Abstract

The sequence of eutectoid microstructures, obtained by lowering the temperature of the isothermal transformation, was studied in synthetic steel with 4.12 mass pct Cr 0.88 mass pct C. The results were compared with observations on plain carbon steels with 1.65 and 1.67 mass pct C. In both cases, the main features can be explained as an effect of a lowered temperature on the increasing supersaturation of cementite in austenite and an even stronger effect on that of ferrite. One distinction was a continuous change in the pearlite structure toward a more acicular structure. This structure is named acicular pearlite.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The temperature ranges for the well-known eutectoid transformations in steel, pearlite, and bainite were well defined by the classical work by Davenport and Bain[1] in 1930, where each degree of transformation was represented with a single curve. For hypoeutectoid plain carbon steels, its shape does not reveal that it is composed of two C curves, one for each transformation product, pearlite and bainite, because parts of them overlap. The bainitic transformation has a horizontal asymptote at the bainite start temperature, B s , which should be depressed to lower temperatures as the carbon content is increased. One may thus expect the temperature range of pearlite to extend to lower temperatures. However, in 1939, Jolivet[2] called attention to the occurrence of more spiky microstructures in the temperature range for the transition between pearlite and bainite. Their shapes sometimes reminded him of dendrites formed on solidification, and he described them as arborescent. He stated that they appear “only in little-used eutectoid or hypereutectoid steels other than the plain carbon steels.” This phenomenon was later studied in steels with 1 mass pct C and 3 mass pct Cr by Klier[3] and by Lyman and Troiano.[4] The latter authors also studied steels with other chromium contents and found a very similar behavior of a steel with 4 mass pct Cr. Several studies were published in more recent years and the field was reviewed recently by Goldenstein et al.[5] in a publication on “Non classical decomposition products morphologies in Fe-Cr-C and Fe-Cr-Mo-C steels.”

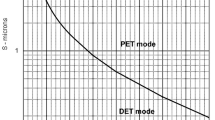

Several variations of the eutectoid microstructure in plain carbon steels with 1.65 or 1.67 mass pct C were recently discussed.[6] It was found that the microstructure changed, when lowering the temperature, from pearlite to inverse bainite to fanlike bainite and finally to bainite. This change seemed possible to explain first as an effect of the increase of the supersaturation of cementite in austenite at decreasing temperature and, second, at lower temperatures, as an effect of the even more rapid increase of the supersaturation of ferrite. It was observed how the increased supersaturation of cementite in austenite favors the tendency to form Widmanstätten plates of cementite, which strongly affects the eutectoid microstructure favoring inverse bainite, whereas plates of ferrite may play the same role at lower temperatures for the formation of bainite. With these observations in mind,[6] it would be interesting to examine how much these microstructures resemble those found in steels alloyed with carbide forming elements such as Cr. If there are evident similarities, then the same explanation may apply. Due to the detailed documentation available through References 3 and 4, it was decided to compare it with the transformation products in chromium steel with about 1 mass pct C. The time-temperature-transformation (TTT) diagrams in Reference 4 indicate that the B s is about 673 K (400 °C) for 3 mass pct Cr, about 648 K (375 °C) for 4 mass pct Cr, and about 598 K (325 °C) for 6 mass pct Cr. In order to compare with the eutectoid transformations observed in the plain carbon steel with 1.67 mass pct C, a similar B s temperature, slightly below 623 K (350 °C), was desired. In order to depress the ferrite formation by adding Cr to steel with 1 mass pct C, one may thus prefer 6 mass pct Cr. However, so much chromium seemed to have a very strong effect on the formation of Widmanstätten plates of cementite, and about 4 mass pct Cr was thus chosen as a convenient compromise. For this reason, steel with 4.12 mass pct Cr and 0.88 mass pct C was chosen for the present study. The TTT diagram for a similar steel, published by Lyman and Troiano,[4] is reproduced in Figure 1.

TTT diagram for the 4.12 mass pct Cr 0.88 mass pct C steel[4]

2 Experimental Procedure

The steel examined in this study was synthetic. It was homogenized at 1543 K (1270 °C) for 12 hours. The compositions of the steels considered in this work are given in Table I.

Samples with dimensions of 10 × 10 × 1 mm were austenitized at 1373 K (1100 °C) for 10 minutes followed by an isothermal heat treatment in liquid Bi-Sn and, subsequently, quenched to room temperature in brine. Samples were metallographically prepared by sectioning, grinding, and polishing with 55-, 9-, and 3-μm diamond suspension, and final polishing was performed with 0.05-μm alumina suspension. The samples were etched in 2 pct nital. Samples were analyzed using a light optical microscope (LOM) and a field emission gun–scanning electron microscope (FEG-SEM) LEO 1530 (Leo Electron Microscopy Ltd., Zeiss, Oberhochem, Germany), operating at 5 kV and with a working distance of about 5 mm.

The carbide phases in the transformation products were not identified in the present study. It was reported by Lyman and Troiano[4] that the first carbide to form is cementite at all temperatures, but Cr7C3 can appear after prolonged heat treatment, which can be expected according to the vertical section through the Fe-Cr-C phase diagram at 4 mass pct Cr (Figure 2). It is evident that Cr7C3 should play a dominant role for the steel with 1 mass pct C if there is sufficient time for diffusion of Cr. Evidently, in the present study, this was not the case, even at the highest temperatures examined, and diffusion of Cr should be even less important at lower temperatures. In the extreme case, there will be no diffusion of Cr during the transformations and all new phases should form with the same alloy content relative to Fe as the parent austenite, so-called paraequilibrium. Figure 3 shows the vertical section for 4 mass pct Cr showing the austenite equilibria under paraequilibrium conditions together with the equilibrium line for Cr7C3. It reveals that cementite should be completely dominating over Cr7C3 under such conditions. Both Figures 2 and 3 were calculated with the THERMO-CALC Software using the TCFE6 database (Thermo-Calc Software AB, Stockholm, Sweden).[7]

Isopleth for the Fe-Cr-C system at 4.12 mass pct Cr[7]

Equilibria of austenite at 4.12 mass pct Cr in the Fe-Cr-C system assuming no mobility of Fe or Cr, so-called paraequilibrium. The dashed line indicates the γ/M/C3 equilibrium line[7]

3 Comparison Of The Transformation Behavior Of The Plain Carbon 1.67 Mass Pct C And The 4.12 Mass Pct Cr 0.88 Mass Pct C Steel

The microstructures of a plain carbon steel with 1.65 mass pct C were examined by Modin and Modin,[8] and a similar steel with 1.67 mass pct C was more recently studied by Borgenstam et al.[6] In that study, primary plates of cementite were found already above the eutectoid temperature and pearlite appeared below the eutectoid temperature. The growth of pearlite was restricted due to the presence of cementite plates, but, where the pearlite/austenite interface could be seen, it was usually as smooth as for ordinary pearlite. However, at decreasing temperatures, a sudden change occurred. Instead of spreading radially as pearlite, the eutectoid product now covered primary plates of cementite forming acicular shapes (Figure 4), and then such shapes also formed without a central plate of cementite (Figures 5(a) and (b)). It was suggested that this should be regarded as inverse bainite, because cementite seemed to be the leading phase instead of ferrite as in bainite. When nucleated at a point inside a grain of austenite, acicular units grew in many different directions, forming spiky nodules (Figure 6). Toward lower temperatures, the tips of acicular units became blunter and finally developed almost fanlike shapes (Figure 7), which together formed rather spherical nodules. Cementite still seemed to be the leading phase, but that could be seen only at high magnification. Further down in temperature, the nodules again grew spikier (Figure 8), this time with ferrite as the leading phase, although there was still a tendency to form plates of cementite (Figure 9). At an even lower temperature, the acicular units appeared often in a zigzag pattern. They were identified as lower bainite (Figure 10).

Acicular eutectoid formed during 25 s at 773 K (500 °C) in the 1.65 mass pct C steel. LOM micrograph at 700 times magnification[8]

Spiky nodules of inverse bainite formed during 60 s at 723 K (450 °C) in the 1.65 mass pct C steel. LOM micrograph at 600 times magnification[8]

Fanlike eutectoid formed during 600 s at 623 K (350 °C) in the 1.65 mass pct C steel. LOM micrograph at 5000 times magnification[8]

Spiky nodules formed during 2 h at 573 K (300 °C) in the 1.65 mass pct C steel. LOM micrograph at 550 times magnification[8]

Thin spikes of ferrite (white) and shorter plates of cementite (dark). Formed during 1 h at 573 K (300 °C) in the 1.65 mass pct C steel. It was etched for carbides and in the insert also in Nital, which made the primary plate of ferrite dark. Two arrows mark the same platelet of cementite. SEM micrograph at 12,000 times magnification[6]

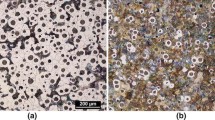

The transformation behavior of the synthetic steel with 4.12 mass pct Cr 0.88 mass pct C was very similar to the commercial steel of similar composition studied by Lyman and Troiano. It was evident that their TTT diagram, reproduced in Figure 1, could also be applied to the present steel. Contrary to the steels with 1.65 and 1.67 mass pct C, there were no primary Widmanstätten plates of cementite close to the pearlite nose, but Widmanstätten plates of carbide reappeared at lower temperatures. The pearlite interface was generally fairly smooth at temperatures above the nose of the TTT curve, but it gradually developed a more jagged growth front (Figure 11) from 923 K (650 °C). No signs of primary carbide plates leading to the jagged front were detected by the SEM (Figure 12).

At 873 K (600 °C), the pearlite developed into an acicular structure (Figure 13). In LOM, the structure was very similar to what was identified as inverse bainite in the 1.65 mass pct C steel (Figure 4). However, the SEM micrograph in Figure 14 reveals that the internal structure is very similar to the pearlite formed at 923 K (650 °C) in Figure 12. It is remarkable that single plates of carbide surrounded by layers of ferrite were often observed sticking out into the austenite. That phenomenon was first observed at 898 K (625 °C). A close examination of the microstructure at that temperature supported that the transition from ordinary pearlite to the acicular units was gradual. At 773 K (500 °C), a similar acicular microstructure was found (Figure 15), but here, Widmanstätten plates of carbide had also formed. This specimen was etched for a longer time in order to reveal these plates better. At the lower left corner, there is an example where the acicular structure is about to cover a primary plate. However, it seems that the acicular shape of the two-phase microstructure is not generally caused by a primary Widmanstätten plate. The same type of microstructure was formed at 723 K (450 °C).

Acicular microstructure together with plates of Widmanstätten carbide formed during 2 h at 773 K (500 °C) in the 4.12 mass pct Cr 0.88 mass pct C steel. Deeper etch than in Fig. 14. SEM micrograph

At 673 (400 °C), a new acicular microstructure appeared (Figures 16(a) and (b)) with a completely different internal structure. Along the centerline of the units in both micrographs in Figures 16(a) and (b), the carbide lamellae are directed in the main growth direction; A memory of the advancing tip of the acicular unit but further away from the centerline, the lamellar structure is generally directed at an angle to the main growth direction. The carbide constituent now seems to branch frequently, but that is less evident because the lamellae have broken up into laths and the main growth direction in Figure 16(a) may not fall very close to the plane of sectioning. The tip of the unit in Figure 16(b) illustrates a plate of carbide that is covered by layers of ferrite. In Figure 16(a), there are some examples of ferrite sticking out from the two-phase mixture but not as thin plates. This is shown at higher magnification in Figure 17, which also shows some thin plates of carbides sticking out. Figure 18 from 578 K (375 °C) resembles the fanlike structure found in the plain high-carbon steel (Figure 7). It is still present in Figure 19 from 623 K (350 °C), but now together with a new acicular microstructure with ferrite as the leading phase. It is shown better at higher magnification in Figure 20.

(a) Acicular microstructure formed during 3 h at 673 K (400 °C) in the 4.12 mass pct Cr 0.88 mass pct C steel with central carbide lamellae in the main growth direction. Identified as inverse bainite. SEM micrograph. (b) Another area similar to (a), but the tip of the acicular unit is carbide covered by layers of ferrite

Same specimen as in Figs. 16(a) and (b). Black arrows show thin plates of carbide sticking out from the two-phase mixture. White arrow shows ferrite sticking out. SEM micrograph

At 573 K (300 °C), there is another drastic change. At this temperature, only thin acicular units appear (Figure 21), and sometimes they appear in zigzag pattern (Figure 22). Their internal structure was similar to the one in the zigzag units in the 1.67 mass pct carbon steel (Figure 10), which was classified as regular lower bainite.[6] A similar microstructure was observed at 523 K (250 °C, Figure 23). In particular, at the lower right-hand corner of Figure 23, there is a thin plate of ferrite without direct contact to any carbide in this specific section through the specimen. It is evident that ferrite was the leading phase for edgewise growth, just as it was in Figure 20 from 623 K (350 °C). Similar observations were made in the 1.67 mass pct C steel.[6]

4 Discussion

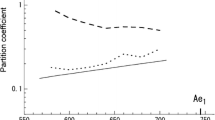

The microstructural changes occurring from 923 K to 723 K (650 °C to 450 °C) and illustrated in Figures 12, 14, and 15 did not appear in the plain, high-carbon steels. These changes were recently studied by Goldenstein et al.[10] In their steel with 5.2 mass pct Cr and 0.46 mass pct C, the microstructure quickly developed into the so-called arborescent eutectoid with a main stem and sidearms at right angle.[2] There has been general agreement that this is a microstructure found in alloyed steels, and Goldenstein et al. presented a sketch showing how chromium was partitioned between the growing ferrite and carbide at the tip of the outgrowths of a single carbide plate covered by ferrite layers, as the ones shown in Figure 14. They also presented some indication of Cr7C3 carbide in this two-phase mixture. It is uncertain whether the presence of this carbide should be accepted for the present steel with only 4.12 instead of 5.2 mass pct Cr, in particular, since Lyman and Troiano[4] found that cementite is the carbide that forms primarily in a very similar steel.

Regardless of whether the carbide is cementite or Cr7C3, it seems quite reasonable that the two-phase mixture in Figures 13 through 15 forms under at least some partitioning of chromium between ferrite and carbide. The formation of the single carbide platelets covered with ferrite could then be explained by the necessity of the carbide to attract chromium in order to grow. It could be supplied by interface diffusion from the ferrite/austenite contact if ferrite is covering the sides of the carbide, and the growth mechanism of the carbide could operate efficiently if the layers of ferrite cover the plate of carbide all the way to the tip. It may be suggested that the transition to the new acicular microstructures in Figure 16 is triggered by a transition from partitional to partitionless growth.

The arborescent eutectoid was not observed in the present steel, but the related microstructure shown in Figures 13 through 15 continued down to 723 K (450 °C). It is worth noting that in LOM it was not possible to distinguish between the two acicular structures, inverse bainite in the plain high-carbon steel in Figure 4 and the structure originating from pearlite in Figure 13. Since no sharp transition could be seen between the regular pearlite formed close to the eutectoid temperature and the acicular units formed at lower temperatures, it is proposed that this acicular microstructure should be called acicular pearlite.

Goldenstein and Cifuentes[10] only studied transformations down to 823 K (550 °C), and it is not known whether the new acicular microstructure shown in Figure 16 from 673 K (400 °C) should occur in their steel as well. That microstructure is very similar to what was classified as inverse bainite for the plain high-carbon steels and reproduced in Figures 4 and 5. The name was chosen in order to indicate that cementite is the leading phase and not ferrite as in bainite. In the high-carbon steels, inverse bainite appeared at 773 K (500 °C), and in the present steel, it appeared at 673 K (400 °C). The difference may be explained by the need of a critical supersaturation of cementite in austenite, because at comparable temperatures, it is lower in the present steel. The similarity with the plain high-carbon steels is further demonstrated by the appearance of the fanlike eutectoid before bainite appears and dominates completely at lower temperatures. Compare Figures 7 and 18.

It may be concluded that, except for the gradual development of pearlite into an acicular microstructure, which might be connected to the presence of chromium, the changes from pearlite at the higher temperatures to inverse bainite, to fanlike eutectoid, and finally to lower bainite are the same in the chromium steel as in the plain, high-carbon steels, recently studied by Borgenstam et al.[6] A summary of the change in microstructures with decreasing temperature can be observed in Table II.

In both steels, lower bainite quickly predominates after the first appearance of acicular ferrite. In the plain 1.67 mass pct C steel, the first thin units had an irregular microstructure, possibly because there was a strong tendency to nucleate new plates of cementite in contact with the leading plate of ferrite (Figure 9). That phenomenon was not observed in the Cr steel, possibly because of the much lower carbon content, 0.88 instead of 1.67 mass pct. The thin units of lower bainite were thus of the regular type that predominated at temperatures below the irregular type in the plain high-carbon steel.

The observation of very thin plates of ferrite, possibly leading the edgewise growth of lower bainite, as in Figure 23 from 523 K (250 °C), may be taken as an indication that the diffusionless hypothesis of bainite formation does not even apply at such low temperatures. Such a plate with a thickness of less than 40 nm is not much thicker than the platelets of cementite in the bainite unit. Considering the size of the cementite particle, the plate of ferrite is too thin to be the subunit postulated by Oblak and Hehemann,[11] who suggested that the cementite particles should later precipitate inside the plate of ferrite.

5 Comparison With Other Steels

With this new understanding of the eutectoid transformations in steel, it may be possible to reinterpret earlier metallographic studies. In particular, Modin and Modin, who made the study of a steel with 1.65 mass pct carbon,[8] which was the starting point of the renewed interest in inverse bainite, actually studied five plain carbon steels from 0.18 to 1.65 mass pct carbon.[8,12,13] They presented some further results that may be relevant to the present discussion of inverse bainite. The microstructure in Figure 24 was observed at 873 K (600 °C) together with large amounts of pearlite in the steel with 1.18 mass pct carbon. It was originally identified as bainite, but it now seems more probable that it is inverse bainite with cementite as the leading phase. A similar structure was observed at 823 K (550 °C) together with a small pearlite nodule on one side of a grain boundary (Figure 25). Electron microscopy revealed that a layer of cementite covered the grain boundary in similar regions, indicating that cementite forms before ferrite. In this case, Modin and Modin were more careful and described the structure as bainitelike. At 773 K (500 °C), pearlite was still quite predominant, but at 723 K (450 °C), an acicular microstructure suddenly dominated the picture completely by forming spiky nodules (Figure 26). At 673 (400 °C), the spikes developed fanlike units (Figure 27). The microstructures in Figures 26 and 27 were identified as bainite by Modin and Modin,[8] but the sequence of microstructures rather indicates that they are inverse bainite, the latter one being of the fanlike type. At 623 K (350 °C), spikes again appeared but seemed to be of a different kind (Figure 28), now known to be a sign of the transition to bainite.[6] At 573 K (300 °C), lower bainite predominated completely (Figure 29). This steel with 1.18 mass pct C was, thus, found to display the same microstructural changes with temperature as the steels with 1.65 and 1.67 mass pct C.

Inverse bainite formed during 2 s at 873 K (600 °C) in a 1.18 mass pct C steel. LOM micrograph at 1800 times magnification[8]

Inverse bainite on both sides and pearlite on one side of a grain boundary formed during 2 s at 823 K (550 °C) in a 1.18 mass pct C steel. LOM micrograph at 1800 times magnification[8]

Spiky nodules formed during 34 s at 723 K (450 °C) in 1.18 mass pct C steel. LOM micrograph at 600 times magnification[8]

Fanlike inverse bainite formed during 120 s at 673 K (400 °C) in 1.18 mass pct C steel. LOM micrograph at 1800 times magnification[8]

Spiky microstructure formed during 540 s at 723 K (450 °C) in 1.18 mass pct C steel. LOM micrograph at 750 times magnification[8]

Lower bainite formed during 30 min at 573 K (300 °C) in 1.18 mass pct C steel. LOM micrograph at 150 times magnification[8]

In the plain carbon steel with 0.86 mass pct C, studied by Modin and Modin,[12] the role of inverse bainite seems more uncertain. Figure 30 from 873 K (600 °C) and Figure 31 from 823 K (550 °C) very much resemble Figures 24 and 25 and were originally identified as bainite. It is now tempting to identify them as inverse bainite with cementite as the leading phase. This identification is supported by an electron micrograph that indicated that there was a layer of cementite covering the grain boundaries. At 773 K (500 °C), there was suddenly a large amount of feathery bainite with clear evidence of ferrite being the leading phase.

Pearlite and an acicular microstructure, possibly inverse bainite formed during 2 s at 873 K (600 °C) in plain carbon steel with 0.86 mass pct C. LOM micrograph at 1600 times magnification[8]

Pearlite and an acicular microstructure, possibly inverse bainite formed during 2 s at 873 K (550 °C) in 0.86 mass pct C steel. LOM micrograph at 1800 times magnification[8]

The occurrences of various microstructural constituents in the three steels studied by Modin and Modin are compared in Table III. It should be remembered that the occurrence of each constituent depends on the competition with other constituents. As a consequence, the range of existence of a specific constituent does not only represent its own properties.

6 Summary

Goldenstein et al.[5,10] recently reviewed studies of nonpearlitic eutectoid microstructures formed above the bay in alloyed steels and added new information on a steel with 5.2 mass pct Cr and 0.46 mass pct C. In the present work, information on steel with 4.12 mass pct Cr 0.88 mass pct C was added. The information was compared to microstructures in plain carbon steels with 1.65 and 1.67 mass pct C. The change of a microstructure looking like ordinary pearlite close to the eutectoid temperature to acicular shapes at decreasing temperatures was confirmed, but the dendritelike shapes, studied by Goldenstein et al., were not observed. The development of the acicular shape was very gradual, and whatever role some crystallographic aspect may play, it is proposed that all these structures should be regarded as closely related to pearlite and the term acicular pearlite is suggested. At lower temperatures, a striking similarity with the high-carbon steels was found, and it is thus proposed that the nonpearlitic eutectoid microstructures in alloyed steels have the same origin as in plain carbon steels with very high carbon contents. The microstructural changes with temperatures below the pearlitic range of temperatures should then depend simply on the effect of temperature on the supersaturation of cementite in austenite and an even stronger effect on the supersaturation of ferrite at lower temperatures. An acicular eutectoid with cementite as the leading phase, which was previously identified as inverse bainite,[6] is kinetically favored to ordinary pearlite as the supersaturation of cementite in austenite increases toward lower temperatures, but at even lower temperatures, acicular ferrite will be even more favored and bainite will form.

It is concluded that inverse bainite is favored by depressing the bainite start temperature to lower temperatures. That can be accomplished either by alloying additions, particularly of carbide forming elements as chromium, or by increasing the carbon content well over the eutectoid composition. It is possible that the first appearance of inverse bainite on lowering the transformation temperature of Cr steels coincides with the transition from transformation under diffusion of Cr to transformation without.

Even though there is no bay in the TTT diagram of the plain carbon steels, the development of the eutectoid products with decreasing temperature seems to be repeated in alloyed steels with a bay. It has been proposed[6] that the development simply depends on the competition between platelike growth of cementite and ferrite. Ferrite is favored by sufficiently low temperatures due to the increasing supersaturation of ferrite in austenite resulting from the shape of the Fe-C phase diagram.

References

E.S. Davenport and E.C. Bain: Trans. AIME, 1930, vol. 90, pp. 117–54.

H. Jolivet: J. Iron Steel Inst., 1939, pp. 391–419.

E.P. Klier: Trans. AIME, 1945, vol. 162, pp. 186–95.

T. Lyman and A.R. Troiano: Trans. AIME, 1945, vol. 162, pp. 196–222.

H. Goldenstein, J.A.B. Cifuentes, and A. Sinatora: Solid-to-Solid Phase Transformations in Inorganic Materials, TMS, Warrendale, PA, 2005, pp. 673–86.

A. Borgenstam, P. Hedström, M. Hillert, P. Kolmskog, A. Stormvinter, and J. Ågren: Metall. Mater. Trans. A, 2011, vol. 42A, pp. 1558–74.

J.O. Anderson, T. Helander, L. Höglund, P.F. Shi, and B. Sundman: CALPHAD, 2002, vol. 26, pp. 273–312.

H. Modin and S. Modin: Microstructures in Three Isothermally Transformed Carbon Steels with High-Carbon Contents, Meritförlaget, Stockholm, 2000.

H. Warlimont: Special Report 93, Iron Steel Institute, London, 1965, pp. 149–51.

H. Goldenstein and J.A.B. Cifuentes: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 1747–55.

J.M. Oblak and R.F. Hehemann: Transformation and Hardenability in Steels, Climax Molybdenum Co., Ann Arbor, MI, 1967, pp. 15–38.

H. Modin and S. Modin: Jernkont. Ann., 1955, vol. 139, pp. 481–515.

H. Modin and S. Modin: Jernkont. Ann., 1958, vol. 139, pp. 37–80.

Acknowledgments

This work was performed within the VINN Excellence Center Hero-m, financed by VINNOVA, the Swedish Governmental Agency for Innovation Systems, Swedish Industry, and KTH (Royal Institute of Technology). The authors express their profound appreciation to Professor Emeritus Mats Hillert for his contributions to this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 10, 2011.

Rights and permissions

About this article

Cite this article

Kolmskog, P., Borgenstam, A. Eutectoid Transformations in 4.12 Mass Pct Cr 0.88 Mass Pct C Steel. Metall Mater Trans A 42, 3941–3951 (2011). https://doi.org/10.1007/s11661-011-0794-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-011-0794-9