Abstract

After waterflooding, the distribution of the remaining oil in low-permeability porous reservoirs is quite complicated. Strong heterogeneity of formations makes the waterflooding performance more complex. Therefore, accurate prediction and evaluation of the spatial distribution of the remaining oil and the waterflooding performance of low-permeability reservoirs are essential for understanding the waterflooding process and improving oil recovery. In the study, an empirical method is proposed to predict waterflooding performance combined with static and dynamic data for porous reservoirs. Static data, including logging curves, core porosity and permeability data, are adopted to classify the formation into three hydraulic flow units (HFUs). The proportions of the thicknesses of different HFUs (HFUp) are proposed to characterize the remaining oil distribution. In addition, a waterflooding performance prediction method based on the Koval method was built using dynamic production data. The results show that the HFUp plays the key role in predicting the distribution of the remaining oil in the research well group. The K-factor-based waterflooding prediction method is highly correlated with the history matching in low-permeability waterflooded layers. The study also found Type 3 HFUp shows a great effect in predicting the duration of the low water-cut oil production. Therefore, the empirical method can provide a quick and intuitive evaluation of waterflooding performance in space and time of low-permeability waterflooded reservoirs with the local average K-factor and the HFUp results. The empirical method is of great significance to evaluate the remaining oil, infilling of well pattern, and improving oil recovery.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Water injection can supply the formation pressure and achieve improved oil recovery, and has become the most common secondary development method (Kou et al. 2022; Rendel et al. 2022; Vledder et al. 2010). Now, many oil fields have developed by water injection, leading to the evaluation of waterflooding reservoirs more and more critical (Nasralla et al. 2018; Sari et al. 2020; Zhou et al. 2020). Therefore, prediction of the performance of the waterflooding process is significant to select the best candidates and implement of a successful oilfield development project.

After flooding, the injected water displaces the oil in the pore space, resulting in the reduction in oil saturation. The flooding process will be heterogeneous and unsynchronized due to the inherent inner heterogeneity of the reservoir rock (Al-Ibadi et al. 2020; Wang et al. 2021). The saturation and distribution of the remaining oil of the developing reservoir will continue to change during the waterflooding process (Jiang et al. 2022, 2021). Formation conditions, including the physical properties and fractures of the reservoir, will greatly influence the flooding process, also resulting in a complicated remaining oil distribution (Aljuboori et al. 2020; Gu et al. 2014). When there are some fractures in reservoirs, the injected water will advance preferentially along the fracture, so the remaining oil will generally distribute on both sides of the fractures (Belayneh et al. 2009; Chen et al. 2020). While in low-permeability porous reservoirs, the strong heterogeneity of the reservoirs is the most significant factor determining the waterflooding performance, making it very difficult to evaluate the distribution of remaining oil after the waterflooding (Friesen et al. 2017; Li et al. 2018). Therefore, accurately characterizing reservoir heterogeneity and quantifying its impact on production performance is an important basis for establishing a waterflooding prediction model.

The main governing factors of heterogeneity within reservoirs are mineralogy, lithology, and pore structure (Chen et al. 2021; Qiao et al. 2019; Wang et al. 2022). When the internal components of the reservoir rock are relatively stable, the heterogeneity of the reservoirs is chiefly determined by porosity, permeability, and pore structure. In order to better characterize and quantify the heterogeneity of the reservoir, Hearn et al. (1983) first proposed the concept of a hydraulic flow unit (HFU). A HFU refers to a reservoir with similar porosity, permeability, pore throat attributes and bedding characteristics, which is both connected horizontally and vertically. Meanwhile, the seepage characteristics in the same HFU are analogous, and the seepage characteristics between different HFUs are different. Amaefule et al. (1993) proposed the flow zone indicator (FZI) from the modified Kozeny–Carman equation and used it to predict the permeability of reservoirs. FZI refers to a well-defined reservoir parameter, incorporating the geological features of mineralogy and texture in distinguishing the different formation facies or HFUs. Therefore, FZI is usually used to quantify the heterogeneity and quality of the reservoirs. In general, a larger FZI value indicates the better physical properties and the lower degree of heterogeneity of reservoirs. Nooruddin and Hossain (2011) revised the tortuosity term of the Kozeny–Carman model and proposed the definition of enhanced hydraulic flow unit, which obtained good results in some high-permeability reservoirs. In recent years, the concept of HFU has gained increasing attention in the study of reservoir characterization, and many researchers (Abu-Hashish et al. 2022; Kassab et al. 2021; Kou et al. 2022) have used HFU to characterize and classify different reservoirs.

The HFU is the macroscopic parameter that is determined by the pore structure of the rock (Chen et al. 2017; Khurpade et al. 2021). In addition to the porosity and permeability analyzed from core samples, many researchers also use other core physical experiments to descript and classify the pore structure, including mercury intrusion capillary pressure (MICP), nuclear magnetic resonance (NMR), N2 adsorption, and some imaging methods (Jiang et al. 2018; Ma et al. 2019; Yan et al. 2018; Zhao et al. 2017). These studies are all based on rock sample experiments. However, core sampling is relatively rare in common producing wells, because of its high cost and time consumption. Well logs are measured in almost all production wells. They contain more information and have good vertical continuity. It will be more meaningful to classify reservoirs through logging curves. So far, many scholars (Al-Mudhafar 2019; Mou et al. 2015) have used logging curves to classify reservoirs and lithofacies and achieved good results.

Static data such as core analysis and logging curves can only reflect the state of the reservoir at a specific time. Reservoir characterization and evaluation based on static data is still of relatively limited help in understanding the waterflooding performance of reservoirs. The oil cut data can calculate the oil saturation, oil/water ratio, recovery factor, and displacement efficiency, to further characterize the waterflooding performance. Therefore, it is very essential to predict the oil cut at different times after flooding in low-permeability waterflooded layers based on dynamic production data.

In 1963, Koval proposed the K-factor method for evaluating and predicting the flooding performance of unstable miscible fluids in heterogeneous reservoirs and verified the reliability of the method through a series of experiments with a wide variety of sandstone core samples and viscosity ratios. Mollaei and Delshad (2019) parameterized the physical dimension and thickness of the Koval method with the K-factor to predict the behavior of waterflooding. History matching shows that the actual production data is in well-agreement with the predicted results. Coupling the influence of the reservoir heterogeneity and the viscosity ratio, the K-factor can provide an efficient approach to analyze and predict the flooding process.

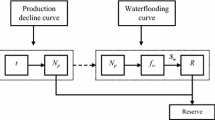

In this research, an empirical method for predicting waterflooding performance in low-permeability porous waterflooded reservoirs combining static and dynamic data was purposed. First, the low-permeability reservoirs in the study area were classified into three types of HFU according to core porosity and permeability. Next, an HFU classification method based on well logging curves was established with results similar to those of the core-based HFU. Considering the actual reservoir and logging conditions of Jingan Oilfield, the acoustic (AC) curve and the natural gamma (GR) curve are selected for calculating the HFUs. The study found that the proportions of thicknesses of different HFUs (HFUp) in the development zone have a good control effect on the production water cut, which can indicate the remaining oil distribution in the waterflooded zone. In order to accurately and quickly describe the waterflooding dynamics of low-permeability reservoirs, a rapid waterflooding performance prediction method based on the K-factor method was established. The history matching showed good agreement between the actual cut oil data and the forecasting results. The study also found that Type 3 HFUp can well-predict the duration of low water-cut production and determine the time coefficient \(\alpha\). Combining with the local average K-factor and the time coefficient \(\alpha\), the waterflooding performance evaluation method can be established to predict waterflooding behavior for wells in a low water-cut production period.

Methodology

Geological setting

The Ordos Basin, covering more than 320,000 square kilometers in the shape of approximately rectangular (Fig. 1a), is the second-largest sedimentary basin with the most oil and gas production basin in China. Therefore, it makes the research on the Ordos Basin significant. Low permeability, coupled with strong heterogeneity, is the most critical feature of the sandstone reservoir in the studied Chang 6 member.

a Geological setting of the Ordos Basin (modified from Jiang et al. (2018)). The study area is marked with the red dashed box. b The location of well group L8-4

The study area is marked by a red dashed square in Fig. 1a. In well group L8-4 (shown in Fig. 1b), Chang 6 member is the capital oil producing reservoir of the research area, with an average porosity of 11.62% and an average permeability of 4.4mD. The producing wells L7-4, L7-5, L9-3, L9-4, L9-5, L8-3, L8-5, L8-4 and injecting well L8-4 were all drilled and put into producing and injecting between 1997 and 1998, marked with red and blue circles, respectively. The producing wells L7-31, L7-41, L9-31, L9-41, and L9-51 were infilled in 2012, represented by orange diamonds. And the last infill wells LJ7-3, LJ7-5, LJ9-3, and LJ9-5 were designed and began to produce oil in 2016, marked with brown triangles.

HFU theory

A hydraulic flow unit (HFU) is an important evaluation method for reservoir quality, and refers to a collection of geological units with similar seepage characteristics. Core porosity and permeability data are the most common basis for HFU classification of reservoirs. The porosity and permeability data from the core experiments are of strong objectivity and accuracy. The HFU parameters can be calculated according to the core physical property analysis data (Hearn et al. 1983), as shown in the following formula:

where the flow zone index FZI and the reservoir quality index RQI are useful evaluation parameters of the hydraulic flow unit system, μm. \(\phi\) and K are the porosity (fraction) and permeability (mD) data obtained through rock analysis, respectively. \(\phi_{{\text{z}}}\) is the normalized porosity, fraction.

According to the principle of statistics, the results of repeated measurements or experimental observation of the same thing under the same conditions should obey the law of normal distribution. Therefore, the variable has a normal distribution in the linear coordinate system and an approximately straight line in the normal distribution coordinate system. Due to the unavoidable random errors, the FZI value of the same HFU will be the Gaussian distributed around its real mean. Different HFUs show different normal distribution functions reflecting different characteristics of pore throat. When existing multiple HFUs, the overall distribution of FZI is superimposed by several Gaussian distributions, and it is represented as a broken line with different slopes in the normal distribution coordinate system.

K-factor method

Based on the 1-D Buckley–Leverett method, Koval (1963) presented the K-factor method to predict the solvent cut in immiscible displacement process as the function of injected pore volumes. There are two important relations developed in Buckley–Leverett’s theory as follows. The frontal advance formula is:

where \(f_{{\text{s}}}\) is the solvent cut, \(S_{{\text{s}}}\) is the solvent saturation, \(x_{D}\) is the location of frontal advance at the time \(t_{D}\).

When gravity is not considered, the fractional flow equation is:

where \(k_{r}\) and \(\mu\) represent the relative permeability and viscosity, respectively. The subscript s and o stand for solvent and oil.

If this total lack of interaction between solvent and oil is assumed, there will be a good linear relationship for relative permeability as a function of saturation in immiscible displacement:

In the K-factor method, it is assumed that a single parameter can be used to represent heterogeneity. In order to explain heterogeneity and transverse mixing, Koval introduced the K-factor into the fractional flow equation:

where K is the K-factor; \(E\) is the effective viscosity ratio; and \(H_{k}\) is the heterogeneity factor calculated from the experiment data. The fractional flow equation proposed by the K-factor method is:

Taking the derivative of \(f_{s}\) with respect to \(S_{s}\), substituting Eq. (9) into Eq. (4) and eliminating the \(S_{s}\), resulting in oil cut \(f_{o} = 1 - f_{s}\) as the function of K, for position \(x_{D}\) and time \(t_{D}\):

Figure 2 shows the relationship between the oil cut and the injected pore volume with different K-factors. As shown in Fig. 2, when the K-factor of reservoirs is higher, indicating the heterogeneity or viscosity ratio is greater, the water breakthrough will be earlier and the flooding process will be slower.

Results and discussion

HFU classification results

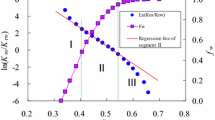

The core porosity and permeability data can provide the most objective and reliable geological information. The flow zone index FZI from the core experiment data can well-reflect the heterogeneity of formation. Based on the probability accumulation function (PCF) of FZI, Chang 6 reservoir in this research area was divided into three types of HFU. According to the quality of reservoirs from good to bad, there are Type 1, Type 2 and Type 3, respectively. When existing multiple HFUs, the overall distribution of FZI is superimposed by several Gaussian distributions. It can be represented as a broken line with three different slopes in the normal distribution coordinate system, as shown in Fig. 3.

Different types of HFUs show obvious characteristics in porosity and permeability, as shown in Table 1. Type 1 HFU has the best physical properties and is the dominant flow channel in rock. The porosity and permeability of Type 3 HFU are relatively low. Therefore, these Type 3 HFU are often the accumulation place of the remaining oil, and utilization degree of these reservoir is low. The HFU classification based on core data is the most reliable, but the rock core of formation is relatively expensive, making this method difficult to popularize. In this study, a HFU evaluation method from logging curves is established, referring to the HFU results based on the core data.

The acoustic (AC) curve and the natural gamma (GR) curve are selected for the calculation of the HFUs. Calculate the shale content \(V_{{{\text{sh}}}}\) according to the GR curve, and then introduce the AC curve to calculate the effective porosity, as follows:

where \({\text{GR}}_{\max }\), \({\text{GR}}_{\min }\) is the GR value of the ideal mudstone and sandstone; \({\text{Por}}_{e}\) is the effective porosity; \(T_{m}\), \(T_{f}\),\(T_{{{\text{sh}}}}\) are the acoustic values of the rock matrix, fluid and shale, respectively.

The studied formation can be continuously divided into three types of HFUs by logging curves, according to the classification criteria in Table 2. Type 1 HFU reservoir has the largest porosity and permeability, is the dominant channel of flooding, and its effective porosity is greater than 9%. The porosity and permeability of Type 2 HFU are slightly smaller, and the effective porosity is between 5 and 9%. Type 3 HFU has the worst physical properties, and these reservoirs are relatively tight or have a high shale content.

As the logging interpretation results in Fig. 4 show, the HFU results from logging curves have a high consistency with the results based on the core analysis data. The results allow those wells without coring can be classified the HFUs by well loggings.

The HFU classification results from the core analysis data and the logging curves in well LJ9-5 are shown in Fig. 4. Track 1–3 are the conventional logging curves. Track 4 and 5 are calculated and core experimental permeability and porosity, respectively. Track 6 presents the HFU classification results from logging curves and core analysis data. Track 7 presents the waterflooding results based on core observations. The calculated lithology section and interpretation conclusion are shown in the last three tracks present, together with the depth data.

In the studied formation of well LJ9-5, most of the formation belongs to Type 3 HFU, and the degree of water washing is low (UF and WF). While the strongest washing traces were observed in the rock core of Layer 87. Coincidentally, the HFU results from core analysis and well logs both show this layer belongs to Type 1 HFU reservoir. The results show it is an excellent alternative method to calculate the HFUs by logging curves with no core data.

Remaining oil distribution prediction based on HFUp results

The thickness of the same studied layer will be different in various parts of the underground, and it will be inappropriate in evaluating the fluid distribution only by the thickness of reservoirs in HFUs. In this paper, the proportions of thicknesses of different HFUs (HFUp) are proposed to characterize and evaluate the waterflooding performance. Figures 5 and 6 are the distribution of Type 3 HFUp (Figs. 5a and 6a) and the distribution of water cut (Figs. 5b and 6b) at different times in well group L8-4 well. In 2014, there were 13 wells in the researched well group. It was in the middle stage of flooding, with an average water cut of approximately 60%, as shown in Fig. 5. In 2016, well group L8-4 included 17 wells, and in the late stage of displacement, with the water cut of the most wells above 90%, shown in Fig. 6.

The result shows that Type 3 HFUp from the logging curves is an excellent index for the distribution of water cut in different stages of waterflooding. When Type 3 HFUp is relatively lower (blue area), the average physical properties will be better. Therefore, it is easy to form the dominant channel of waterflooding and corresponds to the higher water content. On the contrary, the higher Type 3 HFUp (red area) should indicate the enrichment area of the remaining oil, within the control range of the well group. This study is of great significance for indicating the distribution of remaining oil in porous reservoirs.

An empirical evaluation method of waterflooding performance based on the K-factor method

Type3 HFUp can indicate the spatial enrichment of the remaining oil. However, this method in Session 3.2 lacks the characterization of time-dependent waterflooding performance. According to the K-factor method, the dynamic evaluation method of waterflooding performance can be established by fitting the production oil content data in the process of water injection development, as follows:

where \(f_{o}\) is the average monthly oil content; \(\alpha\) is the time coefficient, which is a function of the duration of low water-cut oil production; \(k\) is the K-factor, which can characterize the seepage capacity of the reservoir. In the same development layer of the same oilfield, the same K-factor can be chosen. \(k\) and \(\alpha\) can be determined by fitting the production data. \(t_{D}\) is the dimensionless time:

where \(q_{{{\text{in}}}}\) is the injection rate, \(V_{p}\) is the injection volume, \(t_{T}\) is the production time, month. In this study, \({{q_{{{\text{in}}}} } \mathord{\left/ {\vphantom {{q_{{{\text{in}}}} } {V_{p} }}} \right. \kern-\nulldelimiterspace} {V_{p} }}\) is assumed to be 0.008 for the convenience of calculation. \(t_{{{\text{lw}}}}\) is the dimensionless low water cut (\(f_{w}\) < 20%) production duration. Figure 7 is the oil content fitting situation of well L8-5. The blue point is the actual production data, and the red dotted line is the value calculated by this method. The calculated data of oil cut are in good agreement with the actual values, and the correlation coefficient R2 = 0.973.

The other wells in the study well group were also fitted and analyzed. Their water cut gradually increased from less than 5%, during the development process. The fitting results are listed in Table 3. The results show that the oil content predicted by this method is generally consistent with the actual value in well group L8-4. When the production time of low water-cut tTlw is relatively short, the accuracy of the fitting results of this method is high, such as well L7-4, L7-5, L8-5 and L9-4.

Local k is the average K-factor in the study area. The production time of low water-cut tTlw is the production time with water content less than 20%, month. As shown in Fig. 8, the time coefficient α and the production time of low water cut tTlw have a good linear relationship. In case of lack of sufficient production data from low water cut to high water cut, Type3 HFUp can also be used to estimate the time coefficient α.

Conclusions

In this study, first, based on the porosity and permeability data of rock analysis, the low-permeability porous waterflooded reservoir was divided into three types of HFUs. Then, in order to popularize the HFU method, a HFU classification method with logging curves was established. The HFU classification results were used to indicate the distribution of the remaining oil. Lastly, based on the K-factor method, the dynamic evaluation method of waterflooding performance was established with historical fitting. The following conclusions are drawn:

-

(1)

When the rock data are insufficient, the HFU can also be well-divided with the logging curves.

-

(2)

The proportion of HFU thickness (HFUp) of Type 3 from logging curves is a good index for the distribution of water cut in different stages of waterflooding.

-

(3)

The empirical evaluation method of waterflooding performance based on the K-factor method is established in this study. With a local average k and Type 3 HFUp, the method can predict the waterflooding performance in newly drilled wells.

-

(4)

This method is only applicable to reservoirs with connected pores and few fractures. When the fractures and cracks existing, the injected water will form a dominant channel along with them. Moreover, this method cannot be appropriately applied in wells with a high water production rate before production.

References

Abu-Hashish MF, Al-Shareif AW, Hassan NM (2022) Hydraulic flow units and reservoir characterization of the Messinian Abu Madi formation in West El Manzala development Lease, onshore Nile Delta Egypt. J Afr Earth Sci. https://doi.org/10.1016/j.jafrearsci.2022.104498

Al-Ibadi H, Stephen K, MacKay E (2020) Heterogeneity effects on low salinity water flooding. In: Soc Pet Eng SPE Eur Featur 82nd EAGE Conf Exhib https://doi.org/10.2118/200547-ms

Aljuboori FA, Lee JH, Elraies KA, Stephen KD (2020) The effectiveness of low salinity waterflooding in naturally fractured reservoirs. J Pet Sci Eng. https://doi.org/10.1016/j.petrol.2020.107167

Al-Mudhafar WJ (2019) Integrating lithofacies and well logging data into smooth generalized additive model for improved permeability estimation: Zubair formation, South Rumaila oil field. Mar Geophys Res 40:315–332. https://doi.org/10.1007/s11001-018-9370-7

Amaefule JO, Altunbay M, Tiab D, Kersey DG, Keelan DK (1993) Enhanced reservoir description: using core and log data to identify hydraulic (flow) units and predict permeability in uncored intervals/ wells. In: Proceeding of SPE annual Technical Conference and Exhibition Omega, pp 205–220. https://doi.org/10.2523/26436-ms

Belayneh MW, Matthai SK, Blunt MJ, Rogers SF (2009) Comparison of deterministic with stochastic fracture models in water-flooding numerical simulations. Am Assoc Pet Geol Bull 93:1633–1648. https://doi.org/10.1306/07220909031

Chen X, Yao G, Cai J, Huang Y, Yuan X (2017) Fractal and multifractal analysis of different hydraulic flow units based on micro-CT images. J Nat Gas Sci Eng 48:145–156. https://doi.org/10.1016/j.jngse.2016.11.048

Chen H, Li H, Li Z, Li S, Wang Y, Wang J, Li B (2020) Effects of matrix permeability and fracture on production characteristics and residual oil distribution during flue gas flooding in low permeability/tight reservoirs. J Pet Sci Eng. https://doi.org/10.1016/j.petrol.2020.107813

Chen S, Gong Z, Li X, Wang H, Wang Y, Zhang Y (2021) Pore structure and heterogeneity of shale gas reservoirs and its effect on gas storage capacity in the Qiongzhusi formation. Geosci Front. https://doi.org/10.1016/j.gsf.2021.101244

Friesen OJ, Dashtgard SE, Miller J, Schmitt L, Baldwin C (2017) Permeability heterogeneity in bioturbated sediments and implications for waterflooding of tight-oil reservoirs, Cardium formation, Pembina Field, Alberta. Canada Mar Pet Geol 82:371–387. https://doi.org/10.1016/j.marpetgeo.2017.01.019

Gu S, Liu Y, Chen Z, Ma C (2014) A method for evaluation of water flooding performance in fractured reservoirs. J Pet Sci Eng 120:130–140. https://doi.org/10.1016/j.petrol.2014.06.002

Hearn CL, Ebanks WJ, Tye RS, Ranganathan V (1983) Geological factors influencing reservoir performance of the hartzog draw field, Wyoming. In: Soc Pet Eng AIME, SPE

Jiang Z, Mao Z, Shi Y, Wang D (2018) Multifractal characteristics and classification of tight sandstone reservoirs: a case study from the Triassic Yanchang Formation, Ordos Basin China. Energies. https://doi.org/10.3390/en11092242

Jiang Z, Fu J, Li G, Mao Z, Zhao P (2021) Using resistivity data to study the waterflooding process: a case study in tight sandstone reservoirs of the Ordos Basin, China. Geophysics 86:B55–B65. https://doi.org/10.1190/geo2020-0401.1

Jiang Z, Liu Z, Zhao P, Chen Z, Mao Z (2022) Evaluation of tight waterflooding reservoirs with complex wettability by NMR data: a case study from Chang 6 and 8 members, Ordos Basin NW China. J Pet Sci Eng 213:110436. https://doi.org/10.1016/j.petrol.2022.110436

Kassab MA, Elgibaly A, Abbas A, Mabrouk I (2021) Identification and distribution of hydraulic flow units of heterogeneous reservoir in Obaiyed gas field, Western Desert, Egypt: a case study. Am Assoc Pet Geol Bull 105:2405–2424. https://doi.org/10.1306/06222119083

Khurpade PD, Kshirsagar LK, Nandi S (2021) Characterization of heterogeneous petroleum reservoir of Indian Sub-continent: an integrated approach of hydraulic flow unit–Mercury intrusion capillary pressure–Fractal model. J Pet Sci Eng. https://doi.org/10.1016/j.petrol.2021.108788

Kou Z, Wang H, Alvarado V, Nye C, Bagdonas DA, McLaughlin JF, Quillinan SA (2022) Effects of carbonic acid-rock interactions on CO2/Brine multiphase flow properties in the upper minnelusa sandstones. SPE J. https://doi.org/10.2118/212272-pa

Koval EJ (1963) A method for predicting the performance of unstable miscible displacement in heterogeneous media. Soc Pet Eng J 3:145–154. https://doi.org/10.2118/450-pa

Li J, Liu Y, Gao Y, Cheng B, Meng F, Xu H (2018) Effects of microscopic pore structure heterogeneity on the distribution and morphology of remaining oil. Pet Explor Dev 45:1112–1122. https://doi.org/10.1016/S1876-3804(18)30114-9

Ma X, Guo S, Shi D, Zhou Z, Liu G (2019) Investigation of pore structure and fractal characteristics of marine-continental transitional shales from Longtan Formation using MICP, gas adsorption, and NMR (Guizhou, China). Mar Pet Geol 107:555–571. https://doi.org/10.1016/j.marpetgeo.2019.05.018

Mollaei A, Delshad M (2019) Introducing a novel model and tool for design and performance forecasting of waterflood projects. Fuel 237:298–307. https://doi.org/10.1016/j.fuel.2018.09.125

Mou D, Wang ZW, Huang YL, Xu S, Zhou DP (2015) Lithological identification of volcanic rocks from SVM well logging data: case study in the eastern depression of Liaohe Basin. Acta Geophys Sin 58:1785–1793. https://doi.org/10.6038/cjg20150528

Nasralla RA, Mahani H, van der Linde HA, Marcelis FHM, Masalmeh SK, Sergienko E, Brussee NJ, Pieterse SGJ, Basu S (2018) Low salinity waterflooding for a carbonate reservoir: experimental evaluation and numerical interpretation. J Pet Sci Eng 164:640–654. https://doi.org/10.1016/j.petrol.2018.01.028

Nooruddin HA, Hossain ME (2011) Modified Kozeny-Carmen correlation for enhanced hydraulic flow unit characterization. J Pet Sci Eng 80:107–115. https://doi.org/10.1016/j.petrol.2011.11.003

Qiao J, Zeng J, Jiang S, Feng S, Feng X, Guo Z, Teng J (2019) Heterogeneity of reservoir quality and gas accumulation in tight sandstone reservoirs revealed by pore structure characterization and physical simulation. Fuel 253:1300–1316. https://doi.org/10.1016/j.fuel.2019.05.112

Rendel PM, Mountain B, Feilberg KL (2022) Fluid-rock interaction during low-salinity water flooding of North Sea chalks. J Pet Sci Eng, 110484

Sari A, Chen Y, Myers MB, Seyyedi M, Ghasemi M, Saeedi A, Xie Q (2020) Carbonated waterflooding in carbonate reservoirs: experimental evaluation and geochemical interpretation. J Mol Liq. https://doi.org/10.1016/j.molliq.2020.113055

Vledder P, Fonseca JC, Wells T, Gonzalez I, Ligthelm D (2010) Low salinity water flooding: proof of wettability alteration on a field wide scale. Proc SPE Symp Improv Oil Recover 1:200–209. https://doi.org/10.2118/129564-ms

Wang M, Yang S, Li M, Wang S, Yu P, Zhang Y, Chen H (2021) Influence of heterogeneity on nitrogen foam flooding in low-permeability light oil reservoirs. Energy Fuels 35:4296–4312. https://doi.org/10.1021/acs.energyfuels.0c04062

Wang H, Kou Z, Bagdonas DA, Phillips EHW, Alvarado V, Johnson AC, Jiao Z, McLaughlin JF, Quillinan SA (2022) Multiscale petrophysical characterization and flow unit classification of the Minnelusa eolian sandstones. J Hydrol. https://doi.org/10.1016/j.jhydrol.2022.127466

Yan J, Fan J, Wang M, Li Z, Hu Q, Chao J (2018) Rock fabric and pore structure of the Shahejie sandy conglomerates from the Dongying depression in the Bohai Bay Basin, East China. Mar Pet Geol 97:624–638. https://doi.org/10.1016/j.marpetgeo.2018.07.009

Zhao P, Wang Z, Sun Z, Cai J, Wang L (2017) Investigation on the pore structure and multifractal characteristics of tight oil reservoirs using NMR measurements: Permian Lucaogou Formation in Jimusaer Sag, Junggar Basin. Mar Pet Geol 86:1067–1081. https://doi.org/10.1016/j.marpetgeo.2017.07.011

Zhou X, Wang Y, Zhang L, Zhang K, Jiang Q, Pu H, Wang L, Yuan Q (2020) Evaluation of enhanced oil recovery potential using gas/water flooding in a tight oil reservoir. Fuel. https://doi.org/10.1016/j.fuel.2020.117706

Acknowledgements

This work was sponsored by the China Postdoctoral Science Foundation (No. 2021MD703881), the State Key Laboratory of Petroleum Resources and Prospecting, China University of Petroleum (No. PRP/open-2208), the Natural Science Foundation of Shaanxi Province (No. 2022JQ-233), the Young Talent Fund of Association for Science and Technology in Shaanxi, China (No. 20220718), and the National Natural Science Foundation of China (No. 41904112).

Author information

Authors and Affiliations

Contributions

ZJ involved in conceptualization, writing–original draft, data curation, and funding acquisition. GL involved in investigation, resources, and data curation. LZ involved in writing—review and editing and supervision. ZM involved in data curation, project administration, and validation. ZL involved in investigation. XH and PX involved in formal analysis, supervision, and investigation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Edited by Dr. Liang Xiao (ASSOCIATE EDITOR) / Prof. Gabriela Fernández Viejo (CO-EDITOR-IN-CHIEF).

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jiang, Z., Li, G., Zhang, L. et al. An empirical method for predicting waterflooding performance in low-permeability porous reservoirs combining static and dynamic data: a case study in Chang 6 formation, Jingan Oilfield, Ordos Basin, China. Acta Geophys. 71, 1693–1703 (2023). https://doi.org/10.1007/s11600-022-00990-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11600-022-00990-6