Abstract

Sodium ion conducting solid polymer blend electrolyte thin films have been prepared by using polyvinyl alcohol (PVA)/poly(vinyl pyrrolidone) (PVP) with NaNO3 by solution cast technique. The prepared films were characterized by various methods. The complexation of the salt with the polymer blend was identified by X-ray diffraction (XRD) and Fourier transforms infrared spectroscopy (FTIR), Differential scanning calorimetry was used to analyze the thermal behavior of the samples, and the glass transition temperature is low for the highest conducting polymer material. The scanning electron microscopy gives the surface morphology of the polymer electrolytes. The frequency and temperature dependent of electrical conductivities of the films were studied using impedance analyzer in the frequency range of 1 Hz to 1 MHz. The highest electrical conductivity of 50PVA/50PVP/2 wt% NaNO3 concentration has been found to be 1.25 × 10−5 S cm−1 at room temperature. The electrical permittivity of the polymer films have been studied for various temperatures. The transference number measurements showed that the charge transport is mainly due to ions than electrons. Using this highest conducting polymer electrolyte, an electrochemical cell is fabricated and the parameters of the cells are tabulated.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the most recent two decades, solid polymer electrolytes (SPEs) have been extensively studied because of their impending applications in many technological areas, such as solid-state batteries, electrochemical sensors, and electrochromic devices [1,2,3]. For solid-state battery applications, a polymer electrolyte must have high ionic conductivity at ambient temperature, good mechanical strength, appreciable transference number, good thermal and electrochemical stabilities, and better compatibility with electrodes. The ionic conductivity of SPEs occurs in the amorphous phase mainly due to the motion of dissolved ionic species (cations and anions) in a polymeric matrix.

In polymer blends, there exists a physical mixture of two or more structurally different homopolymer or copolymers and they interact in the course of secondary forces with no covalent bonding. The polymers used for blending are soluble in water which is a remarkable characteristic for film formation [4]. One of the polymer used for blending is polyvinyl alcohol (PVA),which is a semicrystalline polymer, water soluble, nontoxic, better film and fiber forming, biocompatible, excellent chemical resistance, and good mechanical properties with varied applications [5, 6]. A semicrystalline polymeric material has regions of structural order and disorder called crystalline and amorphous regions, respectively, separated by regions of intermediate order [7]. The second polymer is polyvinyl pyrrolidone (PVP), which is also a biocompatible polymer used as blood plasma expander for trauma victims. But PVP is an amorphous polymer possessing high Tg due to the presence of the rigid Pyrrolidone group, which form various complexes with many inorganic salts. Among the conjugated polymers, PVP has good environmental stability, easy processability and moderate electrical conductivity. It has broad range of applications such as electrochemical devices (batteries, displays) [8].

The blending of PVA/PVP has good charge storage capacity and dopant-dependent electrical properties [9, 10]. Many researchers have studied the properties of PVA–PVP blend doped with different salts [11,12,13]. The composition of 50PVA/50PVP has been selected for their stability and also the particular composition has the highest conductivity value than the other compositions.

Due to the low cost and the availability of sodium metal ion, recent studies have dominated sodium ion conducting systems for their potential use in solid-state batteries with high cell voltages and energy densities. There are few attempts to increase the sodium ion conductivity based on sodium ion complexed films [14,15,16,17,18,19].

The present study deals with the synthesis of polymer blend based on PVA and PVP complexed with NaNO3 salt in different compositions using solution casting technique. The prepared films are characterized by X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FTIR), differential scanning calorimetry (DSC), and AC impedance spectroscopy. Dominant conducting species in the present electrolyte system was determined using Wagner polarization technique, and dominant conducting species were found to be ions rather than electrons. Solid-state batteries were developed using anode/polymer electrolyte/cathode configuration by using highest conducting polymer electrolytes. The discharge characteristics of the cell were studied for a load of 100 kΩ.

Materials and methods

PVA, molecular weight, M w = 125,000 g mol−1 (S D Fine Chem Ltd., India); PVP with molecular weight, M w = 90,000 g mol−1 (S D Fine Chem Ltd., India); and sodium nitrate (NaNO3) (Merck India) were used as raw materials. Doubly distilled water was used throughout the experiment.

To prepare the polymeric films filled with 1, 2, 3, 4, and 5 wt% of NaNO3, stoichiometric quantities of PVA, PVP, and NaNO3 were dissolved in distilled water and then stirred until homogeneous solution was obtained. The solution was stirred continuously until the mixture became homogeneous viscous liquid. The final solution was poured into polypropylene dishes and dried in an oven at 50 °C for 6 days to ensure the removal of solvent traces. After drying, the prepared films were peeled from Petri dishes. The smooth, uniform, and transparent films had been obtained and kept in desiccators for further studies.

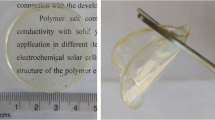

Experimental cell assembly made with the configuration Na (anode)/polymer electrolyte/I2 + C + electrolyte) (cathode) using (PVA/PVP/X NaNO3) polymer electrolyte films. The discharge voltage–current, open circuit voltage–time, charge voltage/current–time, and discharge voltage/current–time characteristics of cell were measured at room temperature by using Digital Multimeter. All other data points of voltage vs current discharge characteristics were obtained by measurement of voltage and current at different values of load.

Characterizations

The X-ray diffraction pattern of the blend polymer electrolytes was recorded using Cu Kα (λ = 1.5406 Å), Bruker made X-ray diffractometer. FTIR measurement was made with a Shimadzu-IR Affinity-1 spectrometer instrument in the wave number range of 400–4000 cm−1. DSC of the prepared films was studied using PerkinElmer 4000 system. The samples were put in an Al pan and heated in the temperature range between 50 and 400 °C at the rate of 10 °C min−1. The surface morphology of the polymer electrolytes has been examined with Carl ZEISS EVO 18 scanning electron microscope. The impedance was measured for the polymer films in the temperature range of 303–353 K over a frequency range of 1 Hz–1 MHz using a computer-controlled HIOKI 3532 LCR meter. The transference number measurement has been done by using Wagner polarization technique and also Bruce–Vincent method.

Using these polymer electrolyte films, electrochemical cells were fabricated with configuration Na/(PVA/PVP/NaNO3)/(I2 + C + electrolyte) and their discharge characteristics like open circuit voltage (OCV), short circuit current (SCC), power density, and energy density were evaluated and compared with the earlier reports.

Results and analysis

XRD analysis

The influence of NaNO3 contents on the 50PVA/50PVP blend with different weight percentages of NaNO3can be studied by using X-ray diffraction patterns. The recorded pattern is shown in the Fig. 1. The observed broad peak at (2θ) 20° is due to the presence of PVA [8, 20] and decreases with increasing concentration of NaNO3, indicating further increase in amorphous nature of blend polymers. There is a beginning of appearance of intense peak from 4% NaNO3 located at 2θ = 30° that indicates the presence of NaNO3 in the blend polymer matrix.

FTIR analysis

FTIR spectroscopy is an important technique for the investigation of bond formation in the polymer structure, since it provides information about the complexation and interactions between the various constituents in the composite polymer materials. The IR spectra of 50PVA/50PVP blend with different Mwt% of NaNO3 are shown in Fig. 2.

In addition of salt into the polymer host, the cation of the salt is expected to coordinate with the polar groups in the host polymer matrix resulting in the complexation. This type of interaction influences the local structure of the polymer backbone and certain infrared active modes of vibration will be affected [2]. It is observed from the spectra that the wideband that occurs in the region of 3640–3000 cm−1 is pertaining to the intermolecular hydrogen-bonded O–H stretching in pure PVA [21]. The C–H stretching frequency of PVA is observed at 2862 cm−1 for all samples. The band corresponding to C–N stretching observed at 2174 cm−1 for pure PVP has been shifted to 2137–2144 cm−1 for 50PVA/50PVP with different concentrations of NaNO3 polymer blend electrolytes with variation in intensity. The shift in stretching modes of the carbonyl bonds due to pyrrolidone rings are seen from peaks in the region 1643–1604 cm−1 [20].

Figure 2 shows the mainly significant characterizing IR absorption bands of pure PVA detected at 1428.03 and 1080 which are ascribed as CH2 bending and C–O stretching, respectively [10]. There is no significant shift in the vibrational frequencies due to the inclusion of different percentages of NaNO3. The vibrational band in the region 1641 cm−1 corresponds to C=O stretching of PVA and PVP [23, 24].

By heating the polymer electrolytes to temperature of 50 °C, the vibrations that are absent in the Fig. 2 are present and it is displayed in Fig. 2. The presence of all vibrations may be due to the decrease in intensity of water molecules. The vibrational assignments are given in Table 1.

In Fig. 2, it is observed from the spectra that the wideband in the region 3640–3000 cm−1 is pertaining to the intermolecular hydrogen bonded O–H stretching in pure PVA [9]. The band corresponding to CH2 asymmetric stretching vibration occurs at about 2918 cm−1. The intensity of the band varies due to the inclusion of NaNO3. The C–H stretching frequency of PVA is observed at 2818 cm−1 for all samples. The stretching modes of the carbonyl bonds due to pyrrolidone rings are seen in the region 1644–1613 cm−1 [20]. The CH2 bending is observed at 1291 cm−1 and disappeared for 5 wt% NaNO3.

Figure 2b shows the mainly significant characterizing IR absorption bands of pure PVA detected at 1428.03 and 1014 cm−1 which are ascribed as CH2 bending and C–O stretching, respectively with the variation in intensity [21].The band observed at 927 cm−1 is due to the C–C stretching with varied intensity. The band observed at 857 cm−1 shows increase in intensity due to the inclusion of NaNO3. All the FTIR bands are slightly shifted towards lower wave number region which may confirm the increment of mixed NaNO3 salt in the blend polymer matrix.

Differential scanning calorimetric analysis

DSC is a technique used to investigate the response of polymers to heating. DSC can be used to study the melting of a crystalline polymer or the glass transition.

At the glass transition temperature (Tg), the mechanical properties of the polymer change from those of an elastic material to those of a brittle one due to changes in chain mobility. DSC thermograms obtained for different salt concentrations are shown in the Fig. 3. Differential scanning calorimetry (DSC) analysis has been done to correlate the glass transition temperature with the amorphousity. The glass transition temperature for 50PVA/50PVP with different weight percentages of NaNO3 blend polymer electrolytes is shown in Table 2. Thermograms obtained for the blends gave a single glass transition temperature between the Tg of the two homopolymers. The presence of a single glass transition indicates miscibility in the system [25]. The glass transition temperature of the semicrystalline PVA polymer is 100 °C, and the PVP is 350 °C. The Tg values of the PVA–PVP blend may lie between 120 and 350 °C [26, 27] .

This may be due to the softening of the complexation by the salt (plasticization of the electrolyte with addition of salt) which enhances amorphous nature of the blend polymer electrolyte. The plasticization effect is related to a weakening of the dipole–dipole interaction between the PVA and PVP chains due to the presence of salt. The low glass transition temperature causes the highest segmental motion of the polymer electrolyte. Such segmental motion produces free volume, which enables the easy flow of ions through the polymer chain network under applied electric field. The exothermic peak obtained at 350–380 °C indicates the decomposition temperature of polymer blend electrolyte.

However, for higher concentrations, the Tg has been found to increase which may be due to the presence of some undissociated salt in the host polymer matrices [28]. The glass transition temperature for 50PVA/50PVP/2 wt% NaNO3 is lower than other composition.

SEM analysis

Scanning electron microscopy (SEM) is frequently used to understand the compatibility between dissimilar components in which compatibility has been formed through the perception of phase separations and interfaces. The surface morphology of NaNO3 mixed at various concentrations with PVA/PVP blend is shown in Fig. 4. SEM images have showed variation of the distribution of sodium nitrate in blend polymer matrix. In Fig. 4, the smooth surface observed up to 4% of NaNO3 indicates the uniform distribution and also the complete dissolution of salt in the blend polymer. Above 4 wt% of NaNO3, some crystallites are observed. The formed crystallites are obtained due to the increase in concentration of NaNO3 which is coincided with the XRD results.

Conductivity studies

Impedance analysis

The impedance of the blend polymer electrolyte was measured using AC impedance analyzer. The Cole–Cole plot for PVA/PVP with different NaNO3 concentrations at room temperature is shown in Fig. 5. The inset of Fig. 5 gives the Cole–Cole plot for 2–4 wt%. Typical plot consists of a high-frequency semicircle followed by a low-frequency spike. The high-frequency semicircle represents the bulk conductance, which is equivalent to the parallel combination of bulk resistance and bulk capacitance of the polymer electrolytes [29, 30]. The low-frequency spike is due to the blocking electrode. The bulk resistance of the electrolyte (R b) has been retrieved from the intercept of the straight line on the Z′ axis. The conductivity is also calculated using the formula

where l and A are the thickness and known area of the electrolyte film, and R b is the bulk resistance of the electrolyte film. The highest conductivity at ambient temperature is found to be 1.25 × 10−5 S cm−1 for the composition of 50PVA/50PVP/2 wt.% NaNO3. From the Table 2, the conductivity values obtained from the conductivity plot coincide well with the conductivity value calculated from the Cole–Cole plot. The system with 2% NaNO3 has the highest conductivity.

It has also been observed that the ionic conductivity increases with the increase of salt concentration up to 2 wt% and decreases at highest salt concentration. The increase in the conductivity with increasing salt concentration is due to the increase in the number of mobile charge carriers. The amorphous nature of polymer blend increases, and at the same time, the NaNO3 salt is evenly distributed in the materials, which is shown in the XRD results. The decrease in conductivity at highest salt concentrations can be attributed to either incomplete dissociation of salt or the formation of ion multiples [32]. The highest conductivity for 2 wt% salt-doped system is consistent with the lowest Tg of DSC results.

Conductance spectra analysis

The variation in the frequency-dependent AC conductivity spectra for the polymer blend electrolyte 50PVA/50PVP/X NaNO3 (1–5 wt%) at room temperature is shown in Fig. 6. As seen from Fig. 6, the frequency-dependent conductivity plot shows two distinct regions: frequency-independent plateau region and the high-frequency dispersion region. The frequency-independent plateau region is connected with the DC conductivity of the polymer blend electrolytes. This conductivity value has been assigned to the bulk conductivity of the sample. The σ dc value was calculated and tabulated in Table 2. In the high-frequency region, the conductivity increases with the frequency. The mobility of charge carriers is highest in the high-frequency region [19]. The frequency dependence of conductivity in the high-frequency dispersion region for polymer blend electrolytes at room temperature is analyzed using the universal Jonscher’s power law relation.

where σ o is the limiting zero frequency conductivity and A is the pre-exponential constant. ω is the angular frequency and n is the power law exponent where 0 < n < 1. Hoping frequency is calculated from σ dc vs log ω. Due to the variation in n value, there is slight variation in Cole–Cole plot conductivity value and conductance spectra value. Hoping frequency is calculated from the angular frequency-dependent conductivity plot. Hoping frequency can be calculated from the log ω and σ dc. Hoping frequency can be calculated at the point (σ ac = 2 σ dc). The hoping frequency ω p of the charge carrier increases for 2 wt% of NaNO3; it may be due to the decrease of the relaxation time [31]. The hoping frequency of the charge carriers is tabulated in Table 2. From the table, the DC conductivity values coincide with the calculated conductivity value from the Cole–Cole plot. The high hoping frequency was observed for the high-conductivity composition.

Temperature-dependent conductivity

The temperature dependence of ionic conductivity and hopping frequency for all the prepared PVA/PVP/NaNO3 polymer blend electrolytes over the temperature range 303–353 K are shown in Fig. 7a, b, respectively. It is seen that the conductivity increases with the increase in temperature for all compositions of blend polymer electrolytes. The polymer blend doped with 2 wt% NaNO3 salt exhibits the highest ionic conductivity.

The dc conductivity values follow the Arrhenius type thermally activated process given by the relation

where σ 0 is the pre-exponential factor, Ea—the activation energy, and k—Boltzmann constant; E a and U H the activation energies of the dc conductivity and the hopping frequencies of the carriers, respectively; and σ o and ω o the pre-exponential factors. Both the dc conductivity and the hopping frequency are found to be thermally activated following Arrhenius dependence (Eqs. 4.2 and 4.3). The activation energy for all the prepared polymer blend electrolytes is calculated by fitting of the Arrhenius plot. The ionic conductivity and the activation energy values are tabulated in Table 2. The activation energy is found to be low of the order of 0.40 eV for the highest conductivity sample (50PVA/50PVP/2 wt% NaNO3). From the Fig. 7c indicates the variation of conductivity with activation energy of the polymer electrolytes. From the figure, it is concluded that the activation energy attains the minimum value for high conductivity polymer electrolyte. At highest salt concentrations, the activation energy increases due to aggregation of ions, leading to the formation of ion clusters, thus decreasing the number of mobile charge carriers.

Dielectric analysis

The Fig. 8a, b denotes the variation of dielectric constant and dielectric loss as a function of frequency for 50PVA/50PVP/2 wt% NaNO3 polymer blend electrolyte. From the figures, it is confirmed that there is an increase in ε with temperature. At high frequencies, the dielectric loss attains a constant value due to negligible contribution of space charge polarization. The electrolyte acts as a polar material and enables the dipole orientation [5] and increases the mobility of charge carriers. As the temperature increases, the movement of ion increases due to kinetic energy and thermal energy. The same trend can be observed for the imaginary part of dielectric permittivity of the polymer system. The increase in the dielectric loss by increasing temperature is owing to the hopping of the charge carriers.

Modulus analysis

Figure 9a, b shows that the frequency dependence real and imaginary part of the modulus for 50PVA/50PVP/2 wt% NaNO3 polymer blend electrolyte at different temperatures. Electric modulus M*is well-defined in terms of the reciprocal of the complex relative permittivity ε*, i.e.,

The real and imaginary parts of the dielectric modulus is given by

The real and imaginary parts of the modulus approach to zero at low frequencies, representing the negligible contribution of electrode polarization phenomenon. At lower frequencies, there exists a long tail due to the large capacitance associated with the electrodes. The decrease in the height of the tail (M″) with the increase in temperature suggests a multitude of relaxation mechanisms [9].

Loss tangent spectra

Figure 10 shows the variation of tanδ with frequency of 50PVA/50PVP/X NaNO3 (X = 1, 2, 3, 4, 5 wt%) polymer electrolyte at room temperature. The value of tanδ increases with frequency and attains the maximum value and thereafter decreases.

The dielectric loss tangent can be defined as tanδ = \( \frac{\varepsilon^{{\prime\prime} }}{\varepsilon^{\prime }} \), where ε″ imaginary dielectric constant ε′ real dielectric constant. The dispersion observed at low frequencies could be attributed to the interfacial polarization mechanism. The dispersion observed at highest frequencies could be attributed to the dipolar relaxation. The loss tangent peak is described by the relation ωτ = 1 where τ is the relaxation time and ω is the angular frequency of the applied electric field. The relaxation parameters are calculated for all the prepared polymer electrolytes at room temperature and tabulated in Table 3. The shape of the spectrum remains constant, but the position of the peak maximum is shifted to high frequencies for the high conducting polymer electrolyte. This behavior suggests that the relaxation is mainly due to the charge carrier hopping.

Transference number measurement

Transference number tells about the contribution of ions and electrons for the overall transport across the cell. DC polarization techniques are used to find the ionic (t ion) and electronic (t ele) transport numbers for PVA/PVP/X NaNO3 polymer blend electrolyte systems and are shown in Table 4. In this technique, a dc electric potential is applied across the sample sandwiched between two blocking electrodes (stainless steel in the present study) and the current is monitored as a function of time by applying 1.5 V dc bias voltage (at room temperature). The peak current obtained initially decreases rapidly with time due to polarization of mobile ions at the electrode/electrolyte interface; afterwards, the current either approaches zero (for pure ion conductor) or attains a residual constant value (for mixed ionic/electronic conductor). The initial total current (I T) is either due to ions solely or as a result of combined ionic and electronic conduction, while the constant residual current is only due to electron conduction.

The result of dc polarization measurement on 50PVA/50PVP/X NaNO3(X = 1, 2, 3, 4, 5 wt%) polymer electrolytes taken is shown in the Fig. 11.

The transference numbers are calculated from the polarization current vs time plot using the equations

where I f is the final current and I i is the initial current.

The ionic transference number for all PVA/PVP/X NaNO3 electrolyte system has been found to be in the range of 0.9 wt% up to 4 wt% of NaNO3. This suggests that the charge transport in these electrolyte films is predominantly due to ions. The ionic transference number for 5 wt% is found to be 0.66. The electronic transference number increases due the formation of ion clusters, thereby decreasing the number of mobile ions and increasing the electron mobility. So, the ionic transference number decreases for 5 wt% NaNO3.

Bruce–Vincent method

The Bruce–Vincent method is used to determine the cationic and ionic transference number. The transference number corresponding to Na + ion transport determined by means of Bruce and Vincent technique shows that majority charge carriers in the compound are Na + ions. In this technique, the electrochemical cell in the configuration: M | MX (Electrolyte) | M type is polarized potentiostatically applying a small dc voltage ∆V and initial (I o)/final (I s) currents are recorded. Eventually, the cationic transport number (t +) can be estimated following equation:

- t + :

-

Cation transference number

- Ic:

-

Current carried by cations

- Ia:

-

Current carried by anions

One of the simplest and most commonly used is the so-called Bruce and Vincent method/formula. They proposed to characterize the cell (passivation layer) before and after polarization (after reaching the steady state) by means of electrochemical impedance spectroscopy (EIS) and correct the formula by the factor pertaining to the alteration of cell parameters that can be easily obtained from the simple impedance spectrum.

- t Na :

-

Sodium ion transference number

- V :

-

Applied potential

- R :

-

Initial resistance of the passivation layer

- Rss:

-

Resistance of the passivation layer (steady state)

- Io:

-

Initial current

- Iss:

-

Steady-state current

The result of Bruce–Vincent method on 50PVA/50PVP/2 wt% NaNO3 polymer electrolytes taken is shown in the Fig. 12a. The Cole–Cole plot for the same before and after polarization in given in the Fig. 12b. The values of transference number for all the polymer electrolytes was tabulated in the lower part of Table 4.

Discharge characteristics

Solid-state electrochemical cells were fabricated with the configuration Na (anode)/polymer electrolyte/I2 + C + electrolyte) (cathode) using (PVA/PVP/2 wt% NaNO3) polymer electrolyte films. Sodium metal was used as the negative electrode, and a mix of iodine (I2), graphite (C) and electrolyte as the positive electrode. The photograph of the prepared battery is shown in Fig. 13.

The discharge properties of the cell at room temperature at a constant load of 100 kΩ are shown in Fig. 14. Due to the polarization effect, there is a sharp decrease in the voltage initially. Cell parameters, such as open circuit voltage (OCV), short circuit current (SCC), current density, power density, energy density, and discharge capacity, have been evaluated to the highest conducting polymer electrolyte system: 50PVA/50PVP/2 wt% NaNO3 are given in Table 5. From Table 5, it is noticeable that the cell with the composition 50PVA/50PVP/2 wt% NaNO3 exhibits better performance and stability than PEO/NaYF4 (OCV—2.45 V) and PEO/NaI (OCV—0.407 V) (complexed polymer electrolyte systems [33,34,35] and almost compatible with the existing reports of PVA/NaBr (OCV—2.74 V) and PVP/NaI (OCV—2.85 V) complexed polymer electrolytes [36, 15]. In the earlier reports, it is noticed that the stabilized voltage decreases gradually for all electrochemical cell. But for the prepared battery using higher conductivity polymer electrolyte (PVA/PVP/2 wt% NaNO3), the voltage is stabilized and maintained at 1.5 V. The solid polymer battery parameters evaluated indicates the improved battery performance and higher stability than the earlier reports.

Conclusion

PVA–PVP polymer blend mixed with different concentrations of NaNO3 was prepared by solution casting technique using water as solvent. The increase in amorphous nature of the polymer blend is exhibited in XRD analysis. The FTIR analysis reveals that the interchain hydrogen bonding between carbonyl groups of PVP and hydroxyl groups of PVA. Thermal analysis indicates the glass transition temperature, and it is low for PVA/PVP/2 wt% NaNO3) composite blend polymer electrolyte. The SEM shows that sodium particles are dispersed for different wt% of NaNO3in the (PVA–PVP) electrolyte films and changes in surface morphology from smooth to rough due to the presence of low to high concentration of NaNO3 as a dopant. Conductance spectra results are found to obey Jonscher’s power law. The blend polymer electrolytes containing 2 wt% NaNO3 exhibits the highest conductivity 1.25 × 10−5 S cm−1 at ambient temperature, which reveals that this blend polymer electrolyte can be a good candidate for Na rechargeable battery. The increase in the conductivity for the polymer electrolyte containing 2 wt% NaNO3 is explained in terms of reduction of Tg, which reduces the energy barrier to the segmental motion. The charge transport in this polymer electrolyte (PVA + PVP + X NaNO3) was predominantly due to ions. Using this highest conducting polymer electrolyte, an electrochemical cell is fabricated and the parameters of the cells are compared with the earlier work. Thus, (PVA + PVP + 2 wt% NaNO3) electrolyte is found to be worthy candidate for solid-state batteries.

References

Qiao J, Fu J, Lin R, Ma J, Liu J (2010) Alkaline solid polymer electrolyte membranes based on structurally modified PVA/PVP with improved alkali stability. Polymer 51(21):4850–4859

Hema M, Selvasekarapandian S, Hirankumar G, Sakunthala A, Arunkumar D (2009) Structural and thermal studies of PVA:NH4I. Journal of Physics and Chemistry of Solid 70(7):1098–1103

Benedict TJ, Banumathi S, Veluchamy A, Gangadharan R, Ahamad AZ, Rajendran S (1998) J Power Sources 75:171–174

Jones SA, Martin GP, Royall PG, Brown MB (2005) J Appl Polym Sci 98:2290–2299

Pritchard JG (1970) Poly (vinyl alcohol): basic properties and uses. Macdonald and Company, UK

Lai G, Du Z, Li G (2007) The rheological behavior of collagen dispersion/poly(vinyl alcohol) blends. Korea Aust Rheol J 19:81–88

Strobl G (2007) The physics of polymers: concepts for understanding their structures and behavior. Springer-Verlag, Berlin Heidelberg, pp 212–213

Elashmawi S, Abdelrazek EM, Yassin AY (2014) Influence of NiCl2/CdCl2 as mixed filler on structural, thermal and electrical properties of PVA/PVP blend. British Journal of Applied Science & Technology 4(30):4263–4279

Abdelrazek EM, Elashmawi IS, El-khodary A, Yassin A (2010) Structural, optical, thermal and electrical studies on PVA/PVP blends filled with lithium bromide. Curr Appl Phys 10:607–613

Malathi J, Kumara VM, Bramanandhan GM, Hema M, Baskaran R, Selvasekarapandian S (2010) Structural, thermal and electrical properties of PVA-LiCF3SO3 polymer electrolyte. J Non-Cryst Solids 356(43):2277–2281

Abd El-Mohdy HL, Ghanem S (2009) Biodegradability. J Polym res 16:110

Ravindrachary V, Bhajantri RF, Harisha A, Ismayil, Ranganathaiah C (2009) Microstructure and positron behavior in FeCl3 doped PVA/PVP blend. Phys Stat Solidi C 6(11)

Ranganath MR, Blaise L (2007) Experimental investigation of the optical band gap in films of iodine doped polyvinylalcohol–polyvinylpyrrolidone blend. Solid State Physics (India) 52:495–496

Rao V s, Muchakayala Ravi V, Raja P, Bhargav B (2012) Preparation and characterization of PVP-based polymer electrolytes for solid-state battery applications. Iran Polym J 21:531–536

Bhargav PB, Mohan VM, Sharma AK, Rao AVVRN (2009) Investigations on electrical properties of (PVA:NaF) polymer electrolytes for electrochemical cell applications. Curr Appl Phys 9(1):165–171

Reddy CVS, Jin AP, Zhu QY, Mai LQ, Chen W (2006) Preparation and characterization of (PVP + NaClO4 ) electrolytes for battery applications. Eur Phys J E Soft Matter 19:471–476

Jaipal RM, Sreekanth T, Chandrasekar M, Subba Rao UV (2000) Ion transport and electrochemical cell characteristics studies of a new (PVP/NaNO3) polymer electrolyte system. J Mater Sci 35(11):2841–2845

Anantha PS, Hariharan K (2005) Physical and ionic transport studies on poly(ethylene oxide)–NaNO3 polymer electrolyte system. Solid State Ionics 176:155–162

Utracki LA (1990) Polymer alloys and blends-thermodynamics and rheology. Oxford University Press, New York

Ahad N, Saion E, Gharibshahi E (2012) Structural, thermal, and electrical properties of PVA-sodium salicylate solid composite polymer electrolyte. J Nanomater 1:1–9

Rajeswari N, Selvasekarapandian S, Moni P, Karthikeyan S, Sanjeeviraja C (2013) Lithium ion conducting solid polymer blend electrolyte based on bio-degradable polymers. Bull Mater Sci 36(2):333–339

Hatta FF, Yahya MZA, Ali AMM, Subban RHY, Harun MK, Mohamed AA (2005) Electrical conductivity studies on PVA/PVP-KOH alkaline solid polymer blend electrolyte. Ionics 11(5–6):418–422

R. Jayasekara ,R. Harding, I. Bowater,I. Christie, G.B.Y,.and Lonergan, G.T (2004) Preparation, surface modification and characterization of solution cast starch PVOH blended films. Polymer Test, 2317–27.

Abdelaziz EMA (2007) Effect of dopant mixture on structural, optical and electron spin resonance properties of polyvinyl alcohol. Physica B 390:1–9

Laot CM, Marand E, Oyama HT (1999) Spectroscopic characterization of molecular interdiffusion at a poly(vinyl pyrrolidone)/vinyl ester interface. Polymer 40:1095–1108

Zhang G, Zhang J, Wang S, Shen D (2003) Miscibility and phase structure of binary blends of polylactide and poly(methyl methacrylate). J Polym Sci B Polym Phys 41:23–30

Chrissafis K, Paraskevopoulos KM, Papageorgiou GZ, Bikiaris DN (2008) Thermal and dynamic mechanical behavior of bionanocomposites: Fumed silica nanoparticles dispersed in poly(vinyl pyrrolidone), chitosan, and poly(vinyl alcohol). J Appl Polym Sci 110:1739

Seabra AB, Oliveira MG (2004) Poly(vinyl alcohol) and poly(vinyl pyrrolidone) blended films for local nitric oxide release. Biomaterials 25:3773

Ravi M, Pavani Y, Kiran Kumar K, Bhavani S, Sharma AK, Narasimha Rao VVR (2011) Studies on electrical and dielectric properties of PVP:KBrO4 complexed polymer electrolyte films. Mater Chem Phys 130:442–448

Radha KP, Selvasekarapandian S, Karthikeyan S, Hema M, Sanjeeviraja C (2013) Synthesis and impedance analysis of proton-conducting polymer electrolyte PVA:NH4F. Ionics. doi:10.1007/s11581-013-0866-5

Hema M, Selvasekarapandian S, Nithya H, Sakunthala A, Arunkumar D (2009) Structural and ionic conductivity studies on proton conducting polymer electrolyte based on polyvinyl alcohol. Ionics 15(4):487–491

Sreepathi Rao S, Jaipal Reddy M, Narasimha Reddy K, Subba Rao UV (1994) A new Na+ion conducting polymer electrolyte based on (PEO+NaYF4) and its use as an electrochemical cell. Solid State Ionics 74:225

Naresh Kumar K, Sreekanth T, Jaipal Reddy M, Subba Rao UV (2001) Study of transport and electrochemical cell characteristics of PVP:NaClO3 polymer electrolyte system. J Power Sources 101:130

Mohamed NS, Zakaria MZ, Ali AMM, Arof AK (1997) Characteristics of poly(ethylene oxide)-NaI polymer electrolyte and electrochemical cell performances. J Power Sources 66:169

Bhide A, Hariharan K (2007) Ionic transport studies on (PEO)6:NaPO3 polymer electrolyte plasticized with PEG 400. Eur Polym J 43:4253–4270

Subba Rao CV, Ravi M, Raja V, Bhargav PB, Sharma AK, Rao VVRN (2012) Preparation and characterization of PVP-based polymer electrolytes for solid-state battery applications. Iranian Polymer J 21:531

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Duraikkan, V., Sultan, A.B., Nallaperumal, N. et al. Structural, thermal and electrical properties of polyvinyl alcohol/poly(vinyl pyrrolidone)–sodium nitrate solid polymer blend electrolyte. Ionics 24, 139–151 (2018). https://doi.org/10.1007/s11581-017-2169-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-017-2169-8