Abstract

For all-solid-state lithium-ion batteries (ASSBs), they have two key parameters including ionic conductivity and interfacial properties. Considering the previous studies focused more on single property, we aimed to investigate the effects of lithium salts on comprehensive properties of PEO-based SPEs and find out the optimal lithium salts. For the SPE with LiTFSI, it has the highest ionic conductivity (5.3 \(\times\) 10−6 S cm−1 at 25 °C and 2.4 \(\times\) 10−4 S cm−1 at 60 °C) and discharge capacity, mainly due to the lowest crystallinity and the highest lithium-ion transference number. For the SPE with LiFSI, it has the best interfacial properties and cycling performance, mainly due to the denser and flatter LiF SEI layer after cycling. Our work indicates that as for PEO-based ASSBs, LiTFSI can be used to get higher discharge capacities, and LiFSI can be used to get higher retention rate.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

All-solid-state lithium-ion batteries (ASSBs) have been considered in order to improve the energy density and the safety of lithium-ion batteries. ASSBs use solid electrolytes (SEs) instead of liquid electrolytes, but the resulting problems of rate performance and cycling stability need to be solved [1,2,3]. Among these problems, SE-electrode interfacial property is addressed as one of the key issues [4].

SEs can be classified into three groups, including polymer-based, sulfide-based, and oxide-based [5]. For solid polymer electrolytes (SPEs), previous studies focus more on how to increase the ionic conductivity, such as adding nanoparticles and modifying polymer chains [6,7,8]. However, the comprehensive performance of SPEs and their ASSBs depends on not only ionic conductivity, but also interfacial properties [9]. Therefore, in order to make ASSBs commercialized successfully, interfacial properties should be further improved.

Interfacial phenomena of SE-electrode interface can be classified into two aspects [10]. One aspect is due to physical factors, mainly caused by rigid contact. In this aspect, SE-electrode interface is not fully contact, even when there is point-contact interface, especially for oxide-based electrolytes [11, 12]. The other aspect is due to chemical factors, mainly caused by the reaction in the interface and the decomposition of SEs [13,14,15]. In terms of other previous studies, physical factors of PEO-based SPEs can be solved by hot pressed or interface engineering, so they can fit on electrodes tightly [16,17,18]. As a result, chemical factors can dominate interfacial properties, and lithium salts have significant effects on chemical factors, especially for the SPEs-anode interface [19, 20].

For PEO-based ASSBs, their compatible lithium salts are different with liquid lithium-ion battery (LIB). This is due to that inorganic lithium salts, such as LiPF6 and LiBF4, have bad thermal stability; some irreversible reactions take place easily above 50 °C, resulting in decomposition during cycling [21]. For organic lithium salts, their decomposition temperature is above 200 °C, indicating they have good thermal stability [22,23,24]. As a result, it is necessary to find out optimal lithium salts and their effects on PEO-based SPEs. Previous studies have investigated the interfacial properties of liquid lithium-ion battery and found out that LiFSI is the best lithium salt, because its decomposition product is LiF, which can induce the construction of stable solid electrolyte interface (SEI) [25]. However, there is less research on whether LiF has such an effect on ASSBs and the formation of SEI for different lithium salts in ASSBs. Besides, previous works focus more on single properties of SPEs; there is less research about the effects of lithium salts on comprehensive properties of PEO-based SPEs. Consequently, effects of lithium salts on PEO-based electrolytes were systematically explored in this work. For organic lithium salts, LiTFSI, LiFSI, and CF3SO3Li have high ionic conductivity and ease of preparation, so three lithium salts are wildly used in PEO-based SPE, and we chose these three in our work [22,23,24].

Experimental procedures

Preparation of membranes

For PEO-based SPEs with different lithium salts, they were prepared by solution casting. First, polyethylene oxide (PEO, 1 \(\times\) 106 g mol−1, Aladdin), bis (trifluoromethanesulfonyl) imide lithium (LiTFSI, Aladdin), bis (fluorsulfonyl) imide lithium (LiFSI, Aladdin), and lithium trifluoromethanesulfonate (CF3SO3Li, Aladdin) were dried for 24 h at 60 ℃. Then, PEO and different lithium salts with a fixed molar ratio of 16:1 were added into acetonitrile (ACN, Aladdin), which was packed in a closed container to avoid the mixture contact with air and water. After stirring for 24 h, the mixture was cast into a Teflon plate and dried for 48 h. Finally, SPEs were peeled off and then hot pressed at 60 ℃ to make them smooth and flat.

Characterization

X-ray diffraction (XRD, Rigaku 2500, Kyoto, Japan) was performed with Cu Kα radiation (λ = 1.5418 Å) over the 2θ range of 10°–70°. In order to determine the crystallinity (\({\chi }_{\mathrm{c}}\)) of SPEs, differential scanning calorimeter (DSC, Netzsch, Selb, Germany) measurement was performed in the temperature range of 20 to 80 °C, and values of crystallinity were calculated as the Eq. 1:

In this equation, \(\Delta {H}_{\mathrm{m}}\) is the melting enthalpy of each SPE, \(\Delta {H}_{\mathrm{m}}^{*}\) is the melting enthalpy of fully crystallized PEO with the value of 177.8 J g−1, and \(\phi\) is the mass fraction of PEO matrix [26].

Ionic conductivity (\(\sigma\)) is one of the most important parameters of SPEs, and it was measured by an electrochemical work station (CHI660D, Shanghai Chenhua instrument Co., Ltd., China) in the frequency range of 0.1 Hz to 1 MHz. The measurement was performed with the stainless-steel (ss)//SPE//ss, and values of ionic conductivity were calculated as following:

As shown in Eq. 2, L, \({R}_{\mathrm{b}}\), and S are thickness, bulk resistance, and area of SPEs respectively [27].

The activation energy (\({E}_{\mathrm{a}}\)) of SPEs was evaluated to find out the relationship between ionic conductivity and temperature, and values were calculated by the Eq. 3:

where A, K, and T are pre-exponential constant, Boltzmann constant, and absolute temperature respectively [28].

In order to determine the electrochemical stability window, linear sweep voltammetry (LSV) measurement was performed in the voltage range of 0 to 6 V at 60 °C.

In order to determine the interfacial properties, galvanostatic cycling was measured in different currents at 60 °C. In this measurement, Li//SPEs with different salts//Li symmetry cells were assembled, and charge/discharge cycling was periodically changed per 0.5 h. Later, X-ray photoelectron spectroscopy (XPS, ESCALAB 250Xi, Thermo Fisher, America) measurement was performed to find out the changes in the interface.

Cycling performance of ASSBs was measured on a battery testing instrument (CT3001K, LANHE, Wuhan) at 60 °C. First, LiFePO4 (LFP) cathode material was made up of 70 wt% LFP powder (with the tap density of 1.1 g cm−3, Aladdin), 20 wt% Super-P (Aladdin), and 10 wt% Polyvinylidene fluoride (PVDF, 1 \(\times\) 106 g mol−1, Aladdin), which the cathode loading was 2 mg cm−2. Then, LFP//SPEs//Li cells were assembled. Finally, charge/discharge cycling was tested to find out the effects of lithium salts on SPEs.

Results and discussion

Phase structure and crystallinity analysis

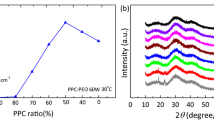

Figure 1a shows the XRD patterns of SPEs with different salts. From the patterns, each SPE has the same characteristic peak position (2θ = 19.2°). Meanwhile, diffraction peak intensity of each PEO matrix is mutually different, indicating crystallinity of each SPE is different. DSC curves are shown in Fig. 1b, and values of crystallinity are shown in Table 1. Consisting with the results from XRD patterns, crystallinity of PEO-LiTFSI is the lowest, so it has the weakest characteristic diffraction peak in Fig. 1a.

Electrochemical measurement of SPEs

As mentioned above, ionic conductivity is one of the key parameters of SPEs. Figure 2a shows the ionic conductivity of SPEs with different lithium salts; all the values are shown in Table 2. From Fig. 2a, SPEs with LiTFSI have the highest ionic conductivity, mainly caused by the following reasons: On the one hand, according to the results from XRD and DSC measurement, SPEs with LiTFSI have the lowest crystallinity, due to the plasticizing effect caused by the high flexibility of TFSI− [29]. Previous studies demonstrate that pathways of lithium-ions conduction are mainly in amorphous regions of PEO-based SPEs [30]. As a result, the lower the crystallinity is, the higher the ionic conductivity will be. On the other hand, according to the results from Table S1 and Fig. S1, SPEs with LiTFSI have the highest lithium-ion transference number (\({t}_{{\mathrm{Li}}^{+}}\)), further improving the ionic conductivity.

Figure 2b shows the linear sweep voltammetry of SPEs with different salts. As shown in Fig. 2b, the electrochemical window of SPEs with different salts is below 4.0 V; as a result, they cannot match LiCoO2 (LCO) and NCM cathodes.

Interfacial properties analysis

The interfacial property is another key parameter of SPEs. In order to find out the effects of lithium salts on interfacial properties, the relationship between interfacial resistance of each SPE and storage days was measured, and results are shown in Fig. 3. It can be seen that interfacial resistance of each SPE decreases during the first day, which is due to the contact improvement between SPEs and Li metal. Later, interfacial resistance of each SPE increases continually, which is due to the decomposition of lithium salts, and the related mechanism is analyzed in the following. Besides, PEO-LiFSI has the lowest interfacial resistance in each storage day, indicating PEO-LiFSI has the best interfacial property. Furthermore, galvanostatic cycling was measured at different currents (0.1 mA cm−2, 0.2 mA cm−2, and 0.5 mA cm−2) at 60 °C. In this measurement, symmetry cells were assembled with the structure of Li//SPEs with different lithium salts//Li. Figure 3b shows the voltage profiles at a current density of 0.1 mA cm−2: On the one hand, polarization voltages of all SPEs remain stable in 1000 cycles, which means cycles of all ASSBs lasted for 1000 times. On the other hand, polarization voltages of SPEs with LiFSI are always the lowest, indicating the lowest interface resistance. Figure 3c shows the voltage profiles at 0.2 mA cm−2, cycles of SPEs with LiTFSI and LiFSI lasted for 1000 times, and the former is fluctuant during cycling, and the latter is always stable. However, the polarization voltage of SPEs with CF3SO3Li increases rapidly in the first 30 cycles, indicating they cannot be used under larger current density. Figure 3d shows the voltage profiles at 0.5 mA cm−2, and both SPEs have similar phenomena: cycles of SPEs with LiTFSI and LiFSI lasted for 300 times with fluctuation and decreased rapidly after 300 cycles, indicating both ASSBs were short-circuited caused by lithium dendrites.

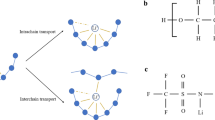

Furthermore, in order to determine the mechanism of these phenomena, XPS measurements were performed on pristine SPEs and cycled SPEs to explore the change of SPEs-Li interface after galvanostatic cycling. Figure 4a–d show the XPS spectra of C 1 s, O 1 s, F 1 s, and S 2p of pristine SPEs and cycled SPEs. In Fig. 4c, F atom exists as LiF and LiFSI, and peaks of FSI− nearly disappear after Ar sputter, indicating FSI− has broken down in the interface. Meanwhile, peaks of Li2CO3, LiF, and Li2S are more significant after Ar sputter, indicating the decomposition materials of LiFSI are LiF, Li2CO3, and Li2S. As shown in Fig. S2 to S3, LiTFSI and CF3SO3Li also break down into different lithium salts in the interface. Previous studies identified the formation of the SEI layer is related to the decomposition of PEO and determined by the decomposition of lithium salts [31, 32]. Corresponding to the mechanism of lithium salt decomposition in the interface, chemical equations are shown as Eqs. 4, 5, and 6 respectively, resulting in the difference of interfacial resistance [33,34,35]:

In order to find out the reason for interfacial property differences of SPEs with different salts, atomic abundance of the cycled SPEs have measured. For SPEs with different lithium salts, the abundance of F and LiF can be determined from XPS spectra, and values are shown in Table 3. From Table 3, no matter how long the sputter time is, the order of LiF abundance is LiFSI > LiTFSI > CF3SO3Li in the interface. Based on previous research, LiF has the largest bandgap (13.6 eV), so LiF SEI layer can stop electron tunneling and increase the interfacial properties [36, 37]. Therefore, the more the content of LiF is, the better the interfacial properties will be. Besides, LiF SEI layer is dense and flat, resulting in the closer contact between Li foils and SPEs [25]. Post-mortem analysis was made to investigate the mechanism of interfacial performance differences of PEO-based SPEs with different lithium salts, and SEM micrographs of cycled SPEs are shown in Fig. 5. Surface morphology of the cycled SPE with LiFSI and its matching Li foil is denser and flatter than others, indicating the SEI layer of LiFSI is denser and flatter than others, caused by the uniform deposition of LiF. As a result, SPEs with LiFSI have the best interfacial properties.

SEM micrographs of cross-section of Li//SPEs//Li symmetric cells at the current density of 0.1 mA cm−2 after 100 cycles with a LiTFSI, b LiFSI, and c CF3SO3Li. SEM micrographs of Li foils of Li//SPEs//Li symmetric cells at the current density of 0.1 mA cm−2 after 100 cycles with d LiTFSI, e LiFSI, and f CF3SO3Li. SEM micrographs of SPEs of Li//SPEs//Li symmetric cells at the current density of 0.1 mA cm−2 after 100 cycles with g LiTFSI, h LiFSI, and i CF3SO3Li

Cell performance of SPEs

In order to investigate the cell performance, LiFePO4/SPEs with different lithium salts/Li ASSBs were assembled. Figure 6a shows the cycling performance of ASSBs at 0.1 C rate. In Fig. 6a, the cell with LiTFSI always has the highest discharge capacities, due to the highest ionic conductivity. For the cell with LiFSI, although its discharge capacities are lower than the former, it has the highest retention rate (84.3%, corresponding to 78.8% for the former), caused by the best interfacial properties.

Figure 6b and c show charge/discharge curves after first and 100 cycles respectively. For initial charge/discharge cycle, polarization voltages of all SPEs are nearly same, indicating the same interface resistance after the first cycle. After 100 cycles, polarization voltage of the cell with LiFSI is the lowest, consisting with the highest retention rate in Fig. 6a. These phenomena reveal that retention rate and cycling stability mainly depend on interfacial properties, which is determined by lithium salts. Also, LiTFSI can be used to get higher discharge capacities, and LiFSI can be used to get higher retention rate.

Conclusion

In this work, we aimed to find out the effects of lithium salt on PEO-based SPEs and their ASSBs. PEO-based SPEs with different lithium salts were synthesized by solution casting; Li//SPEs//Li symmetry cells and LFP//SPEs//Li ASSBs were assembled to investigated the cycling performance. Based on our study, for the SPE with LiTFSI, it has the highest ionic conductivity (5.3 \(\times\) 10−6 S cm−1 at 25 °C and 2.4 \(\times\) 10−4 S cm−1 at 60 °C) and discharge capacity, mainly due to the lowest crystallinity and the highest lithium-ion transference number. For the SPE with LiFSI, it has the best interfacial properties and cycling performance, mainly due to the denser and flatter LiF SEI layer after cycling. Our work indicates that as for PEO-based ASSBs, LiTFSI can be used to get higher discharge capacities, and LiFSI can be used to get higher retention rate.

References

Scrosati B, Garche J (2010) Lithium batteries: status, prospects and future. J Power Sources 195:2419–2430

Trapa PE, Won YY, Mui SC, Olivetti EA, Huang BY, Sadoway DR, Mayes AM, Dallek S (2005) Rubbery graft copolymer electrolytes for solid-state, thin-film lithium batteries. J Electrochem Soc 152:1–5

Croce F, Appetecchi GB, Persi L, Scrosati B (1998) Nanocomposite polymer electrolytes for lithium batteries. Nature 394:456–458

Zhu B, Jin Y, Hu XZ, Zheng QH, Zhang S, Wang QJ, Zhu J (2016) Poly(dimethyl siloxane) thin film as a stable interfacial layer for high-performance lithium-metal battery anodes. Adv Mat 29:1603755

Fergus JW (2010) Ceramic and polymeric solid electrolytes for lithium-ion batteries. J Power Source 195:4554–4569

Zheng J, Tang MX, Hu YY (2016) Lithium-ion pathway within Li7La3Zr2O12-polyethylene oxide. Angew Chem 55:1–6

Aldalur I, Martinez M, Krzton A, Piszcz M, Armand M, Zhang H (2019) Flowable polymer electrolytes for lithium metal batteries. J Power Source 423:218–226

Wang QJ, Song WL, Fan LZ, Shi Q (2015) Effect of alumina on triethylene glycol diacetate-2-propenoic acid butyl ester composite polymer electrolytes for flexible lithium ion batteries. J Power Sources 279:405–412

Ismail I, Noda A, Nishimoto A, Watanabe M (2001) XPS study of lithium surface after contact with lithium-salt doped polymer electrolytes. Electrochim Acta 46:1595–1603

Yamada H (2016) Interfaces of solid electrolytes: fundamentals and applications. J Indian Inst Sci 96:315–323

Ohta S, Komagata S, Seki J, Saeki T, Morishita S, Takahiro A (2013) All-solid-state lithium ion battery using garnet-type oxide and Li3BO3 solid electrolytes fabricated by screen-printing. J Power Source 238:53–56

Liu LL, Xu JR, Wang S, Wu F, Li H, Chen LQ (2019) Practical evaluation of energy densities for sulfide solid-state batteries. eTransportation 1:100010

Liu Z, Qi Y, Lin YX, Chen L, Lu P, Chen LQ (2016) Interfacial study on solid electrolyte interphase at Li metal anode: Implication for Li dendrite growth. J Electrochem Soc 163:592–598

Naoi K, Mori M, Naruoka Y, Lamanna W, Atanasoski R (1999) The surface film formed on a lithium metal electrode in a new imide electrolyte, lithium bis(perfluoroethylsulfonylimide) [LiN(C2F5SO2)2]. J Electrochem Soc 146:462–469

Wu BB, Wang SY, Lochala J, Desrochers D, Liu B, Zhang WQ, Yang JH, Xiao J (2018) The role of the solid electrolyte interphase layer in preventing Li dendrite growth in solid-state batteries. Energy Environ Sci 11:1803–1810

Yang G, Zhai Y, Yao J, Song S, Lin L, Tang W, Wen Z, Hu N, Lu L (2021) Synthesis and properties of poly(1,3-dioxolane) in situ quasi-solid-state electrolytes via a rareearth triflate catalyst. Chem Commun 57:7934–7937

Zhai Y, Yang G, Zeng Z, Song S, Li S, Hu N, Tang W, Wen Z, Lu L, Molenda J (2021) Composite hybrid quasi-solid electrolyte for high-energy lithium metal batteries. ACS Appl Energy Mater 4:7973–7982

Song S, Gao W, Yang G, Zhai Y, Yao J, Lin L, Tang W, Hu N, Lu L (2022) Hybrid poly-ether/carbonate ester electrolyte engineering enables high oxidative stability for quasi-solid-state lithium metal batteries. Mater Today Nano 23:100893

Wan J, Xie J, Mackanic DG, Burke W, Bao Z, Cui Y (2018) Status, promises, and challenges of nanocomposite solid-state electrolytes for safe and high performance lithium batteries. Mater Today Nano 4:1–16

Budi A, Basile A, Opletal G, Hollenkamp AF, Best AS, Rees RJ, Bhatt AI, Mullane A, Russo SP (2012) Study of the initial stage of solid electrolyte interphase formation upon chemical reaction of lithium metal and N-methyl-N-propyl pyrrolidinium-bis(fluorsulfonyl)imide. J Phy Chem C 116:19789–19797

Zhang S, Xu K, Jow R (2002) Study of LiBF4 as an electrolyte salt for a Li-ion battery. J Electrochem Soc 149:586–590

Rey I, Lassegues JC, Grondin J, Servant L (1998) Infrared and Raman study of the PEO-LiTFSI polymer electrolyte. Electrochim Acta 43:1505–1510

Han H, Zhou S, Zhang D, Feng S, Li L, Liu K, Feng W, Nie J, Hong L, Huang X, Armand M, Zhou Z (2011) Lithium bis(fluorosulfonyl)imide (LiFSI) as conducting salt for nonaqueous liquid electrolytes for lithium-ion batteries: physicochemical and electrochemical properties. J Power Sources 196:3623–3632

Ue M, Takeda M, Takehara M, Mori S (1997) Electrochemical properties of quaternary ammonium salts for electrochemical capacitors. J Electrochem Soc 44:2684–2688

Miao RR, Yang J, Feng XJ, Jia H, Wang JL, Nuli Y (2014) Novel dual-salts electrolyte solution for dendrite-free lithium-metal based rechargeable batteries with high cycle reversibility. J Power Source 271:291–297

Choi SW, Jo SM, Lee WS, Kim YR (2003) An electrospun poly(vinylidenefluoride) nanofibrous membrane and its battery applications. Adv Mater 15:2027–2032

Ramya CS, Selvasekarapandian S, Hirankumar G, Savitha T, Angelo PC (2008) Investigation on dielectric relaxations of PVP-NH4SCN polymer electrolyte. J Non-Cryst Solids 354:1494–1502

Croce F, Focarete ML, Hassoun J, Meschinia I, Scrosati B (2011) A safe, high-rate and high-energy polymer lithium-ion battery based on gelled membranes prepared by electrospinning. Energy Environ Sci 4:921–927

Zhang H, Liu CY, Zheng LP, Xu F, Feng WF, Li H, Huang XJ, Armand M, Nie J, Zhou ZB (2014) Lithium bis(fluorsulfonyl)imide/poly(ethylene oxide) polymer electrolyte. Electrochim Acta 133:529–538

Gadjourova Z, Andreev YG, Tunstall DP, Bruce PG (2001) Ionic conductivity in crystalline polymer electrolytes. Nature 412:520–523

Sun B, Xu C, Mindemark J, Gustafsson T, Edstrom K, Brandell D (2015) At the polymer electrolyte interfaces: the role of the polymer host in interphase layer formation in Li-batteries. J Mater Chem A 3:13994–14000

Xu C, Sun B, Gustafsson T, Edstrom K, Brandell D, Hahlin M (2014) Interface layer formation in solid polymer electrolyte lithium batteries: an XPS study. J Mater Chem A 2:7256–7264

Shkrob IA, Martin TW, Zhu Y, Abraham DP (2014) Why bis(fluorsulfonyl)imide is a “magic anion” for electrochemistry. J Phy Chem C 118:19661–19671

Gu WT, Borodin O, Zdyrko B, Lin HT, Kim H, Nitta N, Huang JX, Magasinski A, Milicev Z, Berdichevsky G, Yushin G (2016) Lithium–iron fluoride battery with in situ surface protection. Adv Funct Mater 26:1507–1516

Eshetu GG, Diemant T, Grugeon S, Behm RJ, Laruelle S, Armand M, Passerini S (2016) In-depth interfacial chemistry and reactivity focused investigation of lithium-imide- and lithium-imidazole-based electrolytes. ACS Appl Mater Interfaces 8:16087–16100

Suo LM, Xue WJ, Gobet M, Greenbaum SG, Wang C, Chen YM, Yang WL, Li YX, Li J (2018) Fluorine-donating electrolytes enable highly reversible 5-V-class Li metal batteries. PNAS 115:1156–1161

Pan J, Cheng YT (2015) General method to predict voltage-dependent ionic conduction in a solid electrolyte coating on electrodes. Phys Rev B 91:134116

Funding

This work was supported by National Natural Science Foundation of China (Grant No. 52032005), Ministry of Sciences and Technology of China through National Basic Research Program of China (973 Program 2015CB654604).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhang, Y., Feng, W., Zhen, Y. et al. Effects of lithium salts on PEO-based solid polymer electrolytes and their all-solid-state lithium-ion batteries. Ionics 28, 2751–2758 (2022). https://doi.org/10.1007/s11581-022-04525-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-022-04525-3