Abstract

The correlation of the microstructure and mechanical properties of thermomechanically processed low-carbon steels containing B and Cu was investigated in this study. Eighteen kinds of steel specimens were fabricated by varying B and Cu contents and finish cooling temperatures (FCTs) after controlled rolling, and then tensile and Charpy impact tests were conducted on them. Continuous cooling transformation (CCT) diagrams of the B-free and B-added steel specimens under nondeformed and deformed conditions were constructed by a combination of deformation dilatometry and metallographic methods. The addition of a very small amount of B remarkably decreased the transformation start temperatures near a bainite start temperature (Bs) and thus expanded the formation region of low-temperature transformation phases such as degenerate upper bainite (DUB) and lower bainite (LB) to slower cooling rates. On the other hand, a deformation in the austenite region promoted the formation of quasipolygonal ferrite (QPF) and granular bainite (GB) with an increase in transformation start temperatures. The tensile test results indicated that tensile strength primarily increased with decreasing FCT, while the yield strength did not vary much, except in some specimens. The addition of B and Cu, however, increased the tensile and yield strengths simultaneously because of the significant microstructural change occasionally affected by the FCT. The Charpy impact test results indicated that the steel specimens predominantly composed of LB and lath martensite (LM) had lower upper-shelf energy (USE) than those consisting of GB or DUB, but had nearly equivalent or rather lower ductile-to-brittle transition temperature (DBTT) in spite of the increased strength. According to the electron backscatter diffraction (EBSD) analysis data, it was confirmed that LB and LM microstructures had a relatively smaller effective grain size than GB or DUB microstructures, which enhanced the tortuosity of cleavage crack propagation, thereby resulting in a decrease in DBTT.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Over the past decades, structural steel plates have been steadily developed to have high strength and toughness with good weldability using different alloying elements and heat-treatment conditions, and applied to building, bridge, pressure vessel, pipeline, and offshore structures. The recent development of thermomechanical control process (TMCP) technology composed of controlled rolling and accelerated cooling has shown that it can efficiently produce high-strength steel plates with low carbon or ultralow carbon, which provides a good combination of toughness and weldability by lowering the volume fraction of carbide-containing microconstituents at the expense of strength and hardness.[1–3]

Recently, with ever increasing environmental requirements, many studies of the utilization of scrap in steelmaking process have been actively carried out to reduce the cost for refining tramp elements and to maximize the recyclability of steel scraps. The Cu, a representative tramp element, can contribute to solid solution strengthening as well as precipitation strengthening by Cu precipitation, because it has a relatively high solubility in austenite but is almost insoluble in ferrite.[4–6] It also improves hardenability and lowers the austenite-ferrite transformation temperature, leading to a finer ferrite microstructure. Meanwhile, it is noted that a small amount of B efficiently increases the hardenability of steels, because it retards the diffusional transformation of austenite to ferrite through its segregation to austenite grain boundaries.[7] Therefore, the application of TMCP to the low-carbon or ultralow-carbon steels containing B and Cu is very attractive for the development of high-strength and high-toughness steel plates from the viewpoint of recyclability and economics.

The requirement for high-strength steel plates with high toughness and good weldability has led to intensive examination of continuously cooled microstructures of low-carbon or ultralow-carbon steels. The nonequiaxed ferritic microstructures usually formed during TMCP have been regarded as very complicated compared to the equiaxed or polygonal ferritic microstructures of conventional hot-rolled steels. There are many difficulties in identifying the phases and sometimes serious confusion in the terminology of the microstructures.[8–11] The temperature range for the formation of the nonequiaxed ferritic microstructures with different morphologies and properties is intermediate, between those at which austenite transforms to equiaxed ferrite and to martensite, and thus is similar to that in which bainite forms in medium-carbon steels. These nonequiaxed ferritic microstructures are to be expected over a wide range of cooling rates during continuous cooling, and generally have a variety of mixed phases transformed between purely diffusional and displacive transformations in association with minor islands of carbon-enriched austenite and martensite-austenite (MA) constituents that depend on the level of carbon partitioning in the remaining austenite and the thermal cycle. Therefore, systematic studies of mechanical properties in correlation with their complicated microstructures are needed in thermomechanically processed low-carbon steels.

In the present study, based on the continuous cooling transformation (CCT) diagrams of steels containing B and Cu, steel specimens having various low-temperature transformation phases were fabricated by varying the finish cooling temperature (FCT), and their microstructures were analyzed. Tensile and Charpy impact tests were conducted on them in order to investigate the correlation between the microstructure and mechanical properties of thermomechanically processed low-carbon steels containing Cu and B. In particular, the effective grain size of various low-temperature transformation phases was characterized by determining their crystallographic units using electron backscatter diffraction (EBSD) analysis.

2 Experimental

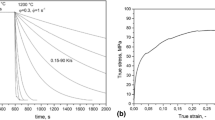

Six kinds of steels with different B and Cu contents, as shown in Table I, were prepared by melting in a vacuum-induction furnace. For convenience, the B-free steels containing 0, 0.5, and 1.5 wt pct Cu are referred to as “0Cu,” “0.5Cu,” and “1.5Cu,” respectively; in addition, the B-added steels are referred to as “0Cu-B,” “0.5Cu-B,” and “1.5Cu-B,” respectively. Nondeformation and deformation dilatometric tests were performed using a deformation dilatometer (model: Gleeble 3500, Dynamic Systems Inc., Los Angeles, CA). Dilatometric specimens were machined into cylindrical rods with a diameter of 8 mm and a length of 12 mm. Figure 1 shows the schedule for the nondeformed and deformed CCT diagrams. The microstructures after deformation and the thermal cycles were characterized using an optical microscope (model: EPIPHOT 200, Nikon, Tokyo, Japan) and a microhardness tester (model: FM-700, Future-tech, Kawasaki, Japan). For a given cooling rate, transformation start and finish temperatures were determined for each specimen by locating the temperature at which the dilatation-temperature curve showed a deviation from linearity. Nondeformed and deformed CCT diagrams were constructed with the microstructure observation, dilatometric, and hardness test results to simulate the controlled hot rolling and cooling of low-carbon steels containing B and Cu.

Based on the deformed CCT diagrams, three TMCP conditions were designed to obtain different microstructures by varying the FCT. After austenitization at 1150 °C for 2 hours, a rolling was started at 980 °C and finished at 820 °C, which was the temperature of the austenite single-phase region above Ar3. A first hot rolling to a reduction of approximately 50 pct was conducted to form plate in 7 passes within a first temperature range in which austenite recrystallizes, while an overall grain refinement effect was expected by a second rolling to a reduction of above 60 pct in 7 passes within a second temperature range, somewhat lower than the first temperature range, at which austenite does not recrystallize and above the Ar3 transformation temperature. After the finish rolling, the specimens were acceleratedly cooled down to the different FCTs of 250 °C, 350 °C, and 450 °C with the cooling rate of approximately 20 °C/s, followed by cooling in air. The initial and final thicknesses of the steel plates were 100 and 15 mm, respectively. Thus, the total rolling reduction ratio was 85 pct.

After the longitudinal-transverse plane of the region at a quarter thickness of the rolled specimens was polished and etched by a 2 pct nital solution, microstructures were observed using an optical microscope and a scanning electron microscope (SEM), and their hardness was measured under a load of 300 g. A more detailed metallographic examination was performed on selected specimens using a transmission electron microscope (model: JEM 2100F, JEOLFootnote 1). Thin foils for transmission electron microscopy (TEM) were prepared in a twin-jet electrolytic polishing apparatus using a solution containing 5 vol pct perchloric acid and 95 vol pct methanol, and were examined at 200 kV. The analysis of the selected area diffraction pattern (SADP) was performed using Desktop Microsoft V2.2 software (Lucuna Laboratory, Beaverton, OR). The EBSD analysis was also conducted on the 0Cu, 0.5Cu, and 0Cu-B specimens by a field emission SEM (model: S-4300SE, Hitachi, Tokyo, Japan) in order to determine their effective grain size. The data were then interpreted by orientation imaging microscopy analysis software provided by TexSEM Laboratories, Inc., Draper, UT.

Round tensile specimens with a gage diameter of 6.35 mm and a gage length of 25.4 mm were prepared in the transverse direction and tested at room temperature at a crosshead speed of 5 mm/min using a 10-ton universal testing machine (model: Instron 5882, Instron Co., Norwood, MA). The data reported in this study represent an average of at least three tests. Charpy V-notch (CVN) impact tests were performed on standard specimens with a 10 × 10 × 55-mm size that were machined in the transverse-longitudinal orientation in the temperature range –196 °C to 20 °C using an impact tester with a 500-J capacity. In order to reduce errors in data interpretation, a regression analysis for absorbed energy as a function of test temperature was done by a hyperbolic tangent curve-fitting method. Based on the data obtained from the regression analysis, the ductile-to-brittle transition temperature (DBTT), which corresponds to the average value of the upper-shelf energy (USE) and lower-shelf energy, was determined.

3 Results

3.1 CCT Characteristics

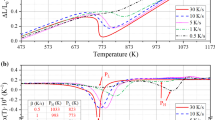

The nondeformed and deformed CCT diagrams of the 0.5Cu and 0.5Cu-B steels are presented in Figures 2(a) through (d). It is evident that the transformation start and finish temperatures gradually decrease as the cooling rate increases and, thus, low-temperature transformation phases are formed in the order of quasipolygonal ferrite (QPF), granular bainite (GB), degenerate upper bainite (DUB), lower bainite (LB), and lath martensite (LM). The QPF has an irregular grain boundary unlike polygonal ferrite, and the GB, as the name implies, is characterized by equiaxed bainitic ferrite grains with dispersions of MA constituents. The DUB has packets of parallel ferrite laths, where continuous metallic phases such as carbon-enriched austenite, martensite, and MA constituents are present in the interlath boundaries, while the LB contains finely dispersed carbides within the bainitic ferrite grains of the lath type. The LM is a highly dislocated structure conserving the prior austenite grain boundary. In this study, the LB/LM is regarded as a mixture of LB and LM, because it is difficult to distinguish between LB and LM except using TEM. The microstructures of the specimens fabricated in the present study were differentiated in terms of these categories.[3,8–11]

As expected, the addition of B shifts the transformation temperature ranges downward, leading to delay in the transformation of austenite to ferrite. In the nondeformed CCT diagrams (compare Figures 2(a) and (b)), the B addition to the 0.5Cu steel remarkably decreases the transformation start temperatures close to a bainite start temperature (Bs) and thus expands the transformation field of DUB and LB to slower cooling rates. The formation of QPF is completely suppressed, even at the slowest cooling rate of 0.2 °C/s. In the B-added steel (0.5Cu-B steel), LM begins to form at relatively slower cooling rates as compared to the B-free steel (0.5Cu steel), because the transformation finish temperatures decrease due to the B addition. The LB is transformed at higher temperatures than the martensite start temperature (Ms) prior to the formation of LM. The effect of B on the transformation behavior of deformed CCT diagrams is almost the same as that observed in the nondeformed CCT diagrams (compare Figures 2(c) and (d)). In general, it is well recognized that a small amount of B dramatically enhances the hardenability of steels by preventing the nucleation of ferrite due to the boron atoms segregated to the austenite grain boundaries.[7,11]

On the other hand, a deformation in the austenite region brings about a significant increase in the transformation start temperatures in both the 0.5Cu and 0.5Cu-B steels, because it accelerates the transformation from austenite to ferrite resulting from the increase in deformation bands and dislocations regarded as ferrite nucleation sites (compare Figures 2(a) and (c) and also Figures 2(b) and (d)). As a result of the increased transformation start temperature, the formation of QPF and GB is increased in the 0.5Cu and 0.5Cu-B steels, respectively. Because the transformation finish temperatures remain almost unchanged by the deformation, the cooling rates at which LM is introduced to the microstructure do not differ noticeably by the deformation. The resultant microstructures can also be finer by the B addition and deformation in the austenite region.

3.2 Microstructure

All the specimens are composed of various low-temperature transformation phases, including GB, DUB, and LB/LM, due to the rapid cooling rate of approximately 20 °C/s and FCTs of 200 °C to 500 °C. Figures 3(a) through (f) are optical micrographs of the specimens fabricated at the FCT of approximately 350 °C. Their microstructures were identified by the hardness and their own morphologies, and the volume fraction of each phase was measured by an image analyzer. The results are summarized in Table II. As indicated by previous deformed CCT diagrams (Figures 2(c) and (d)), GB and DUB, and LB/LM, are usually formed in the 0.5Cu and 0.5Cu-B steels, respectively, at the cooling rate of 20 °C/s, which is the same as the TMCP conditions of the present study. The B-free specimens (0Cu, 0.5Cu, and 1.5Cu specimens) mainly consist of GB, and here, equiaxed MA constituents 0.5 to 2.0 μm in size are uniformly distributed, as shown in Figure 4(a). The Cu addition increases the volume fraction of DUB because Cu, an austenite stabilizing element, enhances hardenability and lowers the transformation temperature of austenite to ferrite, while its matrix shows almost no variations with the FCT (Figures 3(a) through (c) and Table II). In detail, the 0Cu specimen consists of GB overall, whereas the 0.5Cu and 1.5Cu specimens have a DUB of 15 to 35 vol pct together with GB. In the 0.5Cu and 1.5Cu specimens, a small amount of LB and LM is also observed when the FCT goes below 400 °C. As a result, the hardness of the B-free specimens varies from 235 to 305 Hv in accordance with the kind and volume fraction of low-temperature transformation phases. In the B-added specimens (0Cu-B, 0.5Cu-B, and 1.5Cu-B specimens), however, a considerable amount of LB and LM is found, unlike the B-free specimens the microstructure of which consists primarily of GB. In particular, in the 0.5Cu-B and 1.5Cu-B specimens fabricated at the FCTs below the Ms, the volume fraction of LB and LM exceeds 95 pct (Table II). The 0Cu-B specimen contains somewhat more GB and DUB than the 0.5Cu-B and 1.5Cu-B specimens. The SEM observation results exhibit that the average thickness of the prior austenite pancake is approximately 10 μm, as shown in Figure 4(b).

Figures 5(a) and (b) are TEM bright-field and centered dark-field images, respectively. They show a typical DUB microstructure in the 1.5Cu specimen. Second phases are distributed primarily around the lath boundaries of bainitic ferrites. According to the SADP of the area, including second phases (Figures 5(c) and (d)), second phases are identified as MA constituent, because diffraction patterns of ferrite and retained austenite appear simultaneously and have a Kurdjumov–Sachs (K-S) orientation relationship of [111] α //[110] γ and \( (\bar 110)_\alpha //(1\bar 11)_\gamma\), respectively. In general, an excess amount of MA constituents inside GB or DUB readily deteriorates the toughness of high-strength steels, because some applied load is locally concentrated at these constituents and thus should be controlled adequately in strength and toughness considerations.[12,13] It has been found that the MA constituent is formed through the process controlled by carbon diffusion when some part of carbon-enriched austenite transformed to martensite, and the size and amount depend on various parameters such as the chemical composition, cooling rate, FCT, etc.[2,12,13]

3.3 Tensile Properties

Figures 6(a) through (d) show the variations in yield and tensile strengths, yield ratio (YR), and elongation as a function of FCT. The stress-strain curves of all the specimens showed continuous yielding behaviors. The B-added specimens have higher tensile strength by over 300 MPa and lower elongation by 5 to 10 pct than the B-free specimens. In general, the tensile strength varies with the volume fraction of hard phases and with the degree of strain hardening.[1–3,14] The 1.5Cu-B specimen predominantly composed of LB and LM shows the highest tensile strength, having above 1100 MPa at all FCTs. As the FCT decreases, the tensile strength gradually increases, irrespective of B and Cu additions, because the volume fraction of harder phases transformed at a lower temperature in the order of DUB, LB, and LM is increased with decreasing FCT.

The yield strength of most specimens does not vary much with FCT except for the 0Cu-B specimen, which has relatively much higher yield strengths at the FCTs lower than the Ms. Because yielding in multiphase steels primarily occurs in the relatively ductile phase, the yield strength largely depends on the volume fractions of GB and DUB that are relatively softer than LB or LM. Accordingly, compared with the tensile strength, which is sensitive to the volume fraction of harder low-temperature transformation phases, the yield strength does not change much, because the major phases hardly show variation in microstructure. Nevertheless, the Cu addition clearly increases the yield and tensile strengths in both B-free and B-added specimens because of its solid solution strengthening effect as well as the microstructure change caused by the enhanced hardenability. From Figures 6(a) and (b), the beneficial effect of Cu on the yield and tensile strengths is more apparent in the B-free specimens. In the B-added specimens, it changes differently in accordance with the FCT, which affects the presence of LB and LM.

The YR, that is, the ratio of yield strength to tensile strength, is closely associated with the deformability of structural materials.[3] The B-free specimens have lower YRs by 10 pct than the B-added specimens, because the tensile strength increases more abruptly than yield strengths with decreasing FCT. In materials for strain-based applications, a low YR value (<85 pct) is preferred. The elongation of the B-free specimens is approximately 16 to 24 pct, which is higher by 5 to 10 pct than that of the B-added specimens and hardly changes with the variation of FCT. The Cu addition, however, reduces the elongation of the B-free specimens, while it largely does not affect the YR and elongation of the B-added specimens.

3.4 Charpy Impact Properties

Figures 7(a) and (b) show the variations in CVN USE and DBTT as a function of FCT. In the specimens containing the same content of Cu, the B-added specimens usually show a lower USE than the B-free specimens. Specimens primarily consisting of GB have a relatively excellent USE of 100 to 160 J, while those containing LB and LM have a lower USE of 40 to 80 J. With an increase in the Cu content, the USE tends to reduce clearly in both the B-free and B-added specimens. However, it does not vary much according to FCT, except for the 0Cu-B, which has the lowest USE at the FCT of approximately 250 °C because of the rapidly increased volume fraction of LB and LM (Table II).

According to Figure 7(b), the DBTT of all the specimens is below –50 °C, showing good low-temperature toughness, and roughly lowers with the decrease in the FCT. The specimens fabricated at lower FCTs have similar or somewhat lower DBTT than those fabricated at higher FCTs, although those fabricated at lower FCTs have relatively higher strength than those fabricated at higher FCTs. It seems to be because low-temperature transformation phases have a difference in their overall effective grain size from the viewpoint of strength and DBTT. In Section IV, we will discuss the influence of the effective grain size on DBTT by determining the crystallographic units based on the EBSD analysis.

4 Discussion

The Cu addition to ferritic steels generally improves their hardness and strength by increasing the stability of austenite and by causing solid solution and precipitation hardening.[4–6] In the present study, it is confirmed that transformation start and finish temperatures decrease and the volume fraction of low-temperature transformation phases increases by the Cu addition, thereby leading to the increase in yield and tensile strengths. In order to scrutinize the effect of Cu on the phase transformation behavior and mechanical properties, detailed TEM observations were performed on the 0Cu and 1.5Cu specimens. In the 1.5Cu specimen, Cu precipitates such as 9R, 3R, and ε-Cu are hardly observed, but GB primarily constitutes the microstructure. Energy-filtered TEM observation results show that the substructure of the 1.5Cu specimen is changed slightly compared to the 0Cu specimen, as shown in Figure 8. The discrete striation is found perpendicular to the [001] α direction of the matrix. It is a case similar to the modulated structure reported in the alloy systems with spinodal decomposition.[15]

Although extensive studies have been carried out on the precipitation of Cu in ferritic steels, the initial stage of the microstructure prior to Cu precipitation was not fully understood. It was first reported by Hornbogen and Glenn[16] that bcc Cu clusters were initially formed and were coherent with the ferritic matrix in Fe-1.23 pct Cu alloy. Later, Youle, Ralph and Goodman[17,18] confirmed, using field-ion microscopy, that the hardness of the Fe-Cu alloy reached its peak value when the density of coherent bcc Cu clusters in the a matrix attained their maximum. Recent investigations of the Cu precipitation, using extended X-ray absorption fine structure, small-angle neutron scattering, TEM, and computer simulation, have suggested that the bcc Cu clusters are observed in a form of relatively regular morphology.[19] In the 1.5Cu specimen, the periodic array of striations perpendicular to the [001] α direction was observed and could be interpreted as the strain contrast of compositional fluctuations of Cu induced by the formation of fine coherent Cu regions in ferrite matrix, as reported in the alloys with a modulated structure (Figure 8).[15,19] Although the detailed description of the initial stage of the microstructure prior to Cu precipitation is beyond the scope of this study, it is also confirmed that the bcc Cu clusters are arranged in regular form, characterized by a periodic array of striations perpendicular to the [001] α direction.

In general, steels have a wide range of mechanical properties because they include various microstructures according to the chemical composition and heat-treatment conditions. Numerous studies of the correlation of the microstructure and mechanical properties of steels have been carried out for several decades.[1,2] All the steels fabricated in this study show a mixture of various low-temperature transformation phases such as GB, DUB, and LB/LM, due to the addition of B and Cu as well as the different FCTs. As the B and Cu contents increase, the enhanced hardenability promotes the formation of low-temperature transformation phases, irrespective of the FCT. In the B-free specimens, with increasing Cu content, the yield and tensile strengths increase, but the USE decreases because the Cu addition greatly affects the formation of DUB and LB/LM (Table II and Figures 6(a) and (b) and 7(a)). The 0.5Cu and 1.5Cu specimens fabricated at the FCTs lower than the Ms show a slight increase in tensile strength because of the formation of DUB and LB/LM. The variations in the yield strength, elongation, and USE are relatively smaller than that in the tensile strength, because the matrix does not change much with the FCT.

The B-added specimens have higher yield and tensile strengths and relatively lower USE than the B-free specimens at all the FCTs, due to the larger amount of LB/LM, except for the 0Cu-B specimen. Because the microstructure of B-added specimens is more affected by the FCT than that of the B-free specimen, the B-added specimens fabricated at the FCT above the Ms have lower strength, due to the presence of GB or DUB. In particular, the 0Cu-B specimen fabricated at the FCT of approximately 450 °C shows very low yield and tensile strengths among the B-added specimens but a relatively high USE of approximately 130 J, which is almost the same level as the B-free specimens, because their microstructure primarily consists of GB and DUB.

Figure 9 presents the property range of yield strength and USE, and their relation with microstructure. The USE tends to be disproportionate to the yield strength. The specimens primarily consisting of GB show a yield strength of 550 to 700 MPa and a USE of 130 to 170 J. As the volume fraction of DUB increases, the yield strength increases, but the USE decreases. However, the yield strength and USE of the specimens predominantly composed of LB and LM are 950 to 1050 MPa and 40 to 80 J, respectively. With the increase in the volume fraction of DUB, the yield strength decreases, but the USE increases, in contrast with the specimens consisting of GB. Accordingly, it is likely that the specimens composed of GB, DUB, and LB/LM will have properties between the combinations of the yield strength and USE. Indeed, the 0Cu-B specimen fabricated at the FCT of approximately 350 °C provides an excellent combination of a high yield strength of approximately 970 MPa and a high USE of approximately 140 J, among the specimens fabricated in the present study, because the microstructure is optimally mixed with LB/LM and DUB together with a GB of 10 vol pct.

Unexpectedly, the DBTT of the specimens does not seriously increase with decreasing FCT, although the strength increases due to the harder low-temperature transformation phases usually transformed at the lower FCTs. The USE obtained from the CVN impact data is commonly affected by the matrix phase and the type, volume fraction, and size of the secondary phases, while the DBTT mainly depends on the type and size of the phases and especially the effective grain size.[14,20,21] When many high-angled grains with large misorientations are finely formed, the effective grain size decreases, and thus the DBTT lowers. As is well known in the literature, nearly all strengthening mechanisms are accompanied by a reduction in toughness, except for grain size refinement.[1–3] The following modified Hall–Petch and Cottrell–Petch relationships indicate the yield strength (σ y ) and CVN DBTT (V Trs), as a function of common strengthening approaches in structural steels:[3]

where σ 0 refers to the friction strengthening, σ S to the solid solution strengthening, σ D to the dislocation strengthening, σ P to the precipitation strengthening, and D to the effective grain size or facet size for cleavage. In simple ferritic steels, D corresponds to the mean grain size of polygonal ferrite. However, in steels with more complex microstructures, it has been found that the mean effective grain size, usually characterized by crystal misorientations of at least 10 deg, more properly describes the microstructural parameter for D.[3,21]

In order to identify the effective grain size of GB, DUB, and LB/LM, EBSD analysis was conducted on the 0Cu, 0.5Cu, and 0Cu-B specimens. Figures 10(a) through (c) show the high-angle grain boundaries having a misorientation of 10 deg or higher in the specimens. The effective grain size of the 0Cu specimen primarily consisting of GB is roughly 3.5 μm, while that of the 0.5Cu specimen is slightly increased (Figures 10(a) and (b)). According to the distribution of grain boundary misorientations, from which the fraction of high-angle grain boundaries was measured, the 0Cu specimen shows the fraction of high-angle grain boundaries of 0.647, and the 0.5Cu specimen with a partial formation of GB shows the increased fraction of high-angle grain boundaries of 0.701. Kitahara and Morito[22,23] examined the morphology and crystallography of LM in Fe-C alloys in detail by a combination of TEM and EBSD, and observed that a block contains two groups (sub-blocks) of laths that were of two K-S variants with a misorientation of approximately 10 deg in low-carbon steels. Recently, Furuhara[24] studied the crystal orientation of bainitic ferrite in Fe-9Ni-0.15C and confirmed that the effective grain size of LB was relatively smaller than that of upper bainite (UB), because a packet of LB was divided by blocks containing a single variant of laths, whereas that of UB had laths of two K-S variants with a small misorientation (sub-blocks). As with these results, the 0Cu-B specimen predominantly composed of LB and LM has a very fine effective grain size, below 1.5 μm, and shows the highest fraction of high-angle grain boundaries of 0.738, compared to the 0Cu and 0.5Cu specimens (Figures 10(a) through (c)).[3] As mentioned earlier, because the increase in strength can be accompanied by deteriorating toughness, hard LB and LM phases can usually result in a decrease in USE or an increase in DBTT. Nevertheless, the specimens containing LB and LM have a DBTT similar to or rather lower than the other specimens, although they have a higher strength and lower USE. This could be explained in terms of the effective grain size.[20,21]

Figures 11(a) through (c) illustrate the schematic drawings of the cleavage crack propagation path in GB, DUB, and LB/LM structures. The unit crack path (UCP) is generally defined as the length of a crack in which the crack propagates almost linearly. Because subgrains inside the GB structure have similar angles to one another, the UCP classified as the effective grain size is large. The crack propagates long and straight during cleavage fracture and changes its path when meeting with high-angled GB grains (Figure 11(a)). The UCP of the DUB structure is also coarse, because blocks inside the packet of DUB have primarily low-angle boundaries and cracks proceed linearly without changing directions, as with the results of Furuhara (Figure 11(b)). On the other hand, the structure predominantly composed of LB and LM is irregular and has fine effective grains (Figure 11(c)). Thus, the crack frequently bends at high-angle block boundaries of LB or LM, and thus the UCP is short. The decreased UCP more effectively works as obstacles to the cleavage crack propagation because of the frequent tortuosity of cleavage crack, leading to the decrease in DBTT. Consequently, the specimens predominantly composed of LB and LM have near equivalent or rather lower DBTT compared to those containing GB or DUB, because very fine effective grains play a role in decreasing DBTT, in accordance with Eq. [2], although they have relatively higher strength.

In this study, high-strength and high-toughness steels having a varied range of the mechanical properties of yield and tensile strengths, USE, and DBTT, according to the microstructure, were successfully fabricated by controlling B and Cu contents and FCT. These findings represent that low-carbon steels having a high yield strength of above 1000 MPa and a high USE should contain LB and LM in conjunction with a reasonable amount of GB and DUB through the appropriate design of alloying elements and the TMCP conditions, which involves the refinement of prior austenite grains by an increased rolling reduction ratio in a nonrecrystallization region and accelerated cooling to the optimal FCT. Therefore, further studies of the development of high-strength steel plates with more excellent combinations of strength and toughness by modifying chemical compositions and TMCP conditions should be made in the future, and more in-depth studies are required for determining crystallographic microstructural factors and for introducing quantitative correlations between the microstructure and mechanical properties.

5 Conclusions

Based on the present investigation of the microstructure and mechanical properties of thermomechanically processed low-carbon steels containing B and Cu, the following conclusions can be drawn.

-

1.

The addition of a small amount of B remarkably decreased the transformation start temperatures and thus expanded the formation field of low-temperature transformation phases to slower cooling rate regions by improving hardenability, whereas a deformation in the austenite region promoted the formation of QPF and GB, due to the increase in transformation start temperatures during continuous cooling.

-

2.

As the FCT decreased, the tensile strength increased, while the yield strength did not vary much. The addition of B and Cu, however, largely increased both the tensile and yield strengths because of the solid solution strengthening effect and the microstructural change by the enhanced hardenability irrespective of the FCT.

-

3.

The yield strength and USE of the specimens primarily consisting of GB were 550 to 700 MPa and 130 to 170 J, respectively. As the volume fraction of DUB increased, the yield strength increased, but the USE decreased. On the other hand, the specimens predominantly composed of LB and LM showed a yield strength of 950 to 1050 MPa and a USE of 40 to 80 J. With increases in the volume fraction of DUB, the yield strength decreased, but the USE increased, in contrast with those primarily consisting of GB.

-

4.

The 0Cu-B specimen fabricated at the FCT of approximately 350 °C was optimally mixed with DUB and LB/LM together with a GB of 10 vol pct, and thus provided an excellent combination of a high yield strength of approximately 970 MPa and a high USE of approximately 140 J.

-

5.

The specimens predominantly composed of LB and LM had relatively lower USE than those mainly consisting of GB and DUB. However, the former specimens exhibited nearly a DBTT equivalent to or lower than the latter specimens, in spite of the increased strength. This was because the LB or LM microstructure had a relatively smaller effective grain size than the GB or DUB microstructure, according to the EBSD analysis data.

Notes

JEOL is a trademark of Japan Electron Optics Ltd., Tokyo.

References

I. Tamura, H. Sekine, T. Tanaka, and C. Ouchi: Thermomechanical Processing of High-Strength Low-Alloy Steels, Butterworth & Co. Ltd., London, UK, 1988.

T. Gladman: The Physical Metallurgy of Microalloyed Steels, The Institute of Materials, London, UK, 1997.

J.Y. Koo, M.J. Luton, N.V. Bangaru, R.A. Petkovic, D.P. Fairchild, C.W. Petersen, H. Asahi, T. Hara, Y. Terada, M. Sugiyama, H. Tamehiro, Y. Komizo, S. Okaguchi, M. Hamada, A. Yamamoto, and I. Takeuchi: Int. J. Offshore Polar Eng., 2004, vol. 14, pp. 2–10.

Y.N. Malinochka, G.Z. Koval’chuk, and V.N. Yarmosh: Met. Sci. Heat Treat., 1982, vol. 24, pp. 760–65.

S.S. Ghasemi Banadkouki and D.P. Dunne: ISIJ Int., 2006, vol. 46, pp. 759–68.

A. Fatehi, A.M. Elwazri, J. Calvo, and S. Yue: Proc. Materials Science and Technology 2008, TMS, Warrendale, PA, 2008, pp. 1562–70.

S.K. Banerji and J.E. Morral: Proc. Int. Symp. Boron in Steels, TMS-AIME, Warrendale, PA, 1979.

B.L. Bramfitt and J.G. Speer: Metall. Trans. A, 1990, vol. 21A, pp. 817–29.

G. Krauss and S.W. Thompson: ISIJ Int., 1995, vol. 35, pp. 937–45.

T. Hayashi, F. Kawabata, and K. Amano: Proc. Materials Solution '97 on Accelerated Cooling/Direct Quenching Steels, ASM INTERNATIONAL, Materials Park, OH, 1997, pp. 93–99.

P. Cizek, B.P. Wynne, C.H.J. Davies, B.C. Muddle, and P.D. Hodgson: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 1331–49.

B.C. Kim, S. Lee, N.J. Kim, and D.Y. Lee: Metall. Trans. A, 1991, vol. 22A, pp. 139–49.

J.H. Chen, Y. Kikuta, T. Araki, M. Yoneda, and Y. Matsuda: Acta Metall., 1984, vol. 32, pp. 1779–88.

Y.M. Kim, S.Y. Shin, H. Lee, B. Hwang, S. Lee, and N.J. Kim: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 1731–42.

J.C. Zhao and M.R. Notis: Acta Metall., 1998, vol. 46, pp. 4203–18.

E. Hornbogen and R.C. Glenn: Trans. TMS-AIME, 1960, vol. 218, pp. 1064–70.

A. Youle and B. Ralph: Met. Sci., 1972, vol. 6, pp. 149–52.

S.R. Goodman, S.S. Brenner, and J.R. Low, Jr.: Metall. Trans., 1973, vol. 4, pp. 2363–69.

T.-H. Lee, Y.-O. Kim, and S.-J. Kim: Philos. Mag., 2007, vol. 87, pp. 209–24.

B. Hwang, Y.M. Kim, S. Lee, N.J. Kim, and S.S. Ahn: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 725–39.

B. Hwang, Y.G. Kim, S. Lee, Y.M. Kim, N.J. Kim, and J.Y. Yoo: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 2107–14.

H. Kitahara, R. Ueji, N. Tsuji, and Y. Minamino: Acta Mater., 2006, vol. 54, pp. 1279–88.

S. Morito, X. Huang, T. Furuhara, T. Maki, and N. Hansen: Acta Mater., 2006, vol. 54, pp. 5323–31.

T. Furuhara, S. Morito, and T. Maki: Proc. 1st Int. Symp. on Steel Science, ISIJ, Kyoto, Japan, 2007, pp. 51–56.

Acknowledgments

This study was financially supported by a grant (Grant No. M2007010007) from the Fundamental R&D Program for Core Technology of Materials funded by the Ministry of Knowledge Economy, Gwacheon, Korea. The authors thank Professor Sunghak Lee, Dr. Sang Yong Shin, and Mr. Hyo Kyung Sung of Pohang University of Science and Technology (POSTECH, Pohang, Korea) for their help with the Charpy impact test analysis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 3, 2009.

Rights and permissions

About this article

Cite this article

Hwang, B., Lee, C.G. & Lee, TH. Correlation of Microstructure and Mechanical Properties of Thermomechanically Processed Low-Carbon Steels Containing Boron and Copper. Metall Mater Trans A 41, 85–96 (2010). https://doi.org/10.1007/s11661-009-0070-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-009-0070-4