Abstract

With the aim to maintain the advantage of symmetrical solid oxide fuel cells (SSOFCs), quasi-SSOFC with the interstitial oxygen conducting electrode is fabricated by the in situ forming method. The in situ fabrication process is performed by reducing perovskite typed Pr1-xSrxFeO3-δ (x = 0.4 and 0.5) in hydrogen at 800 °C for 10 h. After the reduction treatment, Pr0.6Sr0.4FeO3-δ (PSF64) is decomposed to (Pr0.6Sr0.4)3Fe2O7, (Pr0.6Sr0.4)2FeO4, and Fe nanoparticles, while Pr0.5Sr0.5FeO3-δ (PSF55) is decomposed to (Pr0.6Sr0.4)2FeO4 and Fe nanoparticles. Results show that the formation of RP-typed layered structure (Pr0.6Sr0.4)3Fe2O7 in reducing atmosphere can accelerate the oxygen ion transport rate, which leads to the enhancement of Rp value from 0.36 to 0.16 Ω cm2 at 800 °C and the improvement of power density from 418 to 502 mW/cm2. It is believed that introducing the interstitial oxygen conducting electrode to a quasi-symmetrical oxide fuel cell is an efficient approach to enhance the performance.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Symmetrical solid oxide fuel cells (SSOFCs), employing the same highly active materials as both cathode and anode, have attracted increasing attention as it can reverse the gas flow of electrodes to avoid the corresponding carbon deposition and sulfur poisoning caused by the using of hydrocarbon fuels [1,2,3]. In this configuration, the fabrication cost of cells can be considerably reduced because the fabrication process can be completed in one step. Besides, the compatibility between electrodes and electrolyte can be improved due to the only one interface existed in such configuration [4, 5]. But unfortunately, the requirements of electrode materials for SSOFCs are extremely strict, including mixed ionic and electronic conducting behavior, chemical and thermal compatibility with electrolyte and redox stable. In addition, the symmetrical electrode materials should exhibit high catalytic activity towards oxygen reduction reaction and fuel oxidation reaction [2, 6].

La0.75Sr0.25Cr0.5Mn0.5O3 was the first material used as a symmetrical electrode for SSOFCs, which shows a good redox stable property and excellent electrochemical performance [1]. These attractive features of redox stable perovskites result in extensive attempts to be devoted to developing the symmetrical electrode materials which can be stable in an oxidizing and reducing environment, such as Sr2Fe1.5Mo0.5O6-δ [7], La0.7Ca0.3Cr0.97O3-δ [8], La0.8Sr0.2Sc0.2Mn0.8O3-δ [9], and La0.5Sr0.5Co0.5Ti0.5O3-δ [10]. However, the materials which can be stable in both oxidizing and reducing atmosphere are extremely limited. As a result, some materials with the advantage of redox reversible stability have been widely evaluated as the electrodes for SSOFCs. The structures of these materials are not stable and will decompose to several phases under reducing atmosphere. But the most attractive characteristic of these materials is the redox reversible stability, which means that the decomposed structure can be recovered by annealing at the operating temperature in air. This feature is suitable for SSOFCs and this configuration can be named as quasi-SSOFCs (Q-SSOFCs) since the electrode is the same but different [11]. When the Q-SSOFCs are worked for a long time and the performance starts to decline, an effective approach to solve this problem is to reverse the anode and cathode, and then perform like a new anode and cathode. Besides, the decomposed structure is always accompanied by nano-metal catalyst or nano metal alloy catalyst which could enhance the catalytic performance of anode, such as Pr0.4Sr0.6Co0.2Fe0.7Nb0.1O3-δ [12], La0.6Sr0.4Mn0.2Fe0.8O3 [13], and Pr0.6Sr0.4Fe0.7Ni0.2Mo0.1O3-δ [14].

Recently, layered structure materials like Ruddlesden-Popper (RP) or K2NiF4 oxides with the accelerated oxygen ions transfer property have gained extensive attention [15,16,17]. The existence of interstitial oxygen in layered materials can transport oxygen ions directly which avoids the combination process with oxygen vacancies, thus enhancing the oxygen transport rate and improving the catalytic performance [17]. With the aim to maintain the advantages of layered structure materials, Yang et al. [18] reported a new strategy to synthesize the RP structured oxide (A3B2O7, n = 2) by in situ reduction. A Co-Fe alloy nanoparticle modified (Pr0.4Sr0.6)3(Fe0.85Nb0.15)2O7 (RP-PSFN) ceramic anode for SOFC was fabricated by calcining the cubic perovskite oxides Pr0.4Sr0.6Co0.2Fe0.7Nb0.1O3-δ (CP-PSCFN) in H2 at 900 °C for 2 h and showed an excellent catalytic activity towards hydrogen oxidation reaction. In this study, Pr1-xSrxFeO3 with the Sr content of 0.4 and 0.5 was prepared to investigate the in situ fabrication process and systematically evaluated as the symmetrical electrode for solid oxide fuel cells.

Experimental

Sample synthesis and cell fabrication

The electrode powders of Pr0.6Sr0.4FeO3 (PSF64) and Pr0.5Sr0.5FeO3 (PSF55) were synthesized by modified pechini combustion method, which is detailedly described in our previous works [14, 19]. The synthesized electrodes were then mixed with YSZ (Commercial, SOFCman, China) or GDC (Commercial, SOFCman, China) electrolyte powder by ball milling for 12 h, and pressed into pellets to evaluate the chemical compatibility between electrode and electrolyte. Further reduction treatments of PSF64 and PSF55 electrodes were conducted at 800 °C for 10 h in a wet H2 atmosphere (3%H2O). For polarization and single cell test, commercial YSZ was fabricated into disks with the diameter of 15 mm by dry-pressing, and then sintered at 1400 °C for 10 h to obtain a dense YSZ substrate with the thickness of 400 μm. PSF64 and PSF55 electrode powders were mixed with solvent (terpineol, 90%wt.) and binder (ethyecellulose, 10%wt.) homogeneously and painted on the surfaces of YSZ substrate, followed by calcining at 1000 °C for 3 h. In order to suppress the chemical reaction between electrode and substrate, GDC paste was painted at the interface between electrode and substrate. Silver slurry was printed on the electrode surfaces for current collecting.

Characterization

X-ray diffraction (XRD, DX-2800) was used to characterize the phase structure of PSF64 and PSF55 which calcined at 1000 °C for 3 h and reduced at 800 °C for 10 h, respectively. Electrochemical impedance spectra of PSF64 and PSF55 electrodes under open circuit voltage conditions were measured in the temperature range of 650–800 °C in air and H2 by IM6 (ZAHNER, Germany). The frequency range is 1,000,000 Hz–0.1 Hz. YSZ-supported SSOFC was evaluated by IM6 with one side exposing to the air and another feeding with wet H2 (97% H2–3% H2O). The morphology and element distribution of YSZ-supported SSOFC were detected by scanning electron microscope (SEM, Gemini-300, Germany) and energy-dispersive X-ray spectroscopy (EDS SDD, Oxford Instruments AZtecEnergy, England).

Results and discussion

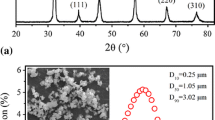

XRD patterns of the prepared PSF64 and PSF55 electrode powders calcined at 1000 °C for 3 h are shown in Fig. 1(a). As is shown, all the characerized peaks of PSF64 and PSF55 are oriented to a perovskite structure with the space group of Pnma. To further investigate the effect of different Sr content in perovskite structure, the magnified (110) peak with the 2θ range of 32–33.6° is shown in Fig. 1(b). Clearly, as the content of Sr increases, the peak of (110) shifts gradually to lower angles. This is probably attributed to the larger ion radius of Sr compared with Pr, which leads to the lattice expansion of perovskite structure, thus resulting in the peak shift. In order to investigate the in situ fabrication process of layered structure materials, PSF64 and PSF55 powders were reduced at 800 °C for 10 h, and XRD patterns are shown in Fig. 1(c, d). It can be seen that PSF64 and PSF55 are not stable in reducing atmosphere. After reduction treatment, the structure of PSF64 and PSF55 exhibits a phase transition from perovskite to layered structure. According to the JCPDS cards, the decomposed phases of PSF64 are confirmed to be K2NiF4-typed (Pr0.6Sr0.4)2FeO4, RP-typed (Pr0.6 Sr0.4)3Fe2O7 and Fe, while the phases of PSF55 in reducing environment are related to K2NiF4-typed PrSrFeO4 and Fe. The schematic diagram of the phase transition of PSF64 and PSF55 in reducing atmosphere is shown in Fig. 2, which can be described as the following equations:

Obviously, the different Sr contents in Pr1-xSrxFeO3-δ perovskite structure result in the different phase transitions in reducing atmosphere.

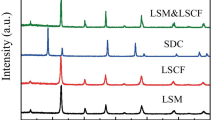

Chemical compatibility property between PSF55 electrode and YSZ (or GDC) electrolyte is evaluated and shown in Fig. 3. By calcining the mixture of YSZ and PSF55 at 1000 °C for 10 h, the XRD peaks exist some extra phases according to Fig. 3(a), which ascribed to the reaction between PSF55 and YSZ. After being compared with standard JCPDS card, the reaction phases are related to SrZrO3 and SrPr2O4, respectively. However, with the same treatment of PSF55 and GDC mixture, the XRD peaks all can be indexed to PSF55 and GDC structure, respectively. That means the chemical compatibility between PSF55 and GDC is much better than YSZ. For the application of PSF55 on the YSZ substrate, GDC buffer layer is absolutely needed to suppress the corresponding reaction.

Polarization resistances (Rp) of PSF64 and PSF55 electrodes under redox atmosphere were measured at 700–800 °C on the configuration of PSF64|GDC|YSZ|GDC|PSF64 and PSF55|GDC|YSZ|GDC|PSF55 to evaluate the catalytic performance for oxygen reduction reaction (ORR) and hydrogen oxidation reaction (HOR). Owing to the two interfaces existed between substrate and electrode, the measured impedance was divided into 2 for calculating polarization resistance. As shown in Fig. 4, the impedance spectra at the whole frequency can be divided into three parts: high-frequency region, medium-frequency region, and low-frequency region, which is related to the ohmic resistance of YSZ electrolyte, the polarization process caused by the dissociation of oxygen, and the charge transfer and the non-charge transfer processes, respectively. The difference between the intercept value at low frequency and high frequency is the polarization resistance [20, 21]. As shown in Fig. 5, Rp values of PSF64 and PSF55 in air are 0.14 and 0.2 Ω cm2 at 800 °C, respectively. It can be seen that the Rp values of PSF55 in air all are lower than that of PSF55 at the measured temperature range. This is probably ascribed to that the larger content of the low valence Sr2+ ion will lead to the formation of oxygen vacancies owing to the charge compensation, further accelerating the process of oxygen adsorption and dissociation on the surface of cathode. However, the Rp values in reducing atmosphere are different; the values of PSF64 are lower than PSF55 at the measured temperature range. This can be explained that the formation of RP-typed layered structure of PSF64 in reducing atmosphere can improve the transfer process of oxygen from the interface between electrode and electrolyte and accelerate the combination process between oxygen ion with H2.

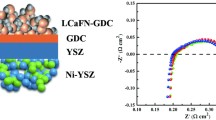

Electrochemical performance of PSF64 and PSF55 single cells with the structure of PSF64|GDC|YSZ|GDC|PSF64 and PSF55|GDC|YSZ|GDC|PSF55 was evaluated at 650–800 °C. As shown in Fig. 6(a, b), the open circuit voltage (OCV) values of PSF64 and PSF55 single cell are 1.074 and 1.076 V at 800 °C, indicating the dense electrolyte and the good seal technology. The maximum power densities of PSF64 at 800 °C, 750 °C, 700 °C, and 600 °C are 502 mW/cm2, 313 mW/cm2, 190 mW/cm2, and 103 mW/cm2, and the maximum power densities of PSF55 are 418 mW/cm2, 266 mW/cm2, 153 mW/cm2, and 79 mW/cm2, respectively. Obviously, the performance of PSF64 is much higher than PSF55, which is attributed to the higher catalytic activity of PSF64 towards HOR. Table 1 listed the performance with several common symmetrical electrodes for SSOFCs. It can be seen that PSF64 and PSF55 exhibit a higher or comparable performance compared with other electrode materials, which can meet the requirement for the operation of SSOFCs. Figure 7 shows the long-term stability performance of SSOFCs with the configuration of PSF64|GDC|YSZ|GDC|PSF64. As is shown, the current densities of SSOFC with PSF64 electrode remain a stable tendency within 80 h, indicating the robust stability performance of PSF64 symmetrical electrode.

The related EIS of PSF64 and PSF55 single cell measured under open circuit condition are shown in Fig. 6(c, d). From the Nyquist diagram of impedance spectra, it can be observed that the high-frequency region represents the ohmic resistance (Ro), and the low-frequency region represents the total resistance (Rt). The difference between the Ro and Rt is polarization resistance (Rp). The corresponding values of Ro, Rt, and Rp are shown in Fig. 8. As is shown, the polarization resistances of PSF64 and PSF55 are 0.14 Ω cm2 and 0.17 Ω cm2 at 800 °C, respectively. In order to further analyze the polarization behavior of PSF64 and PSF55 during the operation, the relaxation time distribution (DRT) method was employed to analyze the impedance obtained at 800 °C. As shown in Fig. 9, the DRT results can be indexed to three peaks (P1, P2, P3). Generally, P1 is the gas diffusion at electrode side and P2 is ascribed to hydrogen/oxygen ion bulk diffusion process. P3 is corresponded to the charge transfer and ion transport process [26,27,28]. It can be seen from the DRT results that the main difference between PSF64 and PSF55 is affected by P3. As for cathode, the larger oxygen vacancies in PSF55 means the lower electron hole concentration, which will lead to the limited charge transfer performance. Besides, the higher oxygen diffusion rate of PSF64 in reducing atmosphere will accelerate the ions transport process.

The cross-section images of PSF64 single cell are shown in Fig. 10(a, b). It can be seen from the images that the symmetrical electrode is porous enough to ensure the gas reaction and adheres well with GDC electrolyte, and the YSZ electrolyte is dense enough to separate the oxidizing and reducing atmosphere. The thicknesses of PSF64 electrode, YSZ substrate, and GDC buffer layer are 30 μm, 400 μm, and 3 μm, respectively. Further, element distribution of PSF64 after I-V test was detected by EDS. As shown in Fig. 10(c–h), all the elements in PSF64 structure are distributed homogeneously and it can be observed that the in situ formed Fe nanoparticles decorate on the surface of PSF64.

Conclusion

An interstitial oxygen conducting electrode with the advantage of fast oxygen ion transport performance was successfully prepared by reducing perovskite typed Pr1-xSrxFeO3 (x = 0.4 and 0.5) in hydrogen at 800 °C for 10 h. The effect of different contents of Sr in perovskite was evaluated, and results showed that the in situ exsolution process with different Sr contents is not the same. The formation of RP-typed layered structure in reducing atmosphere can accelerate the oxygen ion transport rate, leading to the enhancement of Rp value from 0.36 to 0.16 Ω cm2 at 800 °C and the improvement of power density from 418 to 502 mW/cm2. From the DRT analysis, the enhanced performance is attributed to the elevated charge transfer and ion transport process. In summary, introducing interstitial oxygen conduction mechanism to a quasi-symmetrical oxide fuel cell is a potential method to modify the structure and improve the performance.

References

Bastidas DM, Tao SW, Irvine JTS (2006) A symmetrical solid oxide fuel cell demonstrating redox stable perovskite electrodes. J Mater Chem 16(17):1603–1605. https://doi.org/10.1039/b600532b

Ruiz-Morales JC, Canales-Vazquez J, Savaniu C, Irvine JTS, Nunez P (2007) Materials for symmetrical solid oxide fuel cells. Solid Oxide Fuel Cells 10(Sofc-X), Pts 1 And 2 7(1):905. https://doi.org/10.1149/1.2729183

Ruiz-Morales JC, Canales-Vazquez J, Lincke H, Pena-Martinez J, Marrero-Lopez D, Perez-Coll D, Irvine JTS, Nunez P (2008) Potential electrode materials for symmetrical solid oxide fuel cells. Bol Soc Esp Ceram V 47(4):183–188. https://doi.org/10.3989/cyv.2008.v47.i4.172

Liu XJ, Han D, Zhou YC, Meng X, Wu H, Li JL, Zeng FR, Zhan ZL (2014) Sc-substituted La0.6Sr0.4FeO3-δ mixed conducting oxides as promising electrodes for symmetrical solid oxide fuel cells. J Power Sources 246:457–463. https://doi.org/10.1016/j.jpowsour.2013.07.111

Zhang YC, Zhou QJ, He TM (2011) La0.7Ca0.3CrO3-Ce0.8Gd0.2O1.9 composites as symmetrical electrodes for solid-oxide fuel cells. J Power Sources 196(1):76–83. https://doi.org/10.1016/j.jpowsour.2010.07.035

Yang GM, Su C, Chen YB, Tade MO, Shao ZP (2014) Nano La0.6Ca0.4Fe0.8Ni0.2O3-δ decorated porous doped ceria as a novel cobalt-free electrode for “symmetrical” solid oxide fuel cells. J Mater Chem A 2(45):19526–19535. https://doi.org/10.1039/c4ta03485f

Liu QA, Dong XH, Xiao GL, Zhao F, Chen FL (2010) A novel electrode material for symmetrical SOFCs. Adv Mater 22(48):5478–5482. https://doi.org/10.1002/adma.201001044

Lin B, Wang SL, Liu XQ, Meng GY (2010) Simple solid oxide fuel cells. J Alloy Compd 490(1-2):214–222. https://doi.org/10.1016/j.jallcom.2009.09.111

Zheng Y, Zhang C, Ran R, Cai R, Shao Z, Farrusseng D (2009) A new symmetric solid-oxide fuel cell with La0.8Sr0.2Sc0.2Mn0.8O3-δ perovskite oxide as both the anode and cathode. Acta Mater 57(4):1165–1175. https://doi.org/10.1016/j.actamat.2008.10.047

Martinez-Coronado R, Aguadero A, Perez-Coll D, Troncoso L, Alonso JA, Fernandez-Diaz MT (2012) Characterization of La0.5Sr0.5Co0.5Ti0.5O3-δ as symmetrical electrode material for intermediate-temperature solid-oxide fuel cells. Int J Hydrogen Energ 37(23):18310–18318. https://doi.org/10.1016/j.ijhydene.2012.09.033

Su C, Wang W, Liu ML, Tade MO, Shao ZP (2015) Progress and prospects in symmetrical solid oxide fuel cells with two identical electrodes. Adv Energy Mater 5(14):Artn 150018810.1002/Aenm.201500188

Zhang P, Guan GQ, Khaerudini DS, Hao XG, Han MF, Kasai Y, Sasagawa K, Abudula A (2014) Properties of A-site nonstoichiometry (Pr0.4)xSr0.6Co0.2Fe0.7Nb0.1O3-δ (0.9 ≤ x ≤ 1.1) as symmetrical electrode material for solid oxide fuel cells. J Power Sources 248:163–171. https://doi.org/10.1016/j.jpowsour.2013.09.077

Chung YS, Kim T, Shin TH, Yoon H, Park S, Sammes NM, Kim WB, Chung JS (2017) In situ preparation of a La1.2Sr0.8Mn0.4Fe0.6O4 Ruddlesden-Popper phase with exsolved Fe nanoparticles as an anode for SOFCs. J Mater Chem A 5(14):6437–6446. https://doi.org/10.1039/c6ta09692a

Lu XY, Yang Y, Ding YZ, Chen YH, Gu QW, Tian D, Yu WL, Lin B (2017) Mo-doped Pr0.6Sr0.4Fe0.8Ni0.2O3-δ as potential electrodes for intermediate-temperature symmetrical solid oxide fuel cells. Electrochim Acta 227:33–40. https://doi.org/10.1016/j.electacta.2016.12.170

Zhou SJ, Yang Y, Chen H, Ling YH (2020) In situ exsolved Co-Fe nanoparticles on the Ruddlesden-Popper-type symmetric electrodes for intermediate temperature solid oxide fuel cells. Ceram Int 46(11):18331–18338. https://doi.org/10.1016/j.ceramint.2020.05.057

Ling YH, Guo TM, Zhang XZ, Budiman RA, Fujimaki Y, Nakamura T, Lin B, Kawada T, Amezawa K (2018) Evaluation of electrical conductivity and oxygen diffusivity of the typical Ruddlesden-Popper oxide Sr3Fe2O7-δ (vol 43, pg 16264, 2017). Ceram Int 44(2):2632–2632. https://doi.org/10.1016/j.ceramint.2017.10.122

Lee KT, Manthiram A (2006) LaSr3Fe3-yCoyO10-δ (0 ≤ y ≤ 1.5) intergrowth oxide cathodes for intermediate temperature solid oxide fuel cells. Chem Mater 18(6):1621–1626. https://doi.org/10.1021/Cm052645+

Yang CH, Li J, Lin Y, Liu J, Chen FL, Liu ML (2015) In situ fabrication of CoFe alloy nanoparticles structured (Pr0.4Sr0.6)3(Fe0.85Nb0.15)2O7 ceramic anode for direct hydrocarbon solid oxide fuel cells. Nano Energy 11:704–710. https://doi.org/10.1016/j.nanoen.2014.12.001

Tian D, Lin B, Yang Y, Chen YH, Lu XY, Wang ZG, Liu W, Traversa E (2016) Enhanced performance of symmetrical solid oxide fuel cells using a doped ceria buffer layer. Electrochim Acta 208:318–324. https://doi.org/10.1016/j.electacta.2016.04.189

Zhang CJ, Zhao HL (2012) A novel cobalt-free cathode material for proton-conducting solid oxide fuel cells. J Mater Chem 22(35):18387–18394. https://doi.org/10.1039/C2jm32627b

Luo X, Yang Y, Yang Y, Tian D, Lu X, Chen Y, Huang Q, Lin B (2017) Reduced-temperature redox-stable LSM as a novel symmetrical electrode material for SOFCs. Electrochim Acta

Bian LZ, Wang LJ, Duan CC, Cai CK, Song XW, An SL (2019) Co-free La0.6Sr0.4Fe0.9Nb0.1O3-δ symmetric electrode for hydrogen and carbon monoxide solid oxide fuel cell. Int J Hydrogen Energ 44(60):32210–32218. https://doi.org/10.1016/j.ijhydene.2019.10.090

Zhou Q, Yuan C, Han D, Luo T, Li JL, Zhan ZL (2014) Evaluation of LaSr2Fe2CrO9-δ as a potential electrode for symmetrical solid oxide fuel cells. Electrochim Acta 133:453–458. https://doi.org/10.1016/j.electacta.2014.04.104

Cao ZQ, Zhang YH, Miao JP, Wang ZH, Lu Z, Sui Y, Huang XQ, Jiang W (2015) Titanium-substituted lanthanum strontium ferrite as a novel electrode material for symmetrical solid oxide fuel cell. Int J Hydrogen Energ 40(46):16572–16577. https://doi.org/10.1016/j.ijhydene.2015.10.010

Cai HD, Zhang LL, Xu JS, Huang JH, Wei XL, Wang L, Song ZY, Long W (2019) Cobalt-free La0.5Sr0.5Fe0.9Mo0.1O3-δ electrode for symmetrical SOFC running on H2 and CO fuels. Electrochim Acta 320:UNSP 134642. https://doi.org/10.1016/j.electacta.2019.134642

Song WC, Ma ZK, Yang Y, Zhang SH, Ou XM, Ling YH (2020) Characterization and polarization DRT analysis of direct ethanol solid oxide fuel cells using low fuel partial pressures. Int J Hydrogen Energy 45(28):14480–14490. https://doi.org/10.1016/j.ijhydene.2020.03.146

Wang XX, Ma ZK, Zhang T, Kang JH, Ou XM, Feng PZ, Wang SR, Zhou FB, Ling YH (2018) Charge-transfer modeling and polarization drt analysis of proton ceramics fuel cells based on mixed conductive electrolyte with the modified anode-electrolyte interface. Acs Appl Mater Inter 10(41):35047–35059. https://doi.org/10.1021/acsami.8b10429

Cai W, Guo YY, Zhang T, Guo TM, Chen H, Lin B, Ou XM, Ling YH (2018) Characterization and polarization DRT analysis of a stable and highly active proton-conducting cathode. Ceram Int 44(12):14297–14302. https://doi.org/10.1016/j.ceramint.2018.05.035

Funding

This work was supported by the Key Program of Natural Science Foundation of the Anhui Higher Education Institutions of China (KJ2017A462).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhao, X., Yang, X., Tian, D. et al. Tailoring an interstitial oxygen conducting electrode by in situ fabrication for quasi-symmetrical solid oxide fuel cells. Ionics 27, 259–268 (2021). https://doi.org/10.1007/s11581-020-03790-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-020-03790-4