Abstract

Alloying Pt with 3d transition metals can largely promote the electrocatalytic performances of Pt-based nanocatalysts by downshifting the d-band center of Pt and modulating the electronic structure. Here, PtCo nanowire catalysts are obtained by a simple hydrothermal method. Due to the special one-dimensional (1D) nanowire structure and the strong synergistic effect between Pt and Co, the PtCo nanowire catalysts exhibit high electrocatalytic performances for ethanol oxidation reaction (EOR). The mass activity of optimal Pt1Co1 nanowires is 3.69 times of pure Pt. It also shows excellent durability and stability, which can sustain high activity after operating more than 500 cycles of electrochemical cycling. Our works point out a direction for the development of Pt-based nanomaterials with potential industrial application.

.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The non-renewability of traditional fossil fuels and the resulting environmental problems became two major obstacles, which limited the social development. The search for clean, renewable, and low-cost energy is an important strategy to solve these problems [1]. As green energy conversion devices, direct ethanol fuel cells (DEFCs) have been widely regarded as one of the promising technologies to attenuate the crisis caused by energy shortage due to their high energy conversion efficiency, low operating temperature, and low pollution emissions [2, 3]. Electrocatalysts are the core components of DEFCs; therefore, the development of efficient, low-cost, and stable electrocatalysts is the key to achieve the goal of the industrialization of DEFCs [4]. At present, platinum (Pt) and its alloys are the most effective electrocatalysts for driving fuel cell reactions. However, these catalysts are expensive and unstable, which make them difficult to get a practical application [5,6,7,8,9]. Therefore, tremendous efforts have been devoted, such as doping transition metals to reduce the content of Pt, to obtain high-performance electrocatalysts. In this regard, the as-obtained Pt-based nanocatalysts show not only better electrocatalytic activity but also high stability, due to the synergistic effect between Pt and nonprecious metal [10,11,12,13,14]. More importantly, the energy of d-band center of Pt can become lower after the incorporation of 3d transition metals, greatly promoting to the improvement of electrocatalytic performances.

In addition to doping a transition metal element, the synthesis of nanomaterials with specific morphology is also one of the effective methods for improving the electrocatalytic performance [15, 16]. At present, various unique morphologies of Pt-based nanomaterials have been successfully designed, such as flower-like [17,18,19], block [20, 21], film [22, 23], and core-shell structure [24, 25], but most of these structures have the disadvantages of low activity and poor stability [26, 27]. In recent years, one-dimensional (1D) nanowire structures have become a hot research topic, which ascribed to their anisotropy, Ostwald ripening, and various scale combinations [28,29,30]. The Pt-based nanowire structure has also been synthesized. For example, Xu and coworkers reported the well-defined mesoporous Pt nanowire which was prepared by chemical reduction deposition [31], Chen and coworkers showed a facile chemical co-reaction method for fabricating chain-like Pt-Cu nanowire [32], Wang and coworkers documented the Pt-Pd nanowire which was synthesized by a facile one-pot aqueous approach with the assistance of l-histidine [33], and Shen and coworkers exhibited a facile method for preparing trimetallic PtAuCu nanowires [34]. These nanomaterials exhibit excellent performance in terms of water decomposition, alcohol oxidation, and supercapacitance.

PtCo nanowires, as an advanced class of nanomaterials, have been reported. For example, Chen and his coworkers reported the growth of PtCo nanowires on the free-standing carbon foam framework by a two-step process, which could be employed for efficient ethanol oxidation reaction (EOR) [35]. Buay and coworkers reported the fabrication of PtCo nanowires by a direct electrodeposition [36], which was applied for methanol oxidation reaction (MOR). However, lots of efforts have been devoted for fabricating PtCo nanowires toward electro-oxidation reaction; the complexed synthetic method and unsatisfactory electro-oxidation performance still impeded their practical application. Based on the above analysis, we report a class of 1D PtCo nanowire prepared by a simple hydrothermal method. Due to the unique 1D nanowire structure and the synergistic effect of PtCo, the nanomaterials show good ethanol oxidation performance and suggest the potential applicability of such compounds in proton exchange membrane fuel cells.

Experimental section

Chemicals and materials

Chloroplatinic acid (H2PtCl6, 99%), cobaltous chloride (CoCl2·6H2O, AR), potassium hydroxide (KOH, AR), N,N-dimethylformamide (DMF, AR), and ethylene glycol (EG, AR) were all purchased from Sinopharm Chemical Reagent Co. Ltd. (Shanghai, China). All the reagents were used as received without further purification. The water (18 MΩ cm−1) used in all experiments were prepared by passing through an ultra-pure purification system (Aqua Solution).

Synthesis of PtCo nanowire

In the standard synthesis of Pt1Co1 nanowire, 0.02 mM of H2PtCl6, 4.8 mg of CoCl2·6H2O, and 10 mM of KOH were added into the solution containing 6 mL of DMF and 4 mL of EG. After sonicating for 5 min to make all the samples completely dissolved, the homogeneous solution was transferred to a reaction vessel and heated from room temperature to 170 °C and maintained for another 8 h. After cooling at room temperature, the products were then collected after centrifuged and washed with ethanol and acetone mixture for several times, and the final product was dispersed in 10 mL of deionized water for further use. The preparation of Pt1Co0.5 and Pt1Co1.5 nanowires is similar to the above synthetic method except that the amount of CoCl2·6H2O is changed to 2.4 mg and 7.2 mg, respectively. The pure Pt nanocatalyst is similar to the above synthetic procedure without the addition of CoCl2·6H2O.

Characterizations

The transmission electron microscope (TEM) was performed with JEM-2100F at 200 kV. X-ray diffraction (XRD: D/MAX–255) was conducted by a Philips advance powder XRD with Cu Ka radiation source (l = 0.1542 nm). X-ray photoelectron spectroscopy (XPS) was conducted on a Thermo Scientific ESCALab 220i-XL electron spectrometer from VG Scientific with 300 W Al Kα X-ray radiation source.

Electrochemical measurements

All the electrochemical tests were performed by using a CHI760E electrochemical station. The glassy carbon electrode (GCE) was selected as the working electrode, which needed to be polished everytime before electrochemical measurements. To prepare the catalyst-coated working electrode, 5.1 × 10−3 mmol of catalyst was dispersed in a mixture containing 4.95 mL of isopropanol and 50 μL of Nafion (5%) to generate a homogeneous dispersion (0.20 mg Pt/mL). Then, 10 μL of catalyst inks was deposited on a GCE to obtain the catalyst-modified working electrode, and the mass of Pt loaded on the surface of GCE is 2 μg. The cyclic voltammetry (CV) for EOR was conducted in 1 M KOH + 1 M ethanol solution with a rate of 50 mV s−1. The continuous CV of 500 cycles and chronoamperometry (CA) measurement at the potential of 0.8 V (vs RHE) for 1 h have also been conducted to evaluate their durability. All electrochemical experiments were performed at room temperature. For comparison, the pure Pt catalyst was used as the reference catalysts.

Results and discussion

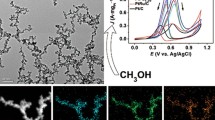

We synthesized PtCo nanowires using a simple hydrothermal method as described in Scheme 1. In order to study the morphology and structural characteristics of the material in detail, we employed the transmission electron microscope (TEM), X-ray diffraction (XRD), and X-ray photoelectron spectroscopy (XPS) to characterize the structural characteristics of these compounds. As shown in Fig. 1a, Pt1Co1 nanomaterials have mutually interlaced network structure, which is helpful to facilitate the mobility of electron. These network structures are composed of many ultrathin uniform nanowires with a diameter of 20 nm. As seen in Fig. 1b, each nanowire is consisted of ultrathin nanowires with rough surface, which can expose more surface active areas. A detailed observation in Fig. 1c indicated that the surface of the Pt1Co1 nanowires contained many pores, which were beneficial for the adsorption and diffusion of intermediates involved in EOR [37]. We used powder X-ray diffraction (PXRD) to characterize the PtCo alloy. As shown in Fig. 1d, the four diffraction peaks of Pt1Co1 nanowires are indexed to Pt (PDF#86-0646). However, the XRD patterns of Pt1Co1 nanowires can also display a slight shift to high angle in comparison with the standard, due to the incorporation of Co atoms into Pt, indicating the successful construction of PtCo alloy nanocatalysts [38].

In order to witness that the strategy is universally applicable, we have therefore attempted to construct PtCo nanocatalysts with different chemical compositions by adjusting the feed ratio of the reactants. As shown in Fig. 2a, c, the Pt1Co0.5 and Pt1Co1.5 nanowires were successfully prepared using the same synthetic method. We also found that the surface of the Pt1Co0.5 and Pt1Co1.5 nanowires was embedded with ultrafine nanoparticles and the diameters of the nanowires are about 15 nm. After a further observation, it is clearly found that the surrounding of the nanowires consists of some small-sized nanowires, indicating that the Pt1Co1 with a suitable ratio is able to maintain the full structure compared with Pt1Co0.5 and Pt1Co1.5 (Fig. 2b, d). And the PXRD patterns of 1D Pt1Co0.5 and Pt1Co1.5 nanowires exhibited a slight high-angle shift, indicating the formation of PtCo alloy (Fig. 1d). These results have also proved that this synthesis strategy could be widely applied to the synthesis of PtCo nanowire catalyst with different chemical compositions [39].

X-ray photoelectron spectroscopy (XPS) was used to study the electronic state and surface chemical components. The XPS spectrum was corrected using C 1s (284.5 eV) as a standard. As shown in Fig. 3a, the binding energies of 4f5/2 and 4f7/2 of Pt0 peaks are 75.30 eV and 72.01 eV, respectively, and the spin-orbit splitting energy between them is 3.29 eV. In addition, the peaks appearing at 73.16 eV and 76.44 eV are assigned to Pt2+ [40]. According to the intensity ratio of Pt0/Pt2+, Pt in PtCo nanowires mainly exists in the form of zero valence state. As shown in Fig. 3b, we can easily see that the two apparent peaks were located at the binding energies of 796.69 and 780.70 eV, which corresponded to the Co 2p1/2 and Co 2p3/2 of Co2+ [39,40,41], respectively. The other two peaks at the binding energies of 802.80 and 785.90 eV were ascribed to their corresponding satellite peaks.

Since the synthesized PtCo nanowires have a porous nanostructure, an aspect ratio, and the strong synergistic effect of PtCo, this material may show a large application potential in liquid fuel oxidation. At the same time, because ethanol has the advantages of flammability, low toxicity, and renewability in biomass raw materials, we chose EOR as a model to evaluate the electrocatalytic oxidation performance of PtCo nanowires. First, we evaluated the electrocatalytic activity of the synthesized catalyst by cyclic voltammetry (CV) at a scanning speed of 50 mV s−1 in a solution containing 1 M KOH and 1 M ethanol. As shown in Fig. 4a, the CV curves of the PtCo nanowires show a distinct peak in both the positive sweep and the reverse sweep. The peak appearing in the positive sweep is due to the oxidation of ethanol adsorbed on the surface of the Pt catalyst, while the peak at the backward sweeping section is produced by the further oxidation of the intermediate produced by the oxidation of ethanol [42]. Therefore, for the EOR, we usually calculate the catalytic activity of the flat-valley catalyst based on the oxidation peak current density of the positive sweep. Therefore, we can clearly see that Pt1Co1 nanowires have the highest electrocatalytic activity of 2203 mA mg−1, followed by Pt1Co1.5 (806 mA mg−1) and Pt1Co0.5 (782 mA mg−1). Pure Pt has the worst electrocatalytic performance (597 mA mg−1). The great enhancement in EOR activity of 1D PtCo nanowires is ascribed to the porous nanowire structure, strong synergistic effect, and modulated electronic structure.

a CV curves of pure Pt, Pt1Co0.5, Pt1Co1, and Pt1Co1.5 toward EGOR. b CA curves of pure Pt, Pt1Co0.5, Pt1Co1, and Pt1Co1.5 for continuous 1 h (at 0.8 V vs RHE). c Retained mass activities and normalized current densities of all the samples. d Long-term stability comparison of pure Pt, Pt1Co0.5, Pt1Co1, and Pt1Co1.5 for continuous CVs of 500 cycles. e The retained mass activities and normalized current densities of all the samples after continuous CVs of 500 cycles

In order to study the electrocatalytic performance of PtCo nanowires in detail, we used the CA test to study the stability of the catalysts. As shown in Fig. 4b, c, the four groups of electrodes showed a large current drop at the initial stage, and then gradually reached to a steady state. The reason why the current density drops significantly during the scanning process can be attributed to the formation of Pt oxide or the intermediates formed in the oxidation process of ethanol, which occupy the active site of the Pt surface and result in the activity decrease [43]. Figure 4c shows the retained mass activities and normalized current percentages of different catalysts after 3600 s. As seen in Fig. 4c, the Pt1Co1 nanowires can maintain the mass activity and normalized current percentage of 114.12 mAmg−1 and 5.15%, respectively, both of which are much higher than pure Pt (17.9 mAmg−1 and 3.75%), Pt1Co1.5 (21.4 mAmg−1 and 2.53%), and Pt1Co0.5 (21.4 mAmg−1 and 3.33%), indicating the best long-term durability of Pt1Co1. To further evaluate the stability of the PtCo alloy and the pure Pt, the continuous CV cycling of 500 cycles has been performed. We took the first circle, the 50th circle, the 100th circle, the 150th circle, the 200th circle, and so on (Fig. 4d). The maximum peak current density of the 500th circle is plotted. The result can be apparently showed in Fig. 4d, where the Pt1Co1 showed the highest current density after 500 cycles, followed by Pt1Co0.5 nanowires, Pt1Co1.5 nanowires, and Pt. From Fig. 4e, it can also be more apparently to understand that the residual current density and normalized current of Pt1Co1 nanowires are 1218.8 mAmg−1 and 55%, respectively, which are significantly higher than Pt1Co0.5 nanowires (373.09 mAmg−1 and 51.8%), Pt1Co1.5 (336.83 mAmg−1 and 44.1%), and pure Pt (27.68 mAmg−1 and 41.4%). Therefore, the electrocatalytic performance of Pt1Co1 nanowires is remarkably better than the other two PtCo alloys and pure Pt. In general, the reason for the apparent increase in Pt1Co1 catalyzed ethanol oxidation performance may be due to the relatively uniform nanowire structure of this material and the synergistic effect between Pt and Co [44,45,46].

Conclusions

In general, we have prepared a class of composition-tunable PtCo alloy nanocatalysts with the unique 1D nanowire structure by a simple hydrothermal method. Compared with the pure Pt, the incorporation of Co not only decreases the cost of Pt, but also increases the electrocatalytic performance for EOR. The synthesized Pt1Co1 nanowires exhibit high performance due to uniform structure and possible synergistic effects and electronic effects between Pt and Co, whose mass activity was 3.69 times higher than that of pure Pt. In addition, all of the PtCo nanowires also possessed good long-term stability, and the optimal Pt1Co1 nanowires could sustain 55% electrocatalytic activity of the initial value after 500 cycles of CV cycling, indicating that we have prepared a new type of nanowire electrocatalyst with excellent catalytic performance for ethanol oxidation.

References

Tian L, Wang J, Wang K, Wo H, Wang X, Zhuang W, Li T, Du X (2019) Carbon-quantum-dots-embedded MnO2 nanoflower as an efficient electrocatalyst for oxygen evolution in alkaline media. Carbon 143:457–466

Liu X, Zhang Y, Gong M, Tang Y, Lu T, Chen Y, Lee J (2014) Facile synthesis of corallite-like Pt–Pd alloy nanostructures and their enhanced catalytic activity and stability for ethanol oxidation. J Mater Chem A 2:13840–13844

Liu M, Zhang R, Chen W (2014) Graphene-supported nanoelectrocatalysts for fuel cells: synthesis, properties, and applications. Chem Rev 114:5117–5160

Liu M, Li X, Chen W (2017) Ternary PtPdTe nanowires winded around 3D free-standing carbon foam as electrocatalysts for oxygen reduction reaction. Electrochim Acta 247:426–434

Xu H, Song P, Fernandez C, Wang J, Zhu M, Shiraishi Y, Du Y (2018) Sophisticated construction of binary PdPb alloy nanocubes as robust electrocatalysts toward ethylene glycol and glycerol oxidation. ACS Appl Mater Interfaces 10:12659–12665

Liu M, Chen L, Wang A, Fang K, Feng J (2017) Ternary PtCoNi flower-like networks: one-step additive-free synthesis and highly boosted electrocatalytic performance for hydrogen evolution and oxygen reduction. Int J Hydrogen Energy 42:25277–25284

Lu S, Eid K, Ge D, Guo J, Wang L, Wang H, Gu H (2017) One-pot synthesis of PtRu nanodendrites as efficient catalysts for methanol oxidation reaction. Nanoscale 9:1033–1039

Zhang C, Sandorf W, Peng Z (2015) Octahedral Pt2CuNi uniform alloy nanoparticle catalyst with high activity and promising stability for oxygen reduction reaction. ACS Catal 5:2296–2300

CaoY YY, Shan Y, Huang Z (2016) One-pot and facile fabrication of hierarchical branched Pt-Cu nanoparticles as excellent electrocatalysts for direct methanol fuel cells. ACS Appl Mater Interfaces 8:5998–6003

Li S, Liu H, Wang Y, Xu W, Li J, Liu Y, Guo X, Song Y (2015) Controlled synthesis of high metal-loading, Pt-based electrocatalysts with enhanced activity and durability toward oxygen reduction reaction. RSC Adv 5:8787–8792

Lu Y, Jiang Y, Chen W (2013) PtPd porous nanorods with enhanced electrocatalytic activity and durability for oxygen reduction reaction. Nano Energy 2:836–844

Ammam M, Easton E (2013) PtCu/C and Pt(Cu)/C catalysts: synthesis, characterization and catalytic activity towards ethanol electrooxidation. J Power Sources 222:79–87

Lu Y, Jing Y, Wu H, Chen W (2013) Nano-PtPd cubes on graphene exhibit enhanced activity and durability in methanol electrooxidation after CO stripping–cleaning. J Phys Chem C 117:2926–2938

Nosheen F, Zhang Z, Xiang G, Xu B, Yang Y, Saleem F, Xu X, Zhang J, Wang X (2014) Three-dimensional hierarchical Pt-Cu superstructures. Nano Res 8:832–838

Zhang N, Bu L, Guo S, Guo J, Huang X (2016) Screw thread-like platinum-copper nanowires bounded with high-index facets for efficient electrocatalysis. Nano Lett 16:5037–5043

Zhang X, Liu X, Zhang L, Li D, Liu S (2016) Novel porous Ag2S/ZnS composite nanospheres: fabrication and enhanced visible-light photocatalytic activities. J Alloy Comp 655:38–43

Thi A, Nguyen N, Shim J (2018) Seedless, one-step synthesis of porous Pt-Pd nanoflowers for electroreduction of oxygen in acidic medium. Appl Surf Sci 458:910–916

Yu S, Li F, Yang H, Li G, Zhu G, Li J, Zhang L, Li Y (2017) Pt-nanoflower as high performance electrocatalyst for fuel cell vehicle. Int J Hydrog Energy 42(2997):1–29976

Wang S, Chang J, Xue H, Xing W, Feng L (2017) Catalytic stability study of a Pd-Ni2P/C catalyst for formic acid electrooxidation. ChemElectroChem 4:1243–1249

Choi S (2016) Facile synthesis of platinum octahedral and cubes through the manipulation of reduction kinetics. Adv Powder Tech 27:1862–1867

Oh J, Lee Y, Park K (2013) Improved photo-catalytic activity of single-crystalline TiO2 nanowires surrounded by Pt cube nanoparticles. J Indust Eng Chem 19:1391–1394

Giarratano F, Arzac M, Godinho V, Hufschmidt D, Jiménez de Haro M, Montes O, Fernández A (2018) Nanoporous Pt-based catalysts prepared by chemical dealloying of magnetron-sputtered Pt-Cu thin films for the catalytic combustion of hydrogen. Appl Catal Environ 235:168–176

Feng L, Chang J, Jiang K, Xue H, Liu C, Cai W, Xing W, Zhang J (2016) Nanostructured palladium catalyst poisoning depressed by cobalt phosphide in the electro-oxidation of formic acid for fuel cells. Nano Energy 30:355–361

Parka H, Parkb J, Kim P, Yoo S (2018) Hollow PdCu2@Pt core@shell nanoparticles with ordered intermetallic cores as efficient and durable oxygen reduction reaction electrocatalysts. Appl Catal B Environ 225:84–90

Zhang C, Zhang R, Li L, Li X, Chen W (2017) Oxygen electroreduction by single PtPd nanocubes encaged in hollow carbon nanospheres: improved durability and strong effect of carbon-shell thickness. Part Part Syst Charact 34:1700034

Huang X, Zhan Z, Cao L, Chen Y, Zhu E, Lin Z, Li M, Yan A, Zettl A, Wang Y, Duan X, Mueller T, Huang Y (2015) High-performance transition metal–doped Pt3Ni octahedra for oxygen reduction reaction. Science 348:1230

Li Z, Jiang Z, Zhu W, He C, Wang P, Wang X, Li T, Tian L (2019) Facile preparation of CoSe2 nano-vesicle derived from ZIF-67 and their application for efficient water oxidation. Appl Surf Sci. https://doi.org/10.1016/j.apsusc.2019.144368

Wang F, Xue H, Tian Z, Xing W, Feng L (2018) Fe2P as a novel efficient catalyst promoter in Pd/C system for formic acid electro-oxidation in fuel cells reaction. J Power Sources 375:37–42

Wang F, Yu H, Tian Z, Xue H, Feng L (2018) Active sites contribution from nanostructured interface of palladium and cerium oxide with enhanced catalytic performance for alcohols oxidation in alkaline solution. J Energy Chem 27:395–403

Lu Y, Steinberger-Wilckens R, Du S (2018) Evolution of gas diffusion layer structures for aligned Pt nanowire electrodes in PEMFC applications. Electrochim Acta 279:99–107

Zhang C, Chen J, Xu L (2018) Dual-templating approach to ordered mesoporous Pt nanowires with various morphologies. Mater Lett 223:97–101

Cao J, Du Y, Dong M, Chen Z, Xu J (2018) Template-free synthesis of chain-like PtCu nanowires and their superior performance for oxygen reduction and methanol oxidation reaction. J. Alloy. Comp. 747:124–130

Ju K, Liu L, Feng J, Zhang Q, Wei J, Wang A (2016) Bio-directed one-pot synthesis of Pt-Pd alloyed nanoflowers supported on reduced graphene oxide with enhanced catalytic activity for ethylene glycol oxidation. Electrochim Acta 188:696–703

Liu Y, Ren G, Wang M, Zhang Z, Liang Y, Wu S, Shen J (2019) Facile synthesis of trimetallic PtAuCu alloy nanowires as high performance electrocatalysts for methanol oxidation reaction. J Alloy Comp 780:504–511

Liu M, He S, Chen W (2016) Free-standing 3D hierarchical carbon foam-supported PtCo nanowires with “Pt skin” as advanced electrocatalysts. Electrochim Acta 199:218–226

Bertin E, Garbarino S, Ponrouch A, Buay D (2012) Synthesis and characterization of PtCo nanowires for the electro-oxidation of methanol. J Power Sources 206:20–28

Wang X, Zhu F, He Y, Wang M, Zhang Z, Ma Z, Li R (2016) Highly active carbon supported ternary PdSnPtx ( x= 0.1–0.7) catalysts for ethanol electro-oxidation in alkaline and acid media. J Colloid Interface Sci 468:200–210

Liu Q, Sun L, Zhao X, Huang J, Han C, Yang X (2018) One-pot synthesis of interconnected Pt95Co5 nanowires with enhanced electrocatalytic performance for methanol oxidation reaction. Nano Res 11:2562–2572

Tian L, Wo H, Wang K, Wang X, Zhuang W, Li T, Du X (2019) Ultrathin wrinkled NiFeP nanosheets enable efficient oxygen evolution electrocatalysis. J Taiwan Instit Chem Eng 97:200–206

Zhong J, Li L, Waqas M, Wang X, Fan Y, Qi J, Yang B, Rong C, Chen W, Sun S (2019) Deep eutectic solvent-assisted synthesis of highly efficient PtCu alloy nanoclusters on carbon nanotubes for methanol oxidation reaction. Electrochim Acta 322:134677–134683

Tian L, Wang K, Wo H, Wang P, Pang X, Zhai X, Zhuang W, Li T, Du X (2019) Bundle-shaped cobalt-nickel selenides as advanced electrocatalysts for water oxidation. Int J Hydrogen Energy 44:2868–2876

Zhang N, Guo S, Zhu X, Guo J, Huang X (2016) Hierarchical Pt/PtxPb core/shell nanowires as efficient catalysts for electrooxidation of liquid fuels. Chem Mater 28:4447–4452

Tian L, Wang K, Wo H, Li Z, Song M, Li J, Li T, Du X (2019) Construction of hierarchical bundle-like CoNi layered double hydroxides for the efficient oxygen evolution reaction. J Taiwan Instit Chem Eng 96:273–280

Zhao L, Qiu G, Shen Y, Wang X, Zhuang W, Li J, Song M, Wang P, Tian L (2020) Ultrafine trimetallic oxyphosphide nanoparticles for efficient electrochemical overall water splitting. J Alloy Compd. https://doi.org/10.1016/j.jallcom.2019.153161

Hong W, Shang C, Wang J, Wang E (2015) Trimetallic PtCuCo hollow nanospheres with a dendritic shell for enhanced electrocatalytic activity toward ethylene glycol electrooxidation. Nanoscale 7:9985–9989

He Y, Wang M, Ma Z, Kundu M, Ma G, Lin N, Tang B, Wang X (2016) Facile synthesis of Pt-/Pd-MODIFIED NiTi electrode with superior electro-catalytic activities toward methanol, ethanol and ethylene glycol oxidation. Surf Rev Lett 23:1550092

Acknowledgements

This work was supported by the Natural Science Foundation of the Jiangsu Higher Education Institutions of China (19KJB150019), the Youth Science and Technology Talents Enrollment Project of the Jiangsu Association of Science and Technology, the Jiangsu province key R & D projects of China (BE2016648), the Key University Science Research Project of Jiangsu Province (16KJA210001), the National Natural Science Foundation of China (no. 21703194), and the Natural Science Foundation of the Jiangsu Higher Education Institutions of China (19KJA430020).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhai, X., Wang, P., Wang, K. et al. Facile synthesis of PtCo nanowires with enhanced electrocatalytic performance for ethanol oxidation reaction. Ionics 26, 3091–3097 (2020). https://doi.org/10.1007/s11581-019-03419-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-019-03419-1