Abstract

A few compositions in the system Ba1 − x La x SnO3 (x = 0.00, 0.01, 0.05, and 0.10) have been synthesized via the solid state ceramic route. The synthesized powders have been characterized using X-ray diffraction, scanning electron microscopy, energy-dispersive X-ray analysis, Raman spectroscopy, Fourier transformation infrared, thermogravimetrical analysis, and differential thermal analysis techniques. The powder X-ray diffraction pattern of the samples confirms the formation of a single-phase solid solution only up to 0.50 ≤ x. It was found that all the samples have a cubic crystal structure. The electrical properties of La-modified BaSnO3 were studied using ac impedance spectroscopy technique over a wide range of temperatures (50–650 °C) in the frequency range of 10 Hz–13 MHz. The complex impedance plots above 300 °C show that total impedance is due to the contributions of grain and grain boundaries. The resistance of these contributions has been determined. Variation of these resistances with temperature shows the presence of two different regions with different slopes. The nature of the variation of conductivity of the grain and grain boundaries is different in different regions. Based on the value of activation energy, it is proposed that conduction via hopping of doubly ionized oxygen vacancies (VO ••) is taking place in the temperature region of 300–450 °C, whereas in the temperature region of 450–650 °C, it is due to proton, i.e., OH• ions, hopping.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Barium stannate and its solid solutions (e.g., BaTi1 − x Sn x O3) have found important applications in materials science and technology due to their dielectric properties [1–5]. Pure and doped barium stannate can be used as material for semiconductor gas sensors. It has been reported that sensors based on BaSnO3 are sensitive to a variety of gases, e.g., CO, O2, C2H5OH, CH3SH, LPG, and NO x [6–12]. Additionally, the results by Borse et al. [13, 14] and Yuan et al. [15] suggest that BaSnO3-based systems could be candidates for photocatalytic applications. Mizoguchi et al. [16] reported that BaSnO3 exhibits strong near-infrared luminescence at room temperature. Recently, barium stannate-based systems BaSn1 − x M x O3 − δ (where M = Fe, Sc, In, Y, Gd, Sm, Nd, and La) have been proposed as proton conductors with potential applications in the fuel cell [17–20].

From the literature survey, it has been noticed that lanthanum can be a substitute for both barium and tin sites in barium stannate. Lanthanum substituted on the tin site of the barium stannate, BaSn1 − x La x O3 − δ , system has been proposed as a proton conductor with potential applications in the fuel cell [21–24]. In these studies, the electrical characterization of the materials is done using complex plane impedance spectroscopy. This technique is used to separate out the contribution of grains and grain boundary resistances and measure the activation energy for conduction within the bulk and grain boundaries separately.

Lanthanum substituted for barium in the perovskite-type Ba1 − x La x SnO3 solid solution has been thoroughly investigated [25–30]. Electrical and thermal properties of this system have been measured in a wide range of temperatures (4.2 K to 1100 °C). The literature survey indicates that the electrical properties of this system have basically been studied by conventional (dc) methods. A few reports are available on the characterization of this system by impedance spectroscopy but only up to 300 °C [31]. However, a systematic analysis of electrical properties by impedance analysis has not been carried out at high temperatures (above 300 °C). The present paper reports our investigations on electrical properties of lanthanum-doped barium stannate, Ba1 − x La x SnO3. The impedance analysis approach has been used to separate out the contribution of grains and grain boundary resistance to the total resistance. This technique is used to separate out the contribution of grains and grain boundary resistance and measure the activation energy for conduction within the bulk and grain boundaries separately.

The impedance spectrum and electrical conductivity have been observed as a function of temperature (50–650 °C) and frequency (10 Hz–13 MHz).

Complex plane impedance spectroscopy is considered to be a promising non-destructive testing method for analyzing the electrical processes occurring in a compound on the application of an a.c. signal as input perturbation. The output response of a polycrystalline compound represents grain, grain boundary, and interfacial properties with a different time constant. Using this technique, one can measure resistance due to grain interiors, grain boundaries, and the electrode independently. From these data and knowledge of the sample dimensions, the bulk (or grain interior) and grain boundary conductivities can be estimated in a rather straightforward manner. The equivalent electrical circuit shown below is widely used to fit impedance data of polycrystalline materials. In this equivalent circuit, it is desired to separate each of the RC components and measure values. *

Complex plane impedance plots (Z′ vs. Z″) of many polycrystalline materials exhibit an arc at high frequencies, a second arc at lower frequencies, and a third arc at even lower frequencies. In a complex plane impedance plot, the ideal semicircle (whose center lies on the Z′ axis) appears only when the contribution to this arc is having a single relaxation time. If the distribution of relaxation times exists, then one gets a depressed arc instead of the ideal semicircle. The frequency at the apex of each of the arcs corresponds to the characteristic frequency, ω o of the respective (RC) subcircuit. The characteristic frequency, ω o, of a material or a region of a material is equal to 1/RC. Since R and C depend on geometric parameters in an inverse manner, therefore, ω o is an intrinsic material property, independent of geometric consideration, and equal to 1/ρε o ε r (where ρ, resistivity, is equal to 1/σ, ε o is the permittivity of free space, and ε r is the relative permittivity of material).

Experimental

Sample preparation

Samples with compositions x = 0.00, 0.01, 0.05, and 0.10 in the lanthanum-doped barium stannate system, Ba1−x La x SnO3, have been synthesized using the solid state ceramic method. The abbreviated names in the figures and text for samples with x = 0.00, 0.01, 0.05, and 0.10 are BS, BSL1, BSL5, and BSL10, respectively. The compounds used for the preparation of these samples are BaCO3 (Merck, India, purity 99.0 %), SnO2 (Sigma-Aldrich, USA, purity 99.9 %), and La2O3 (Indian Rare Earth Ltd., India, purity 99.5 %). Stoichiometric amounts of compounds were mixed in an agate mortar pestle for 3 h using acetone as the mixing medium. The mixed powders were dried by keeping them in an oven overnight. The dried powders were calcined twice at 1000 °C for 6 h in an alumina crucible. The calcined powders were further ground to fine powders and pelletized at an optimum load of 3 tons. These pellets were sintered at 1300 °C for 6 h. After sintering, the pellets were cooled to 500 °C at a cooling rate of 5 °C/min in a programmable furnace.

Characterization

A preliminary study on compound formation and structural parameter was carried out using the X-ray diffraction (XRD) technique with an X-ray powder diffractometer (RigakuMiniflex II). The XRD pattern of the calcined powder was recorded at room temperature with CuKα1 radiation (λ = 1.5418 Å) in a wide range of Bragg’s angles 2θ (20° ≤ 2θ ≤ 80°) at a scan speed of 4°/min. For scanning electron micrographs (SEM) and energy-dispersive X-ray analysis (EDXA), freshly fractured surfaces of the sintered pellets were gold sputtered and scanned in different regions using a JEOL JSM-5800 scanning electron microscope. Raman spectra were recorded using a HORIBA JOBIN YVON LabRAMHR high-resolution Raman microscope. Fourier transform infrared (FTIR) spectra of the sample were recorded using Shimadzu (Model DF 803). The Fourier transform infrared spectrometer was in the wave number range 400–4000 cm−1. Thermal analysis (DTA and TGA curves) of the sample was made using a Perkin-Elmer (Model Pyrix EXST AR 6000) TG-DTA instrument in the temperature range 30–950 °C with a heating rate of 10 °C/min in a nitrogen atmosphere.

For impedance measurements, polished surfaces of the pellets were coated with high-purity air-drying silver paste. These pellets were cured at 700 °C for 10 min. Impedance measurements were done using a computer-controlled impedance analyzer (HP 4192 A LF) over a wide range of temperatures (50–650 °C) and frequencies (10 Hz–13 MHz).

Results and discussion

Crystal structural analysis

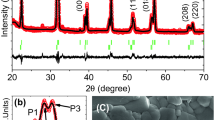

X-ray diffraction (XRD) patterns of samples BS, BSL1, BSL5, and BSL10 are shown in Fig. 1. The XRD pattern of samples BS, BSL1, and BSL5 revealed the formation of a single-phase solid solution. Formation of the single phase was confirmed on the basis of the absence of characteristic lines of the constituent oxides or other phases in the powder XRD patterns. The XRD pattern of sample BSL10 revealed an extra peak (around an angle of 29°) of reflections from the plane of pyrochlore phase La2Sn2O7. It is observed that the intensity of this reflection is weak as compared to the intensity of reflections from the planes of Ba1 − x La x SnO3. A weak intensity of reflections from the planes of pyrochlore phase La2Sn2O7 suggests that the volume fraction of the secondary phase is very small as compared to primary phase Ba1 − x La x SnO3. Therefore, the XRD data of all the compositions is indexed on the basis of the cubic unit cell similar to undoped BaSnO3 reported in the literature (JCPDS card no. 15-0780). The lattice parameter of the samples was calculated using the program CELL. The value of the lattice parameter for all the compositions is given in Table 1. From the table, one infers that the lattice parameter decreases with increasing x, i.e., lanthanum concentration. The decrease in the lattice parameter from samples BS to BSL10 is attributed to smaller ionic radii of La3+ (1.32 Å) as compared to host Ba2+ (1.44 Å) ion.

The crystallite size of the synthesized compositions was calculated using the Debye–Scherrer equation D = 0.9λ/βcosθ max (where D is the crystallite size, λ is the wavelength of CuKα radiation, β is the line width at half peak intensity, and θ max is the diffraction peak angle). The average crystallite size determined from the most intense peak of plane (110) for all the samples is given in Table 1.

The bulk density (d b) of the samples was obtained using Archimedes’ principle. The theoretical density (d th) of the samples was calculated from the molecular weight of the samples and its lattice parameter. The percentage porosity was calculated using the formula:

The bulk density, theoretical density, and percentage porosity of the samples is given in Table 1.

SEM and EDXA analyses

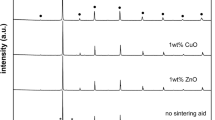

The SEM surface morphology of the samples is shown in Fig. 2. It is observed that the grain size of the samples is small (<1 μm). The porous nature of the samples is also reflected in the SEM photographs. The compositional homogeneity (in terms of the concentration profile of the elements) has been probed by recording the EDXA spectrum of randomly chosen different regions on the surfaces of the samples. Figure 3 depicts the EDXA spectra (corresponding to that region whose microstructure are given in Fig. 2) of the samples. It shows that in these samples, only oxygen, tin, barium, and lanthanum elements are present. The positions of all the peaks observed in Fig. 3a are in agreement with the EDXA pattern reported for BaSnO3 [32]. In the literature, it is reported that the positions of the Ba and La peaks are the same (i.e., almost at the same energy value); therefore, the peaks of La are masked by the peaks of Ba [33]. The average value (using data recorded for different regions) of the weight percent and atomic percent of different elements for all the samples is reported in Table 2. The atomic ratio of Sn/Ba for all the samples is in agreement with the theoretical ratio which confirms doping of lanthanum on the barium site in BaSnO3.

Raman spectroscopy

Raman spectroscopy is yet another tool to explore the incorporation of dopants in the host lattice as it is very sensitive to (local) loss of symmetry and formation of defects such as oxygen vacancies and F-centers [34, 35]. The room temperature Raman spectra ranging from 50 to 800 cm−1 of undoped BaSnO3 (BSL0) and La-doped BaSnO3 (BSL1 and BSL10) samples is shown in Fig. 4. In principle, the centrosymmetric BaSnO3 with the ideal cubic structure belonging to the space group Pm3m should not show first-order Raman scattering [36]. But Fig. 5 exhibits a batch of Raman active modes for all the samples. The Raman active modes for these samples are in agreement with the Raman spectra reported in the literature for undoped and La-doped BaSnO3 samples [37, 38]. Raman active modes in undoped BaSnO3 are induced by defects such as oxygen vacancies which destroy the translational periodicity of the lattice. In the literature, the position of the Raman line for oxygen vacancies is reported to be at 568 cm−1 [39]. This mode is present in all samples, but its intensity increases with an increasing content of La. Two broad modes (at 129 and 225 cm−1) of BaSnO3 are getting sharpened and shifted towards the lower frequency side on doping La3+ at the Ba2+ sites. Moreover, in comparison with Raman spectra of BSL0 and BSL1 samples, two weak modes corresponding to pyrochlore phase La2Sn2O7 at 301 and 495 cm−1 [40] were detected in the BSL10 sample, demonstrating the presence of the secondary phase, analogous to XRD results.

FTIR spectroscopy

To obtain the Fourier transform infrared (FTIR) spectrum of the samples, small amounts of the powders were mixed with KBr and pelletized again using a hydraulic press. The FTIR spectrum of the KBr mixed pellets was recorded in the wave number range 400–4000 cm−1. The FTIR spectrum of the synthesized samples is shown in Fig. 5. It is noticed that the FTIR spectrum of these samples has mainly five absorption bands. The position of these bands in terms of wave number (cm−1) is presented in Table 3. These bands are marked as I, II, III, IV, and V in Fig. 5. Absorption band I present in samples BSL5 and BSL10 is assigned to vibration from hydroxyl metals (Sn-OH) [41], band II to the Sn–O bond, i.e., structural development of perovskite phase [42], and band III to BaCO3 [43]. An intense band IV can be assigned to either BaCO3 and/or M–OH group vibration [43, 44]. The broad band V indicates water in the sample which is absorbed from the atmosphere either by the samples and/or by the KBr pellet [45].

From the Table 3, it is noticed that the position of band II shifts systematically towards a higher wave number, i.e., towards higher energy with increasing concentration of dopant La. Since ionic radii of the barium ion are larger than those of the lanthanum ion (R 3+ La < R 2+ Ba), when La is incorporated at the Ba site, the lattice parameter and unit size decrease. The decrease in the lattice parameter with the increasing concentration of La was experimentally observed from the X-ray studies of the samples (Fig. 1). A decrease in the unit cell size shortens the distance between Sn4+ ion and O2− ion, enhancing the bond strength. Similar results have been reported for the La-doped BaTiO3 samples [46].

It is mentioned in the literature that absorption bands at 856, 1050, and 1450 cm−1 are the characteristic bands of BaCO3 [43]. The presence of bands III and IV indicate that sintered powders have BaCO3 as the impurity phase. This result is in contradiction to the result obtained from the X-ray diffraction analysis. From the JCPDS (file no. 45-1471) file of BaCO3, it has been found that BaCO3 has a strong peak at 23.98°. In the XRD pattern of the samples (Fig. 1), no peak at this angle has been observed. Absence of the peak of BaCO3 in the XRD pattern of the samples may be due to the fact that any BaCO3 left was amorphous, or present as very small crystallites which were below the critical size for Bragg reflection. But strong intensity and XRD results indicate that this band is not merely due to the presence of a trace amount of BaCO3. It is already mentioned that peak IV may be due to the presence of the M–OH group. Therefore, it seems that the band due to the presence of BaCO3 and the M–OH group has been integrated in the broad and intense band.

Thermal analysis

The thermal characterization of the synthesized powders has been carried out using differential thermal analysis (DTA) and thermogravimetric analysis (TGA) up to 1000 °C at a heating rate of 10 °C/min in a nitrogen atmosphere. The DTA and TGA curves of samples BSL0, BSL5, and BSL10 are shown in Fig. 6. Similar behavior is observed for sample BSL1 also. The TGA curves of the samples exhibit an approximately 10 % total weight loss in three steps, the first step from RT to 300 °C (with a loss of 4.5 %), the second step from 300 to 550 °C (with a loss of 1 %), and the third step from 550 to 950 °C (with a loss of 4.5 %). The weight loss in the first step is attributed to the removal of physically adsorbed water; that of the second step to the removal of other gases, for example CO2; and that of the third step to the removal of chemically adsorbed water. The presence of water or the hygroscopic nature of these samples is also reflected from FTIR spectra of the samples.

The enthalpy changes observed in the DTA curve at different temperatures can be attributed to surface reaction taking place in the BS sample. There is no evidence of any phase transition taking place in the samples up to 1000 °C.

Impedance analysis

From Table 2, it is noticed that the conductivity of the samples increases sharply when x changes from 0 to 0.10. For the sake of clarity, the variation of total conductivity σ t (at room temperature) with a concentration of lanthanum is shown in Fig. 7. The observed sharp increase in the conductivity (approximately by four orders of magnitude) on doping La3+ at the Ba2+ (up to 10 mol%) site in barium stannate is believed to be due to the dissolution of La3+ (hetero-cation) at Ba2+ sites within the perovskite structure. An increase in conductivity with increasing lanthanum concentration indicates that electronic charge compensation is taking place according to the equation:

All the samples in the present system, Ba1−x La x SnO3, have been synthesized by the solid state ceramic route at a temperature of 1300 °C; therefore, the loss of oxygen takes place according to the equation

The sharp increase of conductivity from samples BSL0 to BSL10 reveals that global electrons are arising from both Eqs. (2) and (3). The increasing lanthanum concentration at the barium site of barium stannate increases its electronic conductivity.

Complex impedance data of samples BSL5 and BSL10 could not be recorded on account of the high value of conductivity. Complex impedance data of sample BS are already published [47]; therefore, complex plane impedance data of sample BSL1 are presented. Impedance plots of sample BSL1 at different temperatures are shown in Fig. 8. At temperatures 50, 100, and 150 °C, a steep rising of Z″ (almost parallel to the Y-axis) is observed. As the temperature increases to 200 and 250 °C, the curve bends towards the real axis, i.e., Z′ axis, and takes the shape of a semicircle. At and above 300 °C, two distinct semicircular arcs have been observed. The frequency ranges of these arcs overlap. The high-frequency arc at 300 and 350 °C passes through the origin, but the spectrum at 400 °C and above does not pass through the origin. An intercept of approximately 450 Ω is observed which remains almost constant up to the last temperature of measurement, i.e., up to 650 °C. At all the temperatures, the centers of the semicircles are below the real axis, i.e., depressed semicircles have been observed.

For samples in the present system, Ba1−x La x SnO3, the electrode contribution to the impedance data is ruled out on account of the linear V–I characteristics of the samples at room temperature. Therefore, the total impedance has contributions of the grains and grain boundaries. In impedance plots of sample BSL1, two arcs have been observed, and their characteristic frequency, ω o = 1/ρε o ε, differs significantly. The question of whether ω o,g and ω o,gb are significantly different from one another reduces to the question of whether or not the products (ρ g ε g) and (ρ gb ε gb) differ significantly. While the resistances of the materials cover many orders of magnitude, the dielectric constant does not vary that significantly. Thus, it is reasonable to make the assumption that ε g–ε gb and the question reduces further to whether or not ρ g and ρ gb are significantly different from one another. For a material in which σ g > σ gb (by definition ρ gb > ρ g), it is implied that ω o,gb < ω o,g. Consequently, two arcs will be present in the complex plane impedance plot, and the arc at the lower frequency will indeed correspond to the response of the grain boundaries whereas the high-frequency arc will correspond to the response of the grains. The resistance of each arc is given by the distance across the real axis that each arc spans. In addition, the equivalent capacitance, C, of each arc is given by (Rω o)−1. It is reported that in the impedance plot of a polycrystalline material, two arcs only appear when condition σ g > σ gb is satisfied, if a material has the typical microstructure, i.e., g/G < 1 (where G is the average diameter of the grains and g is the grain boundary thickness).

Impedance spectra of the sample BSL1 were fitted using the equivalent circuit containing two parallel resistance(R)–capacitance (C) connected in series, one for the bulk and other for the grain boundaries. The values of resistances and capacitances at different temperatures are obtained from the fitting of the data. As an example, best fitting of impedance spectra yielded parameters R g = 161,000 Ω, C g = 1 · 56 × 10−11 F, R gb = 163,000 Ω, and C gb = 48.8 × 10−11 F at 300°. Total resistance of the sample is given by R t = R g + R gb. Total conductivity (σ t) has been determined using the formula

where L is the thickness and S is the area of the sample. Similarly, the grain conductivity (σ g) and apparent grain boundary conductivity (σ gb) can be determined separately.

According to Verkerk [48] and Christie et al. [49], there exists a relation between the apparent grain boundary conductivity (σ gb) determined from the grain boundary arc of the impedance plot and the specific grain boundary conductivity σ * gb as given by Eq. (4):

where δ gb is the thickness of the grain boundary and d g is the average grain size. If bulk and grain boundary permittivities are similar, then Eq. (5) can be written as

where C g and C gb are the bulk and grain boundary capacitances determined from the impedance plots.

The variation of logarithm of the total conductivity (σ t), grain conductivity (σ g), and specific grain boundary conductivity (σ * gb) with the inverse of temperature is shown in Fig. 9. Two linear regions with different slopes in two different temperature regions have been observed. These two temperature regions are denoted as region I (300–450 °C) and region II (450–650 °C). The linear behavior of conductivities in both the temperature regions indicates that these resistances obey the Arrhenius relation given by

where σ ot is the pre-exponential factor, k is the Boltzmann constant, and T is the absolute temperature. Values of activation energy of the bulk ionic conductivity (E t) for the sample determined from the plot by least square fitting of the data points in Fig. 9 are given in Table 4. The value of activation energy in the low-temperature region varies from 1 · 14 to 1 · 39 eV and in the high-temperature region from 0 · 37 to 0 · 51 eV.

Samples in the present study have been synthesized by the solid state ceramic route at 1300 °C; therefore, there is a possibility that oxygen leaves the lattice according to Eq. (6). The possibility of oxygen vacancies in the sample cannot be ruled out. It is reported that oxygen vacancies (Vo ••) are highly mobile in the perovskite structure and the activation energy for diffusion of these vacancies is approximately 1 eV [50, 51]. Therefore, conduction in the low-temperature range (region I) is proposed to take place due to the motion of doubly ionized oxygen vacancies (Vo ••).

In the literature, the activation energy for proton conduction in perovskite materials is reported to be between 0.40 and 0.50 eV [52, 53]. The activation energy in the high-temperature range (region II) of the sample lies between 0.39 and 0.52 eV. It is also reported in the literature that in the FTIR spectrum of high-temperature proton conductors, an intense band at 1420 cm−1 appears due to the presence of OH− groups [44]. In the FTIR spectrum (Fig. 5) of sample BSL1, an intense band around 1420 cm−1 is also present. Therefore, the possibility of conduction in the sample BSL1 in the high temperature range (region II) by protonic defects cannot be ruled out. This sample has a porosity of approximately 20 %; hence, if electrical properties are measured in an ambient atmosphere, water molecules can be adsorbed by the materials. Adsorption of water molecules by these materials has been confirmed from their FTIR spectrum (Fig. 5) and thermal analysis (Fig. 6). Incorporation of adsorbed water molecules into the oxide lattice can be represented as the process of dissociative dissolution and formation of protonic defect according to reaction (7):

In the above reaction, oxygen vacancies are consumed to produce twice the protonic defect. It seems that in the present sample, the above reaction is taking place at a higher temperature (T ≥ 450 °C). A high concentration of protonic defects with respect to that of oxygen ion vacancies may lead to the change in the conduction mechanism with increasing temperature. At and above 450 °C temperature, protonic defects may be the dominant charge carrier and govern the conduction mechanism. These protons (OH)• may hop from one oxygen vacancy Vo •• to another one. Similar activation energy of both resistances shows that a sufficient amount of protons (OH)• is present in the bulk (grain) of the material, i.e., adsorption of water molecules is not limited to the surface but it has penetrated through grains. It is worthwhile to mention that in the synthesis of this sample, water has not been used at any stage.

Figure 10 shows the variation of the real part of impedance (Z′) as a function of frequency at three different temperatures. A similar behavior is observed at higher temperatures also. The presence of two relaxation processes is clearly seen in these plots. It is also clear that the relaxation time of these processes is temperature dependent. The trend of impedance vs. frequency plot provides an indication of increasing conduction with frequency and temperature (i.e., negative temperature coefficient (NTC) of resistance behavior typical of semiconductors). Total impedance at 10 Hz frequency (since 10 Hz frequency data is very much close to the d.c. value) at different temperatures is obtained from Fig. 10. Using these data, the total d.c. conductivity of the sample is calculated at different temperatures, to attain a maximum value of 5.35 × 10−4 (Ω cm)−1 at 650 °C. On comparing the conductivity value of this sample with the conductivity value of acceptor (La, Y, In, Gd, etc.)-doped barium stannate systems reported to be high-temperature proton conductors [22], it is found that the conductivity of sample BSL1 is almost equal to the conductivity of the above-mentioned acceptor-doped barium stannate systems.

The variation of Z″ with the logarithm of frequency at different temperatures is shown in Fig. 11. It is observed that at and above 300 °C, two peaks are present in these plots. The position of each peak shifts towards the higher frequency side with increasing temperature. The heights of these peaks decrease with an increase in temperature. A typical peak broadening which is slightly asymmetrical in nature can also be observed with a rise in temperature. Broadening in the low-frequency peak is more than broadening in the high-frequency peak. Moreover, broadening in peak is independent of temperature. This suggests that there is a spread of relaxation time, i.e., the temperature-dependent electrical relaxation phenomenon exists in the material. However, for the present sample, FWHM is >1 · 144 decades for both the peaks, which is attributed to the distribution of relaxation time. A peak is observed when the relation ωτ = 1 is satisfied (ω—angular frequency is equal to 2πf, f being the frequency (Hz) and τ, the relaxation time). With an increase in temperature, the relation ωτ = 1 is satisfied at a higher frequency. The relaxation time τ for grains and grain boundaries is determined from the peak position, and plots of log τ (relaxation time) with the inverse of temperature for all the three contributions are shown in Fig. 12. Variation of log τ g with the inverse of temperature shows a single linear region in the entire range of temperatures. The linear behavior of log τ g with 1000/T indicates that the relaxation time obeys the Arrhenius relation given by

where τ go is the relaxation time at infinite temperature, E τ the activation energy for relaxation, k B Boltzmann’s constant, and T the absolute temperature. A linear fit of log τ vs. 1000/T plots has been used to estimate the activation energy of the material. The values so obtained are recorded in Table 4. This value of activation energy (E τ ) estimated for grains at low temperature (≤450 °C) when compared with the activation energy value (E a) is observed to have approximately the same value, well within the experimental error. This result possibly provides an indication that electrical species (charge carriers) involved in the process of relaxation and conduction for the grains in the low-temperature range are the same. This result possibly provides an indication that electrical species (charge carriers) involved in the process of relaxation and conduction are different.

Variation of the logarithm of relaxation time, τ (obtained from Fig. 10) of a grains and b grain boundaries

Conclusions

Powder X-ray diffraction studies confirm the formation of a single phase only up to 0.05 ≤ x. All the samples have a cubic crystal structure. Scanning electron microscopy has confirmed the polycrystalline texture of the material with porous microstructure. EDX analysis confirmed the homogeneous nature of the synthesized material. The FTIR spectrum and TGA curve of the samples exhibited the adsorption of water molecules by the synthesized powders. AC impedance analysis reveals that the total impedance is the contribution of grains and grain boundaries. Two temperature ranges with different activation energies have been observed for both the resistances. The activation energies in both the temperature ranges for both the resistances match well. Therefore, it is concluded that conduction species (phases) responsible for conduction within grains and grain boundaries electrode are the same. The activation energy estimated from the variation of resistances/total resistivity confirmed that conduction in the low-temperature region (300–450 °C) is due to thermal diffusion of doubly ionized oxygen vacancies (Vo ••) whereas in the high-temperature region (450–650 °C), it is due to hopping of (OH)• ions. Based on the high-temperature conduction mechanism and similar activation energy for both grains and grain boundaries, it is concluded that even the donor doped barium stannate for high-temperature proton conductors.

References

Vivekanandan R, Kutty TRN (1990) Grain boundary layer ceramic capacitors based on donor-doped Ba(Ti1−xSnx)O. Mater Sci Eng B 6:221–231

Zhou ZG, Zhao G, Wei M, Zhang ZT (1989) Temperature–humidity–gas multifunctional sensitive ceramics. Sensors Actuators 19:71–81

Singh P, Brandenburg BJ, Sebastian CP, Singh P, Singh S, Kumar D, Parkash O (2008) Electronic structure, electrical and dielectric properties of BaSnO3 below 300 K. Jpn J Appl Phys 47:3540–3545

Movchikova A, Malyshkina O, Suchaneck G, Gerlach G, Steinhausen R, Langhammer HT, Pientschke C, Beige H (2008) Study of the pyroelectric behavior of BaTi1–x Sn x O3 piezo-ceramics. J Electroceram 20:43–46

Wang T, Chen XM, Zheng XH (2003) Dielectric characteristics and tunability of barium stannatetitanate ceramics. J Electroceram 11:173–178

Ostrick B, Fleischer M, Lampe U, Meixner H (1997) Preparation of stoichiometric barium stannate thin films: hall measurements and gas sensitivities. Sensors Actuators B 44:601–606

Tao S, Gao F, Liu X, Sørensen OT (2000) Ethanol-sensing characteristics of barium stannate prepared by chemical precipitation. Sensors Actuators B 71:223–227

Lampe U, Gerblinger J, Meixner H (1995) Carbon-monoxide sensors based on thin films of BaSnO3. Sensors Actuators B 24–25:657–660

Hodjati S, Vaezzadeh K, Petit C, Pitchon V, Kiennemann A (2000) NO x absorption–desorption study: application to diesel and lean-burn exhaust gas (selective NOx recirculation technique). Catal Today 59:323–334

McGeehin P and Williams DE (1993) Sensing gaseous substances international application, Patent No WO 9308467 A1 19930429. Indian Institute of Technology (Banaras Hindu University), Varanasi

Gopal Reddy CV, Manorama SV, Rao VJ (2001) Preparation and characterization of barium stannate: application as a liquefied petroleum gas sensor. J Mater Sci Mater Electron 12:137–142

Dilute XC (2004) Dilute CH3SH-sensing characteristics of BaSnO3 thick film sensor. Mater Sci Eng B 106:305–307

Borse PH, Lee JS, Kim HG (2006) Theoretical band energetics of Ba(M0.5Sn0.5)O3 for solar photoactive applications. J Appl Phys 100:124915–124921

Borse PH, Joshi UA, Ji SM, Jang JS, Lee JS, Jeong ED, Kim HG (2007) Band gap tuning of lead-substituted BaSnO3 for visible light photocatalysis. Appl Phys Lett 90:034103–034111

Yuan Y, Lv J, Jiang X, Li Z, Yu T, Zou Z, Ye J (2007) Large impact of strontium substitution on photocatalytic water splitting activity of BaSnO3. Appl Phys Lett 91:094107–094111

Mizoguchi H, Woodward PM, Park C, Keszler DA (2004) Strong near-infrared luminescence in BaSnO3. J Am Chem Soc 126:9796–9800

Wang Y, Chesnaud A, Bevillon E, Dezanneau G (2012) Properties of Y-doped BaSnO3 proton conductors. Solid State Ionics 214:45–55

Schober T (1998) Protonic conduction in BaIn0.50Sn0.50O2.7. Solid State Ionics 109:1–11

Wang Y, Chesnaud A, Bevillon E, Yang J, Dezanneau G (2011) Synthesis, structure and protonic conduction of BaSn0.875M0.125O3-δ (M = Sc, Y, In and Gd). Int J Hydrog Energy 36:7688–7695

Wang Y, Chesnaud A, Bevillon E, Yang J, Dezanneau G (2011) Influence of ZnO additive on the properties of Y-doped BaSnO3 proton conductor. Mater Sci Eng B 176:1178–1183

Li L, Nino JC (2013) Proton-conducting barium stannates: doping strategies and transport properties. Int J Hydrog Energy 38:1598–1605

Wang Y (2011) Ph.D. thesis Ecole Centrale Paris. Synthesis and characterization of acceptor-doped barium stannate compounds as proton conductors. Indian Institute of Technology (Banaras Hindu University), Varanasi

Wang Y, Chesnaud A, Bévillon E, Xiong J, Yang J (2013) Effects of Sn substitution on structural and electrical properties of BaSn0.75M0.25O3-δ (M = Sc, In, Y, Gd, Nd.). J Alloys Compd 555:395–401

Bévillon E, Geneste G, Chesnaud A, Dezanneau G (2008) Ab initio study of La-doped BaSnO3 proton conductor. Ionics 14:293–301

Hadjarab B, Bouguelia A, Trari M (2007) Optical and transport properties of lanthanum-doped stannate BaSnO3. J Phys D Appl Phys 40:5833–5839

Hadjarab B, Bouguelia A, Benchettara A, Trari MA (2008) The transport and photo electrochemical properties of La-doped stannate BaSnO3. J Alloys Compd 461:360–366

Wang HF, Liu Q, Chen ZF, Gao GY, Wu W (2007) Transparent and conductive oxide films with the perovskite structure: La- and Sb-doped BaSnO3. J Appl Phys 101:106105-1-3

Trari M, Doumerc JP, Dordor P, Pouchard M, Behr G, Krabbes G (1994) Preparation and characterization of lanthanum doped BaSnO3. J Phys Chem Solids 55:1239–1243

Yasukawa M, Kono T, Ueda K, Yanagi H, Hosono H (2010) High-temperature thermoelectric properties of La-doped BaSnO3 ceramics. Mater Sci Eng B 173:29–32

Yasuhuwa M, Kone T, Ueda K, Yanag H, Kim SW, Hosono H (2013) Thermoelectric properties and figure of merit of perovskite type Ba1-xLaxSnO2 with x = 0.002-0.008. Solid State Commun 173:49–53

Upadhyay S, Parkashand O, Kumar D (2004) Synthesis, structure and electrical behaviour of lanthanum-doped barium stannate. J Phys D Appl Phys 37:1483–1491

Azad AM, Hon NC (1998) Characterization of BaSnO-based ceramics part-1: synthesis, processing and microstructural development. J Alloys Compd 270:95–106

Srivastava OP, Kumar N, Sharma IB (2004) Solid state synthesis and structural refinement of polycrystalline La x Ca1–x TiO3 ceramic powder. Bull Mater Sci 27:121–126

Duan LB, Rao GH, Wang YC, Yu J, Wang T (2008) Magnetization and Raman scattering studies of (Co,Mn) codoped ZnO nanoparticles. J Appl Phys 104:013909-1–013909-5

Worlock JM, Porto SPC (1965) Raman scattering by F centre. Phys Rev Lett 15:697–99

Stanislavchuk TN, Sirenko AA, Litvinchuk AP, Luo X, Cheong SW (2012) Electronic band structure and optical phonons of BaSnO3 and Ba0.97La 0.03SnO3 single crystals: theory and experiment. J Appl Phys 112:044108

Balamurugan K, Harish Kumar N, Balachandran B, Ramachandra Rao MS, Chelvane JA, Santhosh PN (2009) Magnetic and optical properties of Mn-doped BaSnO3. Solid State Commun 49:884–887

James KK, Krishnaprasad PS, Hasna K, Jayarajn MK (2015) Structural and optical properties of La-doped BaSnO3 thin films grown by PLD. J Phys Chem Solids 76:64–69

Gao QQ, Yu QX, Yuan K, Fu XN, Chen B, Zhu CX, Zhu H (2013) Influence of annealing atmosphere on room temperature ferromagnetism of Mn-doped ZnO nanoparticles. Appl Surf Sci 264:7–10

Gupta HC, Brown S, Rani N, Gohel VB (2001) A lattice dynamical investigation of the Raman and the infra red frequencies of the cubic A2Sn2O7 pyrochlores. Int J Inorg Mater 3:983–986

Ribeiro SJL, Santilli CV, Pulcinelli SH, Fortes FL, Oliveira L (1994) Spectroscopic characterization of SnO2 gels. J Sol-Gel Sci Technol 2:263–267

Gmelin (1975) Handbuch der Anorganischen Chemie, Zinn C3, 8 Auflageth edn. Springer, Berlin/Heidelberg, p 193

Deepa AS, Vidya S, Manu PC, Solomon S, John A, Thomas JK (2011) Structural and optical characterization of BaSnO3, nano powder synthesized through a novel combustion technique. J Alloys Compd 509:1830–1835

Animista I, Dogodaeva E, Tarasova N, Kosareva O, Neiman A (2011) Oxygen-ion and proton transport in Ba4Na2W2O11. Solid State Ionics 185:1–5

Lu W, Schmidt H (2008) Lyothermal synthesis of nanocrystalline BaSnO3 powders. Ceram Int 34:645–649

Ganguly M, Rout SK, Sinha TP, Sharma SK, Park HY, Ahn CW, Kim IW (2013) Characterization and rietveld refinement of a-site deficient lanthanum doped barium titanate. J Alloys Compd 579:473–484

Upadhyay S (2013) High temperature impedance spectroscopy of barium stannate BaSnO3. Bull Mater Sci 36:1019–1036

Verkerk MJ, Middelhuis BJ, Burggraaf AJ (1982) Effect of grain boundaries on conductivity of high purity ZrO2, Y2O3 ceramics. Solid State Ionics 6:159–170

Christie GM, Berkel FPF (1996) Microstructure–ionic conductivity relationship in ceria-gadolinia electrolytes. Solid State Ionics 83:17–27

Murugraj P, Kreur KD, He T, Schober T, Maier J (1997) High proton conductivity in barium yttrium stannate Ba2YSnO5.5. Solid State Ionics 98:1–132

Lu W, Jiang S, Zhou D, Gong S (2000) Structural and electrical properties of Ba(Sn, Sb)O3 electroceramic. Sensors Actuators A 80:35–37

Kreurer KD (1999) Aspect of the formation and mobility of protonic charge carriers and the stability of perovskite oxides. Solid State Ionics 125:285–302

Kreurer KD (2003) Protonic conducting oxides. Annu Rev Mater Res 33:333–359

Acknowledgments

The authors are grateful to the heads of the Department of Physics, Department of Ceramic Engineering, and Department of Chemical Engineering, IIT (BHU), for providing facilities required for the characterization of the samples. The authors are also grateful to Dr. R.K. Singh, Professor, Department of Physics, Science Faculty, BHU, Varanasi, for providing facilities to record the Raman spectra of the samples.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ansaree, M.J., Upadhyay, S. Electrical characterization of porous La-doped BaSnO3 using impedance spectroscopy. Ionics 21, 2825–2838 (2015). https://doi.org/10.1007/s11581-015-1476-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-015-1476-1