogravimetry (DSC/TG), X-ray diffractometer (XRD), transmission electron microscopy (TEM), selected area electron diffraction (SAED), and high resolution TEM (HRTEM). The purposes of the present work include: (1) study the thermal behavior of TiO2 freeze-dried precursor powders, (2) investigate the phase transformation of the TiO2 freeze-dried precursor powders after calcination, (3) study the crystallite growth behavior of a-TiO2 and r-TiO2, and (4) observe the microstructure of calcined TiO2 powders.

2 Experimental Procedure

2.1 Sample Preparation

Titanium tetrachloride (TiCl4, purity ∼98.5 pct, supplied by Nihon Shiyaku Reagent, Japan) was used as starting material for a coprecipitation process. TiCl4 was dissolved in deionized water with a volume ratio of 1:20, and the mixed solution was stirred using a magnetic stirrer and heated to 348 K (75 °C) for 2 hours, then Ti4+ solution was formed. Since the pH value of Ti4+ solution was very low and no precipitation occurred. In order to increase the pH value for accelerating the precipitation, the mixed solution must be added with the precipitation agent. In the present study, the NH4OH aqueous solution was used as the precipitation agent. When the NH4OH aqueous solution (purity ~28 pct, supplied by Nihon Shiyaku Reagent, Japan) was added to water-TiCl4 mixture, [OH−] concentration increased resulting the pH value increase. This result can be expressed as following reaction:

Moreover, when the pH value of water-TiCl4 mixed solution was adjusted to 0.5, the precipitation reaction reoccurred. The OH− ions will promote the interparticle repulsion to enhance the dispersiveness and caused the particle size decrease. Therefore, the pH value of present study was adjusted to 7.

After precipitation, the precipitates were washed with a large amount of deionized water for five times. Subsequently, the precipitates were freeze-dried at 218 K (−55 °C) in vacuum.

2.2 Sample Characterization

Differential scanning calorimetry/thermogravimetry (DSC/TG) (SDT Q600, TA) analysis was conducted on a 200 mg freeze-dried precursor powders sample at various rates in static air up to 1173 K (900 °C). Al2O3 powders were used as the reference material.

The crystalline phases of the TiO2 freeze-dried precursor powders after calcination were identified by X-ray diffraction (XRD, Model Rad IIA, Rigaku, Tokyo) with Cu K α radiation and an Ni filter, operating at 40 kV, 30 mA and a scanning rate (2θ) of 1 deg/min.

When the TiO2 freeze-dried precursor powders were calcined at various temperatures for 120 minutes, the morphology of calcined TiO2 freeze-dried precursor powders was examined using TEM (JEM 2100F, JEOL, Japan) at an operating voltage 200 kV. The TEM sample was prepared by dispersing the calcined powders in an ultrasonic bath and then collecting them on a copper grid. The TiO2 crystalline structure was determined by SAED based on TEM.

3 Results and Discussion

3.1 Thermal Behavior of TiO2 Freeze-Dried Precursor Powders

The DSC/TG curves of the TiO2 freeze-dried precursor powders heated in static air at a rate of 10 K/min (10 °C/min) from 303 K to 1173 K (30 °C to 900 °C) were shown in Figure 1. The TG curve shows that the mass loss of TiO2 freeze-dried precursor powders took place in a wide temperature range from room temperature to 873 K (600 °C), which indicate that the mass loss was almost present at an exponential decay from 373 K to 723 K (100 °C to 450 °C). The TG curve of TiO2 freeze-dried precursor powders can be divided to three loss stages: (i) from room temperature to 373 K (100 °C), (ii) from 373 K to 723 K (100 °C to 450 °C) as the main mass loss, and (iii) from 723 K to 873 K (450 °C to 600 °C), when heating temperature was higher than 873 K (600 °C), the mass was maintained nearly stable.

In Figure 1, the first mass loss of about 5.7 pct was attributed to the free water of physisorbed water.[19] In the second stage, about 17.9 pct of mass loss occurred. This result can be expressed as following reaction:

The third mass loss of about 1.2 pct can be assigned to the further hydration of the surface water molecules most likely existing in a wide set of energetically non-equivalent surface hydrogen groups.[20]

Nakayama[21] has pointed out that when water molecule and hydroxyl ions decomposed from TiO2·xH2O, residual 82 wt pct of TiO2 was the product. In this study, the residual TiO2 of freeze-dried precursor powders residual was about 77.6 wt pct, which revealed that TiO2·H2O was the main compound in the freeze-dried precursor powders.

In this study, hydrolysis of the titanium cation occurred at a low pH level. The first hydrolysis step caused the formation of [Ti(OH)(OH2)5]3+ species, which were stable under strong acid conditions. These species were not able to condense due to the positive change of the hydroxo group.[22] Condensation to both anatase and rutile began when the solution activity was high enough to allow further deprotonation to [Ti(OH)3(OH2)3]+, depending on the exact pH.[22] At a high pH level, when deoxolation occurred, condensation can proceed along apical direction created the skewed chains of the anatase structure.[23,24]

In addition, the DSC curve also showed that one endothermic peak at 373 K (100 °C), and three exothermic peaks at 611 K, 738 K, and 940 K (338 °C, 465 °C, and 667 °C). The one endothermic peak at 373 K (100 °C) was attributed to the dehydration from the surface of precursor powders.[25] Moreover, the first broad exothermic peak at 611 K (338 °C) due to the hydroxyl groups was eliminated and the Ti-O-Ti bonds were formed.[20] Above results caused the endothermic reaction but the peak at 611 K (338 °C) had a broad exothermic peak, which was due to the anatase TiO2 (a-TiO2) formed. The second exothermic peak at 738 K (465 °C) was attributed to the phase transformation from a-TiO2 to rutile TiO2 (r-TiO2). Furthermore, the final exothermic peak at 940 K (667 °C) was caused by the a-TiO2 fully converted to r-TiO2.

3.2 The Phase Transformation of the TiO2 Freeze-Dried Precursor Powders After Calcinations at Various Temperatures for 120 Minutes

Figure 2 shows the XRD patterns of the TiO2 freeze-dried precursor powders after calcination at various temperatures for 120 minutes. The XRD pattern of the TiO2 freeze-dried precursor powders was shown in Figure 2(a), which revealed that the precursor powders before calcinations maintained its amorphous state. Figure 2(b) shows the XRD pattern of the TiO2 freeze-dried precursor powders after calcination at 473 K (200 °C), it was seen that the (101), (004), and (200) reflection peaks of a-TiO2 first appeared. The XRD pattern of the TiO2 freeze-dried precursor powders after calcination at 573 K (300 °C) was shown in Figure 2(c), and indicated that the phase still maintained the a-TiO2. However, the reflections shown in Figure 2(c) were still weak and broad due to poor crystallinity and a small crystallites in the submicron to nanometer range.[26,27] Figure 2(d) shows the XRD pattern of the TiO2 freeze-dried precursor powders after calcination at 673 K (400 °C), which revealed that the all reflection peaks still maintained the a-TiO2 phase. But the intensity of (101) reflection of a-TiO2 was greater than that of Figure 2(c) due to the enhanced crystallinity of a-TiO2 when raising the calcination temperature from 573 K to 673 K (300 °C to 400 °C). The XRD pattern of TiO2 freeze-dried precursor powders after calcination at 773 K (500 °C) for 120 minutes was shown in Figure 2(e). It was seen that all the reflection peaks still belonged to the a-TiO2 phase, except the (110) reflection of r-TiO2 first appeared but the intensity was very weak. Moreover, according to the Figures 2(b) through (e), it was also seen that the intensities of all reflection peaks of Figure 2(e) were higher than that of other patterns and the half width of full maximum (HWFM) intensity of a-TiO2 (101) decreased. This result was due to the crystallinity and crystallite size of a-TiO2 increased with raising the calcination temperatures. The XRD pattern of the TiO2 freeze-dried precursor powders after calcination at 873 K (600 °C) for 120 minutes was shown in Figure 2(f), which indicated that the a-TiO2 phase still maintained and the (110), (101), (111), and (211) reflections peaks of r-TiO2 first appeared. Although the phases were a-TiO2 and r-TiO2 coexisting but the HWFM of a-TiO2 (101) reflection decreased. In addition, the (110), (101), (111), and (211) reflections of r-TiO2 were improved with raising the calcination temperatures. Figure 2(g) shows the XRD pattern of the TiO2 freeze-dried precursor powders after calcination at 973 K (700 °C), which indicated that the a-TiO2 phase was fully converted to r-TiO2.

Using the intensity of the reflection (h k l) in the XRD pattern to determine the a-TiO2 content has been proposed by Spurr and Myers.[28] The integrated intensity ratio of the a-TiO2 content was defined by

where f A was the fraction of the a-TiO2, I R and I A were the intensities of the (101) and (110) reflections for a-TiO2 and r-TiO2, respectively.

Figure 3 shows the phase contents of a-TiO2 and r-TiO2 when the freeze-dried precursor powders after calcination between 473 K and 973 K (200 °C and 700 °C) for 120 minutes. The results of Figure 3 show that the a-TiO2 was 100 pct when the TiO2 freeze-dried precursor powders after calcination between 473 K and 673 K (200 °C and 400 °C) for 120 minutes. When the TiO2 freeze-dried precursor powders were calcined at 773 K (500 °C) for 120 minutes, the phase contents of a-TiO2 and r-TiO2 were 88 and 12 pct, respectively. When raising the calcination temperature of the TiO2 freeze-dried precursor powders from 773 K to 973 K (500 °C to 700 °C), the phase contents of a-TiO2 decreased from 88 to 0 pct, whereas the r-TiO2 content increased from 12 to 100 pct.

Using TiCl4 and NH4OH as the initial materials for preparing the TiO2 precursor powders by a microemulsion process at room temperature has been reported by Keswani et al.[29] They proposed that the phase of a-TiO2 still existed when calcined at 1173 K (900 °C) for 4 hours. This result did not agree with the ones of the present study. The difference between these investigations can be caused by the different synthesized method and temperature used. On the other hand, Marinescu et al.[30] also used the soluble salts of titanium and NH4Cl as the initial materials by a hydrothermal process for preparing the TiO2 precursor powders. They have pointed out that the anatase to rutile phase transformation depended not only on primary crystallite size but also on the presence of the brookite phase and absorbed water. The presence of the brookite phase accelerated the anatase to rutile transformation.[30] The difference of results between the present study, and the result of Marinescu et al.[30] could be due to the various preparing method.

3.3 The Crystallite Size of the TiO2 Freeze-Dried Precursor Powders After Calcination

The crystallite size (D) of the a-TiO2 and r-TiO2 was calculated using Scherrer’s equation:[31]

where λ = 1.5405 Å was the wavelength of Cu K α radiation, β was the full-width at half-maximum (FWHM) intensity in radians. The (101)a and (110)r reflections at 2θ = 25.32 and 27.48 deg were used to define the FWHM intensity of anatase and rutile TiO2, respectively, within various crystalline phases, and θ was the Bragg’s angle.

The crystallite sizes of the TiO2 freeze-dried precursor powders after calcination at various temperatures for 120 minutes were shown in Figure 4. It was seen that the average crystallite sizes of a-TiO2 and r-TiO2 powders increased with raising the calcination temperatures. Moreover, it was also seen that when duration for 120 minutes, the crystallite size of a-TiO2 increased from 3.5 to 23.2 nm with raising the calcination temperature from 473 K to 873 K (200 °C to 600 °C). Moreover, the crystallite size of r-TiO2 increased from 17.4 to 48.1 nm with raising temperature from 773 K to 1073 K (500 °C to 800 °C).

The result of Figure 4 also revealed that the crystallite sizes of TiO2 still maintained the nanosize range, when the freeze-dried precursor powders were calcined between 473 K and 1073 K (200 °C to 800 °C) for 120 minutes.

3.4 The Crystallization Behavior of TiO2 Freeze-Dried Precursor Powders After Calcination

The DSC curves of the TiO2 freeze-dried precursor powders at various heating rate in static air from 573 K to 1023 K (300 °C to 750 °C) were shown in Figure 5. It was seen that the crystallization temperatures of a-TiO2 were between 593 K and 621 K (320 °C and 348 °C). The temperatures of phase transformation from a-TiO2 to r-TiO2 were between 722 K and 750 K (449 °C and 473 °C), and the final exothermic peak temperatures were between 932 K and 962 K (650 °C and 689 °C). In addition, Figure 5 also shows that the exothermic peaks shifted to higher temperatures with raising the heating rate. This phenomenon was attributed to the higher heating rates and resulting in the transition temperature leaving the equilibrium transition point and shifting to a higher temperature. In the present study, the exothermic peak temperatures of the DSC curves can be used to derive the activation energy of phases crystallization from the TiO2 freeze-dried precursor powders using the Johnson–Mehl–Avrami (JMA) equation;[32]

where β meant the heating rate (K/min), E c denoted the crystallization activation energy (kJ/mol), R was the gas constant (8.314 J/mol), T c was the absolute temperature (K) that corresponded to the exothermic peak of crystallization, and ln CM was a constant.

Figure 6 shows that the linear relationship between ln β and 1/T c for various TiO2 formations in freeze-dried precursor powders. The slopes of the fitting lines were −29.16 ± 4.08 and −32.17 ± 2.30 for a-TiO2 and r-TiO2, respectively. Therefore, the apparent activation energies of a-TiO2 and r-TiO2 formation in the precursor powders were calculated from the slopes to be 242.4 ± 33.9 kJ/mol and 267.5 ± 19.1 kJ/mol, respectively. The phases formed from the different raw materials and synthesis processes were directly dependent on the chemical homogeneity of the components.[33] The activation energy value of r-TiO2 was in agreement with the value of r-TiO2 formation from the precursor obtained by Ti4+ solution with NH4OH coprecipitation at pH 9 and without aging treatment.[16]

Zhang and Banfield[34] have pointed out that the activation energy of the a-TiO2 crystallization was 78 kJ/mol. Moreover, the activation energy of phase transformation from a-TiO2 to r-TiO2 was 147 kJ/mol was reported by Kumar et al.[17,18] These values were smaller than that obtained values in the present study. This result can be suggested to the different initial materials and various prepared processes.

3.5 The TEM Microstructure of the TiO2 Freeze-Dried Precursor Powders After Calcination

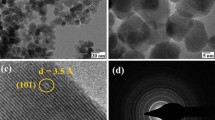

The TEM micrographs, SAED pattern, and HRTEM image of the TiO2 freeze-dried precursor powders after calcination at 673 K (400 °C) for 120 minutes were shown in Figure 7. Figure 7(a) shows the bright field (BF) image of the crystallites with a size of about 10 nm, which was consistent with the results shown in Figure 4. Figure 7(b) shows the dark field (DF) image from a-TiO2 (101) reflection in Figure 7(c). Figure 7(c) shows the SAED pattern which indexed corresponding to a-TiO2. Figure 7(d) shows an image of HRTEM with the d-spacings of (101) and (111) a-TiO2 of 0.347 and 0.165 nm, respectively.

TEM micrographs of TiO2 freeze-dried precursor powders after calcination at 673 K (400 °C) for 120 minutes: (a) BF image, (b) DF image using a-TiO2 (101) in (c), (c) SAED pattern which indexed corresponding to a-TiO2, (d) HRTEM image with d-spacing of the a-TiO2 (101) and (111) were 0.347 and 0.165 nm, respectively

Figure 8 shows the TEM micrographs, SAED pattern, and HR-TEM image of the TiO2 freeze-dried precursor powders after calcination at 973 K (700 °C) for 120 minutes. Figures 8(a) and (b) shows the BF and DF images, which revealed various crystallite agglomerate and individual crystallite with size of about 37 nm. Figure 8(c) shows the SAED pattern which indexed corresponding to r-TiO2. Figure 8(d) shows the lattice image of HRTEM with the lattice fringe. The lattice fringes indexed corresponding to the d-spacings (111) and (110) for r-TiO2 were 0.220 and 0.324 nm, respectively.

TEM micrographs of TiO2 freeze-dried precursor powders after calcination at 973 K (700 °C) for 120 minutes: (a) BF image, (b) DF image using r-TiO2 (110) in (c), (c) SAED pattern which indexed corresponding to r-TiO2, (d) HRTEM image with d-spacing of the r-TiO2 (110) and (111) were 0.324 and 0.220 nm, respectively

4 Conclusions

Thermal behavior and phase transformation of TiO2 freeze-dried precursor powders were investigated using DSC/TG, XRD, TEM, and SAED. The results of the present study are summarized as follows:

-

1.

The main compound of TiO2 freeze-dried precursor powders has been determined as TiO2·H2O.

-

2.

XRD results showed that when the TiO2 freeze-dried precursor powders after calcination at 773 K and 873 K (500 °C and 600 °C) for 120 minutes, the crystalline structures were composed of a-TiO2 and r-TiO2 coexist. The a-TiO2 was fully converted to r-TiO2 when the TiO2 freeze-dried precursor powders after calcination at 973 K (700 °C) for 120 minutes.

-

3.

When the TiO2 freeze-dried precursor powders after calcination between 473 K and 873 K (200 °C and 600 °C) for 120 minutes, the crystallite size of a-TiO2 increased from 3.5 to 23.2 nm. Whereas, the crystallite size of r-TiO2 increased from 17.4 to 48.1 nm when calcined from 773 K to 1073 K (500 °C to 800 °C) for 120 minutes.

-

4.

The activation energy of the a-TiO2 formation from the TiO2 freeze-dried precursor powders was 242.4 ± 33.9 kJ/mol, whereas, the activation energy of phase transformation from a-TiO2 to r-TiO2 was 267.5 ± 19.1 kJ/mol.

References

C. Gelis, S. Girard, A. Mavon, M. Delverdier, N. Paillous, P. Vicendo: Photodermatol Photoimmunol Photomed, Vol. 19 (5) (2003) 242–253.

W. Zhang, Y. He, Q. Qi: Mater. Chem. Phys., Vol. 93 (2005) 508–515.

G. Dagan, M. Tomkiewicz: J. Phys. Chem., Vol. 97 (1993) 12651–12655.

K. Katayama, H. Hasegawa, T. Noda, T. Akiba, H. Yanagida: Sensors and Actuators B, Vol. 2 (1990) 143–149.

U. Diebold: Surf. Sci. Rep., Vol. 48 (2003) 53–229.

U. Balachandran, N. G. Eror: J. Solid State Chem., Vol. 42 (1982) 276–282.

A. Dabler, A. Feltz, J. Jung, W. Ludwig, E. Kaisersberger: J. Therm. Anal. Calorim., Vol. 33 (1988) 803–809.

J. G. Li, T. Ishigaki: Acta. Mater., Vol. 52 (2004) 5143–5150.

H. K. Park, Y. T. Moon, D. K. Kim: J. Am. Ceram. Soc., Vol. 79 (1996) 2727–2732.

Y. Q. Zheng, E. R. Shi, Z. Z. Chen, W. J. Li, X. F. Hu: J. Mater. Chem., Vol. 11 (2001) 1547–1551.

C. H. Lu, M. C. Wen: J. alloys. Compd., Vol. 448 (2008) 153–158.

J. Liu, T. An, G. Li, N. Bao, G. Sheng, J. Fu: Microporous Mesoporous Mater., Vol. 124 (2009) 197–203.

F. Cot, A. Larbot, G. Nabias, L. Cot: J. Eur. Ceram. Soc., Vol. 18 (1998) 2175–2181.

J. Yang, S. Mei, J. M. F. Ferreira: J. Am. Ceram. Soc., Vol. 84 (2001) 1696–1702.

H. I Hsiang, S. C. Lin: Mater. Chem. Phys., 2006, Vol. 95, 275–279.

H. I Hsiang, S. C. Lin: Ceram. Int., 2008, Vol. 34, pp. 557–561.

K. N. P. Kumar, K. Keizer, A. J. Burggraaf: J. Mater. Chem., Vol. 3 (1993) 1141–1149.

K. N. P. Kumar, K. Keizer, A. J. Burggraaf, T. Okubo, H. Nagamoto: J. Mater. Chem., Vol. 3 (1993) 1151–1159.

Y. W. Hsu, K. H. Yang, K. M. Chang, S. W. Yeh, M. C. Wang: J. Alloys Compd., Vol. 509 (2011) 6864–6870.

G. Li, L. Li, J. Boerio-Goates, B.F. Woodfield: J. Am. Chem. Soc., Vol. 127 (2005) 8659-8666.

N. Nakayama, T. Hayashi: Colloids and Surfaces A: Physicochem. Eng. Aspects, Vol. 317 (2008) 543–550.

M. Henry, J.P. Jolivet, J. Livage, Aqueous Chemistry of Metal Cations, Hydrolysis, Condensation, and Complexation, Springer, Berlin, 1992, p.155.

S.T. Aruna, S. Tirosh, A. Zaban: J. Mater. Chem., Vol. 10 (2000) 2388-2391.

D. Zhang, L. Qi, J. Ma, H. Chang: J. Mater. Chem., Vol. 12 (2012) 3677-3680.

H. I Hsiang, S. C. Lin: Mater. Sci. Eng. A, 2004, Vol. 380, pp. 67–72.

H. S. Liu, T. S. Chin, S. Y. Chiu, K. H. Chung, C. S. Chang, M. T. Liu: Ceram. Int., Vol. 23 (1997) 19–25.

C. W. Kuo, Y. H. Shen, S. B. Wen, H. E. Lee, I. M. Hung, H. H. Huang, M. C. Wang: Ceram. Int., Vol. 37 (2011) 341–347.

R. A. Spurr, H. Myers: Anal. Chem. Res., Vol. 29 (1957) 760–762.

R. K. Keswani, H. Ghodke, D. Sarkar, K. C. Khilar, R. S. Srinivasa: Colloids and Surfaces A: Phsicochem. Eng. Aspects, Vol. 369 (2010) 75–81.

C. Marinescu, A. sofronia, C. Rusti, R. piticecu, V. Badilita, E. Vasile, R. Baies, S. Tanasescu: J. Therm. Anal. Calorim., Vol. 103 (2011) 49–57.

B. D. Cullity: Elements of X-ray Diffraction, Addison-Wesley, Reading, MA, Vol. 1967, p. 170.

A. Marotta, A. Buri: Thermchim. Acta, Vol. 25 (1978) 155–160.

Y.F. Chen, M.C. Wang, M.H. Hon: J. Euro. Ceram. Soc., Vol. 24 (2004) 2389-2397.

H. Zhang, J. F. Banfield: Chem. Mater., Vol. 14 (2002) 4145–4154.

Acknowledgments

The authors sincerely thank the National Science Council of Taiwan for its financial support under NSC 100-2221-E-037-001. The authors also gratefully acknowledge Professor M.H. Hon for his suggestion and the help of Mr. S.Y. Yao for TEM and EDS. Authors thank the key reader and reviewers for their constructive suggestions/comments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 14, 2013.

Rights and permissions

About this article

Cite this article

Yeh, SW., Chen, YL., Hsi, CS. et al. Thermal Behavior and Phase Transformation of TiO2 Nanocrystallites Prepared by a Coprecipitation Route. Metall Mater Trans A 45, 261–268 (2014). https://doi.org/10.1007/s11661-013-1963-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-1963-9