Abstract

In this paper, a new, simple, and sustainable method of the Cu2ZnSnS4 (CZTS) thin-film synthesis is presented. The CZTS films have been electrochemically deposited by a single-step electrodeposition from deep eutectic (choline-urea) electrolyte, without sulfurization step, onto fluorine-doped tin oxide (FTO)-coated glass substrates. − 1.3 V/SCE has been selected as the optimum deposition potentials to grow the CZTS thin films. As-deposited CZTS films were characterized using a range of characterization techniques to study the structural, morphological, and compositional properties and confirmed the presence of the Cu2ZnSnS4 phases. The direct band gap energy for the CZTS thin films is found to be about 1.48 eV.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Thin films of semiconductors used in photovoltaics applications are usually deposited from the vapor phase or from the liquid phase. To increase the use of solar energy, there is a need for new technologies to both decrease the production costs and increase the efficiency of photovoltaic systems. Thin-film solar cells offer the opportunity to lower the price of solar energy by using small amounts of materials and low-cost manufacturing technologies. A lot of studies have been focused on semiconductor thin-film depositions and some researchers have adopted a non-vacuum approach in order to reduce the cost and simplify the process, including the spin coating and microwave-assisted solution method [1], sputtering techniques [2], drop coating [3], spray pyrolysis [4], and electro and photochemical deposition [5,6,7,8]. Many semiconductors were employed in order for replacing silicon cells, including binary compounds like ZnO [9], ternary as CIS [10], and quaternary like CIGS [5].

Because of its direct optical band gap of 1.5 eV, Cu2ZnSnS4 (CZTS) is a promising absorber candidate for thin-film heterojunction solar cells. It is a promising quaternary kesterite nontoxic p-type semiconductor [11] and promising for high-efficiency and low-cost thin-film solar cells. This thin-film semiconductor can be synthesized by different techniques such as non-vacuum deposition [12], the spin coating method [13], and by the electrodeposition [14].

To maintain S composition, annealing in the H2S atmosphere is done by many of the research groups. In this paper, we proposed the synthesis of Cu2ZnSnS4 (CZTS) thin using single-step electrodeposition technique and subsequently studied the effects of the electrodeposition potential on its structural, morphological, and compositional properties.

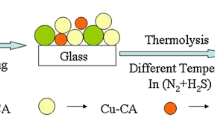

The main purpose of this study is to report the synthesis of CZTS onto FTO substrate by a single-step electrodeposition from a deep eutectic solvent (DES). The DES was chosen as an electrolyte because of its recent importance as new electrolytes for electrochemistry [15]. Many ionic liquids were used for the electrodeposition, among them are choline chloride-carboxylic acids [16] and choline-urea [17] that are the most used. They have some vital advantages, first of all, they are non-inflammable and non-corrosive. Secondly, they have a wide electrochemical window, a high thermal stability, a high electrical conductivity, and a high solvating capability [18].

In this work, the used electrolyte is the deep eutectic solvent choline-urea (1:2), which is a mixture of choline chloride (C5H14ClNO) and urea (CH4N2O) in a 1:2 mole ratio, respectively. The choline has a melting point of 302 °C and urea, 133 °C. The mixture melts at 50 °C.

The specific aims of the research work are as follows: (i) to optimize the electrochemical deposition process on FTO-coated glass, from a deep eutectic solvent (DES), in order to obtain a high-quality CZTS thin film; (ii) to study the influence of some parameters on the electrodeposition process, and (iii) to characterize the electrodeposition of CZTS without the sulfurization route. The CZTS films were characterized by X-ray diffraction (XRD), scanning electron microscopy (SEM-EDS), and ICP analysis. To the best of our knowledge, this is the first report on the electrodeposition of CZTS using choline-based DES as an electrolyte and without the step of sulfurization.

Experimental procedure

Electrodeposition of quaternary precursor layers was performed galvanostatically in a three-electrode electrochemical cell assembly at room temperature using an AMEL-2549 potentiostat controlled by VoltaScope software. Fluorine-doped tin oxide (FTO)-coated transparent conducting glass (1 × 2 cm2) of nominal sheet resistance 7 Ω/sq was used as a working electrode, the platinum wire was used as a counter electrode, and saturated calomel electrode (SCE) was used as a reference electrode.

The supporting electrolyte was prepared by mixing choline chloride (Aldrich 99%) with urea (Aldrich 99%); by heating the two components in 1:2 molar proportions at above 50 °C for 30 min, until a homogeneous uncolored liquid appears. The electrolytic bath consists of 5-mM CuCl2, 10-mM SnCl2, 20-mM ZnCl2, and 20-mM thiourea dissolved in the choline-urea DES under constant heating and magnetic stirring. Depositions were carried out potentiostatically at different potentials in a one-step process at room temperature without proceeding to the sulfurization step.

The morphological, compositional, and structural characterizations of films were done in the as-electrodeposited state without any post-growth high-temperature treatments. The microstructure of films was studied using an emission scanning electron microscope (SEM) equipped with an energy dispersive analyzer (EDS). The crystalline structure of the thin films was determined by X-ray diffraction (XRD) analysis.

Result and discussion

Cyclic voltammetry

The electrochemical properties of the single constituent metal elements of the CZTS semiconductor in choline-urea DES were studied before the co-electrodeposition of the Cu–Zn–Sn–S precursor thin films with CV. As shown in Fig. 1, the potential window of the choline-urea DES ranges from − 1.8 to + 1.2 V.

Figure 2a, b, c, d shows the cyclic voltammograms of CuCl2, SnCl2, ZnCl2, and the thiourea dissolved in the choline-urea (Chl-Urea) DES, respectively and recorded with respect to saturated calomel reference electrode. The peak reduction potentials for the four elements are different. The reduction peak potentials for copper (Cu (II)) and Tin (Sn (II)) at the studied concentration are clearly observed at − 0.68 and − 1.31 V, respectively, while the anodic peak potentials are − 0.58 and − 0.80 V, respectively.

Zinc is an active metal, and its reduction had to be increased with an addition of a complexing agent [19]. The reduction peak potential for zinc (Zn (II)) was observed at − 1.24 V, which was also related to hydrogen evolution. The reduction potential of Zn was too low compared to other metals. Moreover, the anodic peak potential was observed at − 1.46 V.

Researchers have not treated the electrodeposition of sulfur in much detail due to its complicated electrochemical behavior in aqueous media by its high reactivity and its many possible oxidation states [20]. Therefore, the sulfur deposition is not straightforward. In the present bath, we used the thiourea as a sulfur source for its deposition. The reduction and oxidation peaks of sulfur were observed at − 1.10 V and − 0.84 V, respectively.

The potential reduction peak of the four elements is different; in order to optimize the deposition potential for the fourth elements at the same time, we applied three different potentials for choosing the best experimental conditions leading to CZTS films with the suitable composition for solar cell applications.

Material characterization

ICP elemental analysis

Elemental analysis of the film was measured by ICP on liquid solution prepared by dissolving the CZTS thin films in a concentrated nitric acid solution and the results are reported in Fig. 3 together with the estimated charge efficiency of the four elements.

As shown in Fig. 3, the four elements are present in the three samples but in different proportions. ICP compositional analysis confirmed that the films prepared at − 1.3 V and − 1.5 V were overall Zn-rich (Zn/Sn > 1); however, the deposition at − 1.2 V showed that the films were Zn-poor and copper-rich. The Cu / (Zn + Sn) ratio was found to be different between the three samples as shown in Fig. 3.

The content of sulfur is the lower part of the films deposited at − 1.2 V, which means that this potential does not lead to deposit electrochemically the sulfur. However, the films elaborated at − 1.3 V and − 1.5 V showed a quantity of 39% and 29%, respectively. This percentage bears a close resemblance to the one proposed by different researchers [21, 22], who used the sulfurization under high temperature (around 500 °C) and found values of 29.87% and 33.90% of sulfur, respectively.

Referring to James Scragg and his team [23], who studied the effect of the composition of the CZTS thin films prepared by electrodeposition, the best CZTS device composition is either the Zn-rich or Cu-poor regions. As a result, we continued our studies with samples electrodeposited at − 1.3 V and − 1.5 V to choose the optimum.

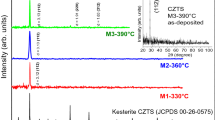

X-ray diffraction

The XRD was used to confirm the presence of the four constituent elements in the CZTS samples. Figure 4 shows a characteristic XRD pattern of CZTS thin films deposited at (a) − 1.3 V and (b) − 1.5 V. FTO peaks were marked by dark solid circles (•) and the CZTS peaks were marked by asterisk (*).

The XRD peaks indicate that the samples have a little of CuS (013) and CuSn (211) as secondary phases. The major peaks of the CZTS diffraction pattern consist of six major peaks located at 2Ө = 33.0°, 37.32°, 45.90°, 61.58°, 62.46°, and 78.5°, assigned to the lattices planes (200), (121), (220), (206), (231), and (204). The planes (200) and (220) are related to the kesterite crystal structure of CZTS (JCPDS #26-0575). The other peaks found in the pattern can be associated with other impurities, which can also coincide with the pattern of kesterite CZTS. The XRD patterns of the two CZTS samples are similar and do not present remarkable differences. It is possible to conclude that the kesterite CZTS phase is present in the two samples.

SEM-EDS analysis

The SEM micrograph area of the CZTS films deposited at − 1.3 V and − 1.5 V is shown in Fig. 5a–c. Referring to the FTO blank sample (Fig. 5a) which represents an empty and a uniform surface, it can be seen that the film deposited at − 1.3 V (Fig. 5b) appears to be homogeneous and less porous with respect to the samples deposited at − 1.5 V, with uniform grain distribution. The grains have a spherical form because of the higher concentration of metallic zinc and they are denser compared to the film deposited at − 1.5 V (Fig. 5c), which have a surface morphology consisting of non-uniform, less compact, and nodular particles. The adhesion of the CZTS films deposited at − 1.3 V is good and the CZTS films show a flat and compact surface morphology with fewer pinholes compared to the CZTS films prepared at − 1.5 V.

The composition of the thin films prepared in − 1.3 V and − 1.5 V was treated by a quantitative EDS analysis. Figure 6 presents an EDS spectrum showing the presence of Sn, Si… peaks which arise from the FTO substrate in addition to peaks of Cu, Zn, Sn, and S that arise from the deposited CZTS thin film.

EDS measurements showed that the films are sulfur rich. Cu is present probably also provided from the CuS and CuSn phases (this is observed in all samples) while Sn-rich grains can be observed in both the samples because it is one of the FTO compositions. These results match well with the ICP analysis due to secondary phases elaborated; however, the presence of secondary phases could be solved by adding some etching steps in a solution of KCN, for example, to remove CuxS from the CZTS surface [24].

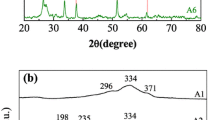

UV-vis spectroscopy

Figure 7 shows the Tauc plot for CZTS deposits prepared at − 1.3 V and − 1.5 V. The Tauc plot was obtained from analysis of the optical absorption spectra of the sample from 200 nm to 1100 nm.

The straight-line portions of the Tauc plots are extrapolated to zero absorption coefficient which gives the intercepts or band gap values. The band gap value for the deposits prepared at − 1.3 V and − 1.5 V is 1.48 eV and 1.7 eV, respectively. The film prepared at − 1.3 V presents a band gap quite close to the optimum band gap energy for thin-film solar cells and is appropriate for the application of thin-film solar cells with high conversion efficiency. This value matches well with the reported values [25, 26].

Conclusion

The Cu2ZnSnS4 (CZTS) thin films have been synthesized by a new single-step electrodeposition method using a choline-urea deep eutectic solvent without the step of sulfurization on the FTO-coated glass. Since all constituents are provided from the same electrolyte, it is attractive in further reducing the manufacturing cost. The structural, morphological, and compositional properties were investigated and the cyclic voltammetry was used to analyze the reduction behavior of Cu, Zn, Sn, and S from the unitary system. XRD showed the existence of kesterite CZTS. Optical absorption study showed the presence of a direct transition with band gap energy of 1.48 eV. From this study, it is concluded that − 1.3 V is the optimum potential to be synthesized by a single-step electrodeposition CZTS thin film for solar cell applications. Further work on the investigation of the CZTS thin-film performance as an absorber layer is underway.

References

Kanuru CS, Shekar GL, Krishnamurthy L, Urs RGK (2014) Surface morphological studies of solar absorber layer Cu2ZnSnS4 (CZTS) thin films by non-vacuum deposition methods. J Nano-Electron Phys 6(2):2004–2001

Jae-Seung S, Sang-Yul L, Jae-Choon L, Hyo-Duk N, Kyoo-Ho K (2003) Electrical and optical properties of Cu2ZnSnS4 thin films prepared by rf magnetron sputtering process. Sol Energy Mater Sol Cells 75:155–162

Guo Q, Ford GM, Hillhouse HW, Agrawal R (2009) Sulfide nanocrystal inks for dense Cu(In1−xGax)(S1−ySey)2 absorber films and their photovoltaic performance. Nano Lett 9(8):3060–3065

Kumar YBK, Babu GS, Bhaskar PU, Raja VS (2009) Effect of starting-solution pH on the growth of Cu2ZnSnS4 thin films deposited by spray pyrolysis. Phys Status Solidi A 206:1525–1530

Hibberd CJ, Chassaing E, Liu W, Mitzi DB, Lincot D, Tiwari AN (2010) Non-vacuum methods for formation of Cu(In, Ga)(Se, S)2 thin film photovoltaic absorbers. Prog Photovolt Res Appl 18(6):434–452

El Manouni A, Casasus R, Mollar M, Marí B (2009) Propriétés optiques de couches minces de ZnCoO préparés par électrodéposition. Afr Sci 5(3):48–64

Lv J, Sun Y, Zhao M, Cao L, Xu J, He G, Zhang M, Sun Z (2016) Rectifying properties of ZnO thin films deposited on FTO by electrodeposition technique. Appl Surf Sci. https://doi.org/10.1016/j.apsusc.2016.01.104

Lincot D, Gomez MH, Kessler J, Vedel J, Dimmler B, Schock HW (1990) Photoelectrochemical study of p-type copper indium diselenide thin films for photovoltaic applications. Sol Energy Mater 20:67–79. https://doi.org/10.1016/0165-1633(90)90018-V

Brouri T (2011) Élaboration et étude des propriétés électriques des couches minces et des nanofils de ZnO. Université Paris-Est

Ahn S, Kim CW, Yun JH, Gwak J, Jeong S, Ryu BH, Yoon KH (2010) CuInSe2 (CIS) thin film solar cells by direct coating and selenization of solution precursors. J Phys Chem C 114:8108–8113

Mg L, Gr B (2016) Electrochemical synthesis and characterization of Cu2ZnSnS4 thin films. J Mater Sci Eng 5:4

Abermann S (2013) Non-vacuum processed next generation thin film photovoltaics: towards marketable efficiency and production of CZTS based solar cells. Sol Energy 94:37–70. https://doi.org/10.1016/j.solener.2013.04.017

Swami SK, Kumar A, Dutta V (2013) Deposition of kesterite Cu2ZnSnS4 (CZTS) thin films by spin coating technique for solar cell application. Energy Procedia 33:198–202

Bazine S, Azmi S, Khoumri E (2014) Study of mechanisms of electrodeposition of thin films semiconductors, for photovoltaic destination. Proc Eng Technol–PET

Shivagan DD, Dale PJ, Samantilleke AP, Peter LM (2007) Electrodeposition of chalcopyrite films from ionic liquid electrolytes. Thin Solid Films 515(15):5899–5903. https://doi.org/10.1016/j.tsf.2006.12.092

Abbott AP, Boothby D, Capper G, Davies DL, Rasheed RK (2004) Deep eutectic solvents formed between choline chloride and carboxylic acids: versatile alternatives to ionic liquids. J Am Chem Soc 126(29):9142–9147

Chen H, Ye Q, He X, Ding J, Zhang Y, Han J, Liu J, Liao C, Mei J, Lau W (2014) Electrodeposited CZTS solar cells from reline electrolyte. Green Chem 16:3841–3845

Reddy RG (2006) Ionic liquids: How well do we know them? J Phase Equilib Diffus 27(3):210–211

Shin S, Park C, Kim C, Kim Y, Park S, Lee JH (2015) Cyclic voltammetry studies of copper, tin and zinc electrodeposition in a citrate complex system for CZTS solar cell application. Curr Appli Phys. https://doi.org/10.1016/j.cap.2015.11.017

Ateya BG, AlKharafi FM, Al-Azab AS (2003) Electrodeposition of sulfur from sulfide contaminated brines. Electrochem Solid-State Lett 6(9):C137-C140

Jeon M, Shimizu T, Shingubara S (2011) Cu2ZnSnS4 thin films and nanowires prepared by different single-step electrodeposition method in quaternary electrolyte. Mater Lett 65:2364–2367

Pawar SM, Pawar BS, Moholkar AV, Choi DS, Yun JH, Moon JH, Kolekar SS, Kim JH, (2010) Electrochim Acta 55(12):4057–4061

Scragg J J (2010) Studies of Cu2ZnSnS4 films prepared by sulfurisation of electrodeposited precursors. University of Bath, PhD Thesis

Ennaoui A, Lux-Steiner M, Weber A , Abou-Ras D , Kötschau I , Schock HW , Schurr R, Hölzing A, Jost S , R. Hock, Voß T, Schulze J, Kirbs A (2009) Cu2ZnSnS4 thin film solar cells from electroplated precursors: novel low-cost perspective. Thin Solid Films 517(7):2511–2251

Ahmed S, Reuter KB, Gunawan O, Guo L, Romankiw LT, Deligianni H (Feb. 2012) A high efficiency electrodeposited Cu2ZnSnS4 solar cell. Adv Energy Mater 2(2):253–259

Sarswat PK, Free ML (2012) A comparative study of co-electrodeposited Cu2ZnSnS4 absorber material on fluorinated tin oxide and molybdenum substrates. J Electron Mater. https://doi.org/10.1007/s11664-012-2042-5

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Azmi, S., Pezzato, L., Sturaro, M. et al. A green and low-cost synthetic approach based on deep eutectic choline-urea solvent toward synthesis of CZTS thin films. Ionics 25, 2755–2761 (2019). https://doi.org/10.1007/s11581-018-2719-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-018-2719-8